tbs electronics powersine 200-12 User manual

Printed in The Netherlands

Owner’s manual

Gebruiksaanwijzing

Bedienerhandbuch

Mode d'emploi

powersine

powersinepowersine

powersine 200-12

powersine

powersinepowersine

powersine 200-24

powersine

powersinepowersine

powersine 200-48

powersine

powersinepowersine

powersine 300-12

powersine

powersinepowersine

powersine 350-24

powersine

powersinepowersine

powersine 450-48

powersine

powersinepowersine

powersine 600-12

powersine

powersinepowersine

powersine 800-24

powersine

powersinepowersine

powersine 800-48

Designed and manufactured in The Netherlands by :

TBS Electronics BV

De Marowijne 3

1689 AR Zwaag

www.tbs-electronics.com

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 1 -

Owner’s manual

Gebruiksaanwijzing

Bedienerhandbuch

Mode d'emploi

powersine

powersinepowersine

powersine 200-12

powersine

powersinepowersine

powersine 200-24

powersine

powersinepowersine

powersine 200-48

powersine

powersinepowersine

powersine 300-12

powersine

powersinepowersine

powersine 350-24

powersine

powersinepowersine

powersine 450-48

powersine

powersinepowersine

powersine 600-12

powersine

powersinepowersine

powersine 800-24

powersine

powersinepowersine

powersine 800-48

Designed and manufactured in The Netherlands by :

TBS Electronics BV

De Marowijne 3

1689 AR Zwaag

www.tbs-electronics.com

COPYRIGHT © 2004-2010 (rev4endf)

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 2 -

English Page 3

Nederlands Pagina 17

Deutsch Seite 30

Francais Page 44

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 3 -

TABLE OF CONTENTS

1. INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . 4

2. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Placement of the inverter . . . . . . . . . . . . . . . . . . . 4

2.2 The “Remote on/off” function (PS600-12 up to PS800-48 models only) . . . 5

2.3 Battery requirements . . . . . . . . . . . . . . . . . . . . 6

2.4 Connection to the battery . . . . . . . . . . . . . . . . . . . 6

2.4.1 General precautions about working with batteries . . . . . . . . . . 6

2.5 Connecting the load. . . . . . . . . . . . . . . . . . . . . 8

2.6 Activating the inverter . . . . . . . . . . . . . . . . . . . . 8

3. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . 9

3.1 The flash sequence table . . . . . . . . . . . . . . . . . . . 9

3.2 Acoustical messages (except PS200-xx models) . . . . . . . . . . . 10

3.3 Troubleshooting guideline. . . . . . . . . . . . . . . . . . . 10

4. WARRANTY / LIMITS OF RESPONSIBILITY . . . . . . . . . . . . . . 12

5. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Powersine 200-12, 200-24 and 200-48 . . . . . . . . . . . . . . 13

5.2 Powersine 300-12, 350-24 and 450-48 . . . . . . . . . . . . . . 14

5.3 Powersine 600-12, 800-24 and 800-48 . . . . . . . . . . . . . . 14

6. DECLARATION OF CONFORMITY . . . . . . . . . . . . . . . . . 16

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 4 -

1. INTRODUCTION

Thank you for choosing a Powersine DC to AC inverter as your power source. The

Powersine inverter series are one of the most sophisticated inverters available today. With

high reliability, efficiency and sine quality as our most important design goals, the Powersine

inverter series is developed to serve you with safe and trouble free operation for years.

Your Powersine inverter features an advanced micro processor control system with a

MOSFET power stage and a low loss toroidal transformer. This toroidal transformer in

combination with well over dimensioned power components, ensures a very reliable

operation, so that extreme overload conditions, like startup of compressors or pumps, can be

handled safely.

To get optimal feedback from your inverter while operating, a build in diagnosis system will

warn you optically by different flash sequences, depending on the error situation. See the

troubleshooting chapter for the flash sequence table. Also, the inverter will warn you

acoustically before it’s going to shut down in a low battery, overload or high temperature

condition (except PS200-xx models).

To get optimal performance and safe operation from your inverter, it must be installed and

used properly. Please read this manual very carefully, especially the warning and caution

statements, before installing and using your Powersine inverter.

