TCM FB10-7 User manual

No. SEB-81BBE

TCM CORPORATION

FORKLIFT TRUCK

FB10-7

FB15-7

FB18-7

FB20-7

FB25-7

FB30-7

FB25-7LB

FB25-7V

FB30-7V

FB35-7S

Counter Balanced

No. SEB-81BBE

FOREWORD

The new TCM’s FB-7 Series battery-powered forklift trucks are provided with a newly designed

speed control system and an AC traction motor to assure high performance.

The trucks of this series are provided with a self-diagnosis function which keeps watching the

operating statuses of the main systems of the truck. If the truck has a trouble, the function detects the

trouble and displays the result of diagnosis. The maintainability is thus improved.

As for mobility, since the high capacity batteries and high power drive motors are used, the rst-class

acceleration, gradeability, and traveling performance are achieved. Controllability is also improved by

the standard equipped power steering unit.

To save power, the acceleration and traveling speeds are selectable in eight stages and made

changeable according to working conditions. Also for effective use of the battery, a regenerative device

is provided to send back counter electromotive force to the battery.

This Service Manual is intended to provide the maintenance personnel with helpful information of

the structures of the major components and with instructions on the maintenance and repair of such

components. We hope it will be much help for your servicing and maintenance operations.

February, 2008

No. SEB-81BBE

No. SEB-81BBE

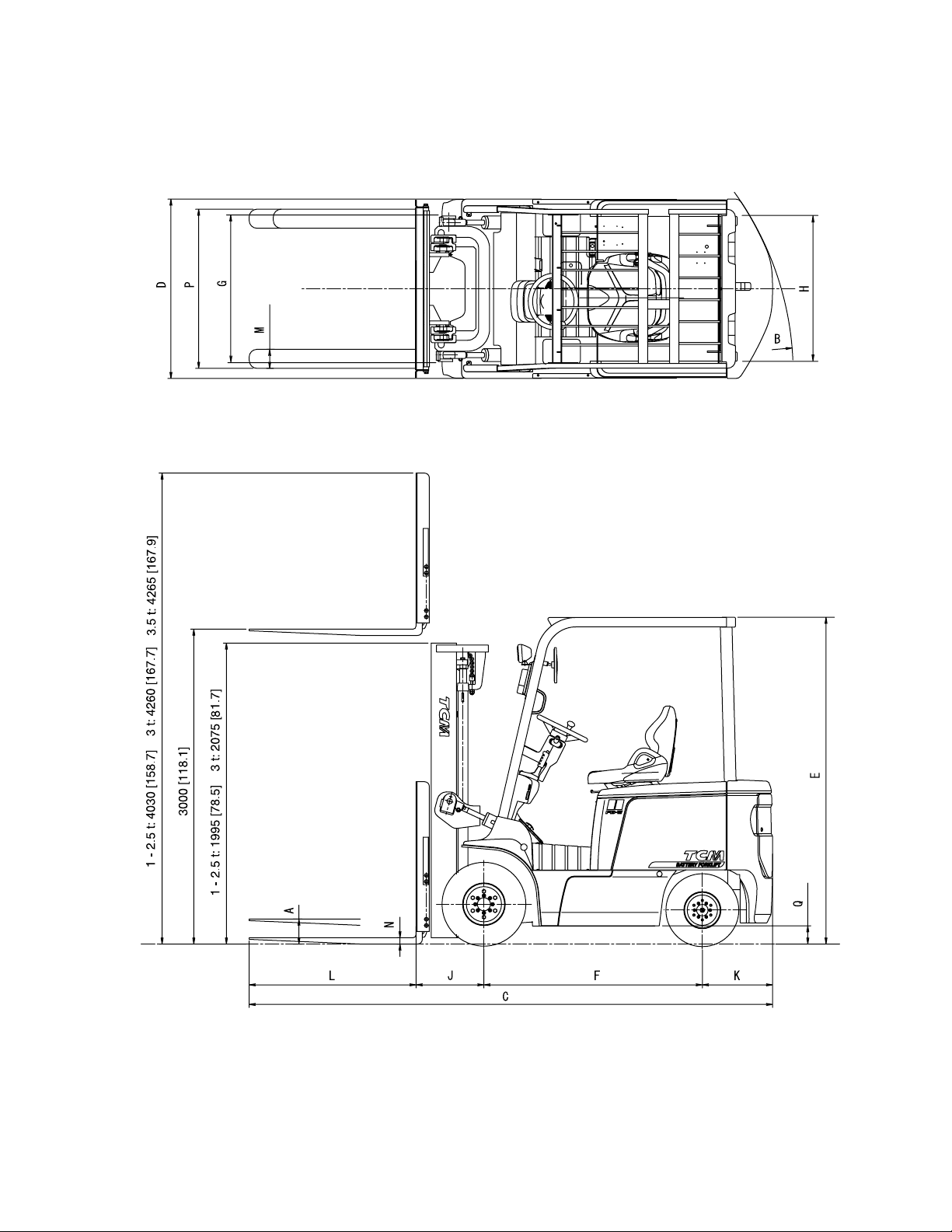

SPECIFICATIONS (1)

Model FB10-7 FB15-7 FB18-7

Item

Performance

Max. load kg [lbf] 1000 [2000] 1500 [3000] 1750 [3500]

