V‐4J

SETTINGUPANDWELDING

10

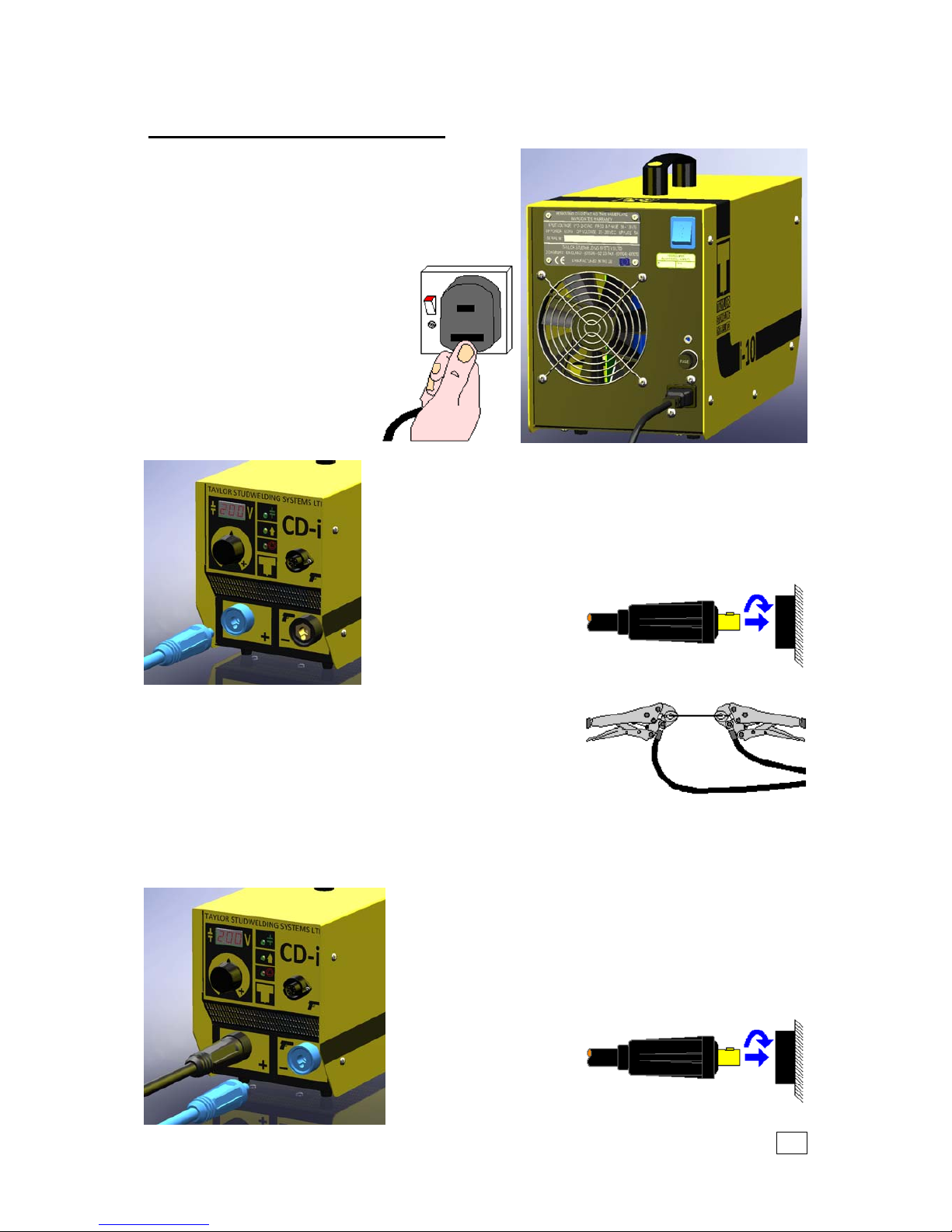

Setupthecontrolunitattheplaceofwork,

ensuringthatthemainsswitchisintheOFF

posion.Ensurethatthisisdoneinlinewiththe

notesandsafetyrecommendaonsonpages5and

6ofthismanual.

Plugthecontrollerintothe

correctmainsACsupply.The

controllerisratedforanysingle

phaseACvoltagebetween100

and250VACat50Hz.Ensure

thecorrectplugisfiedfor

yoursupplyinlinewithlocal/

naonalcodes.

Connecttheweldingearthcabletothecontrollerpanel

mountedplug.

Notethatthecableendplughasapegwhichmateswitha

keyslotinthepanelmountedsocket.

IMPORTANT!

Securetheconnectorwitha

clockwiseturnunlitlocks.

Failuretodothiswillresultin

damagetotheconnector

duringwelding.

Aachtheweldingearthclampstotheworkpieceat

approximately180°toeachother.Thiswillhelptoprevent

"Arcblow"whenweldingtakesplace.Priortofingthe

clamps,ensurethatthecontactareaoftheworkpieceis

freefromrust,paint,greaseetc.Asthiswillresultinapoor

weldingconneconandpoorresults.Wherepossible,route

theearthcablesawayfromtheoperatortopreventtheoperatorbeingposionedbetween

therunofthecableswhilstoperangtheequipment.

Connecttheweldingpistolcabletothecontrollerpanel

mountedsocket.

Notethatthecableendplughasapegwhichmateswith

akeyslotinthepanelmountedsocket.

IMPORTANT!

Securetheconnectorwith

aclockwiseturnunlit

locks.Failuretodothis

willresultindamageto

theconnectorduring