adjust the air flow through the gun.

ADJUSTMENT

3.0 Place a five gallon pail of TEKBOND TB-10 adhesive under the stand with

the opening at the back of the stand. Insert the clear suction hose through the

opening, ensure that sufficient hose is lowered in so as to reach the bottom of the

bucket. Hose extensions are available to allow direct suction from larger cont-

ainers such as 15 gallon buckets and 55 gallon drums.

3.1 Connect the air and slowly turn the regulator clockwise until the gauge

registers 40 PSI. The pump should now be cycling making a clicking sound.

Please note that once primed the pump will stop cycling.

3.2 The spray gun has two adjustment controls. The smaller knob is the spray

adjustment control, while the larger knob controls the flow. Open up the larger

knob 2 or 3 turns (counter-clockwise) to allow the system to prime. Directing the

gun into a trash can or old cardboard box, squeeze the trigger all the way in and

hold it until adhesive starts to come out of the nozzle.

3.3 Once adhesive is spraying out of the nozzle slowly rotate the knob back in

(clockwise) until a fine spray is achieved. The desired setting should produce an

extremely fine spray pattern that is almost invisible. If necessary increase air

pressure, not exceeding 60PSI

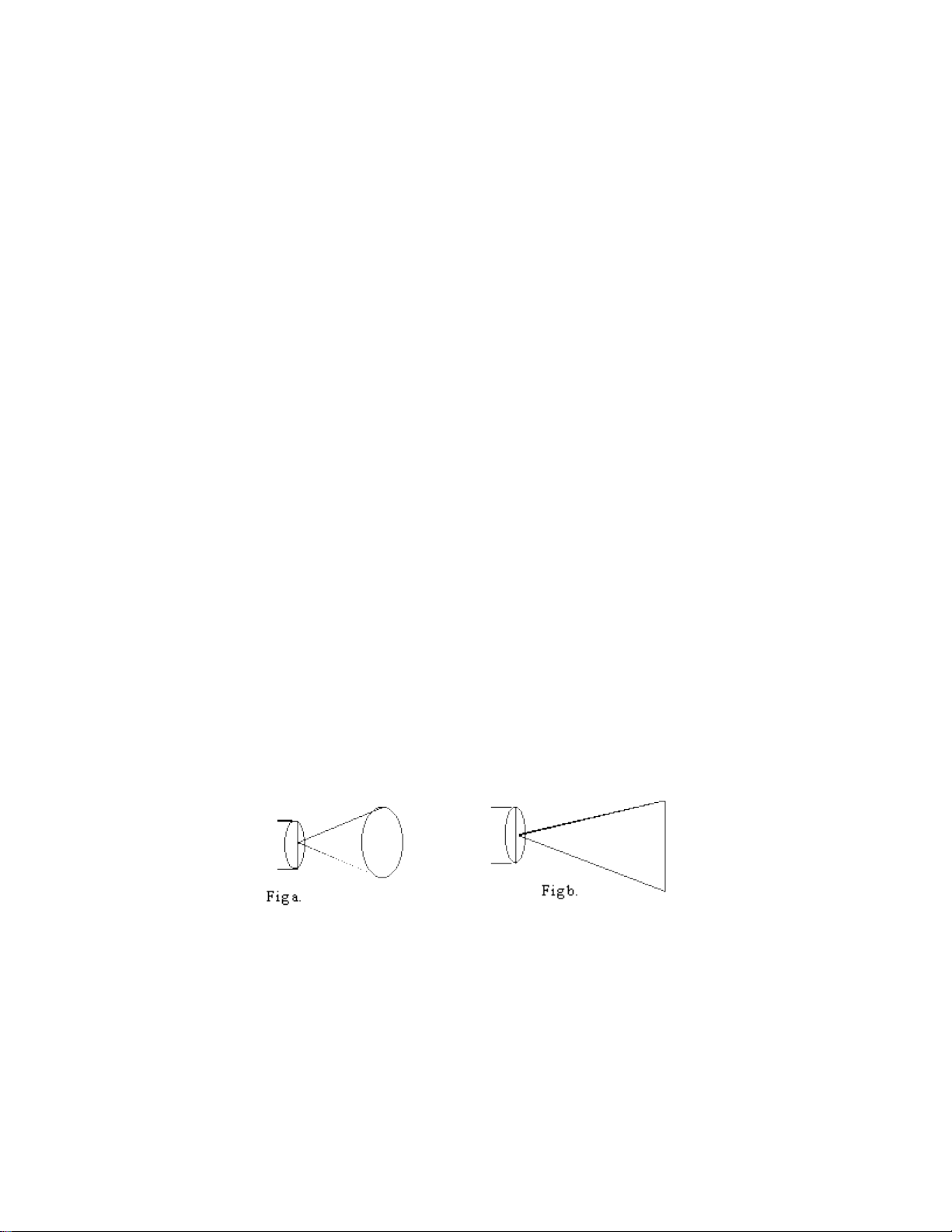

3.4 The smaller silver knob on the gun is used to adjust the spray pattern. With

the knob all the way in a circular spray pattern is achieved (see fig a). By slowly

rotating it counter clockwise a flatter fan type spray pattern can be achieved (see

fig b). The flat fan spray pattern is more suitable for the application of adhesive.

The nozzle should be positioned vertically to produce a horizontal flat fan or

reversed for a vertical spray.

3.5 If more adhesive is required then slowly turn the lower, larger silver knob

counter-clockwise. Once the desired spray has been set, practice spraying on

some scrap cardboard.

3.5 The unit should located as near to the press as possible. Should it be desired

to locate the system away from the press then extension hoses are available for a

maximum extension of 20 ft. Make sure that the unit and hoses are not placed in

such a way so as to present a hazard to anyone. If necessary tape hoses down to

avoid any risk of someone tripping or falling.