Load center mm [in.] 500 [24] ← ←

Max. lifting height mm [in.] 3000 [118.1] ← ←

Tilting angle

Fwd ° 6 ← ←

Bwd ° 12 ← ←

Free lift A mm [in.] 150 [5.9] 155 [6.1] ←

Mast tilting time (Fwd - Bwd) s 2.0 - 1.4 ← ←

Fork lifting speed

Loaded mm/s [fpm] 390 [76.8] 350 [68.9] 330 [65.0]

Unloaded mm/s [fpm] 580 [114.2] ← ←

Travel speed

Loaded km/h [mph] 14 [8.7] ← 13 [8.1]

Unloaded km/h [mph] 16 [9.9] ← ←

Gradeability

(Starting on an uphill when loaded) 1/7 ← ←

Min. turning radius

(Outermost part of truck) B mm [in.] 1700 [66.9] ← 1790 [70.5]

Min. intersecting aisle mm [in.] 1690 [66.5] ← 1730 [68.1]

Dimensions

Overall length (includ. fork) C mm [in.] 2875 [113.2] ← 2975 [117.1]

Overall width D mm [in.] 1070 [42.1] ← ←

Overall height (Overhead guard)E mm [in.] 2050 [80.7] ← ←

Overall extended height mm [in.] 4030 [158.7] ← ←

Wheel base F mm [in.] 1250 [49.2] ← 1350 [53.1]

Tread

Front wheels G mm [in.] 910 [35.8] ← ←

Rear wheels H mm [in.] 900 [35.4] ← ←

Fork overhang J mm [in.] 375 [14.8] ← ←

Rear overhang K mm [in.] 330 [13.0] ← ←

Fork size

(Length Lx Width Mx Thickness N)

mm [in.] 920 x 100 x 35 ← ←

[36.2 x 3.9 x 1.4]

Fork spacing Pmm [in.] 200 - 920 [7.9 - 36.2] ← ←

Minimum under clearance Q mm [in.] 95 [3.7] (Frame) ← ←

Tow pin height mm [in.] 390 [15.4] ← ←

Weight

Service Weight with std. batteries kg [lbf] 2650 [5842] 2710 [5976] 3000 [6600]

The values in the Performance section are given for the trucks in the Super mode.

No. SEB-81BBE

SPECIFICATIONS (2)

Model

FB20-7 FB25-7 FB25-7LB

Item FB25-7V

Performance

Max. load kg [lbf] 2000 [4000] 2500 [5000] ←

Load center mm [in.] 500 [24] ←←

Max. lifting height mm [in.] 3000 [118.1] ←←

Tilting angle

Fwd ° 6 ←←

Bwd ° 12 ←←

Free lift Amm [in.] 160 [6.3] ←←

Mast tilting time (Fwd - Bwd) s 2.7 - 2.0 ←←

Fork lifting speed

Loaded mm/s [fpm] 290 [57.1] 255 [50.2] ←

Unloaded mm/s [fpm] 510 [100.4] ←←

Travel speed

Loaded km/h [mph] 13.5 [8.4] ←13 [8.1]

Unloaded km/h [mph] 15 [9.3] ←14.5 [9.0]

Gradeability

(Starting on an uphill when loaded) 1/7 ←1/8

Min. turning radius

(Outermost part of truck) Bmm [in.] 1950 [76.8] 1970 [77.6] 2065 [81.3]

Min. intersecting aisle mm [in.] 1895 [79.6] 1905 [75.0] 1955 [76.9]

Dimensions

Overall length (includ. fork) Cmm [in.] 3315 [130.5] 3355 [132] 3460 [136]

Overall width Dmm [in.] 1150 [45.3] ←←

Overall height (Overhead guard)E mm [in.] 2095 [82.5] ←LB: 2250 [88.6]

V : 2100 [82.7]

Overall extended height mm [in.] 4030 [158.7] ← ←

Wheel base Fmm [in.] 1400 [55.1] ←1545 [60.8]

Tread

Front wheels Gmm [in.] 955 [37.6] ←←

Rear wheels Hmm [in.] 950 [37.4] ←←

Fork overhang Jmm [in.] 435 [17.1] ←←

Rear overhang Kmm [in.] 410 [16.1] 450 [17.7] 410 [16.1]

Fork size

(Length Lx Width Mx Thickness N)

mm [in.] 1070 x 122 x 40 ←←

[42.1 x 4.8 x 1.6]

Fork spacing Pmm [in.] 245 – 1020 [9.6 – 40.2] ←←

Minimum under clearance Qmm [in.] 100 [3.9] (Front axle) ←←

Tow pin height mm [in.] 440 [17.3] ←←

Weight

Service Weight with std. batteries kg [lbf] 3470 [7650] 3850 [8489] LB: 4350 [9592]

V : 4250 [9371]

The values in the Performance section are given for the trucks in the Super mode.

No. SEB-81BBE

SPECIFICATIONS (3)

Model FB30-7 FB35-7S

Item FB30-7V

Performance

Max. load kg [lbf] 3000 [6000] 3500 [7000]

Load center mm [in.] 500 [24] ←

Max. lifting height mm [in.] 3000 [118.1] ←

Tilting angle

Fwd ° 6 ←

Bwd ° 12 10

Free lift Amm [in.] 165 [6.5] 150 [5.9]

Mast tilting time (Fwd - Bwd) s 2 - 2 ←

Fork lifting speed

Loaded mm/s [fpm] 290 [57.1] 230 [45.3]

Unloaded mm/s [fpm] 490 [96.5] 400 [78.7]

Travel speed

Loaded km/h [mph] 13.5 [8.4] 12.5 [7.8]

Unloaded km/h [mph] 15 [9.3] 14 [8.7]

