TCP Smart SMAWDEHUM20LBD068CF User manual

1

INSTRUCTION MANUAL

TCP Smart 20lt Dehumidifier

SMAWDEHUM20LBD068CF

Please keep this manual carefully for further reference!

Thank you for selecting our dehumidifier.

This device is designed to reduce the humidity levels in your indoor environment, creating a

more comfortable living space and preventing the growth of mould and mildew. To ensure

you get the most out of your dehumidifier, please read this instruction manual carefully

before use.

2

CONTENT

1. BEFORE YOU BEGIN

2. PRODUCT OVERVIEW / DESCRIPTION

3. FOR YOUR SAFETY

3.1 OPERATION PRECAUTIONS

3.2 SAFETY PRECAUTIONS ON SERVICING

4. INSTALLATION

4.1 LOCATION

5. OPERATION

5.1 OPERATING THE DEVICE SAFELY

5.2 EMPTING THE TANK

5.3 CONTINUOUS DRAINING

6. MAINTENANCE

6.1 CLEANING THE AIR FILTER

7. TROUBLESHOOTING

7.1 FUNCTIONAL TEMPERATURE

7.2 TROUBLESHOOTING

8. DECOMMISSIONING

8.1 STORAGE

8.2 DISPOSAL

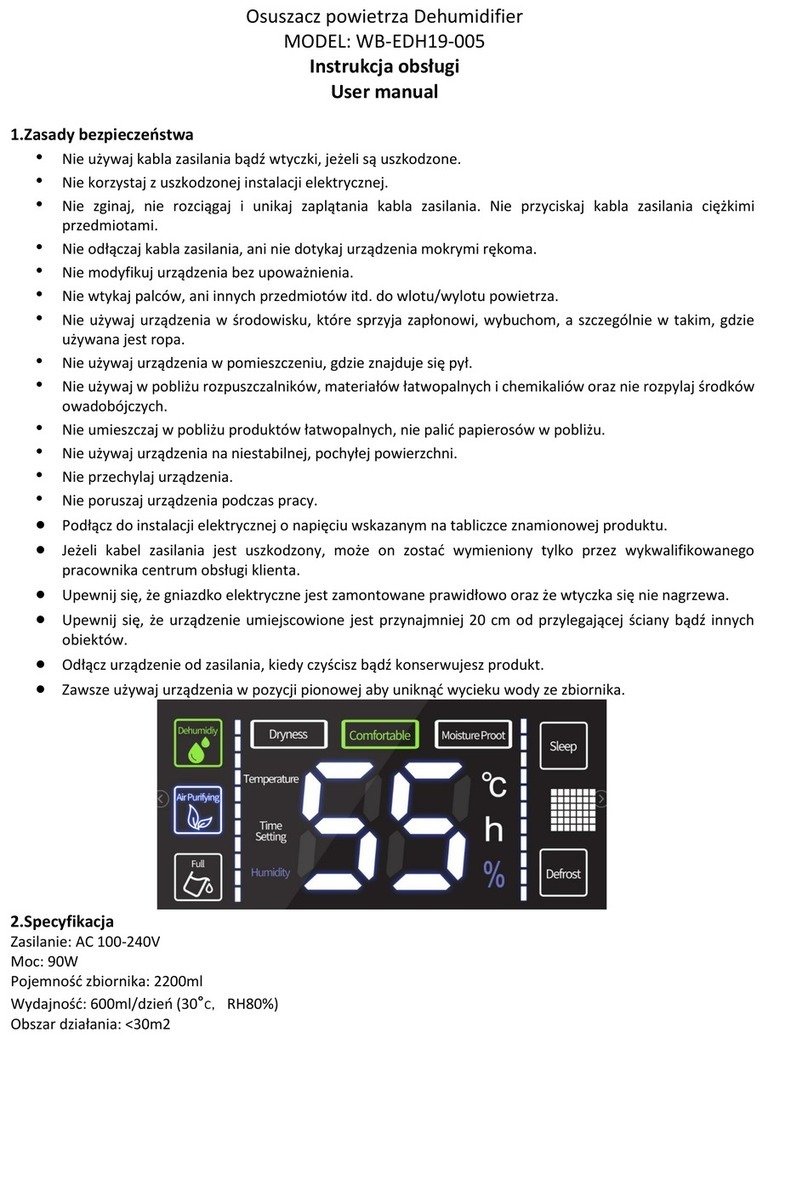

9. OPERATION CONTROL PANEL

9.1 OPERATION

9.2 FUNCTION KEYS AND INDICATORS

10. CONNECTING TO WIFI

11. USING THE TCP SMART APP

3

1.0 BEFORE YOU BEGIN

Please read this manual carefully and fully understand before

operating your dehumidifier.

PRODUCT DESCRIPTION

The dehumidifier is used to remove excessive moisture from the air. The resulting

reduction in relative humidity protects buildings and their contents from the adverse

effects of excess humidity.

This dehumidifier uses the environmentally friendly R290 (propane) as the refrigerant.

R290 (propane) has no damaging influence on the ozone layer (ODP), a negligible

greenhouse effect (GWP) and is available worldwide. Because of its efficient energy

properties, R290 (propane) is highly suitable as a coolant for this application. Special

precautions must be taken into consideration due to the coolant's high flammability.

IMPORTANT SYMBOLS FROM THE UNIT AND USER MANUAL

warning

This unit uses a flammable refrigerant.

If refrigerant leaks and comes in to contact with fire or heating

part, it will create harmful gas and there is risk of fire.

Read the USER MANUAL carefully before operation.

Further information is available in the USER MANUAL, SERVICE

MANUAL, and the like.

Service personnel are required to carefully read the USER

MANUAL and SERVICE MANUAL before operation.

4

Castors

Control panel

