3

2.

2.

2.

2. The

The

The

The o

o

o

o peration

peration

peration

peration place

place

place

place and

and

and

and working

working

working

working

environment

environment

environment

environment of

of

of

of the

the

the

the forklift

forklift

forklift

forklift

1)

1)

1)

1) Ground

Ground

Ground

Ground status

status

status

status

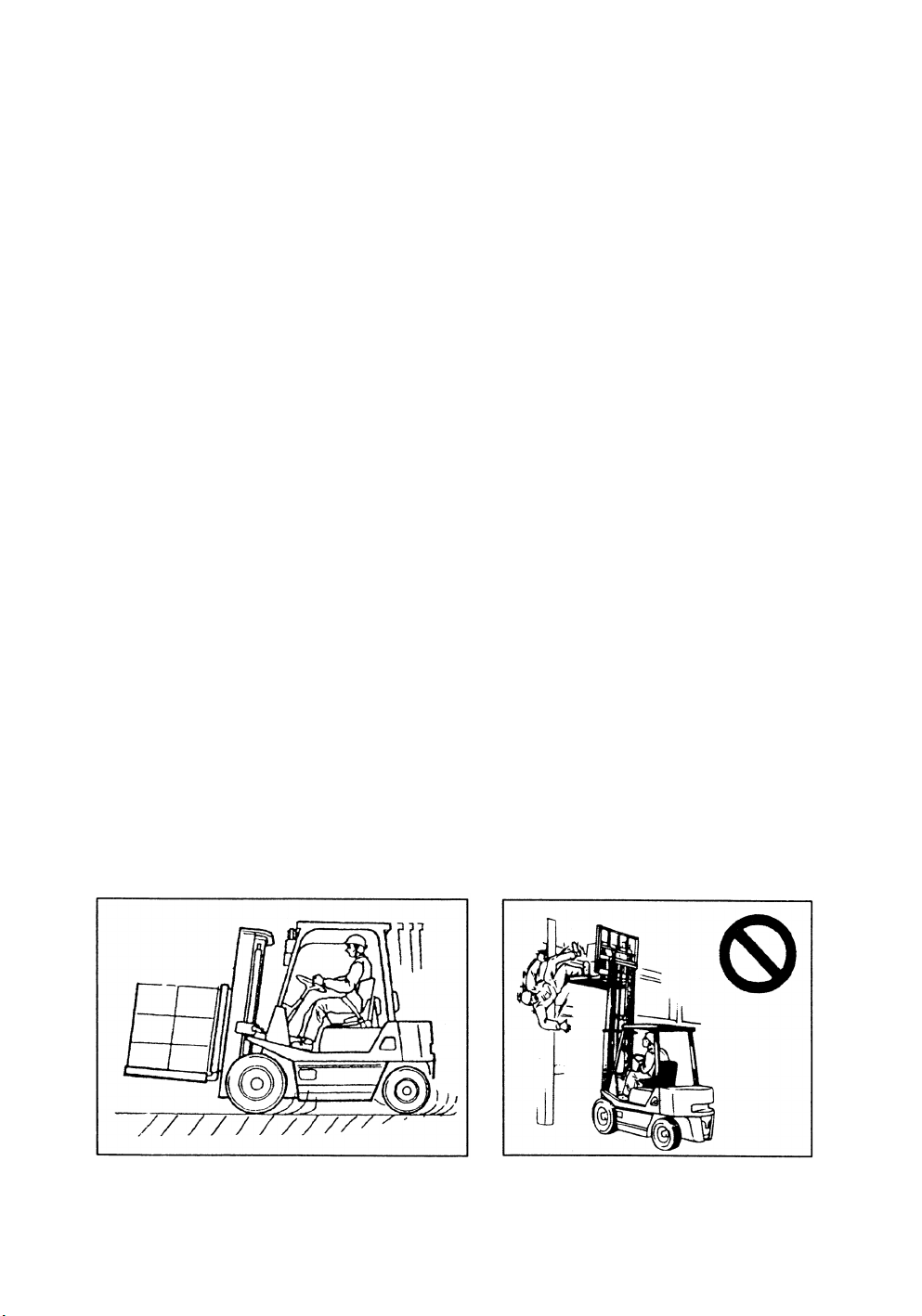

The operation place for forklift s shall be

even and hard road surface or ground

surface with good ventilation.

