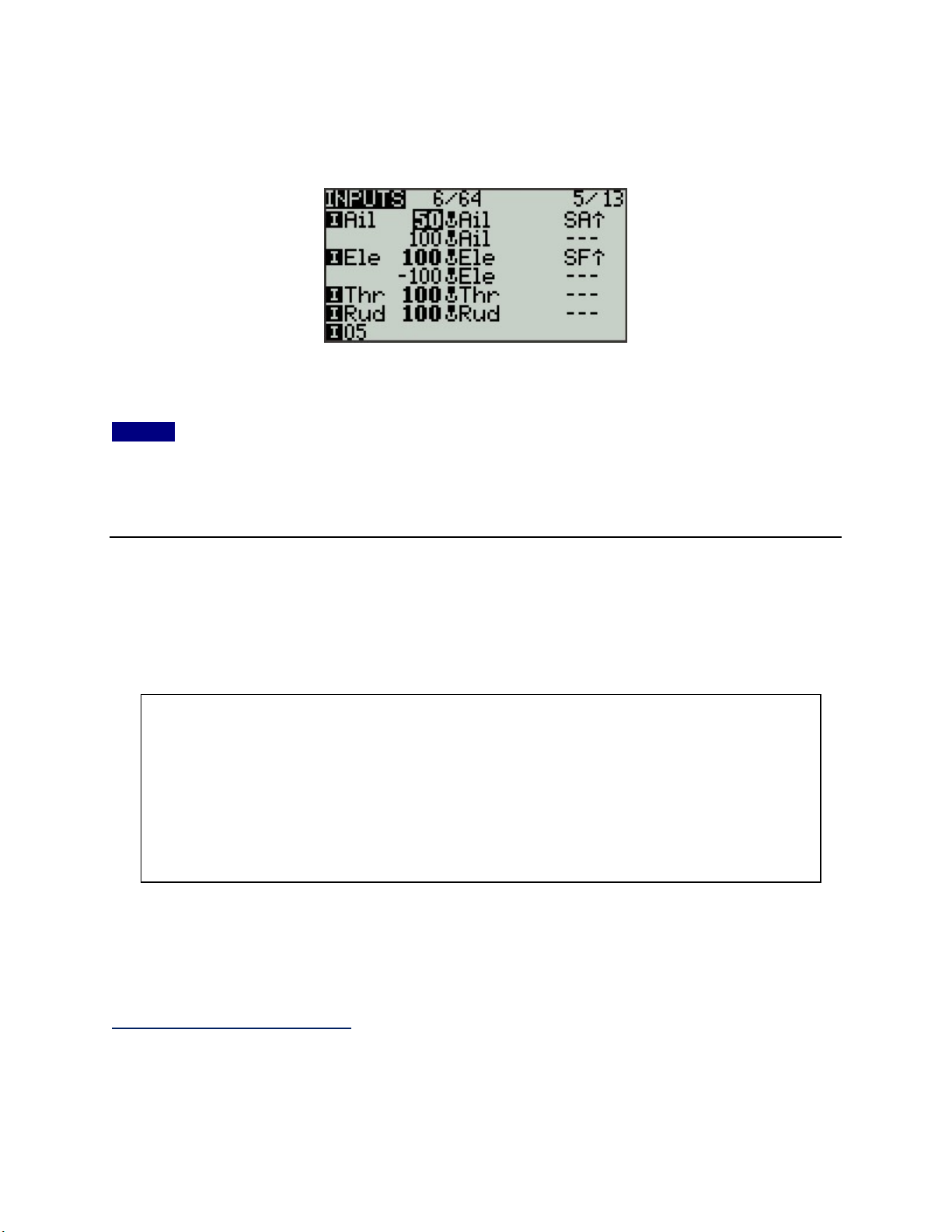

A Simple Invert Switch

So far everything we’ve done in OpenTX has been a little more difficult than it would have been

on a conventional menu-driven transmitter. You’re probably wondering why anyone bothered to

write transmitter firmware that makes things more difficult. It’s not quite like that – Open TX does

make simple things a little more difficult, but it can make complicated things a lot simpler. Here’s

an example.