Air outlet

Front shell

Air Filter

Back shell

Continuous drainage

2.0 PRODUCT OVERVIEW

FRONT VIEW

Recessed handle

BACK VIEW

Water Tank

5

FEATURES

Powerful moisture removal (up to 20L/day dehumidification)

Humidity Monitor shows current air humidity

Auto mode adjusts humidity levels

24-hour timer to set the time of operation

Effectively remove moisture, dust from the air

Low power consumption-energy efficient

Quiet fan has two speed settings

Auto-Defrost at low temperature

Auto shut-off/ auto restart

Electronic control

Nylon Filter

Continuous drainage or 4.5L water tank

6

3.0 FOR YOUR SAFETY

3.1 OPERATIONAL PRECAUTIONS

THE FOLLOWING SHOULD ALWAYS BE OBSERVED FOR SAFETY

This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without supervision.

The unit is designed only for use with R-290 (propane) gas as the designated

refrigerant.

The refrigerant loop is sealed. Only a qualified technician should attempt to

service!

-R-290 (propane gas) is flammable and heavier than air.

-It collects first in low areas but can be circulated by fans.

If R - 2 9 0 ( propane gas) is suspected, do not allow untrained personnel to

attempt to find the cause.

-The R-290 (propane gas) used in the unit has no odour.

-The lack of smell does not indicate a lack of escaped gas.

If a leak is detected, immediately evacuate all persons from the room/area,

ventilate the room and contact the local fire department to advise them that a

propane leak has occurred.

Do not let any persons back into the room until a qualified service technician

advises that it is safe to return to the store.

No open flames, cigarettes or other possible sources of ignition should be used

inside or in the vicinity of the units.

Component parts are designed for propane and non-incentive and non-

sparking. Component parts shall only be replaced with identical repair parts.

FAILURE TO ABIDE BY THIS WARNING COULD RESULT IN AN

EXPLOSION, DEATH, INJURY AND PROPERTY DAMAGE

7

WARNING- to reduce the risk of fire, electric shock or injury to persons

or property:

If the supply cord is damaged, it must be replaced by the manufacturer, its service

agent or similarly qualified persons in order to avoid a hazard.

Always operate the unit from a power source of AC220-240V, 50Hz and

maximum 160W as indicated on the product identification plate.