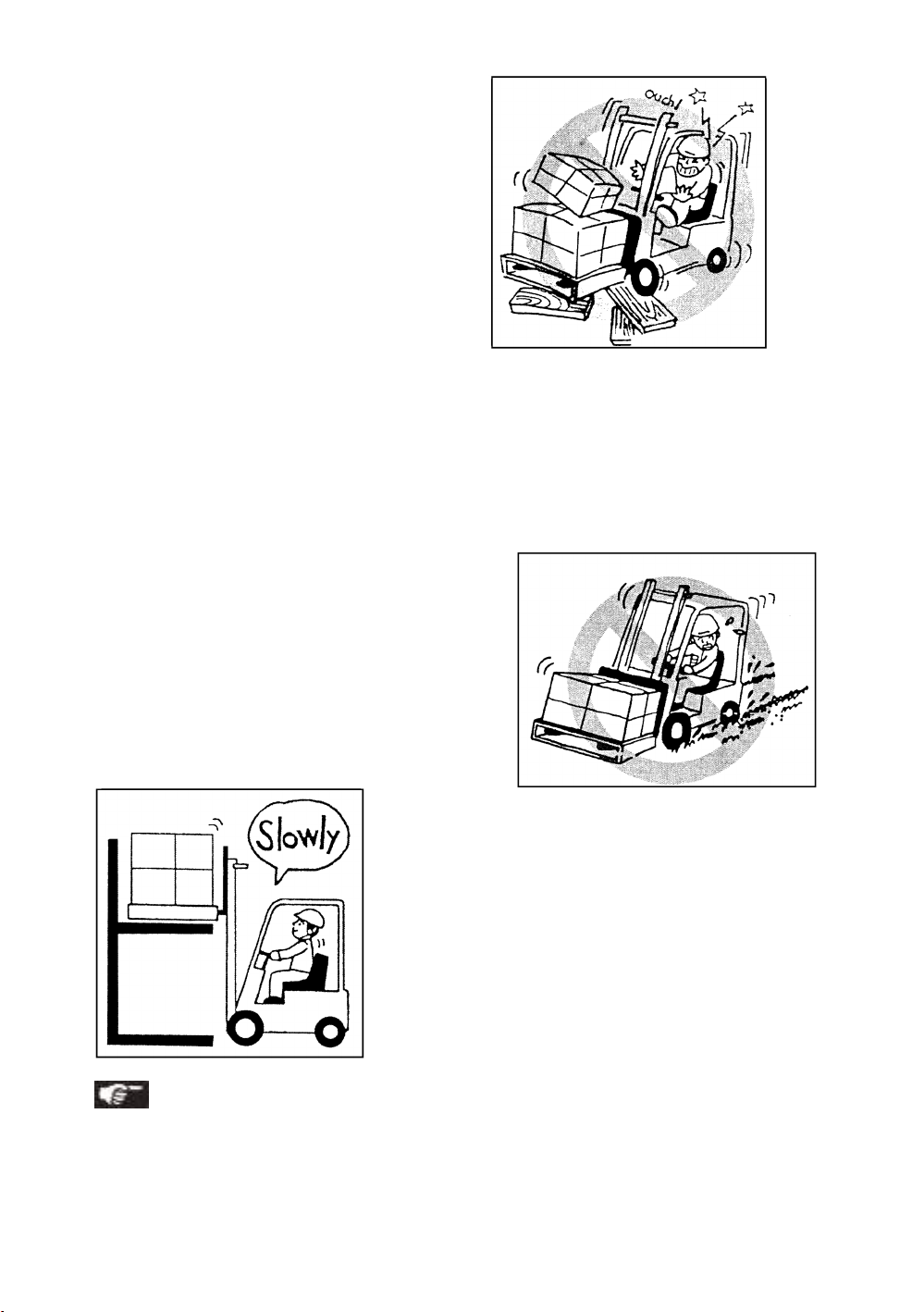

The forklift performance depends on the

ground condition . Pay special attention

when driving on the slope or rough road.

Travel speed should be decelerated to

make the machine travel slowly.

