2

Contents

VEGADIF 85 • Modbus and Levelmaster protocol

53571-EN-230814

Contents

1 About this document ............................................................................................................... 4

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety ......................................................................................................................... 5

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 Conformity........................................................................................................................ 5

2.6 NAMUR recommendations .............................................................................................. 6

2.7 Environmental instructions ............................................................................................... 6

3 Product description ................................................................................................................. 7

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 8

3.3 Supplementary cleaning procedures.............................................................................. 10

3.4 Packaging, transport and storage................................................................................... 11

3.5 Accessories.................................................................................................................... 11

4 Mounting................................................................................................................................. 13

4.1 General instructions ....................................................................................................... 13

4.2 Instructions for oxygen applications ............................................................................... 15

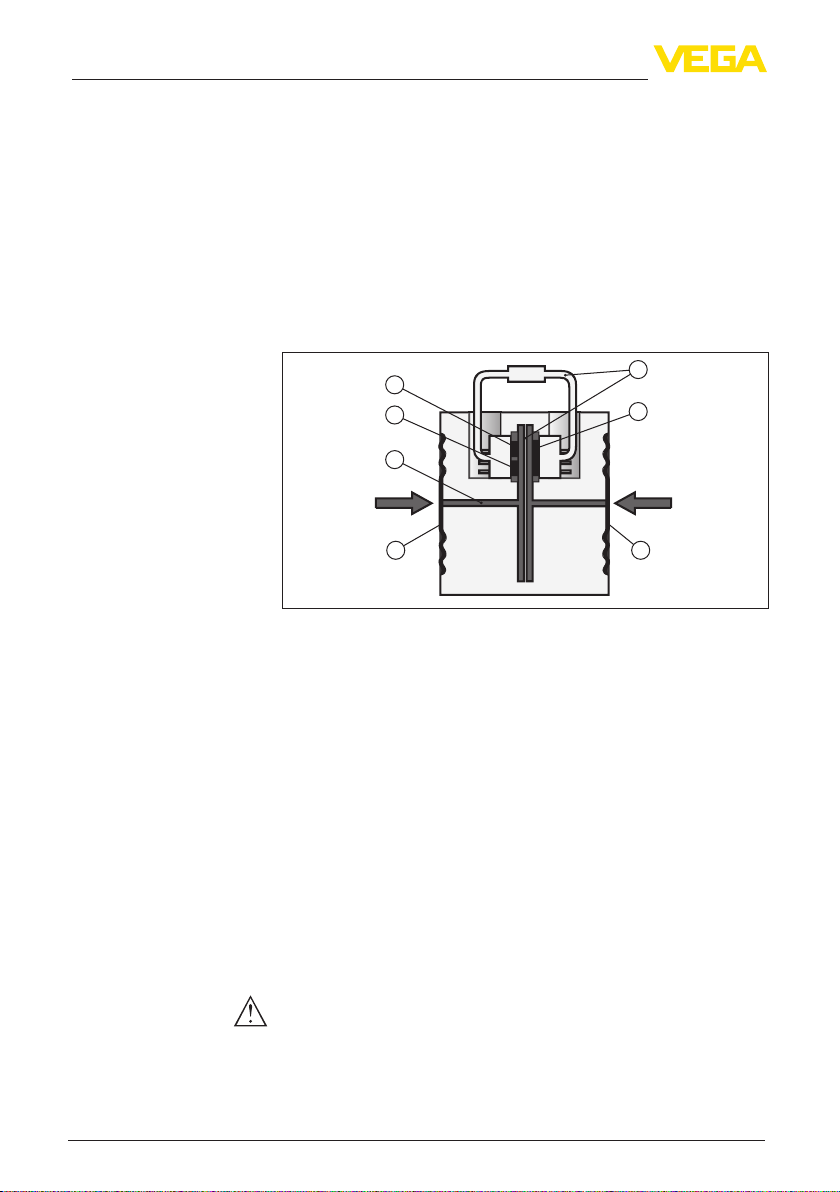

4.3 Connection to the process.............................................................................................. 15

4.4 Mounting and connection instructions............................................................................ 16

4.5 Measurement setups...................................................................................................... 18

5 Connecting to power supply and bus system .................................................................... 27

5.1 Preparing the connection ............................................................................................... 27

5.2 Connecting..................................................................................................................... 28

