TCT Mobile B10C/OT-565 Technical manual

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

1/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

Repair Document

B10C/OT-565

Note: this manual is non-contractual and TCT Mobile phone can modify without prior notice the

characteristics of described equipments.

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

2/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

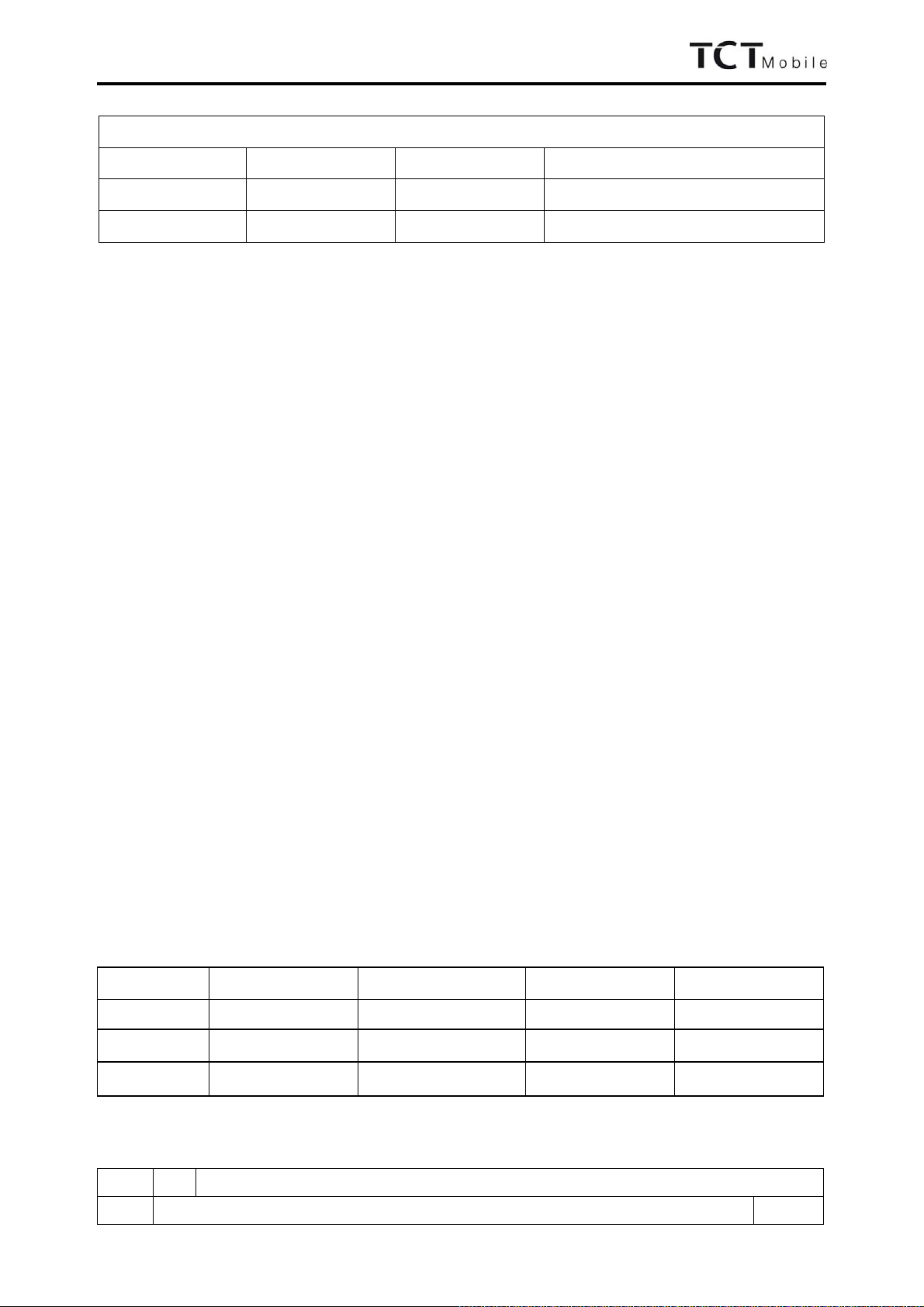

HISTORY

Date Version Author Comments

2010-6-25 0.5 Rao Lihong The first create

2010-07-07 1.0 Frank Tu Release

Function Name Date Signature

Written by CPM Frank

Verified by

Approved by

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

3/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

CONTENT

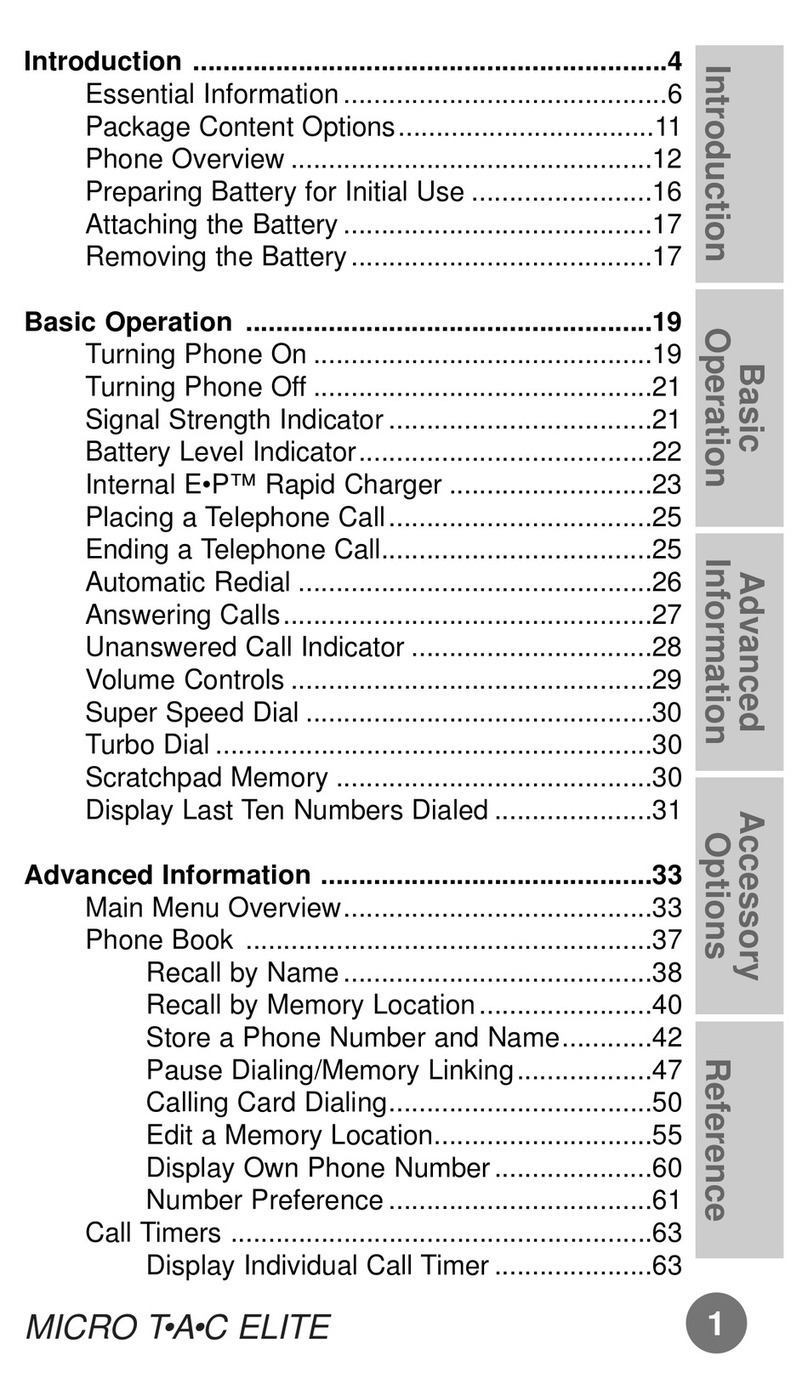

1. LEVEL 2 REPAIR PROCESS ......................................................................................4

2. VISUAL INSPECTION AND WARRANTY CHECK....................................................5

2.1 Warranty Check.........................................................................................................5

2.2 Pretest.......................................................................................................................5

3. CLONING TOOL.........................................................................................................8

4. SAV TEST TOOL (STT)...............................................................................................8

5. SOFTWARE UPGRADING..........................................................................................8

6. LOCAL DOWNLOADING...........................................................................................9

7.

DISASSEMBLY and REASSEMBLY of OT-565

..........................................................11

7.1 ESD Safety..............................................................................................................11

7.2 Disassembly tools ....................................................................................................11

7.3 Process....................................................................................................................11

7.4 Reassembly Process .................................................................................................16

7.5 Disassembly process evaluation.................................................................................17

7.6 Disassembly Complete .............................................................................................19

8. LEVEL 2 REPAIR......................................................................................................20

9. BOARD EXCHANGE.................................................................................................20

10. OTHER COMPONENT EXCHANGE.......................................................................20

11. STICKERS ...............................................................................................................21

12. FINAL TEST ............................................................................................................22

12.1 Function Test.........................................................................................................22

12.2 Measurement .........................................................................................................22

APPENDIX 1 Tools and Equipments for L2 Repair Center.............................................25

APPENDIX 2 Packaging Requirements...........................................................................26

