TCT Mobile Medoc ONE TOUCH 985 User manual

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 1/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

L2 Repair Document

Medoc/ONE TOUCH 985/985(A/N/S)

Note: this manual is non-contractual and TCT can modify it without prior notice on the

characteristics of described equipments.

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 2/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

1.0 2011-1-03 Draft creation Huangzhen Huahan Chen Weibo

Rev. Date Modification description Prepared By Checked By Approved By

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 4/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

1 Level2 repair process

Reassembly

Record in BIG

End

OK

Retest

OK

OK

Start

Visual Inspection

Warranty Check

Pretest & Failure confirm

SW Upgrade

Disassembly

L2 Repair

Retest

Function test

PCBA Replace

NG

NG

NG

Restore User Information

Back up user data

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 5/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

2 Warranty Check and Visual Inspection

Warranty confirmation of L1:

1) IMEI sticker check:

a) The IMEI number MUST be the same with the one on the IMEI sticker. If not, it’s out of warranty

policy

b) IMEI label should not be

Removed

Scratched

Unreadable

Un-approved or un-provided by Alcatel.

2) Humidity sticker: Liquid detection on humidity sticker.

Visual mechanical check:

1) Corrosion

Corrosion on the USB connector, SIM connector, and other metal surfaces

。

2) Hole (diameter > 1mm)

Holes on any surface, including the front casing, furnished frame, battery cover, touch Lens,

keypad…

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 6/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

3) Bump

Bumps (diameter > 1mm) on any surface, including front casing, decorate frame, battery

cover, touch Lens, keypad, etc.

4) Scratch

Scratches (length > 3mm) on any surface, including the front casing, decorate frame, battery

cover, touch Lens, keypad, etc.

5) Distortion

Bend, twisted or crushed on the h/s, cover/casing or connectors, etc.

6) Broken

Touch broken, casing/cover broken, etc.

7) Dropped

Keypad tear off, touch lens, connectors dropped, etc.

8) Gap

External physical damage relating to abnormal use, like front case and frame opened

9) Others

Damage caused by disassembly ,wrong part assembly, loss of components

Use in abnormal environment like high temperature causing plastic melts

Pretest

1) Check that the SIM card is set correctly.

2) Insert the battery.

3) Power on the cell phone.

4) If the cell phone can not power on, visually check the condition of the battery connector.

Replace it if necessary.

5) If the cell phone asks to input NCK code, this means it is SIM locked and can only be worked

with dedicated SIM card. Use the correct SIM card.

6) Enter the phone code if necessary.

7) After the phone power on, test step by step with the auto test code:

Press *#2886# in dial screen and select “Start” to begin the testing. Then you will see the

interface displaying the version. Press pass to continue

If one of the testing failed, it will retest from the first one

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 7/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

TRACABILITY Test

i. You will see the CU_reference, BT address and WIFI address…

ii. Press “Pass” to continue.

LCD MIRE/BLACK/GREYCHART/WHITE Test

i. You will see the LCD color changes if it functions well

ii. Press “Pass” to continue.

KEYPAD Test.

i. Press the key displayed on the screen. The key on the screen will disappear you press

it if it functions well

ii. Press “Pass” to continue.

BACKLIGHT Level Test.

i. You can the screen backlight will flashing.

ii. Press “Pass” to continue.

VIBRATOR Test

i. You can feel the phone’s vibrating if it functions well.

ii. Press “Pass” to continue.

CAMERA IMG Test

i. Scene will be shown on the screen.

ii. Press “Pass” to continue.

CAMERA IMG FRONT Test

i. Scene from front camera will be shown on the screen.

ii. Press “Pass” to continue.

Melody Test.

i. You can hear a melody if it functions well

ii. Press “Pass” to continue.

HEADSET Test.

i. Insert handset and the phone will detect it if it functions well

ii. Press “Pass” to continue.

USB Test

i. Insert the USB cable and the phone will detect it if it functions well

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 8/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

ii. Press “Pass” to continue.

GSENSOR Test

i. put the handset face up and towards up, then to the Left, Right, Up and Down

ii. Press “Pass” to continue

COMPASS Test

i. If it’s OK, press pass to continue

ALS/PS Test

i. Put your thumb on the proximity sensor then remove

ii. Press “Pass” to continue

SIM Test

i. Insert the SIM card and the phone will detect it if it functions well

ii. Press “Pass” to continue

Memory card Test

i. Insert the Memory card and the phone will detect it if it functions well

ii. Press “Pass” to continue

Battery temp Test

i. Battery temperature will be displayed on the screen

ii. Press “Pass” to continue

BT Test

i. The phone will running the BT and show the BT address on screen

ii. Press “Pass” to continue

WIFI Test

i. The phone will running the WIFI and search available network

ii. Press “Pass” to continue

GPS Test

i. The phone will running the GPS and search satellite

ii. Press “Pass” to continue

CALL Test

i. The phone will auto dial emergency phone

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 14/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