Always use a power outlet that is grounded.

Unplug the power cord when cleaning or when not in use.

Do not operate with wet hands. Prevent water from spilling onto the unit.

Do not immerse or expose the unit to rain, moisture or any other liquid.

Do not leave the unit running unattended. Do not tilt or turn over the unit.

Do not unplug while the unit is operating.

Do not unplug by pulling on the power cord.

Do not use an extension cord or an adapter plug.

Do not put objects on the unit.

Do not climb or sit on the unit.

Do not insert fingers or other objects into the air outlet.

Do not touch the air inlet or the aluminum fins of the unit.

Do not operate the unit if it is dropped, damaged or showing signs of

product malfunction.

Do not clean the appliance with any chemicals.

Do not cover the air filter or air outlet.

Ensure the unit is far away from fire, inflammable, or explosive objects.

Do not use means to accelerate the defrosting process or to clean, other than

those recommended by the manufacture.

The appliance must be stored in a room where there are no continuously operating

sources (for example: open flames, an operating gas appliance or an operating electric

heater).

Do not pierce or burn, even after use.

Be aware that refrigerants may not contain an odour.

Pipework shall be protected from physical damage and shall not be

installed in an unventilated space, if that space is smaller than 4m².

Compliance with national gas regulations shall be observed.

8

Keep any required ventilation openings clear of obstruction.

When not in use the appliance must be stored in a well-ventilated area where

the room size corresponds to the room area as specified for operation.

Any person who is involved with working on, or breaking into a

refrigerant circuit, should hold a current valid certificate from an industry-

accredited assessment authority, which authorises their competence to handle

refrigerants safely in accordance with an industry, recognized assessment

specification.

Servicing shall only be performed as recommended by the equipment

manufacturer. Maintenance and repair requiring the assistance of other skilled personnel shall be

carried out under the supervision of the person competent in the use of flammable refrigerants.

If you don't understand something or need help, please contact the TCP helpline.

9

3.2 SAFETY PRECAUTIONS ON SERVICING

Please follow these warnings when to undertake servicing of a dehumidifier with R290.

Checks to the surrounding area

Prior to beginning work on systems containing flammable refrigerants, safety checks

are necessary to ensure that the risk of ignition is minimized. For repair to the

refrigerating system, the following precautions shall be complied with prior to

conducting work on the system.

Work procedure

Work shall be undertaken under a controlled procedure to minimize the risk of a

flammable gas or vapor being present while the work is being performed.

General work area

All maintenance staff and others working in the local area shall be instructed on the

nature of work being carried out. Work in confined spaces shall be avoided. The area

around the workspace shall be sectioned off. Ensure that the conditions within the

area have been made safe by control of flammable material.

Checking for presence of refrigerant

The area shall be checked with an appropriate refrigerant detector prior to and during

work, to ensure the technician is aware of potentially flammable atmospheres. Ensure

that the leak detection equipment being used is suitable for use with flammable

refrigerants, i.e. no sparking, adequately sealed or intrinsically safe.

Presence of fire extinguisher

If any hot work is to be conducted on the refrigeration equipment or any associated

parts, appropriate fire extinguishing equipment shall be available to hand. Have a dry

powder orCO2 fire extinguisher adjacent to the charging area.

Ignition sources

No person carrying out work in relation to a refrigeration system which involves

exposing any pipe work that contains or has contained flammable refrigerant shall use

any sources of ignition in such a manner that it may lead to the risk of fire or explosion.

All possible ignition sources, including cigarette smoking, should be kept sufficiently

far away from the site of installation, repairing removing and disposal, during which

flammable refrigerant can possibly be released to the surrounding space. Prior to work

taking place, the area around the equipment is to be surveyed to make sure that

there are no flammable hazards or ignition risks. “No Smoking” signs shall be

displayed.

10

Ventilated area

Ensure that the area is in the open or that it is adequately ventilated before

breaking into the system or conducting any hot work. A degree of ventilation shall

continue during the period that the work is carried out. The ventilation should

safely disperse any released refrigerant and preferably expel it externally into the

atmosphere.