Gradeability

(Starting on an uphill when loaded) 1/8 ←

Min. turning radius

(Outermost part of truck) Bmm [in.] 2140 [84.3] 2360 [92.9]

Min. intersecting aisle mm [in.] 2050 [80.7] 2250 [88.6]

Dimensions

Overall length (includ. fork) Cmm [in.] 3580 [141] 3835 [151.0]

Overall width Dmm [in.] 1225 [48.2] 1380 [54.3]

Overall height (Overhead guard)E mm [in.] 2190 [86.2] ←

V: 2100 [82.7]

Overall extended height mm [in.] 4260 [167.7] 4265 [167.9]

Wheel base Fmm [in.] 1600 [63.0] 1800 [70.9]

Tread

Front wheels Gmm [in.] 1000 [39.4] 1140 [44.9]

Rear wheels H mm [in.] 950 [37.4] ←

Fork overhang Jmm [in.] 480 [18.9] 530 [20.9]

Rear overhang K mm [in.] 430 [16.9] ←

Fork size

(Length Lx Width Mx Thickness N)

mm [in.] 1070 x 125 x 45 1070 x 150 x 50

[42.1 x 4.9 x 1.8] [42.1 x 5.9 x 2.0]

Fork spacing Pmm [in.] 250 – 1090 [9.8 – 42.9] 300 – 1200 [11.8 – 47.2]

Minimum under clearance Q mm [in.] 110 [4.3] (Rear axle) ←

Tow pin height mm [in.] 475 [18.7] ←

Weight

Service Weight with std. batteries kg [lbf] 4660 [10275] 5590 [12325]

The values in the Performance section are given for the trucks in the Super mode.

No. SEB-81BBE

No. SEB-81BBE

Fig. 1 Overall Dimensions

Unit: mm [in.]

No. SEB-81BBE

No. SEB-81BBE

CONTENTS

1. BATTERY AND CHARGER .............................................................................................. 1

1.1 GENERAL DESCRIPTION....................................................................................................... 2

1.1.1 BATTERY ............................................................................................................................ 2

1.1.2 CHARGER........................................................................................................................... 4

1.1.3 CHARGING PROCEDURES.............................................................................................. 13

1.1.4 CHARGER OPERATION.................................................................................................... 15

2. MOTORS .................................................................................................................................... 17

2.1 GENERAL DESCRIPTION....................................................................................................... 17

2.1.1 DRIVE MOTOR .................................................................................................................. 17

2.1.2 PUMP MOTOR.................................................................................................................... 21

2.2 MAINTENANCE ....................................................................................................................... 23

2.2.1 DRIVE MOTOR .................................................................................................................. 23

2.2.2 PUMP MOTOR.................................................................................................................... 27

3. CONTROL SYSTEM ............................................................................................................. 29

3.1 GENERAL DESCRIPTION....................................................................................................... 29

3.1.1 INVERTER .......................................................................................................................... 29

3.1.2 ACCELERATOR PEDAL.................................................................................................... 34

3.1.3 INTERLOCK SYSTEM ...................................................................................................... 35

3.1.4 BACK-DOWN ALARM SYSTEM ..................................................................................... 36

3.2 MAINTENANCE ....................................................................................................................... 37

3.2.1 TROUBLESHOOTING GUIDE.......................................................................................... 37

4. DRIVE UNIT AND DRIVE AXLE ..................................................................................... 55

4.1 GENERAL DESCRIPTION....................................................................................................... 55

4.1.1 DRIVE UNIT ....................................................................................................................... 55

4.1.2 DRIVE AXLE ...................................................................................................................... 59

5. BRAKE SYSTEM ................................................................................................................... 63

5.1 GENERAL DESCRIPTION....................................................................................................... 63

5.1.1 BRAKE PEDAL................................................................................................................... 63

5.1.2 MASTER CYLINDER ........................................................................................................ 65

5.1.3 WHEEL BRAKE.................................................................................................................. 66

5.1.4 PARKING BRAKE LEVER ................................................................................................ 68

5.2 MAINTENANCE ....................................................................................................................... 71

5.2.1 DISASSEMBLING WHEEL BRAKE................................................................................. 71

5.2.2 INSPECTION....................................................................................................................... 73

5.2.3 REASSEMBLING WHEEL BRAKE .................................................................................. 74

5.2.4 OPERATION TEST OF AUTOMATIC CLEARANCE ADJUSTER ................................. 76

No. SEB-81BBE

5.2.5 ADJUSTING BRAKE PEDAL............................................................................................ 77

5.2.6 TROUBLESHOOTING GUIDE.......................................................................................... 78

6. STEERING SYSTEM ............................................................................................................ 79

6.1 GENERAL DESCRIPTION....................................................................................................... 79

6.1.1 OUTLINE OF STEERING SYSTEM ................................................................................... 80

6.1.2 STEERING GEARBOX........................................................................................................ 81

6.1.3 ACTUATOR .......................................................................................................................... 84

6.1.4 REAR AXLE ......................................................................................................................... 84

6.1.5 ADJUSTING PRELOAD OF REAR WHEEL BEARING ................................................... 88

6.1.6 ASSEMBLING WHEEL ....................................................................................................... 89

6.2 MAINTENANCE ........................................................................................................................ 90

6.2.1 MAINTENANCE OF ACTUATOR ...................................................................................... 90

6.2.2 MAINTENANCE OF STEERING BEARBOX.................................................................... 93

7. HYDRAULIC SYSTEM ........................................................................................................ 103