2. INSTALLATION

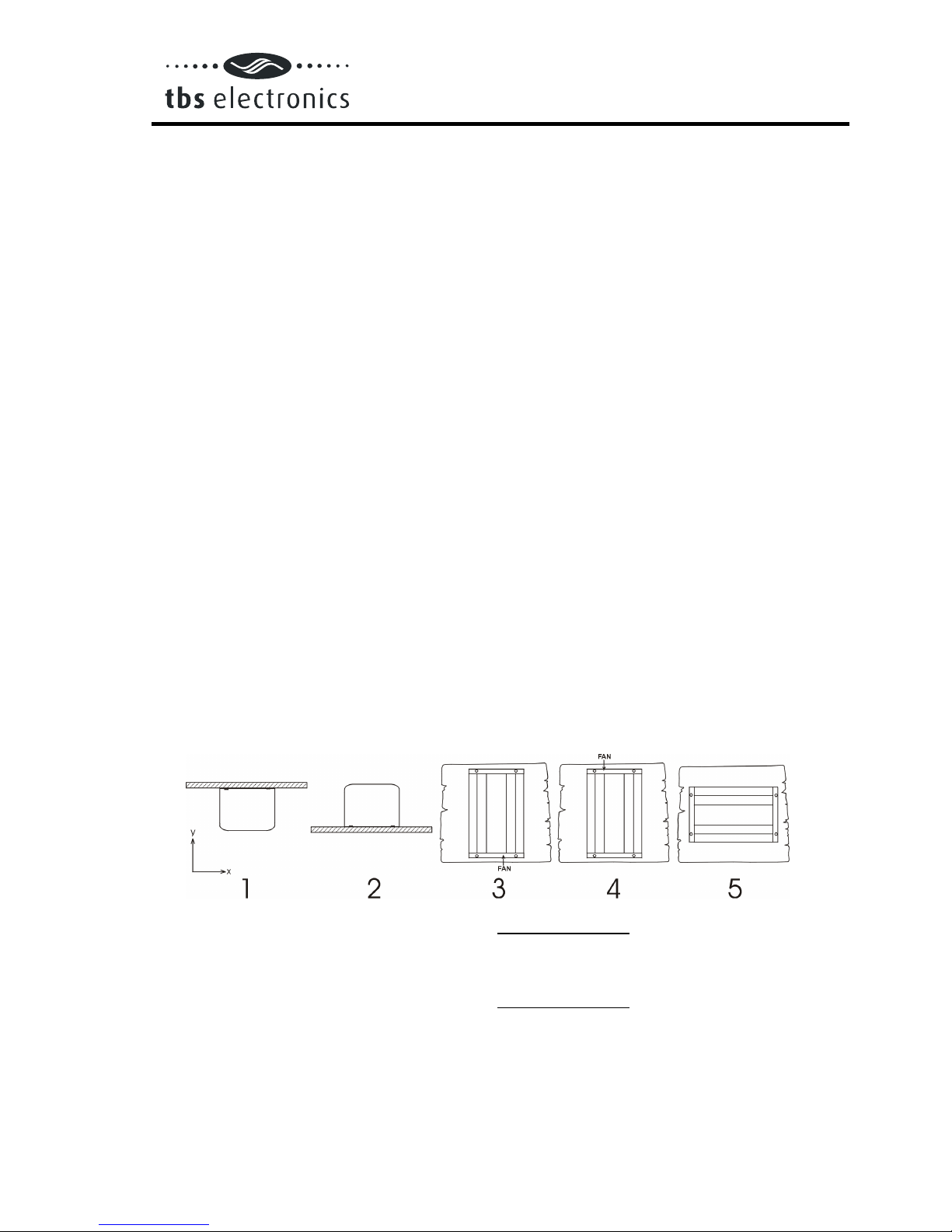

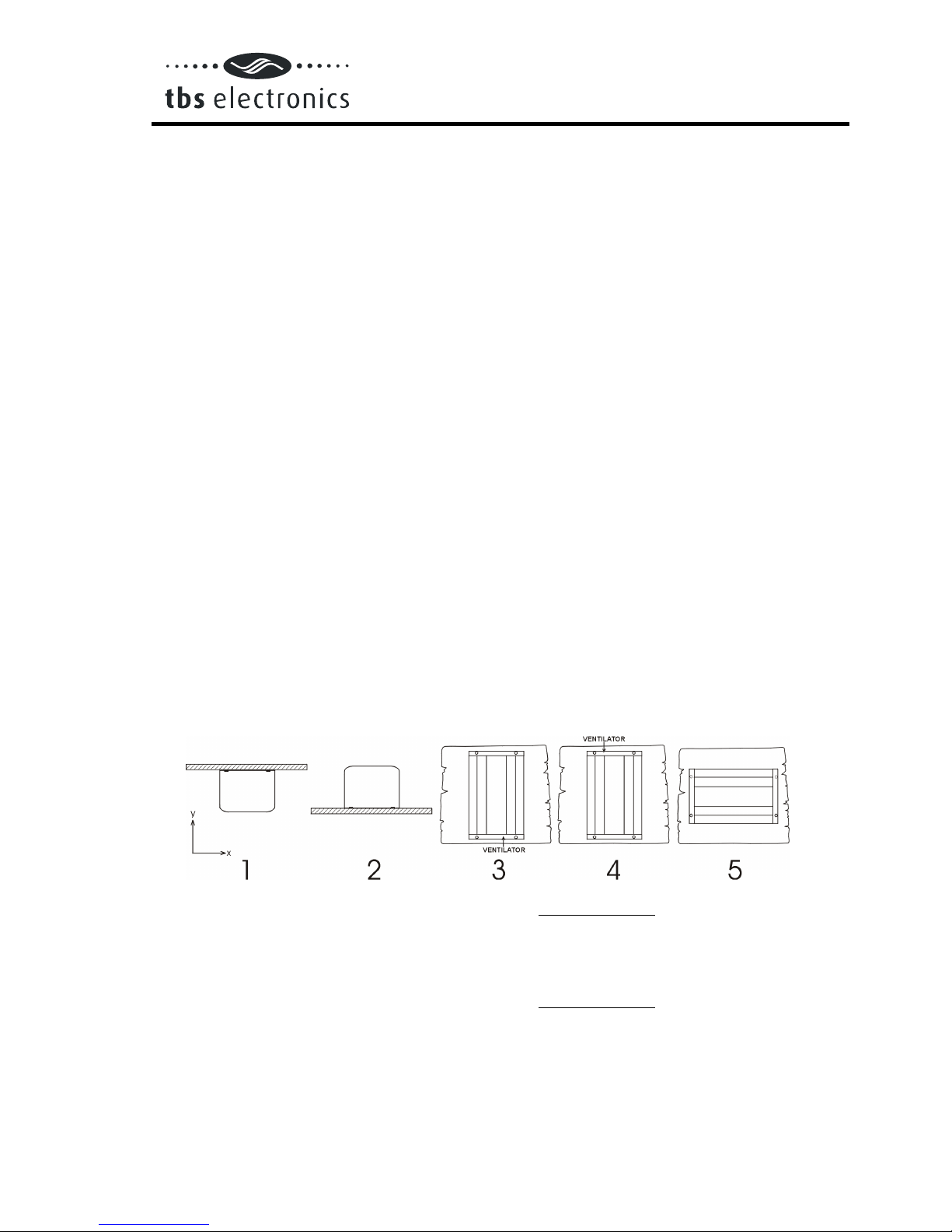

2.1 Placement of the inverter

1. Ceiling mounting : Not recommended

2. Floor mounting : OK

3. Vertical wall mounting, fan at bottom : OK (beware of small objects falling through

the ventilation openings on top)

4. Vertical wall mounting, fan on top : Not recommended

5. Horizontal wall mounting : OK

For best operating results, the inverter should be placed on a flat surface. To ensure a

trouble free operation of the inverter, it must be used in locations that meet the following

requirements :

a. Avoid any contact with water on the inverter. Do not expose the inverter to rain or

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 5 -

moisture.

b. Do not place the unit in direct sunlight or other high temperature environments.

Ambient air temperature should be between 0 °C and 40 °C (humidity < 95% non

condensing). Note that in some extreme situations the inverter’s case temperature can

exceed 70 °C.

c. Do not obstruct the airflow around the inverter. Leave at least 10 centimeters clearance

around the inverter. Do not place items on or over the inverter while it’s operating.

When the inverter is running to hot, it will shut down until a safe temperature level is

reached to restart the inverter.

d. Never use the inverter at locations where there is gas or explosion danger, like for

example directly on top of batteries.

e. Do not expose the inverter to dusty environments

2.2 The “Remote on/off” function (PS600-12 up to PS800-48 models only)

The Powersine 600-12 up to 800-48 models are equipped with “Remote on/off”

terminals for connection to an external on/off switch. The two wires of the external switch

must be connected to these terminals as indicated below. The slide switch on the

frontpanel must be moved to the right (factory setting is left) when operating the unit by a

remote switch as shown below :

max. 50 meters

remote spst

switch

control by remote switch

control by local switch

The local on/off switch on the frontpanel always overrides the remote switch. So in order

to use the remote switch, the local on/off switch must be in the ‘on’ or ‘auto standby’

(ASB) position.

CAUTION

MAKE SURE THAT WHEN INSTALLING THE REMOTE SWITCH, THE

BATTERY IS NOT CONNECTED YET.