Checks to the refrigeration equipment

Where electrical components are being changed, they shall be fit for the purpose

and to the correct specification. At all times the manufacturer’s maintenance and

service guidelines shall be followed. If in doubt consult the manufacturer’s

technical department for assistance.

The following checks shall be applied to installations using flammable refrigerants:

–The charge size is in accordance with the room size within which the refrigerant

containing parts are installed;

–The ventilation machinery and outlets are operating adequately and are not

obstructed;

–If an indirect refrigerating circuit is being used, the secondary circuit shall be

checked for the presence of refrigerant;

–Marking to the equipment continues to be visible and legible. Markings and signs

that are illegible shall be corrected;

–refrigeration pipe or components are installed in a position where they are

unlikely to be exposed to any substance which may corrode refrigerant containing

components, unless the components are constructed of materials which are

inherently resistant to being corroded or are suitably protected against being so

corroded.

Checks to electrical devices

Repair and maintenance to electrical components shall include initial safety checks and

component inspection procedures. If a fault exists that could compromise safety, then

no electrical supply shall be connected to the circuit until it is satisfactorily dealt with.

If the fault cannot be corrected immediately but it is necessary to continue operation,

an adequate temporary solution shall be used. This shall be reported to the owner of

the equipment so all parties are advised.

Initial safety checks shall include:

-those capacitors are discharged: this shall be done in a safe manner to avoid

possibility of sparking;

-that there no live electrical components and wiring are exposed while charging,

recovering or purging the system;

-that there is continuity of earth bonding

11

4.0 INSTALLATION

4.1 LOCATION

1. Place the unit on a firm, level surface in an area with at least 30cm of free space around it to

allow for proper air circulation.

2. Never place the unit where it could be subject to:

Heat sources such as radiators, heat registers, stoves or other products that products that

produce heat.

In an area where oil or water may be splashed

Direct sunlight

Mechanical vibration

Excessive dust

Lack of ventilation, such as cabinet or bookcase

WARNING

Install the unit in rooms which exceed 4 m².

Do not install the unit in a place where inflammable gas may leak

NOTE

The manufacture may provide other suitable example or may provide additional information about the

refrigerant odour.

12

5.0 OPERATING THE DEVICE SAFELY

5.1 SAFETY PRECAUTIONS WHEN USING THE DEVICE

Check the device after unpacking for any damages or scratches on it.

Operate this unit in an ambient temperature from 5°C to 35°C.

Do not use outdoors. This dehumidifier is intended for indoor, residential applications

only.

Do not operate near walls, curtains, or other objects that may block inlet and outlet.

Keep the air inlet and outlet free of obstacles.

If tipped more than 45°, allow the unit to sit upright for at least 24 hours before start up.

Keep doors and windows closed for better energy saving.

Do not operate or store the unit in direct sunlight or rain.

It is normal for air outlet to feel warm to touch after continuous operation on hot days.

Empty the water tank before moving the device.

Make sure the Water tank is correctly fitted otherwise the unit will not operate properly.

The dehumidifier starts up in the mode selected when the unit was last used.

The dehumidifier starts dehumidifying if the room humidity is 3% higher than the

selected humidity.

There is a protective 3-minute time delay of the compressor. Wait 3 minutes for the

dehumidifier to resume dehumidification.

13

5.2 EMPTYING THE WATER TANK

There are two ways of removing collected water produced by the unit.

A. Manual draining: Empty water tank by manual.

B. Continuous draining: Use gravity to drain condensated water by attaching a drain

hose.

When the water tank is full the unit will automatically shut down. It will start again once the

water tank has been emptied and re-installed properly.

When the tank is full, the unit will make a buzzing sound, and the “Water Full” light will turn on

Press the POWER button to turn off the unit.

Pull the water tank and simply slide out of the body of the dehumidifier.

Empty the water into an area with a drain or outside.

Clean the inside of the tank as well as the outside.