7.1 GENERAL DESCRIPTION ........................................................................................................ 103

7.1.1 MAIN PUMP ......................................................................................................................... 104

7.1.2 CONTROL VALVE ............................................................................................................... 104

7.1.3 HYDRAULIC OIL TANK..................................................................................................... 108

7.1.4 LIFT CYLINDER .................................................................................................................. 109

7.1.5 FLOW REGULATOR VALVE .............................................................................................. 114

7.1.6 TILT CYLINDER .................................................................................................................. 116

7.2 MAINTENANCE ........................................................................................................................ 118

7.2.1 MAINTENANCE OF PUMP ................................................................................................ 118

7.2.2 TRIAL RUN........................................................................................................................... 130

7.2.3 TROUBLESHOOTING GUIDE ........................................................................................... 131

8. LOAD HANDLING SYSTEM ............................................................................................ 133

8.1 GENERAL DESCRIPTION ........................................................................................................ 134

8.1.1 OUTER AND INNER CHANNELS ..................................................................................... 134

8.1.2 CARRIAGE ........................................................................................................................... 136

8.1.3 LOCATIONS OF ROLLERS ................................................................................................ 139

8.2 MAINTENANCE ........................................................................................................................ 142

8.2.1 ADJUST LIFT CYLINDER ROD WITH SHIMS ................................................................ 142

8.2.2 ADJUSTING HEIGHT OF CARRIAGE .............................................................................. 142

8.2.3 PROCEDURE FOR REPLACING ROLLERS AT CARRIAGE SIDE................................ 144

8.2.4 PROCEDURE FOR REPLACING ROLLERS AT MAST SIDE ......................................... 146

8.2.5 PROCEDURE FOR ADDING OR SUBTRACTING SHIMS.............................................. 147

9. ELECTRIC WIRING .............................................................................................................. 149

1. BATTERY AND CHARGER

- 1 -

1. BATTERY AND CHARGER (OPTION)

The description in this section applies to our optional batteries and chargers. For other types of

batteries and chargers, refer to their respective instruction manuals. The description of the VTM unit

applies to all the trucks because the VTM unit is standard equipment.

