TCM FB-8 Series User manual

No. SEB‑7POBE

TCM

⑮

@~æ.

WD@

国間

A

間切

I&

[S

FORKLIFTTRUCK

Counter 8alanced

FB唱O‑S

FB唱5‑s

FB

唱8‑s

FB20‑s

FB25‑s

FB30‑s

FB25‑SLB

FB25‑sv

FB30‑sv

FB35‑ss

TCMCORPORATION

FOREWORD

The new TCM’s FB-8 Series battery-powered forklift trucks are provided with a newly designed

speed control system and AC motors for both the traveling and load handling systems to assure

high performance operation.

The trucks of this series are also provided with a self-diagnosis function which keeps watching

the operating statuses of the main control systems of the truck. If the truck has a trouble, the

function detects the trouble and displays the result of diagnosis. The maintainability is thus

improved.

As for mobility, since the high capacity batteries and high power drive motor are used, the rst-

class acceleration, gradeability, and traveling performance are achieved.

Controllability is also improved by the standard equipped power steering unit.

To save power, the acceleration and traveling speeds are selectable and made changeable

according to working conditions. Also for effective use of the battery, a regenerative device is

provided to send back counter electromotive force to the battery.

This Service Manual is intended to provide the maintenance personnel with helpful information

of the structures of the major components and with instructions on the maintenance and repair of

such components. We hope it will be much help for your servicing and maintenance operations.

December 2012

SPECIFICATIONS (1)

Truck model

Item FB10-8 FB15-8 FB18-8 FB20-8

Performance

Max. load kg [lbs] 1000 [2000] 1500 [3000] 1750 [3500] 2000 [4000]

Load center mm [in.] 500 [24] ←←←

Max. lifting height mm [in.] 3000 [118.1] ←←←

Tilting angle

Fwd °6←←←

Bwd °12 ←←←

Free lift Amm [in.] 155 [6.1] ← ← 110 [4.3]

Mast tilting time (Fwd - Bwd) s 2.0 - 1.4 ← ← 2.7 - 2.0

Fork lifting speed

Loaded mm/s [fpm] 390 [76.8] 350 [68.9] 330 [65.0] 290 [57.1]

Unloaded mm/s [fpm] 580 [114.2] ← ← 510 [100.4]

Travel speed

Loaded km/h [mph] 14 [8.7] ←←←

Unloaded km/h [mph] 16 [9.9] ←←←

Gradeability

(Starting on an uphill when loaded) 1/7 ←←←

Min. turning radius

(Outermost part of truck)

EPS: Bmm [in.] 1700 [66.9] ←1790 [70.5] 1950 [76.8]

Orbitrol type: 1800 [70.9] ←1890 [74.4] 2070 [81.5]

Min. intersecting aisle Cmm [in.] 1690 [66.5] ←1730 [68.1] 1895 [79.6]

Dimensions mm [in.]

Overall length (includ. fork) D2875 [113.2] ←2975 [117.1] 3315 [130.5]

Overall width E1070 [42.1] ← ← 1150 [45.3]

Overall height (Overhead guard)

F2080 [81.9] ← ← 2125 [83.7]

EXN:

2140 [84.3] ← ← 2185 [86.0]

Overall extended height 4030 [158.7] ←←←

Wheel base G1250 [49.2] ←1350 [53.2] 1400 [55.1]

Tread

Front wheels H910 [35.8] ← ← 955 [37.6]

Rear wheels J900 [35.4] ← ← 950 [37.4]

Fork overhang K375 [14.8] ← ← 435 [17.1]

Rear overhang L330 [13.0] ← ← 410 [16.1]

Fork size

(Length Lx Width Mx Thickness N)

920x100x35

[36.2x3.9x1.4] ← ← 1070x122x40

[42.1x4.8x1.6]

Fork spacing Q200 - 920

[7.9 - 36.2] ← ← 245 -1020

[9.6 - 40.2]

Minimum under clearance 90 [3.5]

(Rear axle) ← ← 100 [3.9]

(Rear axle)

Tow pin height 390 [15.4] ← ← 440 [17.3]

Weight

Service Weight with std. batteries kg [lbf] 2680 [5908] 2710 [5976] 3030 [6680] 3500 [7716]

The values in the Performance section are given for trucks operating in the Super mode.

SPECIFICATIONS (2)

Truck model

Item FB25-8 FB25-8LB

FB25-8V FB30-8

FB30-8V FB35-8S

Performance

Max. load kg [lbs] 2500 [5000] ←3000 [6600] 3500 [7000]

Load center mm [in.] 500 [24] ←←←

Max. lifting height mm [in.] 3000 [118.1] ←←←

Tilting angle

Fwd °6←←←

Bwd °12 ←←10

Free lift Amm [in.] 110 [4.3] ←165 [6.5] 170 [6.7]

Mast tilting time (Fwd - Bwd) s 2.7 - 2.0 ←2.5 - 2.0 3.5 - 2.5

Fork lifting speed

Loaded mm/s [fpm] 265 [52.2] ←290 [57.1] 240 [47.2]

Unloaded mm/s [fpm] 510 [100.4] ←490 [96.5] 410 [80.7]

Travel speed

Loaded km/h [mph] 14 [8.7] 13.5 [8.4] 14 [8.7] ←

Unloaded km/h [mph] 16 [9.9] 15.5 [9.6] 15 [9.3] ←

Gradeability

(Starting on an uphill when loaded) 1/7 1/8 ←1/10

Min. turning radius

(Outermost part of truck)

EPS: Bmm [in.] 1970 [77.6] 2065 [81.3] 2140 [84.3] 2360 [92.9]

Orbitrol type: 2100 [82.7] 2200 [86.6] 2290 [90.2] 2500[98.4]

Min. intersecting aisle Cmm [in.] 1905 [75.0] 1955 [76.9] 2050 [80.7] 2250 [88.6]

Dimensions mm [in.]