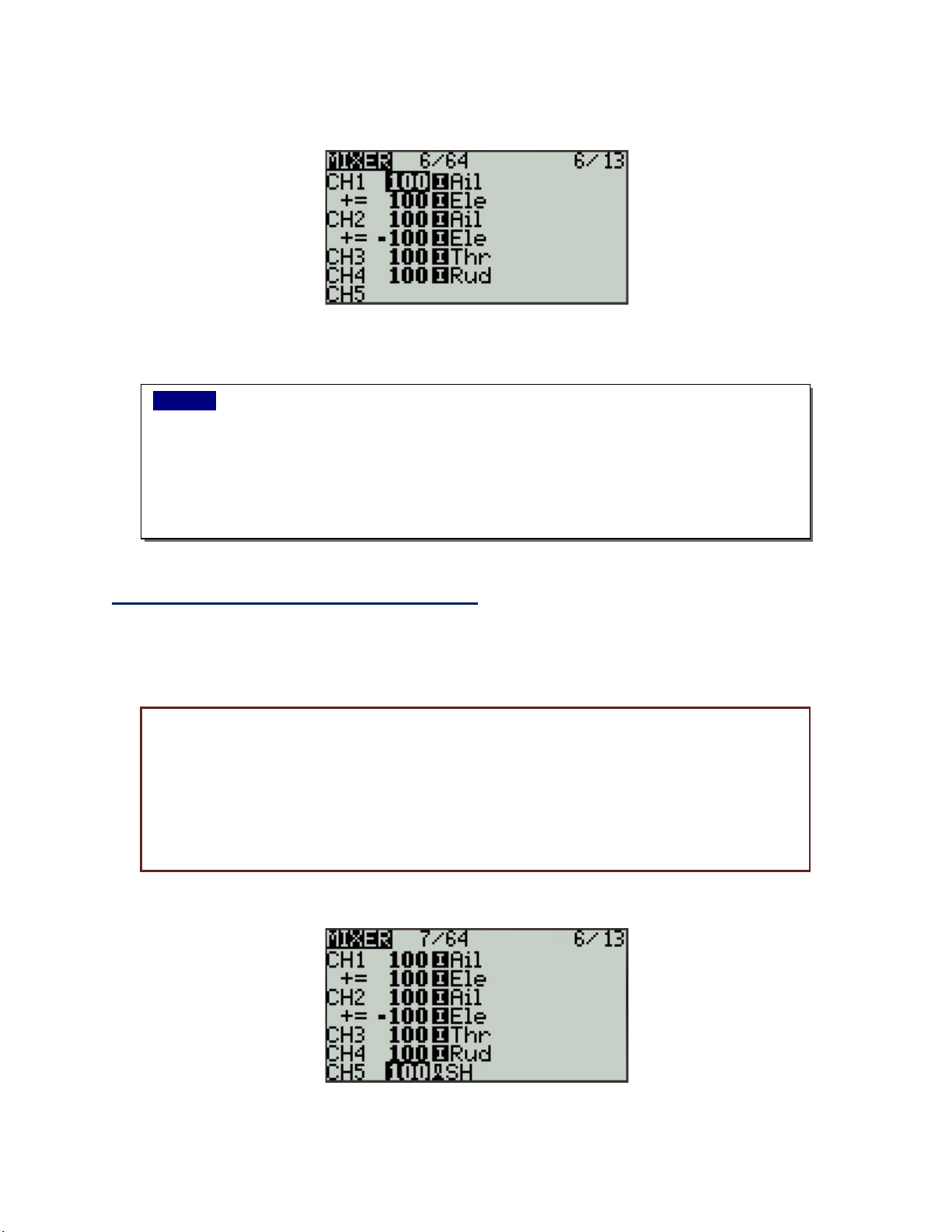

When a wheeled robot is inverted the steering remains correct, but the throttle

direction is reversed. Assigning a switch to reverse the response of the Elevator stick

axis in a conventional transmitter is complex, but in OpenTX it’s simple. On the

INPUTS screen:

Use the scroll wheel to highlight the Ele line, then long-press the ENTER

button to bring up an action menu.

Tap ENTER to enter the Edit screen.

Scroll down to Switch, tap ENTER, flip switch SF down then back up.

Tap enter, tap EXIT twice.

Long-press the ENTER button again.

Scroll to Insert After and tap ENTER.

Scroll down to Weight, tap ENTER, scroll the value down to -100.

Tap enter, tap EXIT twice.

