INTRODUCTION

INTRODUCTION

The complete range of Taylor Studwelding Systems Capacitor Discharge

units are compact, portable Stud Welding equipment's. The units are specifi-

cally designed to enable a small diameter range of ferrous and non-ferrous

weld studs to be welded to light gauge, self-finish or pre-coated materials,

in most cases with little or no reverse marking.

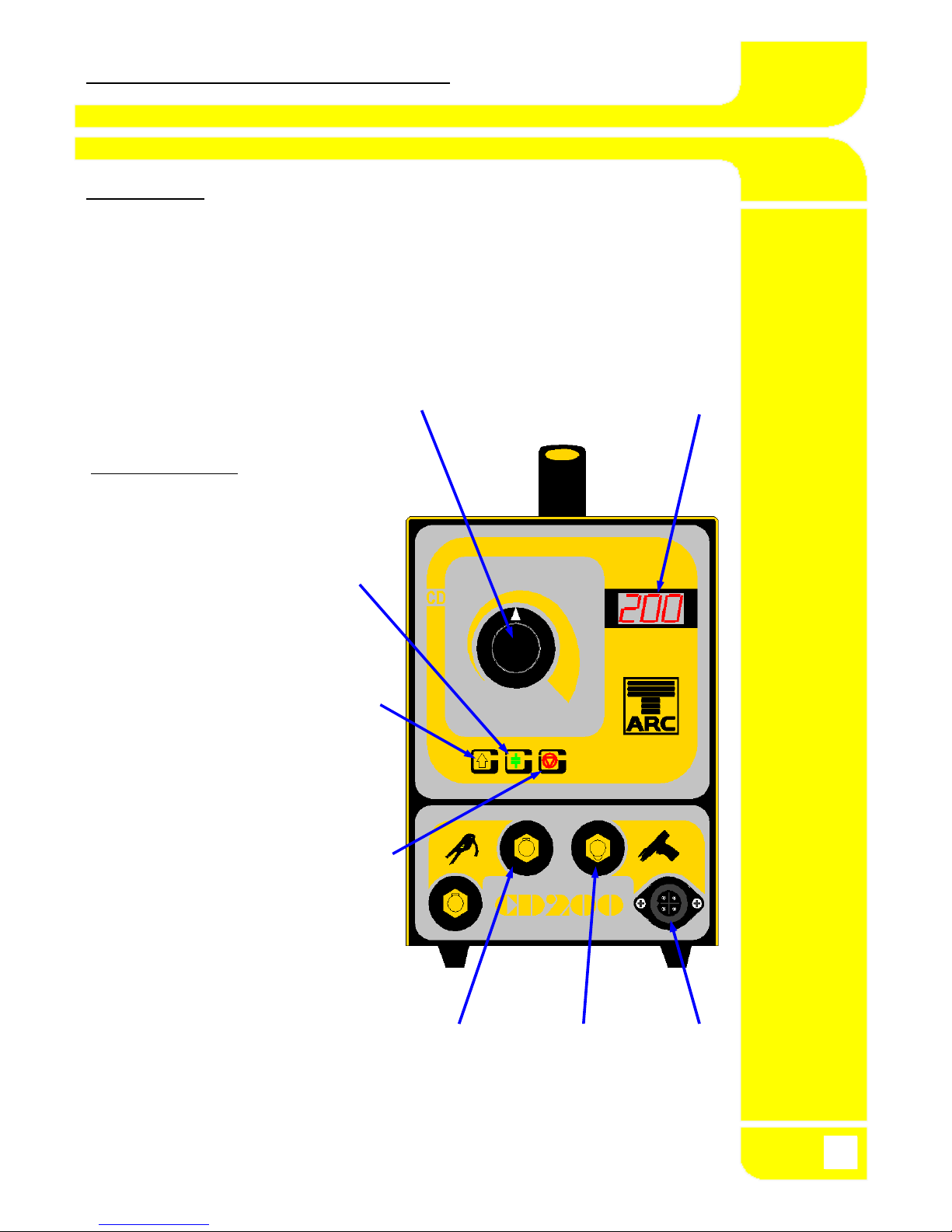

The equipment consists of a control unit, a welding pistol and the nec-

essary interconnecting cables and accessories (see page 4 for the equip-

ment schedule).

THE PROCESS

Capacitor Discharge stud welding is a form of welding in which the en-

ergy required for the welding process is derived from a bank of charged ca-

pacitors. This stored energy is discharged across the gap between the two

surfaces to be welded as they are propelled towards each other. The arc pro-

duced heats the two surfaces, melting a thin film of metal on each surface

and the propelling force closes the gap between the two faces, thus forming

a weld.

In contact welding the stud to be welded is forced by spring pressure on

to the plate. At this point the arc gap between the two components is main-

tained by a small pip on the welding face of the stud. On initiation of the

high current pulse from the capacitors, this pip vaporises and an arc is

drawn between the work piece and the stud. The heat from this arc melts the

base of the stud and the area of the work piece directly beneath the stud,

whilst the spring pressure from the pistol accelerates the towards the work

piece. Within 3 to 4 milliseconds the stud hits the work piece and the arc is

extinguished. The kinetic energy contained in the moving stud and the re-

maining spring pressure, forge the molten parts together to form a weld.

3