Overall length (includ. fork) D3355 [132] 3460 [136] 3580 [140.9] 3805 [149.8]

Overall width E1150 [45.3] ←1225 [48.2] 1380 [54.3]

Overall height (Overhead guard)

F2125 [83.7]

LB: 2250 [88.6]

V: 2100 [82.7]

2190 [86.2]

V: 2100 [82.7] 2190 [86.2]

Overall extended height 4030 [158.7] ←4260 [167.7 ] ←

Wheel base G1400 [55.1] 1545 [60.8] 1600 [63.0] 1800 [70.9]

Tread

Front wheels H955 [37.6] ←1000 [39.4] 1140 [44.9]

Rear wheels J950 [37.4] ←←←

Fork overhang K435 [17.1] ←480 [18.9] 500 [19.7]

Rear overhang L450 [17.7] 410 [16.1] 430 [16.9] ←

Fork size

(Length Lx Width Mx Thickness N)

1070x122x40

[42.1x4.8x1.6] ←1070x125x45

[42.1x4.9x1.8] 1070x150x50

[42.1x5.9x2.0]

Fork spacing Q245 - 1020

[9.6 - 40.2] ←250 - 1090

[9.8 - 42.9] 300 - 1090

[11.8 - 42.9]

Minimum under clearance 100 [3.9]

(Rear axle) 90 [3.5]

(Rear axle) ← ←

Tow pin height 440 [17.3] ←475 [18.7] ←

Weight

Service Weight with std. batteries kg [lbf] 3910 [8620]

LB: 4400 [9700]

V: 4290 [9460]

4640 [10200] 5240 [11600]

The values in the Performance section are given for trucks operating in the Super mode.

Unit: mm [in.]

Fig. 1 Overall Dimensions

E

N

J

Q

H

B

C

A

1~2.5t : 4030 3~3.5t : 4260

3000

P

F

M K DG L

1 - 2.5 t: 4030 [158.7] 3 - 3.5 t: 4260 [167.7]

3000 [ 118.1]

Table 1. Maintenance Standard List

Truck model

Item FB10-8

FB15-8 FB18-8 FB20-8

FB25-8

FB25-8LB

FB25-8V

FB30-8

FB30-8V FB35-8S

Electric system

Motor brush size and wear

limit

Traction mm [in.] * * * * *

Pump mm [in.] * * * * *

Power steering

(EPS type only)

mm [in.]

22 - 13 [0.87 - 0.51]

←←←←

Motor brush spring force

Traction

N{kgf}[lbf]

*****

Pump

N{kgf}[lbf]

*****

Power steering

(EPS type only)

N{kgf}[lbf]

11.8 {1.2} [2.7] ←←←←

Voltage relay check voltage (20°C) (V) 58.8±0.2 ← ← 87.0±0.2 ←

Timer operating time Normal (h) 14 ←←←←

Fail (h) 16 ←←←←

Controller current limit value

(Traction motor lock current) P (A) * * * * *

E (A) * * * * *

Fuses

Traveling system main circuit

(A) 400 ←500 400 ←

For control circuit

(battery power supply) (A) 10 ←←←←

Lift lock (A) 2 ←←←←

Battery charger primary side

(thermal relay) (A) 24 ←34 40 ←

Battery charger secondary side

(A) 130 ←130/200 130 ←

For control circuit

(key switch power supply) (A) 10 ←←←←

For accessory circuit (A) 10 ←←←←

Steering axles and wheels

Tire air

pressure

Front (single)

(double)

MPa{kgf/cm2}[psi]

0.85±0.03 {8.5±0.3}

[123.3±4.35]

0.7±0.03 {7.0±0.3}

[101.5±4.4]

1.00±0.03 {10.0±0.3}

[145.0±4.35]

←

←

←

0.8±0.03 {8.0±0.3}

[116.0±4.35]

←

0.85±0.03 {8.5±0.3}

[123.3±4.35]

←

Rear

MPa{kgf/cm2}[psi]

0.85±0.03 {8.5±0.3}

[123.3±4.35]

←

0.90±0.03 {9.0±0.3}

[130.5±4.35]

←*

Hub nut tightening torque Front

N-m{kgf-m}[lbf-ft]

150-175 {15-17.5}

[110.6-129.1]

←

370-420 {37.8-42.8}

[273-310]

470.7-549.2

{48-56} [347-405] ←

Rear

N-m{kgf-m}[lbf-ft]

127.5-190.3 13.0-19.4}

[94-140]

←←←←

Axle shaft mounting bolt tightening torque

N-m{kgf-m}[lbf-ft]

96.1-110.8 {9.8-11.3}

[70.9-81.7]

←*

96.1-110.8 {9.8-11.3}

[70.9-81.7]

←

Split rim assembly bolt

tightening torque

Front

N-m{kgf-m}[lbf-ft]

60.8-90.2 {6.2-9.2}

[44.8-66.5]

←***

Rear

N-m{kgf-m}[lbf-ft]

30.4-45.1 {3.1-4.6}

[22.4-33.3]

←

60.8-90.2 {6.2-9.2}

[44.8-66.5]

← ←

Steering axle gap in fore-and-aft direction

mm [in.] less than 1 [0.039] ←←←←

Steering axle center pin diameter (EPS type only)

mm [in.] 40+0

-0.1 [1.57+0

-0.004 ]←50+0

-0.1 [1.97 +0

-0.004 ]← ←

Steering axle bushing inner diameter mm [in.] 40+0.1

-0 [1.57+0

-0.004 ]←50+0

-0.1 [1.97 +0

-0.004 ]← ←

Steering system

Steering wheel play in rotating direction

mm [in.] 75±25 [2.95±0.98] ←←←←

Camber angle °1←←←←

Minimum turning radius

mm [in.]

EPS type 1700+50

-0 [66.9+1.97

-0 ] 1790+50

-0 [70.5+1.97

-0 ]

FB20: 1950

+50

-0

[76.8

+1.97

-0

]

2140+50

-0 [84.3+1.97

-0 ] 2360+50

-0 [92.9+1.97

-0 ]

EPS type

FB25: 1970

+50

-0

[77.6

+1.97

-0

]

Orbitrol type 1800 [70.9] 1890 [74.4] FB20: 2070 [81.5]

FB25: 2100 [82.7] 2290 [90.2] 2500 [98.4]

Power steering relief pressure setting

MPa{kgf/cm2}[psi]

*****

Brake system

Brake pedal height mm [in.] 97 [3.8] ← ← 110 ←

Brake pedal play mm [in.]

10±5 [0.393±0.197]

←←←←

Brake pedal height when depressed fully

mm [in.]