Truck model

FB10-7 FB15-7 FB20-7 FB25-7

Item FB18-7

Battery

Capacity 330AH/5h 400AH/5h 450AH/5h 565AH/5h

Name VSDX330M VSDX440M VSDX450M VSDX565HM

Voltage 48 V

Specic gravity of

electrolyte 1.280

Weight 650 kg 695 kg 830 kg 915 kg

Charger

Type Truck-mounted type, 3-phase AC semiconstant voltage charger

Rated power 6.0 kVA 8.5 kVA

Rated current 17 A 24 A

Power supply voltage

380 / 440 V

Applicable battery

capacity 320 - 500 AH/5h 450 - 700 AH/5h

Output

Voltage 51 - 64 V

Current 80 - 20 A 115 - 29 A

Truck model

FB25-7LB FB25-7V FB30-7 FB35-7S

Item FB30-7V

Battery

Capacity 935AH/5h 865AH/5h 450AH/5h 545AH/5h

Name VSF935 VSF865 VSDX450MZ VSDX545MH

Voltage 48 V 72 V

Specic gravity of

electrolyte 1.280

Weight 1450 kg 1350 kg 1130 kg 1285 kg

Charger

Type

Truck-mounted type, 3-phase AC semiconstant voltage charger

Rated power 12 kVA

Rated current 34 A

Power supply voltage

380 / 440 V

Applicable battery

capacity 320 - 500 AH/5h 450 - 700 AH/5h

Output

Voltage 51 - 64 V 76.5 - 96 V

Current 160 - 40 A 105 - 26 A

1. BATTERY AND CHARGER

- 2 -

1.1 GENERAL DESCRIPTION

1.1.1 BATTERY

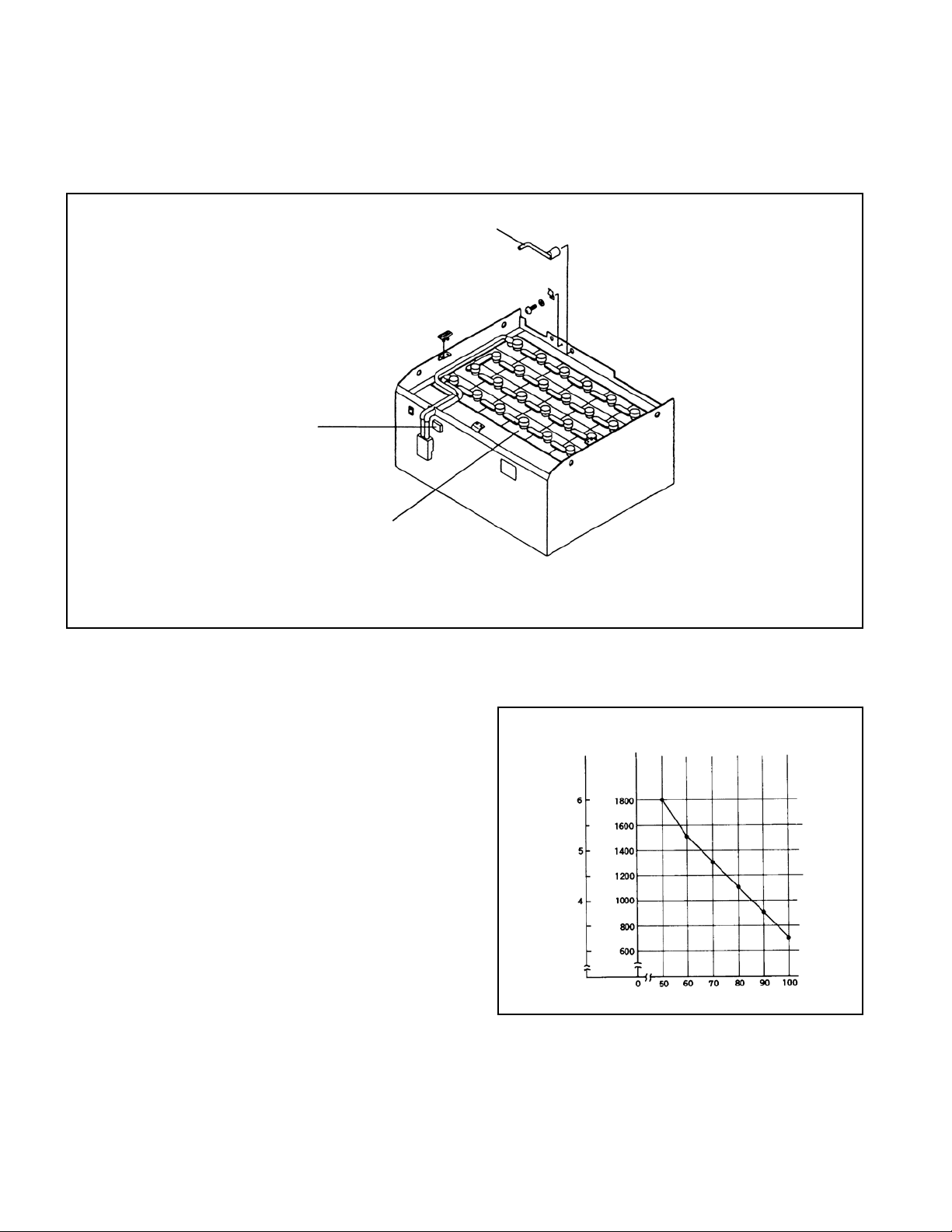

The battery unit consists of twenty-four 2-volt battery cells connected in series. Figure 1.1 shows its

construction.

(1) Battery care

The most important point in battery care is to

prevent overdischarge. The deeper the battery

discharges, the shorter its life becomes (See Fig. 1.2).

The approximate depth of discharge can be known

by measuring the specic gravity of the electrolyte

(See Fig. 1.3)

Check the level of electrolyte every ten days.

Add distilled water if the level is found lower than

the specied level before charging the battery.

Fig. 1.2

Relation Between Depth of Discharge

and Service Life (Example)

Service life

Cycles of

charge and

discharge

Depth of discharge (%)

BATTERY CELL WITH

ELECTROLYTE LEVEL SENSOR

LOCK PIN

ELECTROLYTE

LEVEL INDICATOR

Fig. 1.1

Battery Unit

Note: The sketch shows a 48-volt battery unit. The 72-volt battery unit has 36 battery cells.

1. BATTERY AND CHARGER

- 3 -

(2) Charging the battery

When discharged, the battery should be recharged as soon as possible. Leaving the battery discharged

for a long time may cause sulfation, which will result in a drop of the battery performance.

If the battery is kept out of service for a long time, it should be thoroughly charged before put in

storage. An additional charge is also required once a month.

Do not leave a fully discharged battery longer than a day as it is. Be sure to recharge it as soon as

possible.