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

4/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

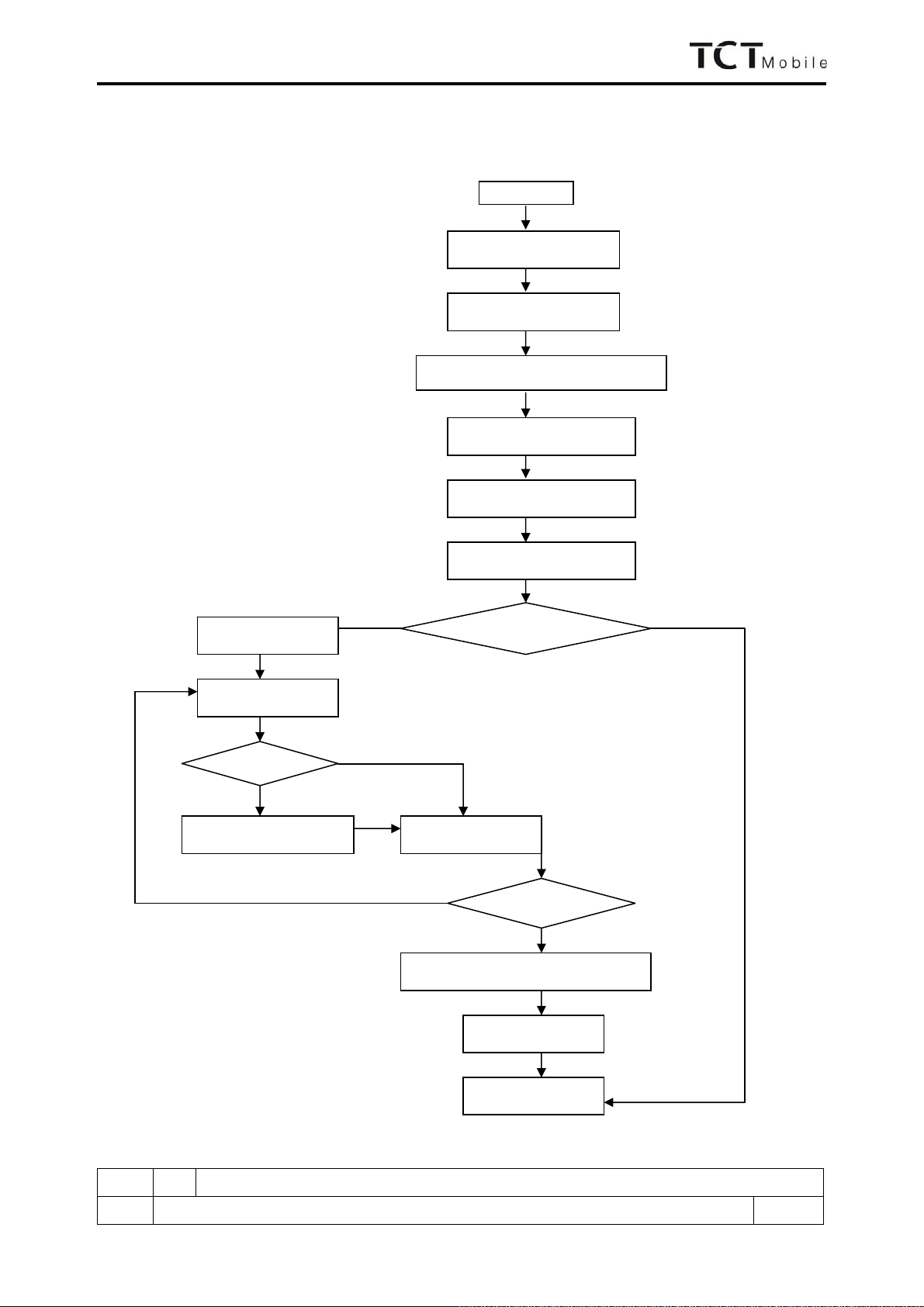

1. LEVEL 2 REPAIR PROCESS

R

ecord

in BIG

Function Test

Restore the user information

SW Upgrading

Data

Cloning

STT

Visual inspection

Start

Pretest & Faulty confirmation

NG

Disassembly

NG

L2 repair

Reassembly

Board replacing

Retest Ok

NG

Retest

The End

Warranty check

Ok

OK

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

5/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

2. VISUAL INSPECTION AND WARRANTY CHECK

2.1 Warranty Check

Warranty confirmation of L1:

¾IMEI sticker check:

1) The IMEI number MUST be the same with the one on the IMEI sticker. If not, it’s out of warranty

policy

2) IMEI label should NOT be removed/ scratch or unreadable/ not approved or provided by Alcatel.