Warning

Warning

Warning

Warning

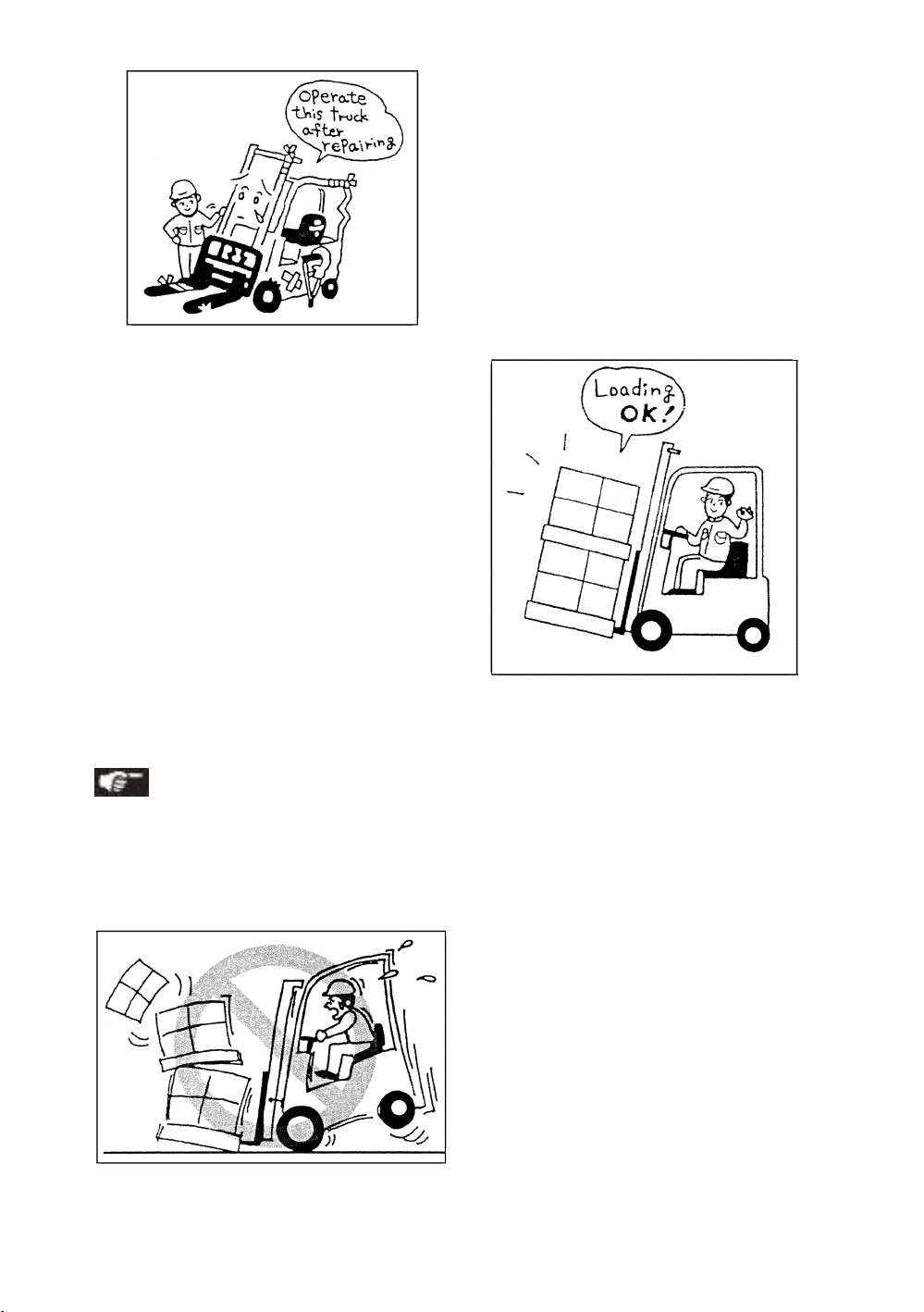

•Ensure the forklift won ’ t be trapped into

the muddy road.

•Round the obstacle, when the obstacle

can't be avoided, drive slowly and do

not damage the vehicle chassis.

When the forklift is driven on the road

surface with ice and snow, the tire chain

shall be used, sudden acceleration, hard

braking and sharp turn shall be avoided,

and the travel speed sh ould be controlled

by the force from accelerator pedal

Warning

Warning

Warning

Warning

•Tire chain can increase the adhesion

between the forklift and the ground

surface, but the sideslip performance

will be reduced , which shall be paid

special attention to.

2

2

2

2)Climate

Climate

Climate

Climate conditions

conditions

conditions

conditions

Warning

Warning

Warning

Warning

In case of heavy wind, try not to perform

the high lifting operation as possible as

you can. Otherwise, the falling of the

goods may cause accidental injuries to the

driver.

3)

3)

3)

3) Measures

Measures

Measures

Measures for

for

for

for cold

cold

cold

cold and

and

and

and hot

hot

hot

hot weather

weather

weather

weather

a) Oil

Use the oil suitable for ambient temperature as

different seasons.

b) Battery

•In cold season , u nder normal charging

condition, the freezing point of electrolyte

is about -35 ℃.

Battery shall be charged under excellent

condition . assure the battery is at the normal

condition, under which the battery can start

the machine. If he battery lose power, park

the forklift at the place with the high

temperature. After the electrolyte frozing, the

battery shell will be damaged due to volume

expansion of the battery. in order to prevent

electrolyte being frozen, battery shall be

charged to at least 75% of gross capacity.

T he best method is to maintain specific

gravity at 1.260 , but do not exceed this

value.

•In the hot season , Because the water in

the electrolyte will be vaporized , please add

distilled water at any moment, check the

electrolyte once a week and add distilled

water. W hen the ambient temperature is

higher, the electrolyte specific gravity