Replace the empty tank back into the unit.

Press the POWER button to resume operating.

If the Water Full light does not extinguish, check that the float is correctly in place.

14

5.3 CONTINUOUS DRAINING

For continuous operation or unattended dehumidification, please connect the attached

drain hose to the unit. Condensate water can be automatically flow into a bucket or drain

by gravity.

Set the unit in a horizontal surface and stable position.

Switch off the unit before operating.

Securely and properly connect the drain hose and make sure it is not kinked and clear of

obstruction.

Place the outlet of hose over a drain or bucket and ensure that water can freely flow out of

the unit.

Do not submerge the end of hose into water; this can cause an "Air Lock" in the hose.

drain-pipe

To avoid water spillage:

As the negative pressure of condensate drain pan is large, tilt the drain hose downward

toward the floor. It is appropriate that the degree of inclination should exceed 20 degrees.

Straighten the hose to avoid a trap existing in the hose.

15

6.0 MAINTENANCE

6.1 CLEANING THE AIR FILTER (every two weeks, or if notably dusty)

Dust collects on the filter and restricts the airflow. The restricted airflow reduces the

efficiency of the system and if it becomes blocked it can cause damage to the unit.

The air filter requires regular cleaning. The air filter is removable for easy cleaning. Do not

operate the unit without an air filter, or the evaporator may be contaminated.

1. Remove the air filter frame.

2. Use a vacuum cleaner to gently absorb the dust on the surface. If the filter is very dirty, wash

it with water and a soft detergent and a l l o w i t t o dry thoroughly before replacing back

into the unit.

3. Put the filter back on to the unit.

16

7.0 TROUBLE SHOOTING

7.1 FUNCTIONING TEMP

Temperature is between 5°C and 35°C

When the ambient temp is lower or higher than the functioning temp, the dehumidifier

stops.

Temperature is between 5°C and 16°C

The compressor automatically defrosts at intervals; during defrosting, the compressor stops

and the fan keeps running.

7.2 BEFORE CALLING FOR SERVICE

Before contacting professional service, please review the trouble shooting list that includes

common occurrences that are not the result of a defect in workmanship or materials.

Problem

Possible Cause

Solution

Not working

No power supply

Connect to a functioning outlet and

switch on

Water Full Indication Flashes

Drain water tank and reset it, or

re-position the water tank to right place

Room temperature below 5°C, or

above 35°C

Self-Protection designed to protect the

unit.

Not

functioning

correctly

Is the air filter clogged?

Clean the air filter as instructed

Is the intake duct or discharge

duct obstructed?

Remove the obstruction from the

discharge duct or intake duct.

No air intake

Is the filter clogged?

Wash the filter

Loud noise

when

running

Is the machine on flat ground?

Put the machine on the flat ground

Is the filter clogged?

Wash the filter

E2

Humidity sensor problem

Change the sensor

LO

Environmental humidity is below

20%

The dehumidifier shuts down for self-

protection

HI

Environmental humidity is above

90%

CL

Low temperature protection, the

environmental temperature<5℃

CH

High temperature protection, the

environmental temperature >35℃

17

8.0 DECOMMISIONING

8.1 STORAGE

Long-term storage - If you will not be using the unit for an extended period of time (more

than a few weeks) it is best to clean the unit and dry it out completely. Please store the

unit per the following steps:

Press power button to switch off and unplug the unit.

Drain the remaining water from the unit.

Clean the filter and let the filter dry completely in a shaded area.

Collect the power cord at the water tank.

Re-install the filter in its correct position.

The unit must be kept in upright position when in storage.

Store the unit in a well -ventilated, dry, safe place indoors. Ensure the area does not contain any

corrosive gas.

ATTENTION:

The evaporator inside the machine has to be dried out before the unit is packed to avoid

component damage and mould. Unplug the unit and place it in a dry open area for a few

days to dry it out. Another way to dry the unit is to set the humidity point more than 5%

higher than the ambient humidity to force the fan to dry the evaporator for a couple of

hours.