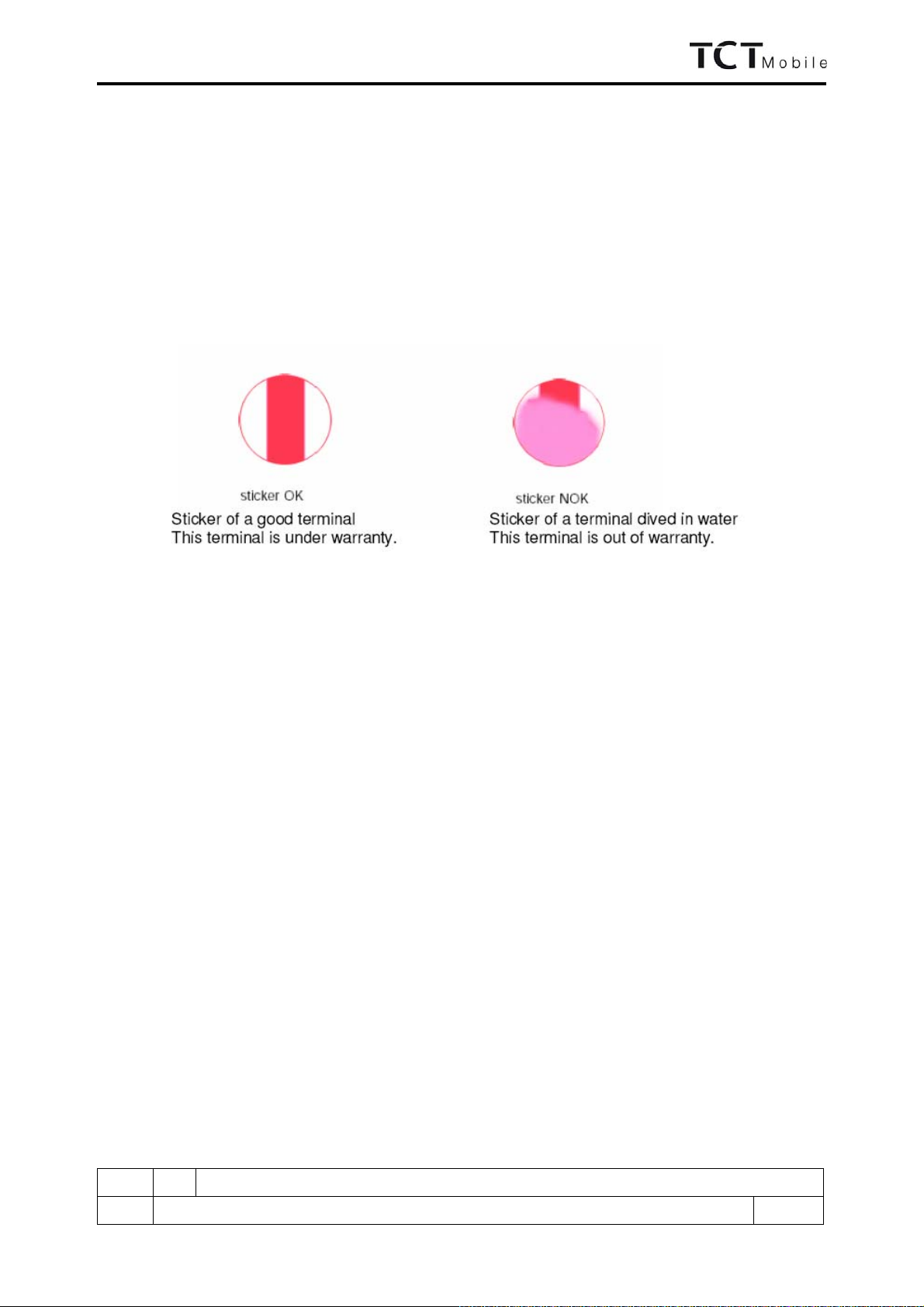

¾Humidity sticker: Liquid detection on humidity sticker

¾Visual mechanical check;

1) Corrosion: corrosion on the USB connectors, SIM connectors, and other metal surfaces

2) Holes (diam > 1mm): Holes on any surface, including the front casing, furnished frame, battery cover,

LCD Lens, keypad…

3) Big bumps (diam > 1mm): Bumps on any surface, including the front casing, furnished frame, battery

cover, LCD Lens, keypad…

4) Long scratch (length > 3mm): Scratches on any surface, including the front casing, furnished frame,

battery cover, LCD Lens, keypad…

5) Distortion: Bend, twisted or crushed on the h/s, cover/casing or connectors…

6) Broken: LCD broken, casing/cover broken…

7) Fallen off: Keypad tear off, LCD lens, connectors fallen off …

8) Gap: External physical damage relating to abnormal use, like front case and frame opened

9) Others:

-Damage caused by disassembly like wrong part assembly, lost of components

-Use in abnormal environment like too high temperature with plastic melts

2.2 Pretest

¾Power on the cell phone.

¾Insert a battery, plug a charger on product, and check the icon on main display or sub display.

¾If the cell phone asks to input NCK code, which means it’s SIM locked, and can only be worked with

dedicated SIM card. Use the correct SIM card.

¾Enter the super code to unlock the phone if necessary.

¾If power on OK, test step by step with the auto test code. Press *#2886# on the idle screen to start auto test.

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

6/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

a) Check Traceability Information:

Screen display the traceability information. If they are all right, press Pass to continue.

b) LCD display test:

The patterns are displayed on the main screen from "COLOR" pattern, "BLACK" pattern,

"CHECKER" pattern, "GREY CHART" pattern, "WHITE" pattern, "MENU" pattern, "MacBeth"

pattern. If they are all right, press Pass to continue.

c) Sub-LCD display test:

Display “Hello my friend!” in the sub-LCD.

Display confirm information in main LCD.

If they are all right, press Pass to continue.

d) Main LCD backlight test:

The backlight will be auto on and off, if it works all right, press Pass to continue.

e) Keypad backlight test:

Keypad backlights begin flashing, if it works all right, press Pass to continue.

f) Keypad test:

The operator presses all keys. If all keys are pressed, go to next text item automatically. Timeout is

fixed to 40s.

g) Vibrator test:

Vibrator begins to work, if it works all right, press Pass to continue.

h) Camera Test:

Display the Camera Screen then go to result confirm screen. If it works all right, press Pass to

continue.

i) Camera Zoom Test:

Display Camera zoom screen first. If it works all right, press Pass to continue.

j) SIM card test:

Display “testing…” during the wait of the status.

Display “Insert SD card” if no SD card inserted

Timeout is fixed to 15s.

If pass, screen display “OK” for 1s and go to the next test item automatically.

k) USB charger test:

Display “testing…” during the wait of the status.

Display “Insert USB charger” if no USB charger inserted

Timeout is fixed to 15s.

If pass, screen display “OK” for 1s and go to the next test item automatically.

l) SD card test:

Display “testing…” during the wait of the status.

Display “Insert SD card” if no SD card inserted

Timeout is fixed to 15s.

If pass, screen display “OK” for 1s and go to the next test item automatically.

m) Bluetooth test:

Display “searching…” during the wait of the status.

Timeout is fixed to 20s.

If pass, screen display “OK”(include BT device info and address ) for 1s and go to the next test item

automatically.

n) Audio connector test:

Display “testing…” during the wait of the status.

Display “Insert audio connector”, if no audio connector inserted.

Timeout is fixed to 15s.

If pass, screen display “OK” for 1s and go to the next test item automatically.

o) Headset left test:

The operator does a small acoustic test, he speaks in the headset microphone and estimates the audio

quality when he ears the signal in headset left earphone. If it works all right, press Pass to continue.

p) Headset right test:

The operator does a small acoustic test, he speaks in the headset microphone and estimates the audio

quality when he ears the signal in headset right earphone. If it works all right, press Pass to continue.

q) Headset test:

The operator does a small acoustic test, he speaks in the headset microphone and estimates the audio

quality when he ears the signal in headset earphone. If it works all right, press Pass to continue.

r) FM play test:

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

7/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

The default frequency is 103.6MHz (1036)

Press "Enter" key to listen the radio.