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 6 -

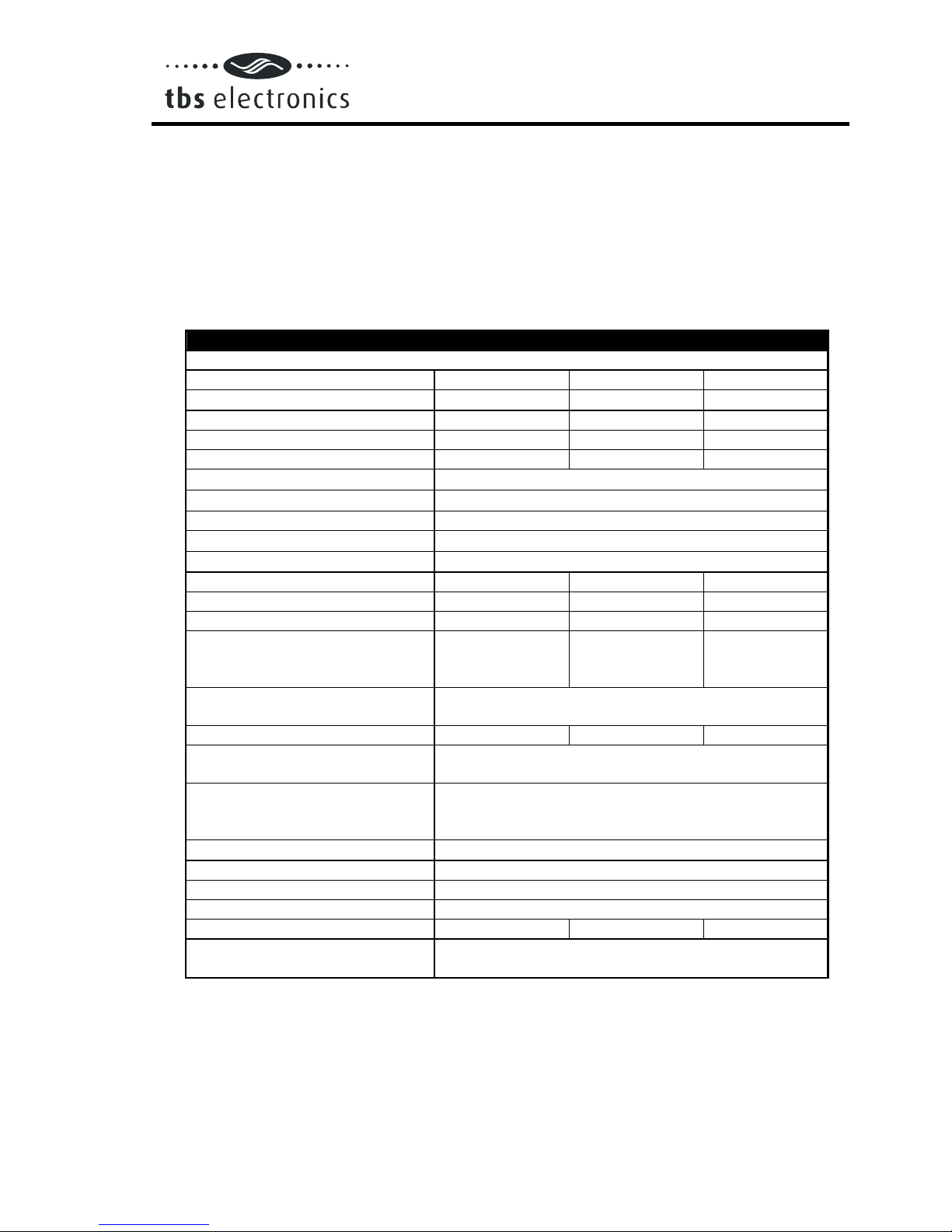

2.3 Battery requirements

For correct operation, the battery voltage should be between 0.92xVnom and 1.23xVnom

where Vnom is 12V, 24V or 48V depending on model, and must be able to supply

sufficient current to your inverter. The following table displays the recommended battery

capacity per inverter type :

Inverter type : Iin at Pnom :

Recommended battery cap. :

PS200-12 18 ADC ≥50 Ah

PS200-24 9 ADC ≥30 Ah

PS200-48 4 ADC ≥20 Ah

PS300-12 26 ADC ≥100 Ah

PS350-24 15 ADC ≥60 Ah

PS450-48 7 ADC ≥30 Ah

PS600-12 47 ADC ≥200Ah

PS800-24 29 ADC ≥120Ah

PS800-48 14 ADC ≥60Ah

For short time inverter usage the recommended battery capacity can be halved. The inverter shuts down when

the battery voltage is below approx. 0.88xVnom or above 1.3xVnom. In a low or high battery situation the

inverter is generating one beep per second to inform you about a possible inverter shut down (except PS200-

xx models). This acoustical message will start at a battery voltage which is close to the shutdown voltage.

CAUTION

ALL 12V INVERTERS MUST BE CONNECTED ONLY TO A 12V

BATTERY.

The inverter will not operate from a 6V battery and will be damaged when

connected to battery voltages higher than 24V.

ALL 24V INVERTERS MUST BE CONNECTED ONLY TO A 24V

BATTERY.

The inverter will not operate from a 12V battery and may be damaged

when connected to battery voltages higher than 31V.

ALL 48V INVERTERS MUST BE CONNECTED ONLY TO A 48V

BATTERY.

The inverter will not operate from a < 40V battery and may be damaged

when connected to battery voltages higher than 60V.

2.4 Connection to the battery

Unless it is absolutely necessary, TBS advises not to extend the battery wires. Extending

the battery wires may increase system losses and can cause inverter malfunctioning. If it

is unavoidable to extend these wires, use a wire gauge of at least 1.5 times larger than

the ones supplied with the inverter. Maximum recommended battery wire length is approx.

3 meters.

2.4.1 General precautions about working with batteries

1. Working in vicinity of a lead acid battery is dangerous. Batteries can generate

explosive gases during operation. Never smoke or allow a spark or flame in vicinity

of a battery. Provide sufficient ventilation around the battery.

2. Wear eye and clothing protection. Avoid touching eyes while working near batteries.

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 7 -

Wash your hands when done.

3. If battery acid contacts skin or clothing, wash immediately with soap and water. If

acid enters eye, immediately flood eye with running cold water for at least 15

minutes and get medical attention immediately.

4. Be careful when using metal tools in vicinity of batteries. Dropping a metal tool onto

a battery might cause a shorted battery and an explosion.

5. Remove personal metal items such as rings, bracelets, necklaces, and watches

when working with a battery. A battery can produce a short-circuit current high

enough to weld a ring or the like to metal, causing severe burns.

CAUTION

THE RED WIRE MUST BE CONNECTED TO THE POSITIVE (+)

TERMINAL AND THE BLACK WIRE TO THE NEGATIVE (-)

TERMINAL OF THE BATTERY.

Reverse polarity connection of the battery wires can damage the

inverter! Damage caused by reversed polarity is not covered by the

warranty. Make sure the powerswitch is in the OFF ‘0’ position before

connecting the battery.