8.2 DISPOSAL

WARNING!!!

Releasing refrigerant into atmosphere is strictly forbidden!

Only dispose of electrical appliances as designated municipal waste facilities. Contact your local

government for information regarding the collection systems available. If electrical appliances are

disposed of in landfills or dumps, hazardous substances can leak into the groundwater and get into

the food chain.

18

9.1 CONTROL PANEL

9.0 OPERATION

9.2 FUNCTION KEYS AND INDICATORS

1.

POWER button

Touch this button to switch the machine on or off.

2.

Mode Button

Touch this button to choose Auto, Sleep and Continuous Dry mode.

3.

HUM Button

Touch this button to adjust the humidity level and choose timer hour

4.

Timer button

Touch this button to set a time for the unit to automatically start or stop.

Through long press the button to active WIFI connection

5.

Fan speed button

Touch this button to select fan speed between high and low.

6.

Lock button

Hold this button to turn child lock function on or off.

7.

Digital Display

Displays humidity value, Timer setting or Temperature.

女

女

女

3

19

Power button

In the standby state, touch this button to turn on, the operation indicator lights up

and the default fan speed is high, and the default humidity is 50%. In the power-on

state, touch this button to turn off, the running indicator light goes off and the

compressor stops immediately, and then the fan shuts down after 30 seconds delay.

Dehumidify Mode

Touch the mode key to switch between automatic, sleep and dry mode. Press once

to switch the mode from one to another, the corresponding indicator lights up.

Auto Mode: when environmental humidity is +3° higher than the set humidity, the fan starts

working; the compressor starts working after 3 seconds.

When environmental humidity is -3° lower than the set humidity, the compressor

stops working and fan stops working after 30 seconds’ delay.

Both fan speed and humidity can be adjusted under auto mode.

Continuously Drying Mode: In this mode, the machine will continue to run in high

fan speed; the compressor keeps working without control due to the humidity.

Fan speed is adjustable but humidity is not adjustable

Sleep Mode: Touch the sleep button, the button lights up and start the sleep

function; the default humidity is 50%. After no operation for 10 seconds, all

indicators turn dark gradually and the fan speed is automatically switched from high

to low. Press any button to wake up the indicator. Touch sleep button again to exit

the sleep mode.

When environmental humidity is equal to or greater than 57% ,the compressor

stops working and the fan shut down after 30 seconds’ delay.

When environmental humidity is equal to or less than 63%,the fan starts working and

compressor starts working after 3 seconds.

Fan speed and humidity cannot be adjusted under sleeping mode.

In sleeping mode, when the water tank is full, the machine will not alarm but the

trouble code will display darkly as a reminder to empty water tank.

20

Timer button

Press the timer button to set the 00-24 hour timing function. Display panel ”88

"flashes and will show timer hour. To increase the time by 1 hour touch hum

button” The value will be displayed on the display screen.

In the running state, use the timer function to turn off the machine regularly.

In the standby state, use the timer function to turn on the machine regularly.

Set the time to "00" to cancel the timing function.

Fan Speed

High speed - low speed cycle. Touch the button once to switch and then the

corresponding indicator lights up.

Child lock

Press for more than 3 seconds to turn on/off the child lock function.

Water Tank Full Alarm

Tank Indicator

When the tank is full the water tank indicator turns red and the unit buzzes 5 times.

Clear the alarm

When the buzzer is on, touch any button to stop it. The compressor and fan will

shut down and all the functions will freeze until the tank is emptied and back in

right position.

Table of contents

Popular Dehumidifier manuals by other brands

Argo

Argo PLATINUM EVO 21 Service manual

P&N Technology

P&N Technology PN-D3024D instruction manual

Mitsubishi Electric

Mitsubishi Electric MJ-E16VX-A1 instruction manual

Heylo

Heylo LGR 6000 COM user manual

NEW WIDETECH

NEW WIDETECH ausclimate WDH-070EBP user manual

Ingersoll-Rand

Ingersoll-Rand D1300IN-A Operator's manual