The input frequency number should be 4 digits.

Delete the digit by pressing "LEFT" key.

The range of frequency is from 0875 to 1080.

Set next frequency by pressing "DOWN" key.

If it works all right, press Pass to continue.

s) Headset unplug test:

Display “Remove headset”, if any audio connector connected.

Timeout is fixed to 20s.

If pass, mini display “OK” for 1s and go to the next test item automatically.

t) Melody Test:

Play music with loud speaker. If it works all right, press Pass to continue.

u) Hall Test:

Screen display “Pls. Close Slide” and try to detect whether the slide is closed. Then, handset detector

whether the slide is opened by operator.

If pass, go to the next test item automatically.

Total timeout is fixed to 10s for waiting.

v) Temperature test:

Screen display the handset temperature. If it is regular, press Pass to continue.

w) Test status memorization

Screen display the test status.

¾Make a call.

¾Receive a call.

¾Reproduce the fault which end user complaint.

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

8/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

3. CLONING TOOL (TO be updated)

1) Find cloning tool on MLDC as below detail location:

2) Install the cloning tool in your computer.

3) Follow the user manual on MLDC to upgrade the mobile.

4. SAV TEST TOOL (STT)

1) Find STT on MLDC as below detail location:

2) Install the cloning tool in your computer.

3) Follow the user manual on MLDC to upgrade the mobile.

5. SOFTWARE UPGRADING

SW Upgrade tool is a method to download the SW from the SW upgrade server. Your internet connection is

necessary during the process.

1) Find software Upgrade tool on MLDC as below detail location:

2) Install the cloning tool in your computer.

3) Follow the user manual on MLDC to upgrade the mobile.

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

9/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

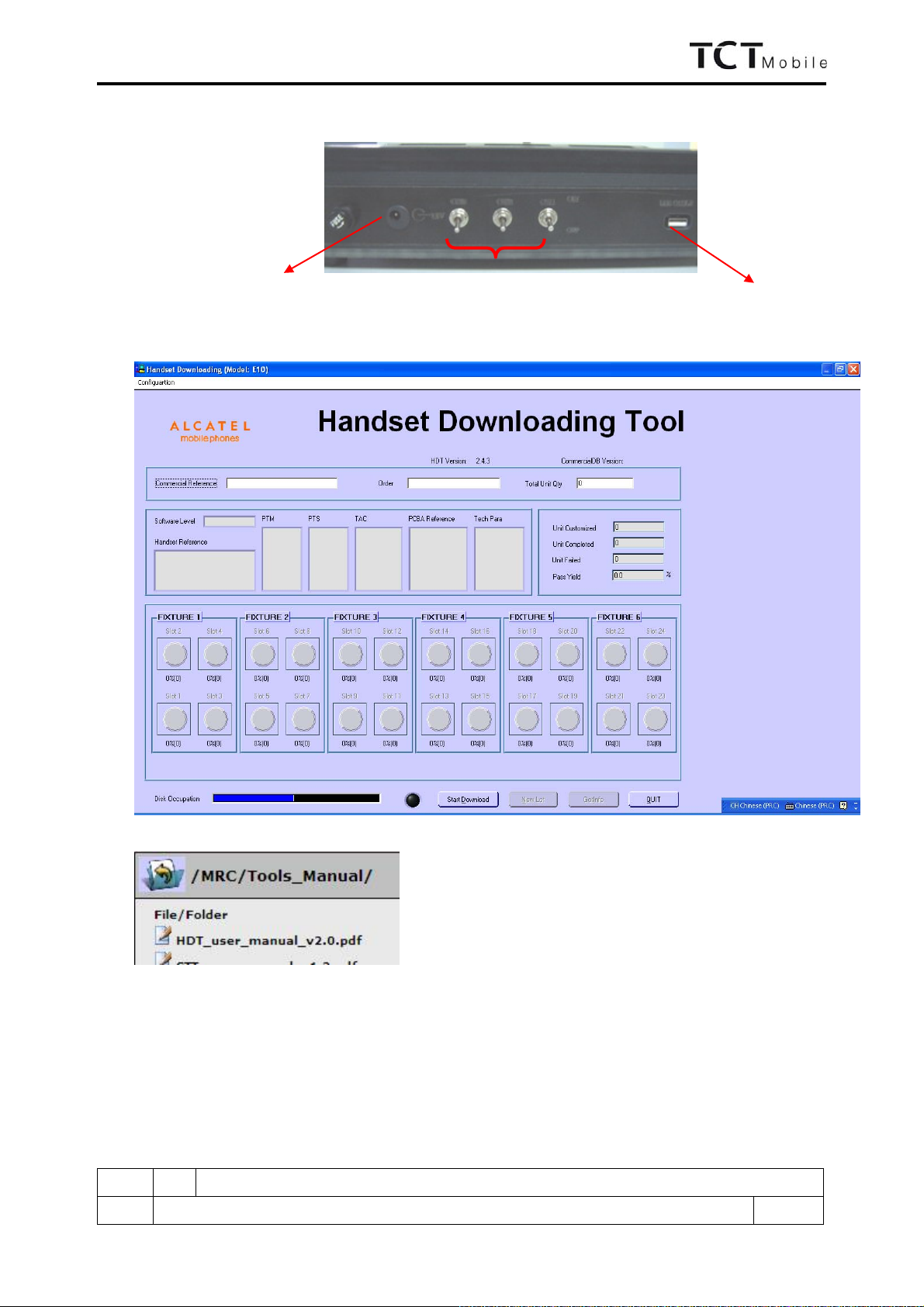

6. LOCAL DOWNLOADING

HDT is a tool for local software

downloading in RSH. There is no need of internet connection in the downloading

progress.