60±10 [2.362±0.393]

←←←←

Foot pedal braking effect Unloaded within 2.5 m ←←←←

Loaded within 2.5 m ←←←←

Parking brake lever operating force

N{kgf}[lbf]

*****

Parking brake braking effect Unloaded

Held in position on

20% slope

←

Held in position on

16.7% slope

← ←

Loaded

Held in position on

14.3% slope

← ←

Held in position on

12.5% slope

←

Clearance between brake drum and lining

mm [in.] 0.25-0.4

[0.0098-0.016] ←←←←

Lining thickness mm [in.] 5+0

-3 [0.197+0

-0.118 ]←5.6+0

-3.6 [0.22+0

-0.142 ] 8+0

-6 [0.31+0

-0.236 ]] ←

Brake drum inner diameter mm [in.] 254+2

-0 [10+0.079

-0 ]←280+2

-0 [11.0+0.079

-0 ] 314+2

-0 [12.4+0.079

-0 ]←

Brake drum mounting bolt tightening torque

N-m{kgf-m}[lbf-ft]

* *

215.7-235.4 {22-24}

[159.1-173.6]

470.7-549.2 {48-56}

[347.2-405.1]

←

Back plate mounting bolt tightening torque

N-m{kgf-m}[lbf-ft]

117.7-137.3

{12-14} [86.8-101.3]

←

205.9-225.6 {

21-23} [151.9-166.4]

← ←

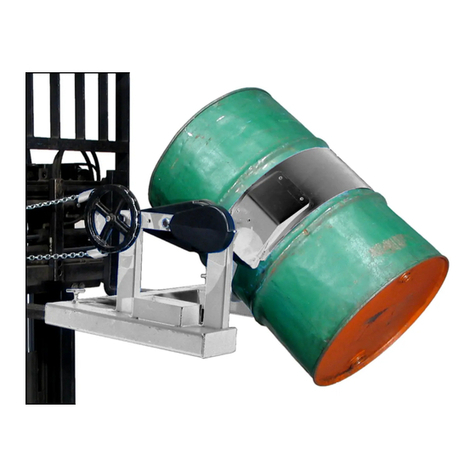

Load han-

dling system

Fork thickness mm [in.] 35+0

-4 [1.38+0

-0.157 ]←40+0

-4 [1.57+0

-0.157 ] 45+0

-6 [1.77+0

-0.236 ] 50+0

-5 [1.97+0

-0.197 ]

Opening of fork tips mm [in.] within 10 [0.394] ←←←←

Difference in height between right and left fork tips

mm [in.] 0±5 [0±0.197] ←←←←

Chain length mm [in.] 19.05+50

-0 ← ← 25.4+50

-0 ←

Hydraulic system

Tilt cylinder piston rod lock bolt and nut

tightening torque

N-m{kgf-m}[lbf-ft]

107.9±20.6 {11.0±2.1}

[79.6±15.2]

←←←←

Lift cylinder natural drop mm [in.]/min

less than 75 [2.95]/10

←

less than 60 [2.36]/10 less than 50 [1.97]/10

←

Tilt cylinder natural tilt (extension of piston rod)

mm [in.]/min

less than 25 [0.98]/10

←

less than 20 [0.79]/10

← ←

Fork lifting speed (Unloaded) mm [in.]/sec 580+50

-0 [22.8+1.97

-0 ]←510+50

-0 [20.1+1.97

-0 ] 490+50

-0 [19.3+1.97

-0 ] 410+50

-0 [16.1+1.97

-0 ]

Control valve relief pressure setting

MPa{kgf/cm2}[psi]

13.7+0.49

-0 {140+5

-0 }

[1990+71.1

-0 ]15.7+0.49

-0 {160+5

-0 }

[2277+71.1

-0 ]17.2+0.49

-0 {175+5

-0 }

[2495+71.1

-0 ]← ←

Safety

device

Overhead guard mounting bolt and nut

tightening torque

N-m{kgf-m}[lbf-ft]

31.4-47.1 {3.2-4.8}

[23.2-34.7]

←←←←

Load backrest mounting bolt tightening torque

N-m{kgf-m}[lbf-ft]

59.3±11.9 {6.05±1.21}

[43.7±8.8]

←←←←

01. CAUTION TO TAKE WHEN SERVICING THE TRUCK

* Before servicing the truck, make sure to:

1. Park the truck on a level surface and jack up the drive wheel off the oor or ground.

Make sure there is no obstacle above and around the truck before operating the load handling

system.

* Caution to take when measuring, inspecting or repairing:

2. Before connecting or disconnecting wire harness couplers, make sure the key switch is turned off

and the battery receptacles are disconnected.

3. When measuring the resistance of wire harness couplers with a multimeter, connect the probes to

the lead wire side of the coupler.

4. When inspecting the truck with the forks raised, support the forks to prevent them from falling

unexpectedly.

5. When inspecting the truck with the mast advanced, put a pallet between the mast and the front

guard of the truck to prevent the mast from retracting unexpectedly.

6. Inspection and repair of the truck must be performed only by qualified service personnel

authorized by TCM.

Reach model

Counterbalanced model

02. BASIC SERVICING KNOWLEDGE

1. Installing bearings

When installing a bearing onto a shaft, tap its

inner race with a mallet as shown in Figure 02.1.

When installing a bearing into a case, tap its outer

race.

When removing, use the same procedure as for

installing.

2. “O”-rings

①Use “O”-rings free from molding fault or damage.

②Clean “O”-rings and their mounting area and apply grease or hydraulic oil to them.

③When installing “O”-rings, do not expand them so excessively that they suffer permanent

deformation. Also do not roll them when installing; otherwise they might stay twisted, causing oil

leakage.

④When using an “O”-ring and back-up ring as

a set, such as when hydraulic pressure is high,

position the “O”-ring at the side which receives

the oil pressure.

3. Oil seals

①Oil seals should be installed with the seal lip pointed toward the lubrication or hydraulic oil.

②When installing an oil seal on a housing, apply a thin coat of packing cementing agent on the

oil seal outer ring and inside the housing to prevent oil leakage through the fitting area. It is

recommended to use a suitable jig to apply uniform pressure when mounting oil seals.

Fig. 02.1 Installing bearings

JIG

Fig. 02.2 “O”-ring location

Pressure

Fig. 02.3 Installing Oil Seal

JIG JIG JIG

③When installing an oil seal onto a shaft, apply

lubricating oil or grease to its seal lip and the

mounting surface of the shaft. For a double-

lip type, fill grease by 1/3 to 1/2 of the space

between the lips.

When inserting an oil seal into a case, use care

to damage the seal lip. It is good practice to use

a suitable conical sleeve.

4. Using LOCTITE

(1) Procedure for using LOCTITE

①Clean or degrease the surface of parts you are going to apply LOCTITE, using trichloroethylene,

acetone, ether or alkaline solution.

② Blow dry them with compressed air or allow to air dry at room temperature sufciently.

③ Apply specied LOCTITE.

(2) Removing parts

When removing parts which were installed with the application of LOCTITE, use tools such as a

spanner, wrench, and pulley remover.

If you fear that a part may break due to the effect of LOCTITE if forcibly removed, heat the part to

200 to 250°C [392 to 482°F] with a soldering iron or gas burner.