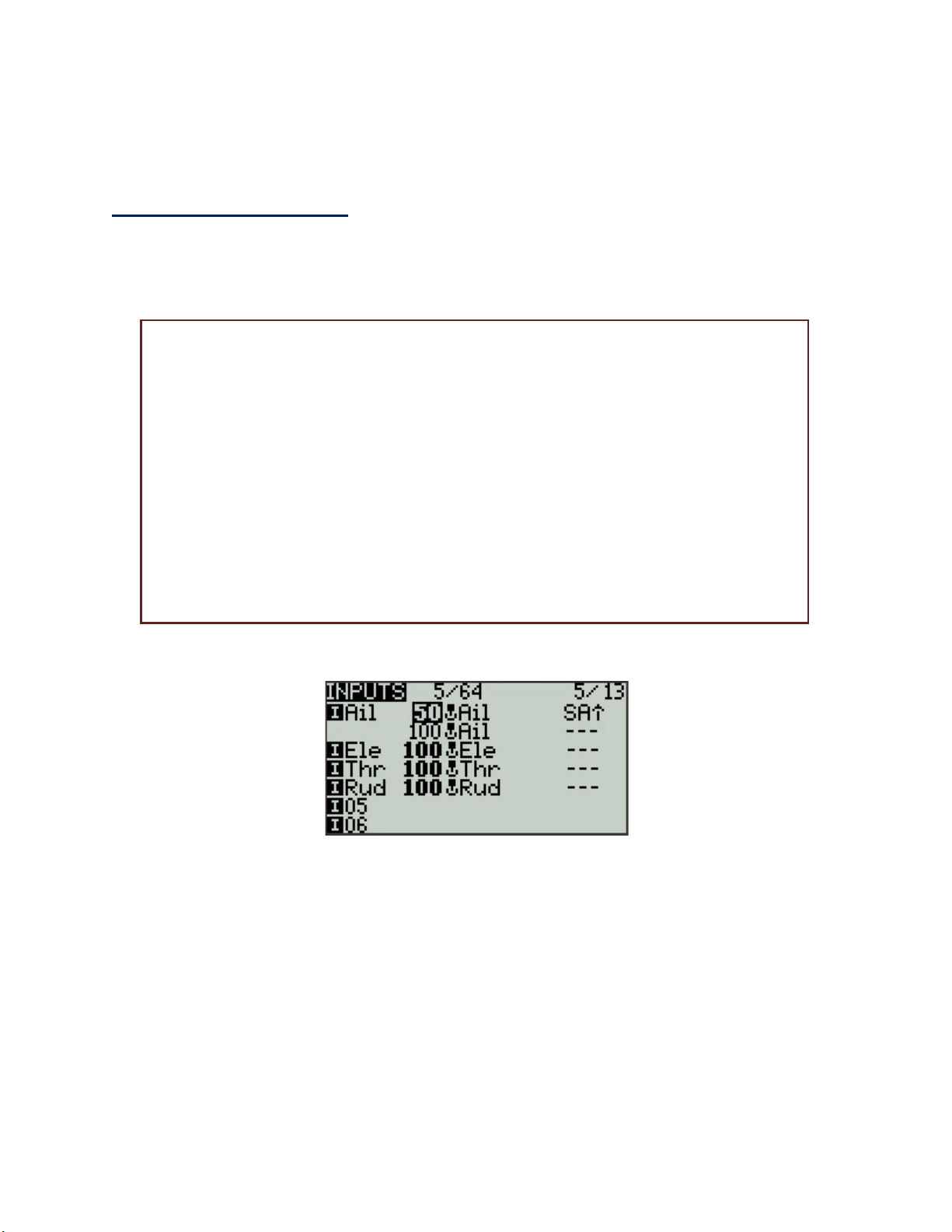

If there are multiple lines entered under a single input, the

transmitter evaluates the first line to see if any conditions it includes are met. If they

are, that line is used. If not, it skips down a line and repeats the evaluation process.

Our first Aileron line has the condition SA⇑ that requires that switch SA be

in the up position – the position the transmitter expects at start-up. If switch

SA is up the line will be accepted and the steering rate will be a controllable

50.

If switch SA is not up, the transmitter will skip down to the second line to

evaluate its condintion. Ths second line has no condition set, so it will be

accepted and the steering rate will be a very quick 100.

You can choose different values for the Weight to suit your driving preference --

and you can choose a different switch. Yes, you can add more lines for additional

conditions, but leave the last line with no conditions.