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 8 -

2.5 Connecting the load

Before you connect your appliance(s) to the inverter, always check it’s maximum power

consumption. Do not connect appliances to the inverter needing more than the nominal

power rating of the inverter continuously. Some appliances like motors or pumps, are

drawing large inrush currents in a startup situation. In these situations, it is possible that

the startup current exceeds the overcurrent trip level of the inverter. In this case the output

voltage will shortly decrease to limit the output current of the inverter. If this overcurrent

trip level is continuously exceeded, the inverter will shut down and restart within 18

seconds. In this case it is advisable to disconnect this appliance from the inverter, since it

requires to much power to be driven by this inverter. Note that at higher ambient

temperature levels, the overload capacity of the inverter is reduced.

WARNING

WHEN CONNECTING MORE THAN ONE APPLIANCE TO THE

INVERTER, IN COMBINATION WITH A COMPUTER, NOTE THAT IF

ONE OF THE APPLIANCES IS STARTING UP, IT CAN CAUSE YOUR

COMPUTER TO REBOOT DUE TO A SUDDEN VOLTAGE DROP.

CAUTION

NEVER CONNECT THE INVERTER’S OUTPUT TO THE AC

DISTRIBUTION GRID, LIKE YOUR HOUSEHOLD AC WALL OUTLET.

IT WILL PERMANENTLY DAMAGE THE INVERTER!

2.6 Activating the inverter

When all the above requirements are checked and satisfied and all connections are made,

it’s time to turn on your Powersine inverter by pushing the powerswitch in the ‘I’ position

(see top label for pushdirection). After a short two tone beep (except PS200-xx models),

indicating that all internal circuits are checked, the sinewave shaped output voltage is

gently rising until 230V/50Hz ±2% (or 115V/60Hz ±3%) is reached.

When the inverter is not supplying power to an appliance for a longer time, it’s

recommended to use the inverter in the "Auto Standby" (ASB) mode to heavily reduce the

inverter's own power consumption. In this case the power switch must be pushed in the

'II' position. In the ASB mode the inverter will generate a testpulse on it's output once per

second, to check if there is a load applied. When the ASB mode is activated (by

generating a reversed two tone beep, (except PS200-xx models), the indicator LED will

be continuously on for 4 seconds while the inverter outputs a continuous 230V (or 115V)

sinewave. After this 4 seconds the continuous output will change to a pulsed output,

indicated by a flashing indicator LED. When a load is connected to the inverter output (or

switched on) drawing more than approx. 5W, 12W or 15W (depending on model), the

inverter jumps to the continuous mode immediately, delivering power to the load. When

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 9 -

the load is disconnected again (or switched off), the indicator LED starts flashing again

after 4 seconds, and the inverter jumps back to the pulsed output ASB mode. This way

the inverter automatically jumps to a low power 'sleep' mode when there is no power

demand on the output.

Note that some loads like TV/video equipment (with standby mode) and alarm clocks

need continuous power so that the ASB mode can not be used. With some small non

compensated loads, it is possible that the inverter jumps from continuous output to pulsed

output and vice versa all the time. In this case you have to connect a small additional load

to the AC output.

WARNING

IF THE INVERTER JUMPED INTO AN ‘ERROR MODE’ (SEE

CHAPTER 3.1) DUE TO AN OVERLOAD OR SHORT CIRCUIT, THE

INVERTER WILL AUTOMATICALLY RESTART AFTER ABOUT 18

SECONDS.

In case of an overtemperature error, the inverter will automatically restart

after it has reached an acceptable temperature. Right before the inverter

will restart, it will warn you with a short two-tone beep (except PS200-xx

models).

NEVER SERVICE THE AC CONNECTIONS WHEN THE INVERTER IS

STILL RUNNING IN AN ERROR MODE!

WARNING

THE BUILD IN LARGE ELECTROLYTIC CAPACITORS CAN HOLD

SIGNIFICANT DC VOLTAGE WHEN THE BATTERIES ARE

DISCONNECTED.

To avoid sparks or short inverter operation, it is advisable to switch on

the inverter for 10 seconds after battery disconnection, before you

transport the inverter.

3. TROUBLESHOOTING

3.1 The flash sequence table

Your Powersine inverter is equipped with a self diagnosis system, to inform you about the

cause of inverter shut down. To make this visible the red error/power LED on the

frontpanel of the inverter, can flash in four different sequences. The duration, or

timeperiod, of this sequence is about 1 second. During this timeperiod the red LED can

flash four times in a row at most. The number of flashes in this time period indicates the

cause of inverter shut down.

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 10 -

In the next table you can find out what kind of flash sequence belongs to which error.

Red LED conditions :

= LED flashing

= LED ON

= LED OFF

Time period (1 second) Type of error

Battery voltage too low, too high (one flash

per second)

Overloaded or shorted output

(two flashes per second)

Inverter temperature too high. Cooling down

(three flashes per second)

Inverter in ASB mode

(four flashes per second)

→Power ON, inverter in normal operation

→Inverter OFF

3.2 Acoustical messages (except PS200-xx models)

To warn you before the inverter might shut down, the inverter is equipped with an

acoustical alarm. There are three kinds of acoustical messages depending on the cause

of possible inverter shutdown. These messages are related to the red LED blinking

sequences mentioned previously.

Message 1: One beep per second. The battery voltage has reached a too low or too

high level. If the battery voltage respectively decreases or increases any

further, the inverter shuts down.

Message 2: Two beeps per second. The inverter will shut down soon due to an

overloaded output. Note that at heavy overloads the alarm will not sound

due to too fast inverter shut down.