Remember that parts are very hot after heating. Use caution not to get burnt when

removing them.

(3) Reinstalling parts

①When destroyed, LOCTITE remains as white powder on the threads of bolts.

You can apply a

new coat of LOCTITE again over their surface.

Note: For example, if a bolt turns slightly due to bolt torque checking, remove the bolt and apply

LOCTITE again and reinstall.

② If LOCTITE is used for the surface of a ange, it is necessary to remove hardened LOCTITE with

a wire brush when reinstalling the ange.

5. How to use a power wrench

Power wrenches have their respective torque multiplying factors. Refer to the product catalog of

each power wrench.

It should be noted that a value obtained by multiplying the output torque of a torque wrench by the

multiplying factor of a power wrench is not necessarily an output torque.

Remember this especially when the tightening torque is strictly specied.

Fig. 02.4 Installing Oil Seal

SLEEVE

JIG

03. CLEANING

1. General metallic parts

① Clean parts thoroughly using cleaning uid. It is recommended that parts be immersed in cleaning

uid and moved up and down slowly until all old lubricant and foreign material is dissolved and

parts are thoroughly cleaned.

②Cast parts should be cleaned with cleaning solvent or steam cleaned.

③If a part is severely contaminated, use a wire brush or a piece of wood or metal to scrape off

contaminants from the part. Wash it in cleaning fluid once, before cleaning it completely.

However, do not use a wire brush for cleaning sliding surfaces or machined surfaces.

④Oil passages must be cleaned with a steam cleaner. After checking for clogging with a piece of

wire, they also should be cleaned with cleaning uid or with compressed air.

⑤Some parts may be cleaned in hot solution tanks with mild alkaline solution. Parts should remain

in solution long enough to be thoroughly cleaned and warmed.

This will aid the evaporation of the cleaning solution and rise water. Parts cleaned in solution

tanks must be thoroughly rinsed with clean water to remove all traces of alkali.

Careshouldbeexercisedtoavoidskinrashes,rehazardsandinhalationofvaporswhen

using solvent type cleaners.

⑥If alloy parts, such as bearing shells or bushings, are cleaned with alkaline solution, they are apt to

corrode due to ionization. Such parts should be cleaned with kerosene, Tricrene solvent vapor or

“Magnus” uid.

⑦After cleaning, parts must be thoroughly dried with compressed air.

2. Bearings

①To dislodge solidified particles of lubricant, immerse bearings in cleaning fluid and remove

them from the uid. On a clean work bench, tap the bearing softly with a soft mallet to dislodge

solidied particles.

②When drying bearings, be careful to direct air stream across bearing to avoid spinning.

3. Rubber parts

①When rubber parts need to be cleaned, use alcohol or wipe them clean with a soft cloth.

②Never use gasoline, diesel fuel or kerosene for cleaning. Use the same kind of oil for which the

rubber part will be used.

04. STANDARD BOLT TIGHTENING TORQUE

See the section “04. STANDARD BOLT TIGHTENING TORQUE” for the torques of standard

bolts when they are used for general applications. Refer to the Shop Manual and Service Manual of

your truck model when:

1) Special nuts are used.

2) Synthetic resin or rubber is used for tightening.

3) Specied tightening torque is given.

Table 04.1 Strength

Strength Indication on bolt Material

4.6

SS400

(The number may be omitted.)

6.8

S45C

8.8

SCM435

Boron steel

(“B” may be omitted.)

10.9

SCM435

Boron steel

(“B” may be omitted.)

Table 04.2

Name Shape Thread size Material Division by

strength Surface

treatment Part number

Hex. head

bolt

Normal M4 - M8 coarse and

M10 - M39 ne

SS400 4.6

Black 01101- Nominal symbol

SS400 4.6

Yellow

chromate

01100- “

S45C 6.8 01103- “

SCM435, Boron steel

8.8 01106- “

SCM435, Boron steel

10.9 01107- “

BsBME1 — 01108- “

Coarse M10 - M39 coarse

SS400 4.6

Black

01112- “

SS400 4.6

Yellow

Chromate

01110- “

S45C 6.8 01113- “

SCM435, Boron steel

8.8 01116- “

SCM435, Boron steel

10.9 01119- “

Full thread

(normal,

coarse) M10 - M39 coarse

SS400 4.6

Black

01115- “

SS400 4.6

Yellow

Chromate

01111- “

S45C 6.8 01114- “

SCM435, Boron steel

8.8 01117- “

Full thread

(normal) M4 - M8 coarse and

M10 - M39 ne

SS400 4.6

Black

01121- “

SS400 4.6

Yellow

Chromate

01120- “

S45C 6.8 01123- “

SCM435, Boron steel

8.8 01126- “

SCM435, Boron steel

10.9 01127- “

BsBME1

— 01128- “

w. socket

head M4 - M8 coarse and

M10 - M39 ne

SS400 4.6

Black

01131- “

SS400 4.6

Yellow

Chromate

01130- “

S45C 6.8 01133- “

SCM435, Boron steel

8.8 01136- “

SCM435, Boron steel

10.9 01137- “

w. hole in

threads M4 - M8 coarse and

M10 - M39 ne

SS400 4.6

Black

01161- “

SS400 4.6

Yellow

Chromate

01160- “

S45C 6.8 01163- “

SCM435, Boron steel

8.8 01166- “

SCM435, Boron steel

10.9 01167- “

• Designation of screws: Each part number consists of a screw type designation and a nominal symbol.

Example: 01130-16050 (hex. bolt 4.6, M16 x 50, w. socket head)