¾

Notice

: from OT-565 product, common MTK bench is used on HDT. This bench supports 3 channels

downloading in one time. The bench does not have a dongle inside, so insert the dongle into your computer

before downloading.

There are 2 kinds of sockets which can match the bench: handset socket for handset downloading, and PCBA socket

for PCBA downloading.

Steps:

1) Download HDT application for Easy from MLDC;

2) Download the SW (main code+perso+latest commercial DB) and install it under the default route;

3) Put the socket on the bench, and make sure they well connected to each other;

Put OT-565 PCBA onto the socket; also make sure they connected well;

+12V switch +12V light, red

+3.8V light, green

+3.8V switch

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

10/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

4) Power supply to the 12V connector; and connect to the computer with USB cable; Turn on the +12V switch,

and +12V light turn red;

5) Create the folder “B10C” under C:\HDTE10\IMEI\Delivery, and put IMEI file on it;

6) Start HDT application by double click “HDT.exe” in the folder of C:/HDTE10/Bin;

7) Detail steps on the user manual which you can find in:

Notice:

1) The bench supports 3-channel downloading, but when you press the red button, at most 2 in one time.

2) Change for handset socket when you need handset downloading; and the socket can be replaced by any other

module when you want to download other MTK product, without changing the bench.

To power supply To computer

Channel switch

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

11/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

7.

DISASSEMBLY and REASSEMBLY of OT-565

7.1 ESD Safety

Please wear static loop or static glove

7.2 Disassembly tools

You may use the following tools during the disassembly and reassembly procedure:

Plastic Wedge Screw driver Tweezers

Soldering iron Hot wind gun Soldering Jig

Hook Knife

Please make reference to APPENDIX 1 and find out the pictures of the tools.

7.3 Process

The steps of disassembly OT-565 are as below.

This module should only be disassembled from bottom to top.

Step 1:

Take off the battery cover, battery and SIM card if there is.

Step 2:

Take off the 6 screws from the furnished frame, take off the commercial label 7 from the battery house,

position as the below picture showed

1

6 4

5

3

2

7

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

12/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

Step3:

Separate the furnished frame and main PBCA.

Step 4:

Take off the main FPC connector 8, separate main PBCA from the furnished keypad casing

Step 5:

Remove keypad from keypad casing

8

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

13/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

Step 6:

Remove left and right cap, take off the two screws below of them

Step 7:

Use knife to remove main LCD lens

Step 8:

Use Plastic Wedge to break the front case and back case then remove the back casing as below picture showed