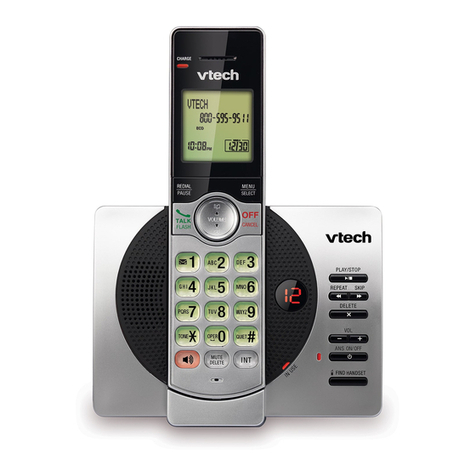

4 Disassembly and assembly ONE TOUCH 536

4.1 ESD Safety

Please wear static loop or static glove

4.2 Disassembly tool

You may use the following tools during the disassembly and reassembly procedure:

4.3Disassembly process

The steps of disassembly ONE TOUCH 985 are as below.

This module should only be disassembled from bottom to top

.

Step : Take off the 6 screws from the furnished frame by screw driver.

Plastic Flake

Tweezers

Hot wind gun

Screwdriver

Soldering iron

Camera Jig

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 15/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

Step 2: Separate the furnished frame from furnished front casing

Step 3

:

Remove Touch Lens and LCD Module FPC connector by Plastic Flake

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 16/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

Step 4: Separate the Main PCBA from Furnished front casing

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 17/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

.

Step 5

:

Extract the camera by camera jig.

Step 6

:

Please use hot wind gun heating around the edge of the touch lens, then separate the touch

lens from furnished front casing. (Temperature: 00

±10℃, Air Level:3, Height:5-10mm, Time:30s)

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 18/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

Step 8: If you find the top of the touch screen is too viscous when you separate the touch screen

from furnished front casing by plastic flake, please first prop the touch screen up by plastic pen and

pay attention the place of TP FPC.

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 19/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

Step 9

:

Separate the LCD Module from Touch lens by Plastic Flake.

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 20/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

Step 0: Remove the following components from main PCBA with hot wind gun.

1-

Touch panel Module connector 2-battery connector 3-SIM connector 4- F connector 5-USB

connector 6-T flash connector 7-camera connector 8-LCD module connector 9-audior jack 10-

volume side key FPC 11- Power side key FPC 12-Microphone 13-Camera key FPC

1

3

2

5

4

6

8

10

7

9

12

13

11

4

12

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 21/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

Disassembly Notice:

Put all the spare parts on right position (don’t let all spare parts mixed and put on the clean place to

avoid vitiated or stained for each spare part) after disassembly. When taking apart of LCD, take care

not to dirty or damage it.

4.4 Reassembly Process

Please make reference to the disassembly process for assembly reverse an order of the disassembly

steps.

Attention: Insert main FPC and assembly main PCBA with furnished keypad casing, lock the main FPC

connector to PCBA connector, and then place the side key, Assembly the furnished frame. Note the

orientations of the main FPC.

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 22/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

4.5Disassembly process evaluation

We list the ONE TOUCH 985 parts disassembly time, technique levels and disassembly methods as below,

for technique levels, Class 1 signifies easy to disassembly, Class 2 signifies normal to disassembly and

Class 3 signifies hard to disassembly.

spare part Time

for

disassembl

y

Jigs for

disassembly

Difficu

lty Class

Remark

battery cover 3s Plastic Flake Class 1

Furnished casing with

screws

20 screwdriver Class 1

PCBA 20s Plastic Flake Class 1

Volume key 5S Tweezers Class 1

Power key 5S Tweezers Class 1

Antenna Module 20S Tweezers Class 1

Speaker 10s Soldering iron Class 1

Camera module 10s Camera jig Class 1

volume key FPC 15s Hot wind gun

screwdriver

Class 2

Power key FPC 15s Hot wind gun

screwdriver

Class 2

Receiver 10s Tweezers Class 1

Receiver mylar 10s Tweezers Class 1

PS rubber 5s Tweezers Class 1

Vibrator 5s Tweezers Class 1

LCD Module 20s Plastic Flake Class 2

LCD connector tape 20s Tweezers Class 2

TP FPC tape 20s Tweezers Class 2

Be careful for

main PCBA pad

and LCD FPC

damage

BTB connector socket

60s Hot wind gun

Tweezers

Class3

The connector is

easy to be

damaged

RF swithch

60s Hot wind gun

Tweezers

Class3

The connector is

easy to be

damaged

USB connector

60s Hot wind gun

Tweezers

Class3

The connector is

easy to be

damaged

2 in 1SIM card connector

120s Hot wind gun

Tweezers

Class 3

The connector

is easy to be

damaged

audio jack 60s Hot wind gun

Tweezers

Class3

The connector is

easy to be

damaged

flash card connector 120s Hot wind gun

Tweezers

Class 3

The connector

is easy to be

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 23/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

damaged

Battery connector 40s Hot wind gun

Tweezers

Class3

The connector

is easy to be

damaged

Microphone 40s Hot wind gun

Tweezers

Class3

LED 60s Soldering iron

Tweezers

Class3

Keypad film 20s Tweezers Class 2

4.6Disassembly Complete

5 Level 2 repair

This chapter describes the LEVEL 2 repair that can be done without any diagnostic equipment.