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 16

M 18

M 20

M 22

M 24

M 27

M 30

M 33

M 36

M 39

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 16

M 18

M 20

M 22

M 24

M 27

M 30

M 33

M 36

M 39

0.50

0.50

0.75

1.00

1.25

1.25

1.50

1.50

1.50

1.50

1.50

2.00

2.00

2.00

2.00

3.00

3.00

0.70

0.80

1.00

1.25

1.50

1.75

2.00

2.00

2.50

2.50

2.50

3.00

3.00

3.50

3.50

4.00

4.00

1.36

2.87

4.59

10.9

21.2

39.1

61.7

95.9

141

198

270

334

489

686

931

1130

1460

1.15

2.36

3.98

9.81

19.5

34.2

55.0

86.9

118

171

234

293

436

588

810

1030

1350

13.9

29.3

46.8

111

216

399

629

978

1440

2020

2750

3410

4990

7000

9490

11500

14900

11.7

24.1

40.6

100

199

349

561

886

1200

1740

2390

2990

4450

6000

8260

10500

13800

1.09 - 1.63

2.30 - 3.44

3.67 - 5.55

8.69 - 13.3

17.1 - 25.4

31.4 - 47.1

49.3 - 74.0

76.8 - 115

113 - 170

159 - 238

216 - 324

268 - 401

391 - 587

550 - 824

744 - 1120

903 - 1350

1170 - 1740

0.92 - 1.38

1.89 - 2.82

3.20 - 4.79

7.84 - 11.7

15.6 - 23.4

27.5 - 41.1

43.9 - 65.9

69.5 - 104

94.6 - 142

136 - 204

187 - 252

234 - 352

349 - 524

471 - 706

648 - 972

828 - 1250

1080 - 1140

11.1 - 16.6

23.5 - 35.1

37.4 - 56.1

88.6 - 133

174 - 259

320 - 480

503 - 755

783 - 1170

1150 - 1730

1620 - 2430

2200 - 3300

2730 - 4090

3990 - 5990

5610 - 8400

7590 - 11400

9210 - 13800

11900 - 17700

9.4 - 14.1

19.3 - 28.8

32.6 - 48.8

79.9 - 119

159 - 239

280 - 419

448 - 672

709 - 1060

965 - 1450

1390 - 2080

1910 - 2570

2390 - 3590

3560 - 5340

4800 - 7200

6610 - 9910

8440 - 12700

11000 - 11650

1.21

2.53

4.06

9.62

18.8

34.5

54.2

84.3

125

175

235

293

429

600

812

991

1280

1.03

2.11

3.56

8.74

17.5

30.4

48.8

77.0

105

150

207

259

385

521

714

914

1190

12.3

25.8

41.4

98.1

192

352

553

860

1270

1780

2400

2990

4370

6120

8280

10100

13100

10.5

21.5

36.3

89.1

178

310

498

785

1070

1530

2110

2640

3930

5310

7280

9320

12100

0.96 - 1.44

2.02 - 3.00

3.25 - 4.87

7.70 - 1.15

15.0 - 22.6

27.7 - 41.5

43.4 - 65.3

67.5 - 100

99.1 - 148

139 - 208

188 - 282

234 - 351

342 - 515

480 - 720

650 - 974

792 - 1190

1020 - 1540

0.82 - 1.24

1.70 - 2.53

2.85 - 4.29

7.00 - 10.5

13.9 - 20.9

24.4 - 36.6

39.0 - 55.8

61.6 - 92.4

84.1 - 127

121 - 180

165 - 248

208 - 312

308 - 463

417 - 624

572 - 857

731 - 1100

953 - 1430

9.8 - 14.7

20.6 - 30.9

33.1 - 49.7

78.5 - 117

153 - 230

282 - 423

443 - 666

1688 - 1030

1010 - 1510

1420 - 2120

1920 - 2880

2390 - 3580

3490 - 5250

4890 - 7340

6630 - 9930

8080 - 12100

10400 - 15700

8.4 - 12.6

17.3 - 25.8

29.1 - 43.7

71.4 - 107

142 - 213

249 - 373

398 - 597

628 - 942

858 - 1290

1230 - 1840

1680 - 2530

2120 - 3180

3140 - 4720

4250 - 6360

5830 - 8740

7450 - 11200

9720 - 14600

0.99

2.08

3.34

7.93

15.5

28.4

44.7

69.5

102

143

194

241

352

493

669

815

1050

0.8

1.7

2.9

7.2

14.3

25.1

40.2

63.5

86.6

125

171

214

318

429

588

753

981

10.1

21.2

34.1

80.9

158

290

456

709

1040

1460

1980

2460

3590

5030

6820

8310

10700

8.66

17.8

30.0

73.5

146

256

410

647

883

1270

1740

2180

3240

4370

6000

7680

10000

0.79 - 1.19

1.66 - 2.50

2.68 - 4.01

6.34 - 9.51

12.5 - 18.6

22.7 - 34.1

35.9 - 53.7

55.5 - 83.4

81.5 - 123

114 - 172

155 - 233

193 - 289

282 - 424

395 - 592

534 - 802

652 - 979

844 - 1270

0.68 - 1.02

1.39 - 2.08

2.35 - 3.53

5.77 - 8.65

11.5 - 17.3

20.1 - 30.1

32.3 - 48.3

50.8 - 76.1

69.3 - 104

99.1 - 149

136 - 204

172 - 257

254 - 381

342 - 515

471 - 706

602 - 903

785 - 1180

8.1 - 12.1

16.9 - 25.5

27.3 - 40.9

64.6 - 97.0

127 - 190

231 - 348

366 - 548

566 - 850

831 - 1250

1160 - 1750

1580 - 2380

1970 - 2950

2880 - 4320

4030 - 6040

5450 - 8180

6650 - 9980

8610 - 12900

6.9 - 10.4

14.2 - 21.2

24.0 - 36.0

58.8 - 88.2

117 - 176

205 - 307

329 - 493

518 - 776

707 - 1060

1010 - 1520

1390 - 2080

1750 - 2620

2590 - 3890

3490 - 5250

4800 - 7200

6140 - 9210

8000 - 12000

0

㨙kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙

Lubrication

condition

Class Nominal

size Pitch Target value Allowable value

Dry

Table 04.3 Tightening torque chart (Division by strength: 4.6)