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

14/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

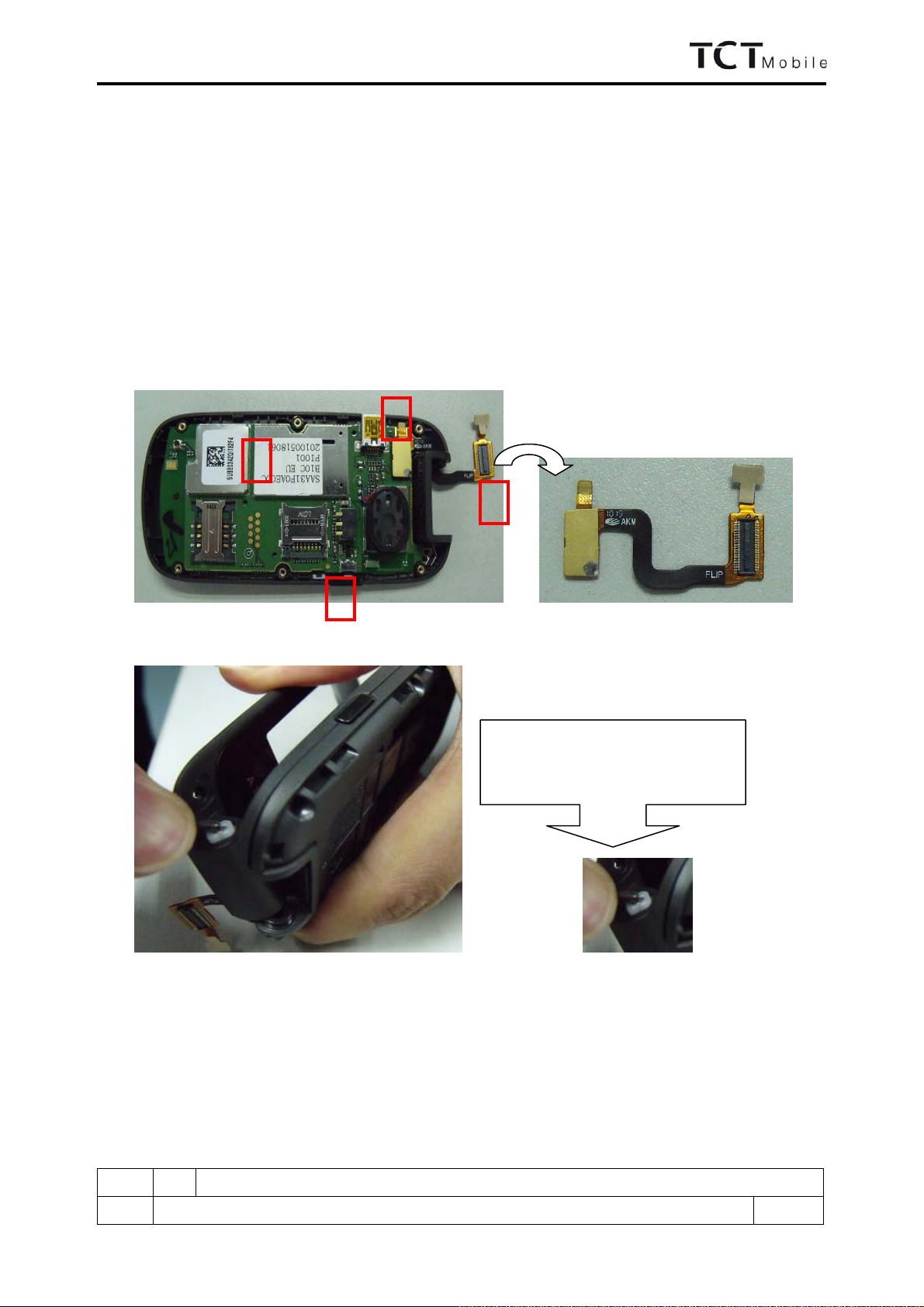

Step 9:

Turn over the flip PBCA, remove the connector 9, and then take off the LCD module and camera module

Step 10:

Use Tweezers push the hinge stopper into the house, then separate the front casing and furnished keypad

casing

Step 11:

Use knife to take off the key film from main PBCA

9

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

15/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

Step 12:

Remove the following components from main PCBA with hot wind gun.

1-speaker 2-battery connector 3-SIM connector 4-RF connector 5-USB connector

6, 7, 8, 9, 10, 11, 12-LED

12-vibrator 13-receiver

Disassembly Notice:

1 32

5 4

6

7 8

10 9

11

13

12

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

16/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

Put all the spare parts on right position (don’t let all spare parts mixed and put on the clean place to

avoid vitiated or stained for each spare part) after disassembly. When taking apart of LCD and key film,

take care not to dirty or damage it.

7.4 Reassembly Process

Please make reference to the disassembly process for assembly reverse an order of the disassembly steps.

Attention:

1) Insert main FPC and assembly main PCBA with furnished keypad casing, lock the main FPC connector to

PCBA connector, and then place the side key, Assembly the furnished frame. Note the orientations of the

main FPC.

2) Assembly the front casing with furnished keypad casing

3) Assembly flip PBCA with the front casing, insert camera connector and main PFC connector to flip PBCA,

then assembly the back casing.

1

2

4

3

Push the hinge stopper into house,

then press front casing

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

17/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

4) Lock the four screws and place the LCD lens and the right and left caps.

