33

4

4

2

2

5

1

5

02

Steer axle

4

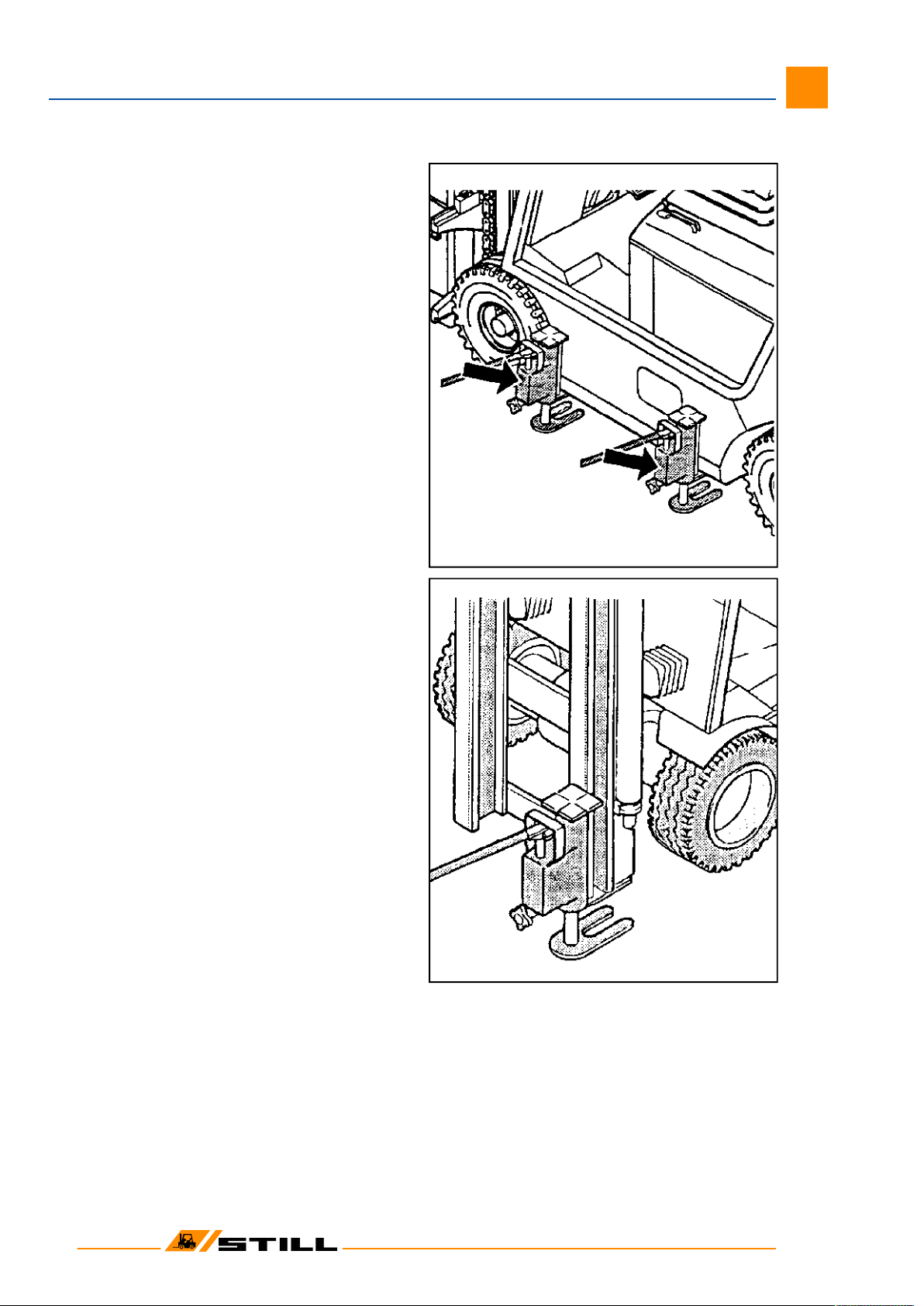

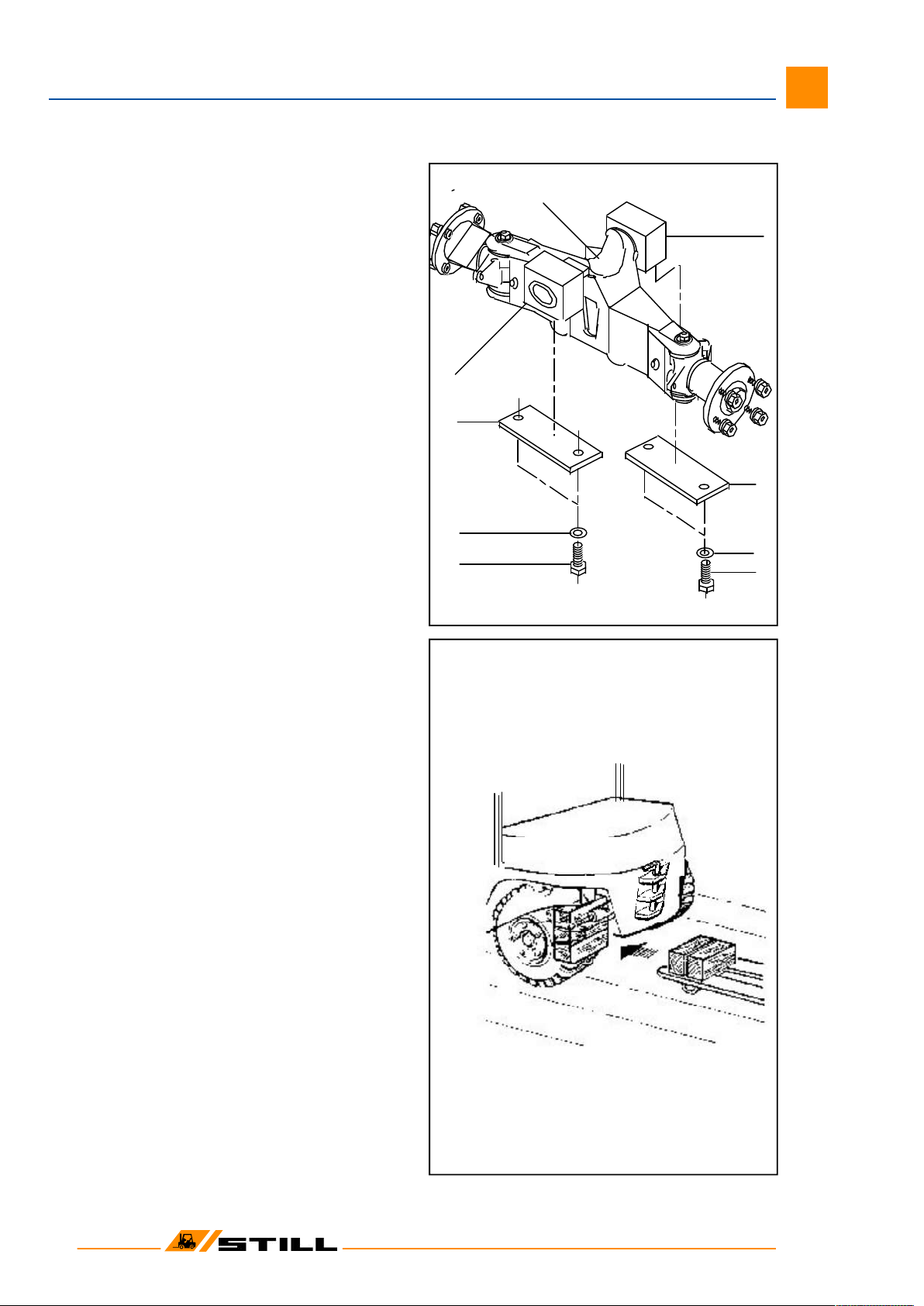

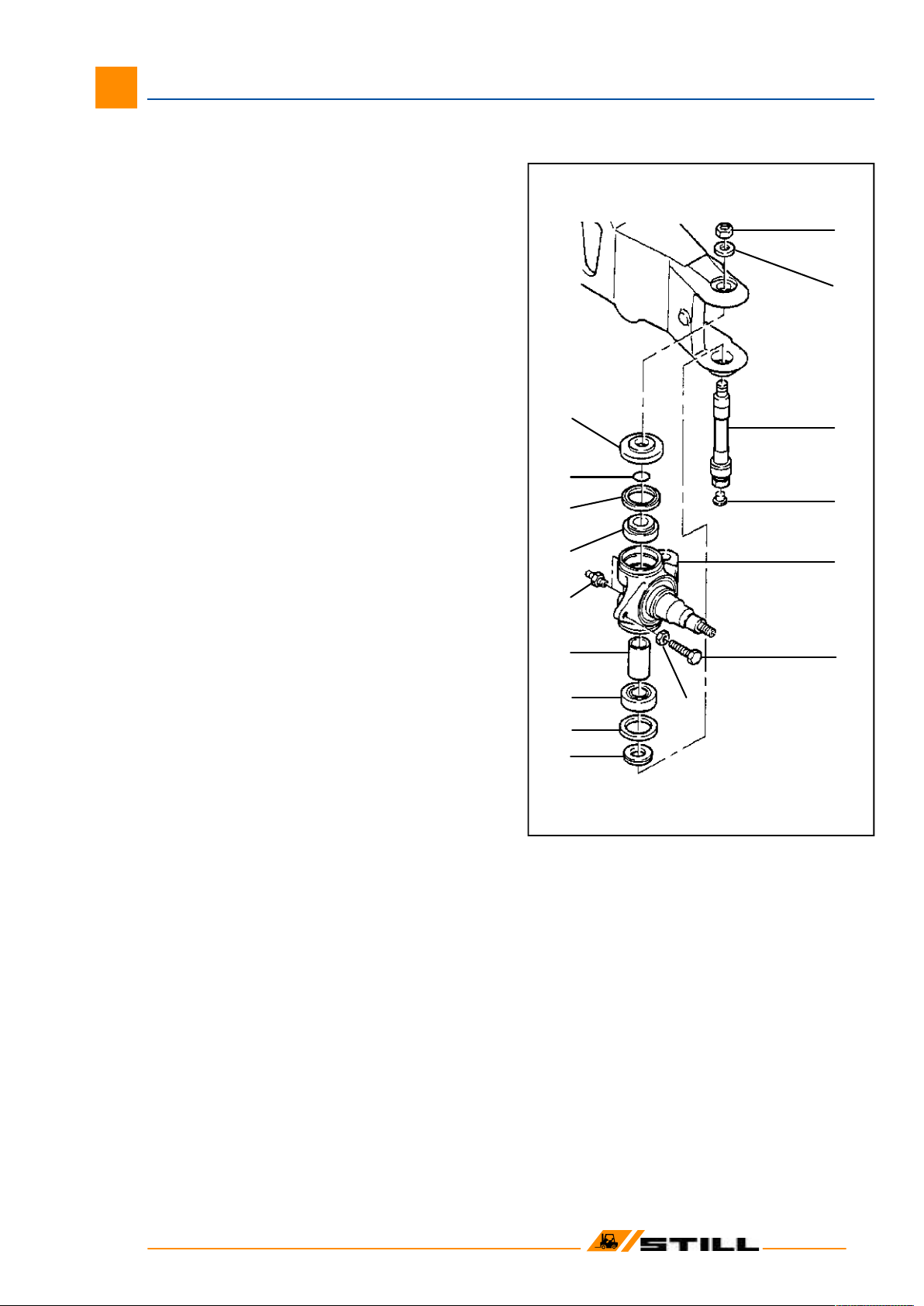

Configuration of steer axle

The articulating steer axle suspended from the

counterweight is mounted in 2 neoprene blocks. The

stub axles are supported in the axle beam on tapered

roller bearings. Steering is limited by stop screws on

the stub axles.

1 axle beam

2 fixing plates

3 hex. hd. bolt

4 spring washer

5 neoprene blocks

Steer axle removal

CAUTION: Remove steer axle only with mast in

position on the truck!

Risk of tipping!