LOCTITE262 Lubricant

Target value Allowable value Target value Allowable value

Metric, fine systemMetric, coarse system

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 16

M 18

M 20

M 22

M 24

M 27

M 30

M 33

M 36

M 39

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 16

M 18

M 20

M 22

M 24

M 27

M 30

M 33

M 36

M 39

0.50

0.50

0.75

1.00

1.25

1.25

1.50

1.50

1.50

1.50

1.50

2.00

2.00

2.00

2.00

3.00

3.00

0.70

0.80

1.00

1.25

1.50

1.75

2.00

2.00

2.50

2.50

2.50

3.00

3.00

3.50

3.50

4.00

4.00

2.71

5.74

9.14

21.7

42.4

78.3

123

192

282

396

537

668

978

1370

1860

2250

2920

2.29

4.72

7.95

19.6

38.6

68.4

110

174

235

338

468

585

872

1180

1620

2070

2700

27.6

58.5

93.2

221

432

798

1250

1960

2870

4040

5480

6810

9970

14000

19000

22900

29800

23.3

48.1

81.1

200

397

697

1120

1770

2400

3450

4770

5970

8890

12000

16500

21100

27500

2.17 - 3.26

4.59 - 6.87

7.32 - 11.0

17.4 - 26.0

33.8 - 50.9

62.6 - 93.9

98.1 - 148

153 - 229

225 - 337

317 - 476

431 - 645

534 - 800

782 - 1170

1100 - 1650

1490 - 2330

1790 - 2700

2330 - 3510

1.82 - 2.75

3.77 - 5.66

6.36 - 9.55

15.7 - 23.4

31.2 - 46.8

54.6 - 82.1

87.8 - 132

139 - 208

189 - 282

271 - 407

374 - 562

469 - 702

697 - 1050

940 - 1410

1280 - 1940

1650 - 2480

2160 - 3240

22.1 - 33.2

46.8 - 70.1

74.6 - 112

177 - 265

345 - 519

638 - 957

1000 - 1510

1560 - 2340

2290 - 3440

3230 - 4850

4390 - 6580

5440 - 8160

7970 - 11900

11200 - 16800

15200 - 22700

18300 - 27500

23800 - 35800

18.6 - 28.0

38.4 - 57.7

64.9 - 97.4

160 - 239

318 - 477

557 - 837

895 - 1350

1420 - 2120

1930 - 2880

2760 - 4150

3810 - 5730

4780 - 7160

7110 - 10700

9580 - 14400

13100 - 19800

16800 - 25300

22000 - 33000

2.40

5.05

8.10

19.2

37.5

68.9

109

169

247

347

471

585

855

1200

1620

1980

2560

2.06

4.21

7.13

17.5

34.8

60.9

97.6

154

210

300

413

519

770

1040

1430

1820

2380

24.5

51.5

82.6

196

382

703

1110

1720

2520

3540

4800

5970

8720

12200

16500

20200

26100

21.0

42.9

72.7

178

355

621

995

1570

2140

3060

4210

5290

7850

10600

14600

18600

24300

1.92 - 2.87

4.04 - 6.06

6.48 - 9.72

15.4 - 23.0

30.0 - 45.0

55.1 - 82.7

86.9 - 129

135 - 202

198 - 296

278 - 416

376 - 565

469 - 702

685 - 1030

958 - 1440

1290 - 1950

1580 - 2370

2050 - 3070

1.65 - 2.47

3.36 - 5.06

5.70 - 8.54

14.0 - 21.0

27.8 - 41.7

48.6 - 73.1

78.1 - 117

123 - 185

168 - 252

240 - 360

330 - 495

414 - 623

616 - 924

831 - 125

1140 - 1710

1460 - 2190

1900 - 2840

19.6 - 29.3

41.2 - 61.8

66.1 - 99.1

157 - 235

306 - 459

562 - 843

886 - 1320

1380 - 2060

2020 - 3020

2830 - 4240

3830 - 5760

4780 - 7160

6980 - 10500

9770 - 14700

13200 - 19900

16100 - 24200

20900 - 31300

16.8 - 25.2

34.3 - 51.6

58.1 - 87.1

143 - 214

283 - 425

496 - 745

796 - 1190

1250 - 1890

1710 - 2570

2450 - 3670

3370 - 5050

4220 - 6350

6280 - 9420

8470 - 12700

11600 - 17400

14900 - 22300

19400 - 29000

1.98

4.15

6.68

15.8

30.9

56.8

89.4

139

203

285

386

481

704

991

1340

1630

2110

1.70

3.47

5.87

14.4

28.6

50.2

80.3

127

173

247

340

428

634

855

1180

1500

1960

20.2

42.3

68.1

161

315

579

912

1420

2070

2910

3940

4910

7180

10100

13700

16600

21500

17.3

35.4

59.9

147

292

512

819

1290

1760

2520

3470

4360

6460

8720

12000

15300

20000

1.58 - 2.38

3.33 - 4.98

5.34 - 8.01

12.7 - 19.0

24.7 - 37.1

45.5 - 68.2

71.6 - 107

111 - 168

163 - 244

229 - 343

310 - 465

385 - 579

564 - 845

788 - 1180

1070 - 1600

1290 - 1950

1690 - 2530

1.36 - 2.03

2.78 - 4.17

4.70 - 7.04

11.5 - 17.3

22.9 - 34.4

40.1 - 60.1

64.2 - 96.4

101 - 152

138 - 208

198 - 297

272 - 409

341 - 513

507 - 760

685 - 1030

940 - 1410

1200 - 1790

1570 - 2340

16.1 - 24.3

33.9 - 50.8

54.4 - 81.7

129 - 194

252 - 378

464 - 695

730 - 1090

1130 - 1700

1660 - 2490

2330 - 3500

3160 - 4740

3930 - 5900

5750 - 8620

8040 - 12000

10900 - 16300

13200 - 19900

17200 - 25800

13.9 - 20.7

28.3 - 42.5

47.9 - 71.8

117 - 176

233 - 351

409 - 613

655 - 983

1030 - 1550

1410 - 2120

2020 - 3030

2770 - 4170

3480 - 5230

5170 - 7750

6980 - 10500

9580 - 14400

12200 - 18300

16000 - 23900

0

㨙kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙

Lubrication

condition

Class Nominal

size Pitch Target value Allowable value

Dry

Table 04.4 Tightening torque chart (Division by strength: 6.8)