Message 3: Three beeps per second. The inverter will shut down when it’s

temperature is rising another three degrees Celsius.

3.3 Troubleshooting guideline

PROBLEM : Inverter is not working (red LED OFF)

Possible cause : Remedy :

Power switch in OFF (0) position Push the power switch in the ON (1)

position.

Poor contact between the inverter’s battery

wires and the battery terminals. Clean battery terminals or inverter wire

contacts. Tighten battery terminal screws.

Blown inverter fuse The inverter has to be returned for service.

Very poor battery condition Replace battery

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 11 -

PROBLEM : ‘Battery voltage too low or too high’ error keeps on appearing

Possible cause : Remedy :

Poor battery condition Replace battery or charge it first

Poor connection or inadequate wiring

between battery and inverter, resulting in

too much voltage drop

When extending the battery wires of the

inverter make sure you use the correct wire

gauge (≥1.5 times larger than the fixed

battery wires). It’s not advisable to extend

the battery wires to more than 3 meters.

General failure in your electrical system (in

case of no direct battery connection) Check your electrical system or consult an

electrical engineer to check it for you

PROBLEM : ‘Overloaded or shorted output’ error keeps on appearing

Possible cause : Remedy :

Inverter is overloaded Make sure that the total power rating of the

connected equipment is lower than the

nominal inverter power rating.

Connected equipment features a bad power

factor (cosϕat sinusoidal currents)

reduce the required power consumption of

the load. Please note that for example most

computer loads feature a bad power factor,

which causes a reduction of the maximum

output power of the inverter by approx.

20%.

Connected equipment causes a short circuit

at the inverter’s output Make sure that the connected equipment is

not broken or malfunctioning. Check if the

AC power cord between the inverter and

the connected equipment is ok. Any

physical damage on the power cord can

produce a short circuit. Be careful in these

kind of situations!

Connected equipment produces a too large

inrush current Try to power-up connected equipment

successively, and not simultaneously. Or

connect the load first and then turn-on the

inverter. Otherwise stop using the

connected load, it’s not suitable to drive it

with this inverter

PROBLEM : ‘Inverter temperature too high. Cooling down’ error keeps on

appearing

Possible cause : Remedy :

Airflow around the inverter is obstructed Make sure there is at least 10 centimeters

of clearance around the inverter. Remove

any items placed on or over the inverter.

Keep the inverter away from direct sunlight

or heat producing equipment

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 12 -

Too high ambient temperature Move the inverter to a cooler place or

provide additional cooling by an external

fan

Note : Don’t turn off the inverter when it’s operating in an ‘Inverter temperature too high.

Cooling down’ error. The inverter needs this error time to cool down.

PROBLEM : Inverter jumps between continuous mode and ASB mode all the time

Possible cause : Remedy :

Connected load is not compensated or the

ratio between inrush current and continuous

current is too large.

Connect an additional load to the output.

If none of the above remedies will help solving the problem you encounter, it’s best to

contact your local TBS distributor for further help and/or possible repair of your inverter.

Do not open the inverter yourself, there are dangerous high voltages present inside.

Opening the inverter will directly void your warranty.

4. WARRANTY / LIMITS OF RESPONSIBILITY

TBS Electronics (TBS) warrants this inverter to be free from defects in workmanship or

materials for 24 months from the date of purchase. During this period TBS will repair the

defective inverter free of charge. TBS is not responsible for any costs of the transport of

this inverter.

This warranty is void if the inverter has suffered any physical damage or alteration, either

internally or externally, and does not cover damage arising from improper use

1)

,

attempting to operate the inverter with excessive power consumption requirements, or

from use in an unsuitable environment.

This warranty will not apply where the product has been misused, neglected, improperly

installed or repaired by anyone other than TBS. TBS is not responsible for any loss,

damage or costs arising from improper use, use in an unsuitable environment, improper

installing of the inverter and inverter malfunctioning.

Since TBS cannot control the use and installation (according to local regulations) of their

products, the customer is always responsible for the actual use of these products. TBS

products are not designed for use as cricital components in life support devices or

systems, that can potentially harm humans and/or the environment. The customer is

always responsible when implementing TBS products in these kind of applications. TBS

does not accept any responsibility for any violation of patents or other rights of third

parties, resulting from the use of the TBS product. TBS keeps the right to change product

specifications without previous notice.

1)

Examples of improper use are :

- Too high input voltage applied

- Reverse connection of battery polarity

- Mechanical stressed enclosure or internals due to harsh handling and/or incorrect

packaging

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 13 -

- Backfeed via inverter output from external power source like public grid or generator

- contact with any liquids or oxidation caused by condensation

5. TECHNICAL DATA

5.1 Powersine 200-12, 200-24 and 200-48

TECHNICAL DATA

PS200-12 PS200-24 PS200-48

Output power

1)

: @ Ta = 25°C

Pnom 175VA 175VA 175VA

P10minutes 210VA 220VA 220VA

Psurge 400VA 500VA 500VA

Output voltage 230Vac ±2% or 115Vac ±2%

Output frequency 50Hz ±0.05% or 60Hz ±0.05%

Output waveform True sinewave (THD < 5%

1)

@ Pnom)

Permissible cos ϕof load 0.2 – 1 (up to Pnom)