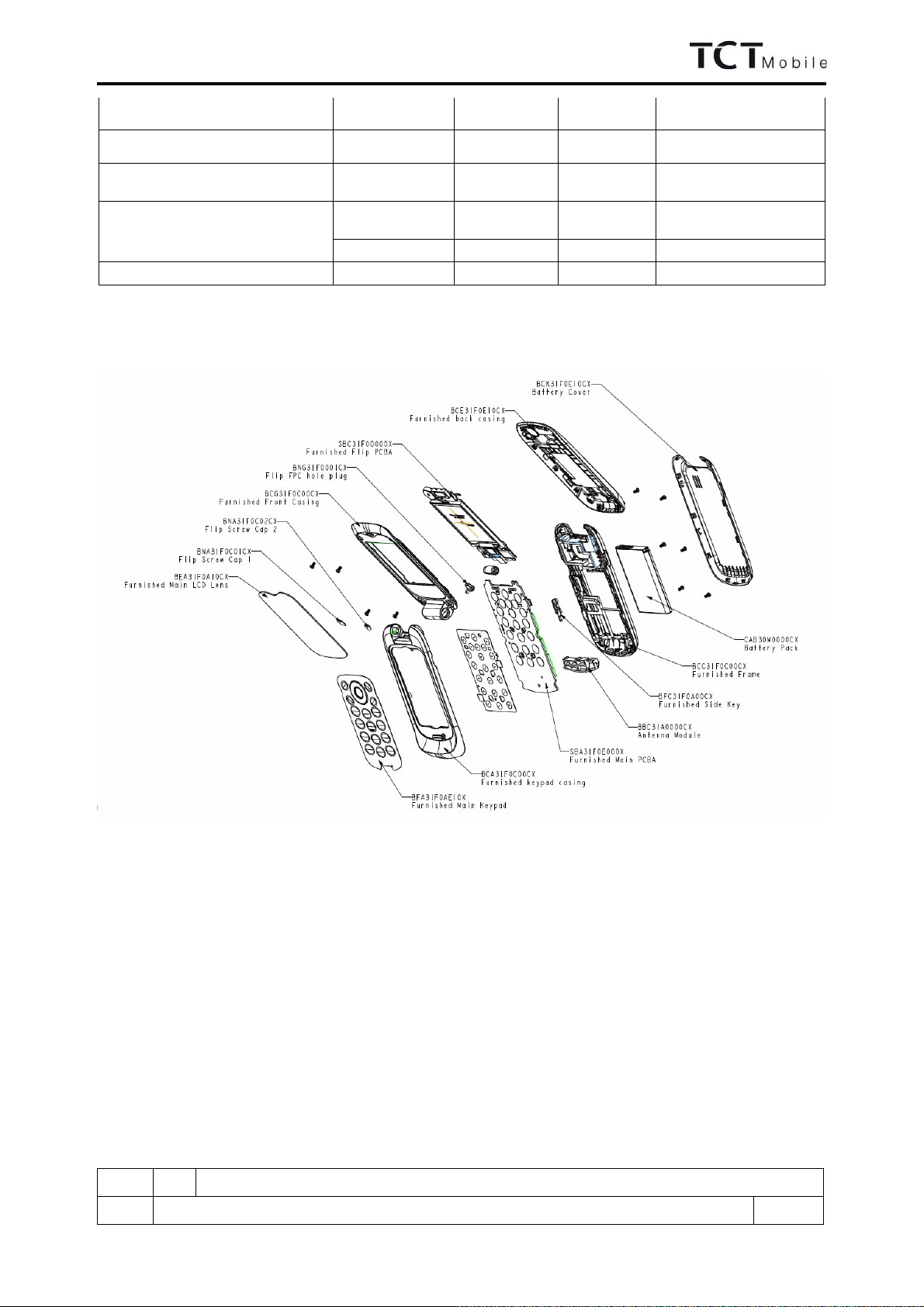

7.5 Disassembly process evaluation

We list the OT-565 parts disassembly time, technique levels and disassembly methods as below, for technique

levels, Class 1 signifies easy to disassembly, Class 2 signifies normal to disassembly and Class 3 signifies hard

to disassembly.

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

18/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

spare part Time for

disassembly Jigs for

disassembly Difficulty

Class Remark

screw 3s screwdriver Class 1

Battery cover & side key 10s Plastic Wedge Class 1

Main PCBA & keypad 2s Class 1

Keypad casing with screws 20s screwdriver Class 1

Keypad sticker 5s Tweezers Class 1

Back casing 10s Plastic Wedge Class 2

Hinge with screws 20s Tweezers Class 1

Top keypad PCBA 1s Class 1

Main LCD module 3s Class 1

Main FPCA 5s Class 1

Receiver 3s Tweezers Class 1

LCD Conductive Foam 1s Tweezers Class 1

Top keypad 1s Tweezers Class 1

panel & front casing 10s Class 2

Main key film 10s Tweezers Class 1

Top key film 5s Tweezers Class 1

camera module Camera jig Class 2

vibrator 2s Soldering jig Class 1

speaker 2s Soldering jig Class 1

microphone 3s hot wind gun Class 2 easy to damage after

soldering for 2 or 3 times

LED 3s hot wind gun Class 2

camera socket 120s hot wind gun Class 3 easy to damage

USB connector 100s hot wind gun Class 2 easy to damage

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

19/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

battery connector 80s hot wind gun Class 3 Plastic parts are easily

damaged during heating

SIM connector 70s hot wind gun Class 3 Plastic parts are easily

damaged during heating

RF connector 15s hot wind gun Class 2

T-flash card connector 80s hot wind gun Class 3 Plastic parts are easily

damaged during heating

7.6 Disassembly Complete

B10C/OT-565(A) Repair Document

ED 1.0 B10C Level 2 Repair Document

20/26

All right reserved. Passing on and copying of this document, use and communication are not permitted

without authorization

8. LEVEL 2 REPAIR

This chapter describes the LEVEL 2 repairs that can be done without any diagnostic equipment.

Problem description Action And Solution

Charging Bad

or

No Charge

1.Check voltage of the battery: if 0V, charge some

minutes and check the charge indicator;

2.Check the battery contact, change the battery

connector if broken;

3.Check the charge plug on B cover, change it if

necessary;

Switch on with battery

power Can ‘t Switch on 1.Check voltage of the battery;

2.Check the battery contact, change the battery

connector if broken;

3.Check the keypad

4.Check BTB connector socket pin

Main display and Sub

display Missing line or column; no display;

bad or no LCD backlight Check Connection flex (FPC cable),change it if

necessary;

Replace display module if necessary;

Keyboard Keyboard backlight or keyboard

function Check keypad film or keypad PCB, change it if

necessary

Vibrator The vibrator does not work Check the contact on the PCBA (dirty or oxidized),

replace the vibrator if necessary;

Network Problem No emission or No reception Check the antenna contactor on the B cover;

Check the contact on the PCBA (dirty or oxidized);

TF card No communication between the

phone and the TF card Check the TF connector on the PCBA;

Camera Camera doesn't work Check camera module

Check also camera FPC broken or not

Audio Bad or no emission (TX audio from

mobile);

Bad or no reception (RX audio on

mobile);

Hands-free problem;

Key beep and melody problem

Check microphone, replace it if necessary;

Check the contact on the PCBA (dirty or oxidized)

Check loud speaker, replace it if necessary;

Check the contact on the PCBA (dirty or oxidized)

In case the LEVEL 2 repairs can’t solve the problem, or if the board is damaged, exchange the board.

9. BOARD EXCHANGE

In case that LEVEL 2 repair does not solve the failure, it is mandatory to change the board and apply the following

process:

1) Collect the fault PCBA board (without accessories LCD, vibrator, and camera), with microphone, and key

metal dome.

2) Get a new PCBA from swap stock. Reuse those accessories to assemble the mobile.

3) Fill in the fault sticker with IMEI number, the fault code, the short code, the Hardware Technical Level, and the

software version.

4) Send the fault PCBA with fault sticker back to L3 repair center with the suggested packaging method, the detail

packaging method please see solution 1 of APPENDIX 2.

10. OTHER COMPONENT EXCHANGE

The other components exchange like LCD module, keypad, vibrator, receiver, speaker, microphone, camera, FPC

connection, audio/camera connector and related mechanical components, please follow the detail steps from

paragraph 7(Disassembly and Reassembly process), but need to be very careful to handle the components with

related special tool or jig (especially replacing new components) and better to handle it with plastic tools (plastic

Table of contents

Other TCT Mobile Telephone manuals