LOCTITE262 Lubricant

Target value Allowable value Target value Allowable value

Metric, fine systemMetric, coarse system

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 16

M 18

M 20

M 22

M 24

M 27

M 30

M 33

M 36

M 39

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 16

M 18

M 20

M 22

M 24

M 27

M 30

M 33

M 36

M 39

0.50

0.50

0.75

1.00

1.25

1.25

1.50

1.50

1.50

1.50

1.50

2.00

2.00

2.00

2.00

3.00

3.00

0.70

0.80

1.00

1.25

1.50

1.75

2.00

2.00

2.50

2.50

2.50

3.00

3.00

3.50

3.50

4.00

4.00

3.62

7.65

12.2

28.9

56.5

104

164

256

377

529

718

890

1300

1830

2480

3010

3900

3.06

6.30

10.6

26.1

52.1

91.2

146

232

315

452

624

782

1160

1570

2160

2770

3600

36.9

78.0

124

295

576

1060

1670

2610

3840

5390

7320

9080

13300

18700

25300

30700

39800

31.2

64.2

108

266

531

930

1490

2370

3210

4610

6360

7970

11800

16000

22000

28200

36700

2.89 - 4.34

6.12 - 9.18

9.78 - 14.7

23.1 - 34.7

45.2 - 67.9

83.6 - 126

131 - 197

204 - 307

301 - 451

423 - 635

574 - 861

712 - 1070

1040 - 1570

1460 - 2190

1980 - 2970

2400 - 3610

3120 - 4680

2.45 - 3.67

5.03 - 7.55

8.50 - 12.7

20.9 - 31.0

41.6 - 62.5

73.1 - 109

117 - 177

185 - 279

252 - 379

362 - 543

499 - 749

626 - 938

931 - 1400

1260 - 1880

1730 - 2590

2210 - 3310

2880 - 4320

29.5 - 44.3

62.4 - 93.6

99.7 - 150

236 - 354

461 - 692

852 - 1280

1340 - 2010

2080 - 3130

3070 - 4600

4310 - 6470

5850 - 8780

7260 - 10900

10600 - 16000

14900 - 22300

20200 - 30300

24500 - 36800

31800 - 47700

25.0 - 37.4

51.3 - 77.0

86.7 - 130

213 - 319

424 - 638

745 - 1110

1190 - 1800

1890 - 2840

2570 - 3860

3690 - 5540

5090 - 7640

6380 - 9560

9490 - 14300

12800 - 19200

17600 - 26400

22500 - 33800

29400 - 44100

3.20

6.73

10.8

25.6

50.1

92.0

145

226

330

463

629

782

1140

1600

2160

2640

3410

2.7

5.6

9.5

23.3

46.4

81.2

130

205

280

401

551

692

1030

1390

1900

2430

3170

32.6

68.6

110

261

511

938

1480

2300

3360

4720

6410

7970

11600

16300

22000

26900

34800

27.9

57.3

96.9

238

473

828

1330

2090

2860

4090

5620

7060

10500

14200

19400

24800

32300

0.26 - 0.39

0.54 - 0.81

0.87 - 1.30

2.05 - 3.08

4.01 - 6.01

7.37 - 11.0

11.6 - 17.4

18.0 - 27.0

26.4 - 39.5

37.0 - 55.5

50.2 - 75.3

62.6 - 93.8

91.3 - 137

128 - 192

173 - 259

211 - 316

273 - 409

2.19 - 3.30

4.49 - 6.74

7.60 - 11.4

18.6 - 28.0

37.1 - 55.7

64.9 - 97.4

104 - 156

164 - 246

224 - 336

320 - 482

441 - 662

554 - 831

821 - 123

1110 - 1660

1520 - 2290

1950 - 2920

2540 - 3810

26.1 - 39.3

55.0 - 82.4

88.2 - 133

209 - 314

409 - 613

751 - 1120

1180 - 1770

1840 - 2750

2690 - 4030

3770 - 5660

5120 - 7680

6380 - 9560

9310 - 14000

13100 - 19600

17600 - 26400

21500 - 32200

27800 - 41700

22.3 - 33.6

45.8 - 68.7

77.5 - 116

190 - 286

378 - 568

662 - 993

1060 - 1590

1670 - 2510

2280 - 3430

3260 - 4910

4500 - 6750

5650 - 8470

8370 - 12500

11300 - 16900

15500 - 23300

19900 - 29800

25900 - 38900

2.64

5.55

8.91

21.1

41.3

75.8

119

185

271

381

517

643

940

1320

1780

2170

2810

2.27

4.63

7.85

19.2

38.2

66.9

107

169

231

330

454

570

846

1140

1570

2010

2610

26.9

56.6

90.9

215

421

773

1210

1890

2760

3890

5270

6560

9590

13500

18200

22100

28700

23.1

47.2

80.0

196

390

682

1090

1720

2360

3370

4630

5810

8630

11600

16000

20500

26600

2.12 - 3.17

4.44 - 6.66

7.13 - 10.7

16.9 - 25.3

33.0 - 49.5

60.6 - 90.9

95.4 - 143

148 - 222

217 - 327

305 - 457

413 - 620

514 - 773

752 - 1130

1050 - 1580

1420 - 2140

1740 - 2610

2260 - 3370

1.81 - 2.71

3.70 - 5.56

6.28 - 9.40

15.4 - 23.0

30.6 - 45.9

53.5 - 80.3

85.8 - 1290

135 - 203

185 - 278

264 - 396

363 - 545

456 - 685

678 - 1020

913 - 1370

1260 - 1880

1600 - 2410

2090 - 3140

21.6 - 32.3

45.3 - 67.9

72.7 - 109

172 - 258

337 - 505

618 - 927

973 - 1460

1510 - 2260

2210 - 3330

3110 - 4660

4210 - 6320

5240 - 7870

7670 - 11500

10700 - 16100

14500 - 21800

17700 - 26600

23000 - 34400

18.5 - 27.6

37.7 - 56.7

64.0 - 95.9

157 - 235

312 - 468

546 - 819

875 - 1320

1380 - 2070

1890 - 2830

2690 - 4040

3700 - 5560

4650 - 6980

6910 - 10400

9310 - 14000

12800 - 19200

16300 - 24600

21300 - 32000

0

㨙kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙

Lubrication

condition

Class Nominal

size Pitch Target value Allowable value

Dry

Table 04.5 Tightening torque chart (Division by strength: 8.8)