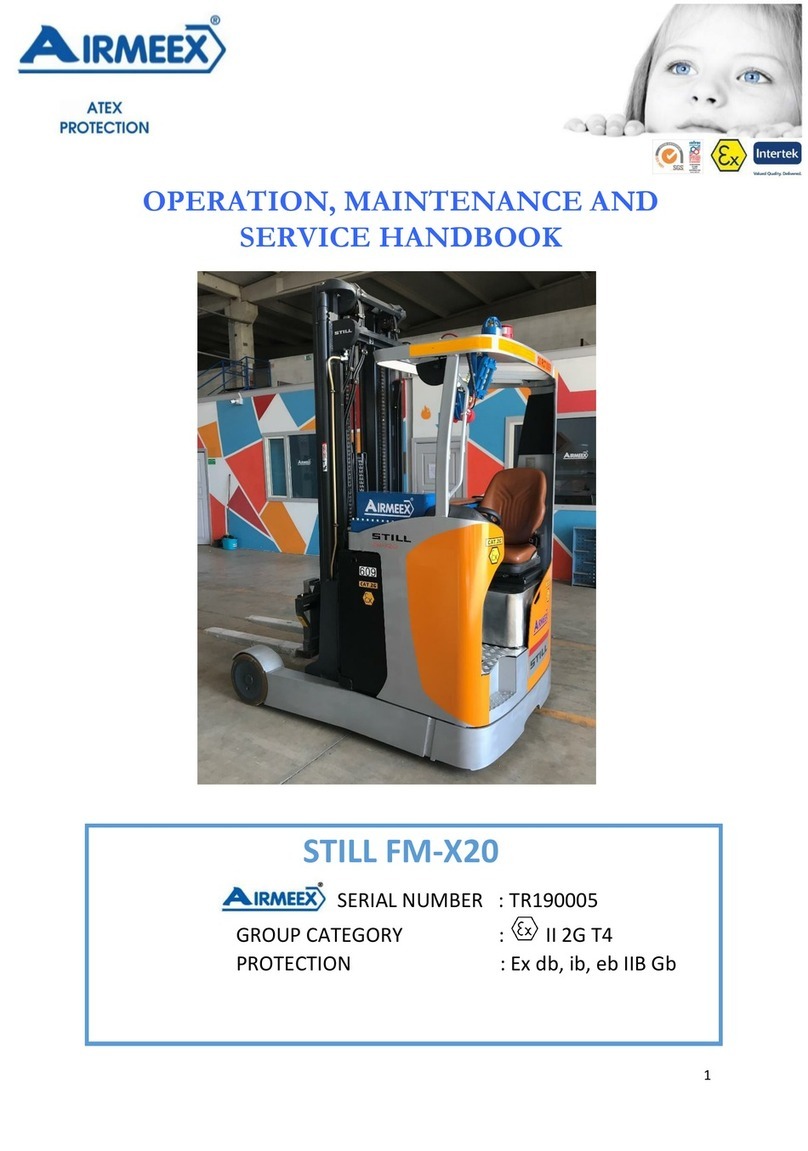

- Apply the parking brake.

-Securely chock the front wheels to prevent

rolling of the truck.

- Slacken steer wheel nuts.

- Jack up rear of the truck at counterweight (x)

and place wooden blocks under the counter-

weight in front of the axle.

- Remove wheels.

- Disconnect the hydraulic connections at steer

cylinder.

CAUTION: Prepare for oil spillage when

disconnecting the hydraulic connections!

Catch oil in a pan of adequate capacity

and dispose of the used oil in accordance

with laws and regulations.

- Remove the 4 socket head screws which re-

tain the steer axle in place.

- Slide a hand pallet truck under the steer axle

with wooden blocks placed on the fork ends

of the hand pallet truck.

- Using a lever, drive steer axle out of roll pins

and lower the axle onto the hand pallet truck.

Steer axle installation

- Reverse the removal procedure.

- The slots of the roll pins must face the direc-

tion of forward travel.

-Torque the 4 socket heads to: MA = 195 Nm

CAUTION: Do not swap hydraulic connec-

tions left and right!

Workshop Manual 7052/56/74-76, 7054/58/77-79