Input voltage (±3% tolerance) :

Nominal 12Vdc 24Vdc 48Vdc

Range 10.5

2)

– 16Vdc 21

2)

– 31Vdc 41

2)

– 60Vdc

Maximum efficiency 90% 91% 93%

No load power consumption at

nominal input voltage

[ASB]

< 2.8W

[0.6W] < 3W

[0.8W] < 4W

[1.2W]

Operating temperature range

(ambient) -20°C to +50 °C

ASB threshold Pout = 12W Pout = 15W Pout = 15W

Protections against Short circuit, overload, high temperature and low

battery voltage

Indications (by pre-programmed

flashing sequences of the power

LED)

Power on, short circuit/overload, high temperature,

high/low battery voltage and ASB mode

DC input connection Two wires, length 1.5 meters, ∅4mm²

AC output connection IEC-320 AC outlet

Enclosure body size (l x h x w) 154 x 98 x 130mm (without mounting brackets)

Protection class IP20

Total weight 2.4 kg 2.4 kg 2.4 kg

The inverter complies with the

following standards : See page 16

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 14 -

5.2 Powersine 300-12, 350-24 and 450-48

TECHNICAL DATA

PS300-12 PS350-24 PS450-48

Output power

1)

: @ Ta = 25°C

Pnom 250VA 300VA 300VA

P10minutes 330VA 360VA 450VA

Psurge 700VA 800VA 800VA

Output voltage 230Vac ±2% or 115vac ±2%

Output frequency 50Hz ±0.05% or 60Hz ±0.05%

Output waveform True sinewave (THD < 5%

1)

@ Pnom)

Permissible cos ϕof load 0.2 – 1 (up to Pnom)

Input voltage (±3% tolerance) :

Nominal 12Vdc 24Vdc 48Vdc

Range 10.5

2)

– 16Vdc 21

2)

– 31Vdc 41

2)

– 60Vdc

Maximum efficiency 91% 93% 95%

No load power consumption at

nominal input voltage

[ASB]

< 3W

[0.7W] < 3.5W

[0.8W] < 6.5W

[1.3W]

Operating temperature range

(ambient) -20°C to +50 °C

ASB threshold Pout = 12W Pout = 15W Pout = 15W

Protections against Short circuit, overload, high temperature and low

battery voltage

Indications (by pre-programmed

flashing sequences of the power

LED)

Power on, short circuit/overload, high temperature,

high/low battery voltage and ASB mode

DC input connection Two wires, length 1.5 meters, ∅4mm²

AC output connection IEC-320 AC outlet

Enclosure body size (l x h x w) 184 x 98 x 130mm (without mounting brackets)

Protection class IP20

Total weight 3.5 kg 3.5 kg 3.5 kg

The inverter complies with the

following standards : See page 16

5.3 Powersine 600-12, 800-24 and 800-48

TECHNICAL DATA

PS600-12 PS800-24 PS800-48

Output power

1)

: @ Ta = 25°C

Pnom 500VA 600VA 600VA

P10minutes 600VA 800VA 800VA

Psurge 1000VA 1200VA 1250VA

Output voltage 230Vac ±2% or 115Vac ±2%

Output frequency 50Hz ±0.05% or 60Hz ±0.05%

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 15 -

Output waveform True sinewave (THD < 5%

1)

@ Pnom)

Permissible cos ϕof load 0.2 – 1 (up to Pnom)

Input voltage (±3% tolerance) :

Nominal 12Vdc 24Vdc 48Vdc

Range 10.5

2)

– 16Vdc 21

2)

– 31Vdc 41

2)

– 60Vdc

Maximum efficiency 92% 93% 94%

No load power consumption at

nominal input voltage

[ASB]

< 4.8W

[0.4W] < 6.5W

[0.7W] < 8.2W

[0.5W]

Operating temperature range

(ambient) -20°C to +50 °C

ASB threshold Pout = 15W Pout = 15W Pout = 15W

Protections against Short circuit, overload, high temperature and low

battery voltage

Indications (by pre-programmed

flashing sequences of the power

LED)

Power on, short circuit/overload, high temperature,

high/low battery voltage and ASB mode

DC input connection Two wires, length 1.5 meters, ∅10mm²

AC output connection IEC-320 AC outlet

Enclosure body size (l x h x w) 228 x 113 x 163mm (without mounting brackets)

Protection class IP20

Total weight 6.2 kg 6.2 kg 6.2 kg

The inverter complies with the

following standards : See page 16

Note : the given specifications are subject to change without notice

1)

Measured with resistive load. Power ratings are subject to a tolerance of ±4% and are

decreasing as temperature rises with a rate of approx. 1.2%/°C starting from 25°C.

2)

Undervoltage limit is dynamic. This limit decreases with increasing load to compensate

the voltage drop across cables and connections.