LOCTITE262 Lubricant

Target value Allowable value Target value Allowable value

Metric, fine systemMetric, coarse system

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 16

M 18

M 20

M 22

M 24

M 27

M 30

M 33

M 36

M 39

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 16

M 18

M 20

M 22

M 24

M 27

M 30

M 33

M 36

M 39

0.50

0.50

0.75

1.00

1.25

1.25

1.50

1.50

1.50

1.50

1.50

2.00

2.00

2.00

2.00

3.00

3.00

0.70

0.80

1.00

1.25

1.50

1.75

2.00

2.00

2.50

2.50

2.50

3.00

3.00

3.50

3.50

4.00

4.00

5.33

11.3

17.9

42.6

83.1

154

241

376

552

777

1060

1300

1910

2690

3640

4420

5730

4.49

9.24

15.6

38.3

76.5

133

216

341

463

665

918

1150

1720

2300

3170

4060

5290

54.3

115

183

434

847

1570

2460

3830

5630

7920

10800

13300

19500

27400

37100

45100

58400

45.8

94.2

159

391

780

1360

2200

3480

4720

6780

9360

11700

17500

23500

32300

41400

53900

4.26 - 6.38

9.00 - 13.5

14.3 - 21.6

34.1 - 51.0

66.5 - 100

123 - 184

193 - 289

300 - 450

442 - 663

621 - 933

843 - 1270

1050 - 1570

1540 - 2300

2160 - 3230

2910 - 4370

3530 - 5300

4580 - 6860

3.60 - 5.39

7.40 - 11.1

12.6 - 18.7

30.7 - 46.0

61.2 - 91.8

108 - 161

173 - 258

272 - 409

370 - 555

534 - 797

734 - 1100

919 - 1380

1370 - 2050

1840 - 2770

2540 - 3810

3240 - 4860

4240 - 6350

43.4 - 65.1

91.8 - 138

146 - 220

348 - 520

678 - 1020

1250 - 1880

1970 - 2950

3060 - 4590

4510 - 6760

6330 - 9510

8600 - 12900

10700 - 16000

15700 - 23500

22000 - 32900

29700 - 44600

36000 - 54000

46700 - 70000

36.7 - 55.0

75.5 - 113

128 - 191

313 - 469

624 - 936

1100 - 1640

1760 - 2630

2770 - 4170

3770 - 5660

5440 - 8130

7480 - 11200

9370 - 14100

14000 - 20900

18800 - 28200

25900 - 38800

33000 - 49600

43200 - 64800

4.71

9.91

15.9

37.7

73.6

135

213

330

484

681

922

1150

1690

2350

3180

3870

5020

4.03

8.26

14.0

34.3

68.2

120

191

301

412

588

810

1020

1510

2040

2800

3580

4660

48

101

162

384

750

1380

2170

3370

4940

6940

9400

11700

17200

24000

32400

39500

51200

41.1

84.2

143

350

695

1220

1950

3070

4200

6000

8260

10400

15400

20800

28600

36500

47500

3.77 - 5.65

7.92 - 12.0

12.7 - 19.0

30.1 - 45.2

58.8 - 88.4

109 - 162

171 - 255

265 - 396

387 - 582

544 - 815

738 - 1110

919 - 1380

1330 - 2020

1880 - 2820

2540 - 3810

3110 - 4650

4010 - 6020

3.22 - 4.83

6.60 - 9.91

11.2 - 16.8

27.4 - 41.1

54.5 - 81.9

95.4 - 143

153 - 230

241 - 362

330 - 493

471 - 707

648 - 972

814 - 1230

1220 - 1800

1630 - 2440

2240 - 3350

2860 - 4300

3740 - 5590

38.4 - 57.6

80.8 - 122

130 - 194

307 - 461

600 - 901

1110 - 1650

1740 - 2600

2700 - 4040

3950 - 5930

5550 - 8310

7530 - 11300

9370 - 14100

13600 - 20600

19200 - 28800

25900 - 38900

31700 - 47400

40900 - 61400

32.8 - 49.2

67.3 - 101

114 - 171

279 - 419

556 - 835

973 - 1460

1560 - 2350

2460 - 3690

3360 - 5030

4800 - 7210

6610 - 9910

8300 - 12500

12400 - 18400

16600 - 24900

22800 - 34200

29200 - 43800

38100 - 57000

3.87

8.15

13.0

31.1

60.6

112

176

272

398

560

759

946

1380

1930

2620

3190

4130

3.32

6.81

11.5

28.2

56.1

98.1

158

249

338

485

668

838

1250

1690

2300

2950

3830

39.5

83.1

133

317

618

1140

1790

2770

4060

5710

7740

9650

14100

19700

26700

32500

42100

33.9

69.4

117

288

572

1000

1610

2540

3450

4950

6810

8550

12700

17200

23500

30100

39100

3.11 - 4.66

6.52 - 9.79

10.5 - 15.7

24.9 - 37.2

48.5 - 72.8

89.0 - 133

140 - 210

218 - 327

319 - 479

448 - 672

607 - 912

756 - 1140

1110 - 1660

1550 - 2320

2090 - 3140

2550 - 3820

3300 - 4950

2.66 - 3.98

5.44 - 8.18

9.21 - 13.8

22.6 - 33.8

44.9 - 67.5

78.8 - 118

127 - 189

199 - 298

272 - 407

387 - 583

534 - 802

670 - 1010

991 - 1490

1330 - 2020

1840 - 2760

2360 - 3530

3070 - 4610

31.7 - 47.5

66.5 - 99.8

107 - 160

254 - 379

495 - 742

908 - 1360

1430 - 2140

2220 - 3330

3250 - 4880

4570 - 6850

6190 - 9300

7710 - 11600

11300 - 16900

15800 - 23700

21300 - 32000

26000 - 39000

33700 - 50500

27.1 - 40.6

55.5 - 83.4

93.9 - 141

230 - 345

458 - 688

803 - 1200

1290 - 1930

2030 - 3040

2770 - 4150

3950 - 5940

5450 - 8180

6830 - 10300

10100 - 15200

13600 - 20600

18800 - 28100

24100 - 36000

31300 - 47000

0

㨙kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙 0㨙 kgHE㨙

Lubrication

condition

Class Nominal

size Pitch Target value Allowable value

Dry

Table 04.6 Tightening torque chart (Division by strength: 10.9)

LOCTITE262 Lubricant

Target value Allowable value Target value Allowable value

Metric, fine systemMetric, coarse system

05. LUBRICATION

1. Lubricating lift chains

Lubricate the lift chains with engine oil using an oiler or a brush.

To allow oil to enter between each pin and link plate of the lift chain, observe the following

conditions:

Loosen the chains sufciently.

•

After applying engine oil, operate the lift cylinders at least ten times through full travel.

•

NOTE

If your lift truck is used near a port or coastal area, the lift chains might be damaged from salty

breezes. After a storm or typhoon, it is advisable to wash them with water before lubricating in the

above manner.

2. Mast and steering system

Fig. 05.1

Fig. 05.2

■Rear slippers of the mast

WARNING

Do not ride on the mast. Do not put your hand or

foot on the connecting member across the mast

or between the outer and inner mast channels;

otherwise you might get injured if the mast

accidentally moves.

3. Checking hydraulic oil level

Check the hydraulic oil level in the hydraulic oil

tank using the oil level dipstick.

Remove the dipstick of the tank cap, clean the rod

with a clean cloth and reinsert it. Remove the dipstick

again and check the oil level. If the level is low, add

hydraulic oil.

[How to read oil level]

“H” mark: Highest position of the standard truck

“L” mark: Lowest position of the standard truck

“S” mark: For trucks with a lift height of 6 m or more

or for special trucks, the oil level should be

within 10 mm above or below this mark.

NOTE

Too high oil level might cause oil leakage.

•

The oil level check should be performed with the

•

mast vertical, the forks on the ground or floor

surface, and the truck parked on a level surface.

作動油タンクキャップ

レベルゲージ

Fig. 05.3

OIL DIPSTICK

HYDRAULIC OIL TANK CAP

This manual suits for next models

10

Table of contents

Other TCM Forklift manuals