Problem description Action And Solution

Charging Bad

or

No Charge

1.Check voltage of the battery: if 0V,

charge some minutes and check the

charge indicator;

2.Check the battery contact, change the

battery connector if broken;

3.Check the charge plug on B cover,

change it if necessary;

Switch on with

battery power

Can ‘t Switch on 1.Check voltage of the battery;

2.Check the battery contact, change the

battery connector if broken;

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 24/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

3.Check the power on key;

4.Check BTB connector socket pin

Main display Missing line or column; no

display; bad or no LCD

backlight

Check Connection flex (FPC

cable),change it if necessary;

Replace display module if necessary;

Vibrator The vibrator does not work Check the contact on the PCBA (dirty or

oxidized), replace the vibrator if

necessary;

Network Problem No emission or No reception

Check the antenna contactor on the B

cover;

Check the contact on the PCBA (dirty or

oxidized);

TF card No communication between

the phone and the TF card

Check the TF connector on the PCBA;

Camera Camera doesn't work Check camera module

Check also camera socket broken or

not

Audio Bad or no emission (TX

audio from mobile);

Bad or no reception (RX

audio on mobile);

Hands-free problem;

Key beep and melody

problem

Check microphone, replace it if

necessary;

Check the contact on the PCBA (dirty or

oxidized)

Check loud speaker, replace it if

necessary;

Check the contact on the PCBA (dirty or

oxidized)

In case the LEVEL 2 repair can’t solve the problem, or the PCBA is damaged, exchange the PCBA.

6 PCBA exchange

If Level 2 repair does not solve the failure, it is mandatory to change the PCBA and follow the process as

below.

1) Collect the PCBA (without accessories, LCD and camera), with microphone and vibrator.

2) Get a new PCBA from the swap stock. Reuse those accessories to assemble the mobile.

3) Fill in the record sticker with IMEI number, fault code, short code, Hardware Technical Level and

software version.

4) Send the NG PCBA with record sticker back to L3 repair center with the recommended packaging

method,

Note: packaging method please refer item “12. Packaging requirement”.

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 25/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

7 Other component exchange

The other components exchange such as

1) LCD module

2) Vibrator

3) Receiver

4) Speaker

5) Microphone

6) Camera

7) FPC connection

8) Audio connector

9) Camera connector

10) Other related mechanical components

Please follow the detail steps 4.3 (Disassembly and assembly process).

But need to be very careful to handle the components with related special tool or jig (especially replacing

new components)

It is better to handle it with plastic tools (plastic tweezers and wedge etc.).

Besides operator must wear anti-static gloves, fingertips or wear static loop during the whole process of

components exchange.

8 Final test

8.1 Function Test

During the function test, the following items must be checked and validated.

1) Cosmetic aspect of the handset,

2) The Software Technical sticker state on the Board

3) Switch on the handset

4) Default welcome message

5)

Press *#2886# on the idle screen to start the auto test

ByNCKTeam

L2 Repair Document

Rev. Page

1.0 ONE TOUCH 985 Level 2 Repair Document 26/31

All rights reserved. Transfer, copy, use and communication of this file is prohibited without authorization.

8.2 Measurement

Measurements Channel Power

level

Tol.min Tol.max

Condition

GSM

Connection Mobile 63* 9 None None Radiated meas

Call base from mobile 5* 9 None None Radiated meas

Power level measurements 5* 9 22 dBm 28 dBm

Radiated meas

Power level measurement 5* 5 31 dBm 35 dBm

Radiated meas

Peak Phase error

measurements 5* 5 0° 20° Radiated meas

RMS Phase error

measurements 5* 5 0° 5° Radiated meas

Frequency error

measurements 5* 5 -90 Hz +90 Hz Radiated meas

RX Level (BS power level : -

60dBm) 5* 5 45 55 Radiated meas

Power level measurements 120* 5 31 dBm 35 dBm

Radiated meas

Peak Phase error

measurements 120* 5 0° 20° Radiated meas

RMS Phase error

measurements 120* 5 0° 5° Radiated meas

Frequency error

measurements 120* 5 -90 Hz +90 Hz Radiated meas

RX Level (BS power level : -

60dBm) 120* 5 45 55 Radiated meas

This manual suits for next models

3

Table of contents

Other TCT Mobile Telephone manuals