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 16 -

6. DECLARATION OF CONFORMITY

MANUFACTURER : TBS Electronics BV

ADDRESS : De Marowijne 3

1689AR Zwaag

The Netherlands

Declares that the following products :

PRODUCT TYPE : DC TO AC SINEWAVE INVERTER

MODELS : - Powersine 200-12

- Powersine 200-24

- Powersine 200-48

- Powersine 300-12

- Powersine 350-24

- Powersine 450-48

- Powersine 600-12

- Powersine 800-24

- Powersine 800-48

Conform to the requirements of the following Directives of the European Union :

EMC Directive 2004/108/EC

Automotive Directive 95/54/EC

RoHS Directive 2002/95/EC

The above products are in conformity with the following harmonized standards :

- EN61000-6-3 : 2001 EMC - Generic Emissions Standard

- EN61000-6-2 : 2005 EMC - Generic Immunity Standard

Low Voltage Directive (2006/95/EC) : EN60335-1 : 1999

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 17 -

INHOUDSOPGAVE

1. INTRODUCTIE . . . . . . . . . . . . . . . . . . . . . . . . 18

2. INSTALLATIE . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1 Plaatsing van de omvormer . . . . . . . . . . . . . . . . . . 18

2.2 De “Remote on/off” functie (alleen PS600-12 tot en met PS800-48 modellen) . 19

2.3 Accu eisen . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Het aansluiten van de accu . . . . . . . . . . . . . . . . . . 20

2.4.1 Voorzorgsmaatregelen omtrent het werken met accu’s . . . . . . . . 21

2.5 Aansluiten van de belasting . . . . . . . . . . . . . . . . . . 22

2.6 Activeren van de omvormer . . . . . . . . . . . . . . . . . . 22

3. HET OPLOSSEN VAN STORINGEN . . . . . . . . . . . . . . . . . 24

3.1 Optische alarmen . . . . . . . . . . . . . . . . . . . . . 24

3.2 Akoestische alarmen (behalve PS200-xx modellen) . . . . . . . . . . 24

3.3 Storingen met mogelijke oplossingen . . . . . . . . . . . . . . . 25

4. GARANTIE / AANSPRAKELIJKHEID FABRIKANT . . . . . . . . . . . . 26

5. TECHNISCHE GEGEVENS . . . . . . . . . . . . . . . . . . . . 27

5.1 Powersine 200-xx . . . . . . . . . . . . . . . . . . . . . 27

5.2 Powersine 300-12, 350-24 en 450-48 . . . . . . . . . . . . . . . 28

5.3 Powersine 600-12, 800-24 en 800-48 . . . . . . . . . . . . . . . 29

6. CONFORMITEITSVERKLARING . . . . . . . . . . . . . . . . . . 29

Powersine dc to ac sinewave inverters

Powersine dc to ac sinewave invertersPowersine dc to ac sinewave inverters

Powersine dc to ac sinewave inverters

- 18 -

1. INTRODUCTIE

De Powersine sinus omvormers staan bekend als één van de meest geavanceerde op dit

moment verkrijgbare omvormers. Met een hoge betrouwbaarheid, rendement en sinus

kwaliteit als één van de meest belangrijke ontwerp eisen, zijn de Powersine omvormers

ontwikkelt om u te voorzien van een jaren lange veilige en probleemloze werking.

Uw Powersine omvormer maakt gebruik van een geavanceerd microprocessor

besturingssysteem en een MOSFET power stage met een zeer efficiënte ringkern

transformator. Met deze speciale transformator in combinatie met ruim

overgedimensioneerde vermogens halfgeleiders, wordt een zeer betrouwbare werking

gegarandeerd. Hierdoor kunnen extreme overbelastingen, zoals het opstarten van

compressors of pompen, veilig worden doorstaan.

Om volledig op de hoogte te kunnen blijven van de status van uw omvormer, is een diagnose

systeem ingebouwd om u te waarschuwen in het geval van alarm situaties. Aan de hand van

het knipper patroon van de rode LED kan bepaald worden met welk type alarm u te maken

heeft. Daarnaast kan de Powersine omvormer u ook akoestisch waarschuwen voordat de

omvormer uitschakelt vanwege een te lage accuspanning, een overbelastingsconditie of een

te hoge temperatuur (behalve PS200-xx modellen).

Om een optimale en veilige werking van uw omvormer te verkrijgen is het belangrijk dat deze

op de juiste manier geïnstalleerd en gebruikt wordt. Lees daarom eerst zorgvuldig deze

gebruiksaanwijzing voordat u met uw Powersine omvormer aan de slag gaat.

2. INSTALLATIE

2.1 Plaatsing van de omvormer

1. Plafond montage : Niet aanbevolen

2. Vloer montage : OK

3. Verticale muur montage, ventilator onder : OK (pas op kleine objecten die door de

ventilatie openingen aan de

bovenkant kunnen vallen)

4. Verticale muur montage, ventilator boven : Niet aanbevolen

5. Horizontale muur montage : OK

Om een probleemloze werking van de omvormer te kunnen garanderen, moet de lokatie

waarin deze wordt geïnstalleerd aan de volgende eisen voldoen :

a. Vermijd elk contact tussen water en de omvormer. Stel de omvormer niet bloot aan

regen of mist.

This manual suits for next models

8

Table of contents

Languages:

Other tbs electronics Inverter manuals

tbs electronics

tbs electronics Powersine PS200-12 User manual

tbs electronics

tbs electronics Powersine Combi PSC3500-48-40 User manual

tbs electronics

tbs electronics Powersine Combi PSC1600-12-60 User manual

tbs electronics

tbs electronics Powersine Combi PSC1800-24-30 User manual

tbs electronics

tbs electronics powersine PS1000-12 User manual