5.3 Wiring plan ..................................................................................................................... 30

5.4 External housing with version IP68 (25 bar) ................................................................... 31

5.5 Switch-on phase............................................................................................................. 33

6 Set up the sensor with the display and adjustment module............................................. 34

6.1 Insert display and adjustment module............................................................................ 34

6.2 Adjustment system......................................................................................................... 35

6.3 Measured value indication.............................................................................................. 36

6.4 Parameter adjustment - Quick setup .............................................................................. 37

6.5 Parameter adjustment - Extended adjustment................................................................ 37

7 Setting up sensor and Modbus interface with PACTware.................................................. 53

7.1 Connect the PC.............................................................................................................. 53

7.2 Parameterization ............................................................................................................ 54

7.3 Set instrument address .................................................................................................. 55

7.4 Save parameter adjustment data.................................................................................... 56

8 Set up measuring system ..................................................................................................... 57

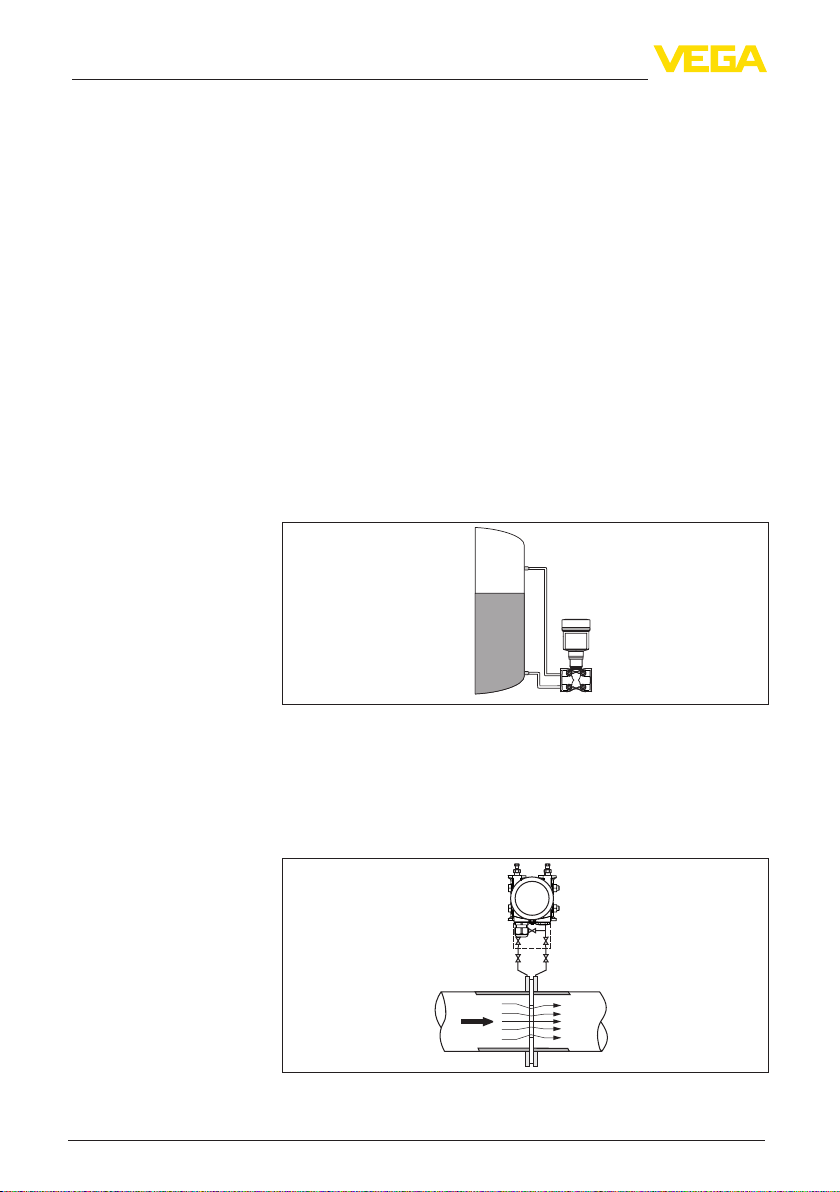

8.1 Level measurement........................................................................................................ 57

8.2 Flow measurement......................................................................................................... 59

9 Diagnosis, asset management and service ........................................................................ 61

9.1 Maintenance .................................................................................................................. 61