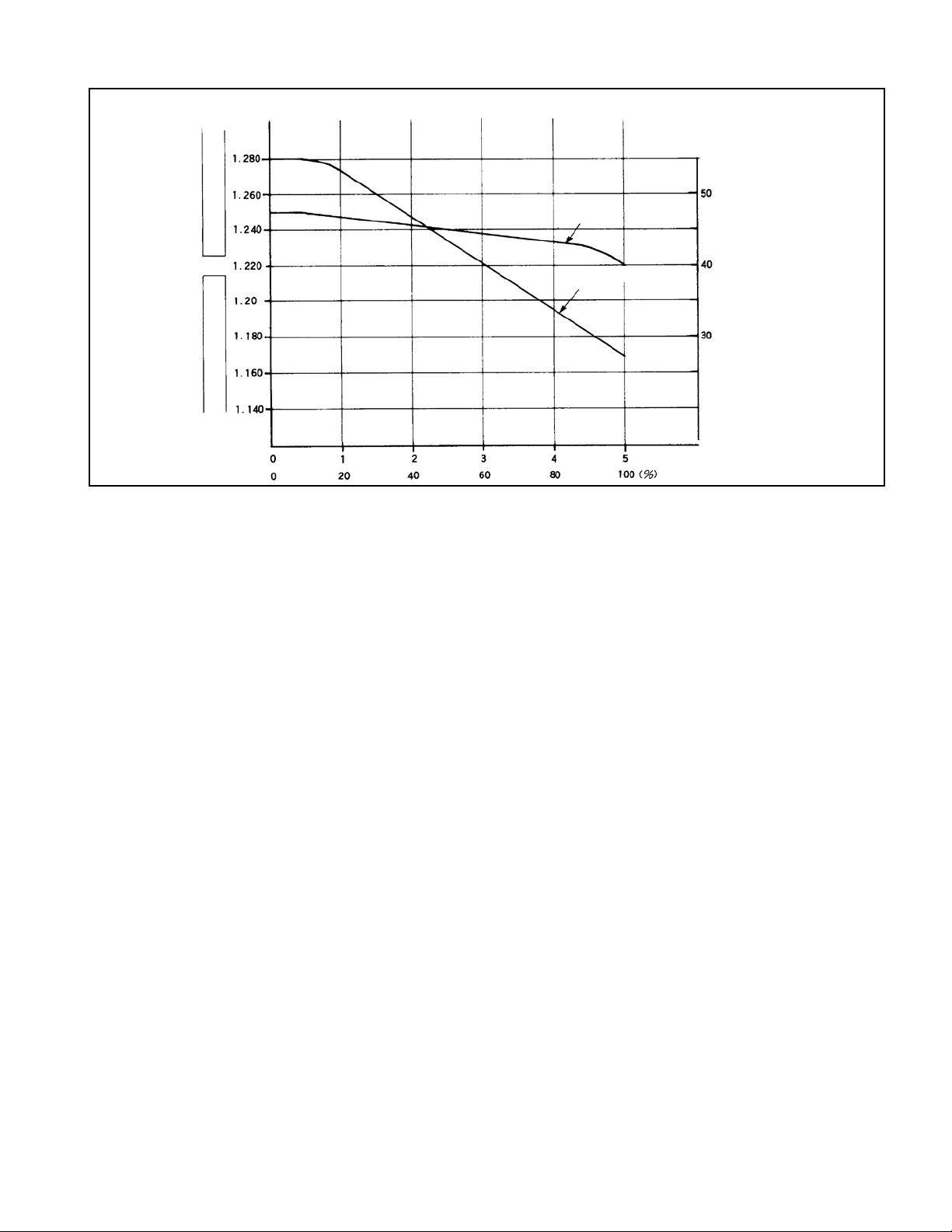

If the amount of discharge is considered to be small, measure the specic gravity of the electrolyte.

If lower than 1.260, recharge the battery.

Equalizing charge is required if the specic gravity varies among the cells by the amount of 0.020 or

larger. Equalizing charge is normally needed between one to four times a month.

If the specic gravity variation is not made smaller by equalizing charge, specic gravity adjustment

will be required.

Giving an equalizing charge more times than necessary will overcharge the battery, and its service

life will be shortened.

For a truck-mounted type charger, a microcomputer determines when an equalizing charge is required

and carries out equalizing charge automatically.

[Cautions on Charging the Battery]

(1) Do not start charging the battery if the electrolyte temperature is higher than 50°C. Leave the

battery for a while until the temperature goes low. Then charge it.

(2) Overdischarge or overcharge raises the electrolyte temperature. While charging the battery, be sure

to keep the battery cover fully open in order to let the generated gas and heat get out.

[Specic Gravity Correction According to Temperature]

The specic gravity of the electrolyte varies as the electrolyte temperature changes. The specic

gravity is generally based on the electrolyte temperature of 20°C. Therefore, if the specic gravity is

measured at the electrolyte temperature if other than 20°C, correct it using the following formula:

S20 = St + 0.0007 (t – 20)

where S20 ............specic gravity for 20°C

St...............specic gravity measured at t

t.................electrolyte temperature measured.

(Discharge rate)

Fig. 1.3 An Example of Specic Gravity Drop

Specic gravity

(at 20°C)

Usable

Alert !

Overdischarge

Voltage (V)

Voltage

(Discharge duration)

Specic gravity

1. BATTERY AND CHARGER

- 4 -

1.1.2 CHARGER

The charger mounted on the truck is a computer-controlled, semiconstant-voltage type consisting of a

transformer, diodes, an operation panel, and a VTM unit.

INSULATION TUBE BAND

INSULATION TUBE

BAND

SECONDARY WIRE CONTACTOR VTM UNIT

PRIMARY WIRE THERMAL RELAY

SECONDARY WIRE CONTACTOR VTM UNIT

PRIMARY WIRE THERMAL RELAY

CONNECTION OF PRIMARY

WIRE (PORTION NOT USED)

CONNECTION OF

SECONDARY WIRE

Thermal relay current settings

Transformer model Setting (A)

M80B 18

M80C 11

M80D

M105B 37

M105C 20

M105D

M115B 29

M115C 15

M115D

Note: The charger for the FB30 and FB35 series is not shown . (It is almost the same design as that for the FB20 series.)

Fig. 1.4

1. BATTERY AND CHARGER

- 5 -

(1) Transformer

The transformer is located at the right side frame and converts input voltage to a voltage of the level

necessary for charging the battery.

There are three taps provided with a 10-volt difference from one to another. Make a selection among

them at the input side according to the input voltage level.

Fig. 1.5 Transformer

PRIMARY WIRE

■

Transformer tap changing

The supply voltage varies with the periods of time. Change therefore the taps from one to

another according to the average of supply voltages which to charger receives for the period of

time during which the battery is normally charged.

GROUND WIRE (GREEN)

SECONDARY WIRE

Supply Voltage (Average) Symbol

380 V 440 V of Tap

50 Hz 60 Hz 50 Hz 60 Hz

350 - 370 360 - 380 400 - 420 410 - 430 L

370 - 390 380 - 400 420 - 440 430 - 450 M

390 - 410 400 - 420 440 - 460 450 - 470 H

Note 1: Change all the three

phases as a set.

Note 2: Give a terminal cap

to each of the taps

which are not used, and

fix them by the wire

binder.

1. BATTERY AND CHARGER

- 6 -

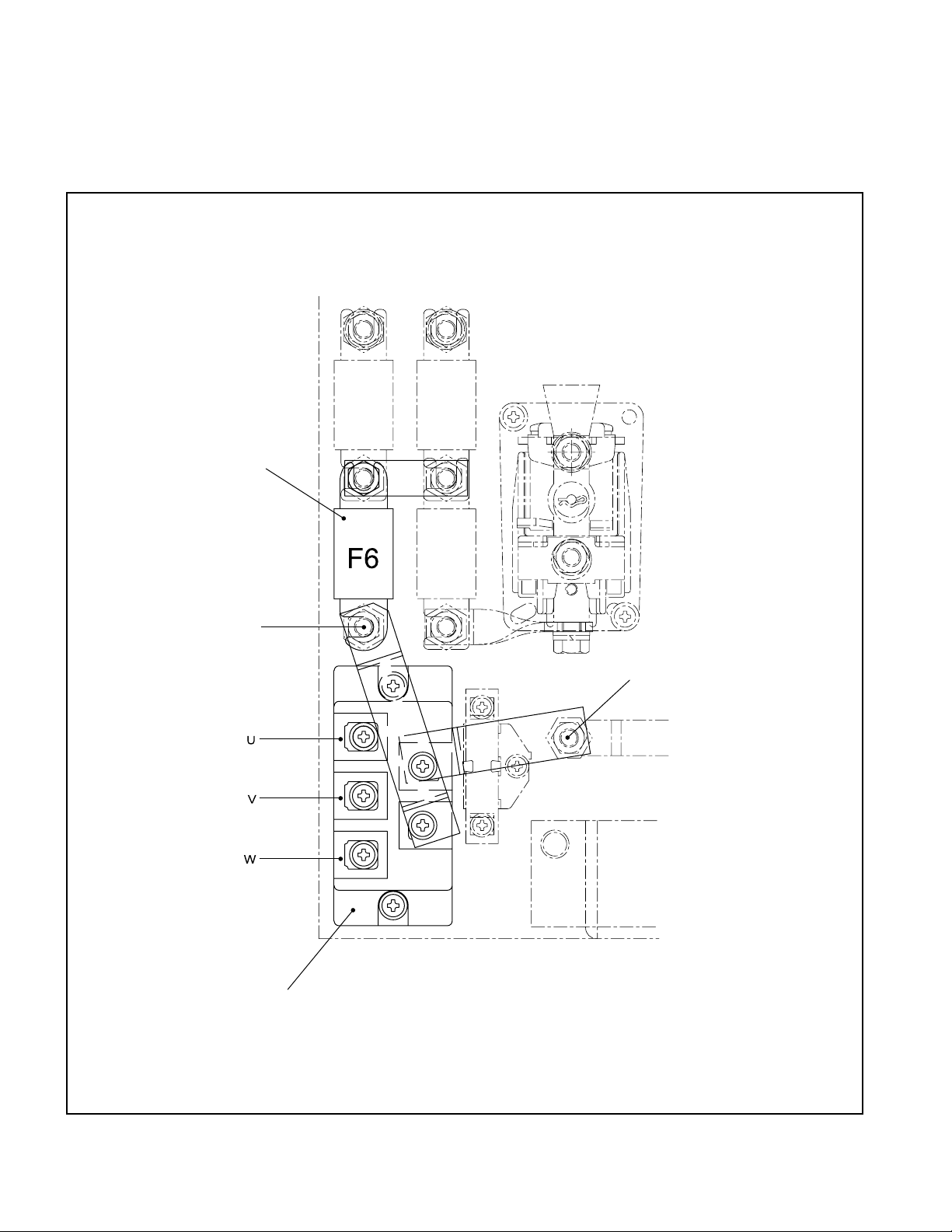

(2) Diode

The diode, installed on the speed controller, is a 3-phase, full-wave rectication type which converts

AC to DC.

The current rectied by the diode ows through the fuse F6 to charge the battery.

FUSE (130A)

(FB25-7LB, FB25-7V: 200A)

CHARGING DIODE

POSITIVE

TERMINAL

NEGATIVE TERMINAL

Fig. 1.6 Diode

1. BATTERY AND CHARGER

- 7 -

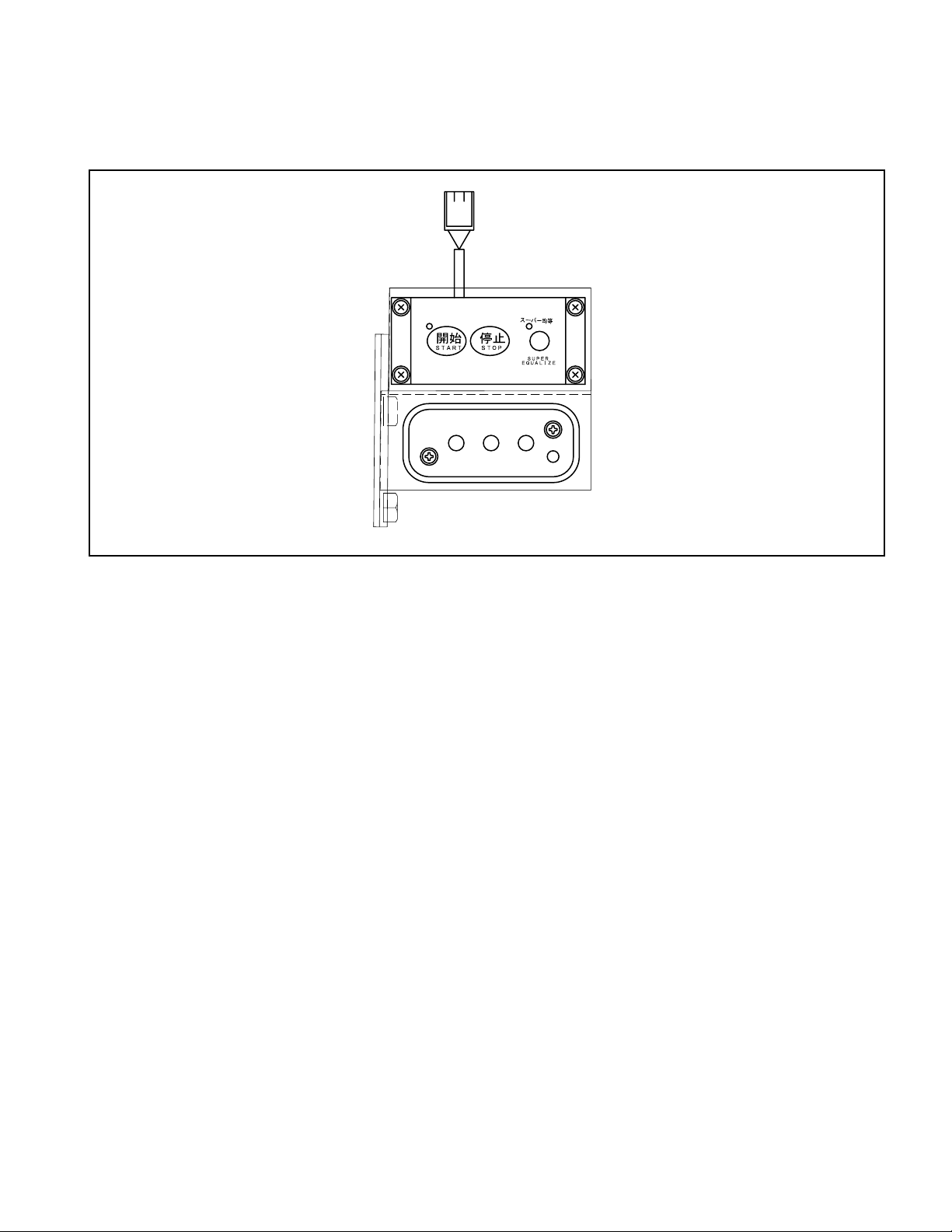

(3) Operation panel

The operation panel is located on the left side of the cabinet and equipped with a charger control

switches, lamps and service power outlet.

(4) VTM unit

The VTM unit is installed inside the right side frame. It sets the charging time for the battery

assembly by the signal from the operation panel.

■

Major features of VTM unit

①

Optimal charge according to battery’s state of charge

Conventionally, overcharge might occur when not so an exhausted battery is charged. On this

charger, the microprocessor judges the battery’s state of charge and changes the normal timer setting

within a specied range for optimal charge.

This setting voltage is compensated properly to provide optimal charge even if there are temperature

changes.

②

Super equalizing charge

The microprocessor counts the charging time and automatically provides equalizing charge when a

specied time is reached. The time setting for super equalizing charge is preset properly according

to the ambient temperature after temperature compensation. This function saves the trouble of the

operator’s bothering to press the equalizing charge button.

③

In case of power failure while charging

Unless power failure continues longer than 120 hours, battery charging is normally completed.

■

VTM unit

The VTM is mainly composed of its timer function. The microprocessor of the VTM unit determines

and sets an optimal duration of charging after checking the state of the battery.

Fig. 1.7 Operation Panel

1. BATTERY AND CHARGER

- 8 -

The VTM unit has two timers: One is called rst timer and the other second timer. It is the rst timer

on which the microprocessor sets the charging time (4 hours maximum).

The time to be set on the second timer is 15 hours for normal charging. If a single charging continues

longer than that duration, charging is treated as an abnormal termination. The lamp on the operation

panel then blinks and the display gives a message to inform the operator of that abnormal termination.

Data of past battery charge are stored in memory of the VTM unit. Based on these data, the

microcomputer judges whether or not the battery needs equalizing charge. The data store in memory

are:

* The changes in battery voltage and electrolyte temperature and voltage settings of charge sessions

performed within the last 40 hours

(94 hours for trucks manufactured earlier than January 31, 2004)

* The total charging hours, and the total hours during which the battery was connected to the charger.

* The number of times the battery got an equalizing charge.

* The number of times charging was terminated by the rst timer.

* The number of times charging was terminated by the second timer.

* The number of times charging was stopped incomplete. (The number of times the stop button is

pressed.)

The VTM unit is also provided with an LED display on its printed circuit board. The LED display

is used for showing various data in connection with the charger/battery so that it helps the operator be

informed of adjustment data or the status of the charger according to the position of the setting switch

located on the printed circuit board.

Fig. 1.8 VTM Unit (for trucks manufactured earlier than January 31, 2004)

Other manuals for FB10-7

1

This manual suits for next models

9

Table of contents

Other TCM Forklift manuals

Popular Forklift manuals by other brands

Noblelift

Noblelift FE4P16-20 Q Series Operation manual

logitrans

logitrans EHS Stainless 1000/1400 instruction manual

Jungheinrich

Jungheinrich DFG 540 operating instructions

logitrans

logitrans Level Control LC4 manual

Still

Still R70-40T operating instructions

albutt

albutt F100 INSTRUCTION MANUAL AND PARTS CATALOGUE