TDI TURBOTWIN T100-MS User manual

AN08-481 From Tech Development

6800 Poe Ave. •Dayton OH 45414

Tel: (937) 898-9600 •Fax: (937) 898-8431

Website: www.tdi-turbotwin.com

Publication: T1-795

Issued: August 1, 2008

INSTALLATION AND OPERATING

MANUAL

MODEL: T100-MS

TURBOTWIN Gas Turbine Engine

Air Starter

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T1-795

Issued: August 1, 2008 Page 1

TABLE OFCONTENTS

SECTION SUBJECT PAGE

1.0 GENERAL INFORMATION ……………………….2

1.1 DESCRIPTION & NEW FEATURES……………..2

1.2 BASIC OPERATION………………………………..2

1.3 PRODUCT IDENTIFICATION……………………. 3

1.4 MOTOR PERFORMANCE & OUTPUT…………..3

2.0 INSTALLING THE MOTOR……………………….4

2.1 ORIENTATION & LUBRICATION…………………5

2.2 SUPPLY & EXHAUST LINE INSTALLATION……6

2.3 MOTOR CONTROLS………………………………7

2.4 INLET PRESSURE CHECK PORT……………….7

2.5 MATCHING MOTOR OUTPUT TO LOAD……….7

3.0 MOTOR OPERATION…………………………….. 7

4.0 PREVENTIVE MAINTENANCE………………….. 8

5.0 TROUBLE SHOOTING GUIDE…………………...9

6.0 TURBOTWIN WARRANTY....................................10

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T1-795

Issued: August 1, 2008

Page 2

1.0 GENERAL INFORMATION

Instructionsfor installation, operationandmaintenance

of TDI TURBOTWIN™Model T100-MS Air Starter.

Theseare suitableforuse on a varietyofSolarTurbine

Engine applications including the Centaur & Taurus.

T100-MS starter motor assemblies are used only in

single starter applications.

Review this manual before installing or operating

T100MS Model Air Starters. Questions? Contact

your Authorized TDI Distributor, OEM or TDI directly.

WARNINGS, CAUTIONS AND NOTES

Certain types of information are highlighted in this

manual for your attention:

WARNINGS: - used where NON-

COMPLIANCE will likely result in injury to

personnel or damage to the equipment.

CAUTIONS: - used where there is possibility

of damage to the equipment.

NOTES/IMPORTANT: - used to point out

special interest information or “optimum” use

scenarios.

1.1 DESCRIPTION & NEW FEATURES

T100-MS air starters are extensively upgraded

versions of previous T100Mmodel. The “S” character

(within in the new model nomenclature) designates the

incorporation of many modifications and new product

features including:

oWet-sump (Splash) Oil Lubrication of

planetary gear set & drive end bearings.

oSealed (Vent-less) Gearbox w/Sight Glass

for easy oil level maintenance.

oHigher (ABEC) Spec Turbine Bearings.

oHigher Spec Double-lip Shaft Seals.

oNitride Treated planetary ring gear.

oHigher precision Dynamically Balanced

Rotors.

oNew Labyrinth-Type Primary Seal.

oProprietary Gearbox Venting System

oBalanced Pressure Venting of aft

seal/bearing

NOTE

THISSTARTER ISTOBE SERVICEDONLY BY AUTHORIZEDTDI

TURBOTWIN™ DISTRIBUTORS, DEALERS, AND REPAIR

STATIONS. DO NOT OPERATE THIS STARTER UNLESS IT IS

PROPERLY ATTACHED TO AN ENGINE.

NOTE

External dimensions of new T100-MS starter motors

are near identical to previous T100-M starter.

However, previous TDI starter models cannot be

economically upgraded to incorporate the many

additional features found in the newer models

oTURBOTWIN Upgrades can be easily installed,

generally without inlet/exhaustpiping changes.

oAll TURBOTWIN motors are designed for

operation on either compressed air or on

natural

oTURBOTWIN materials are compatible with

“sour” natural gas and marine environments.

oTURBOTWIN T100MS starters are ATEX

certified.

oAs with all TURBOTWIN turbine motors, mist or

injection type lubrication of the air/gas supply is

NOT required. (remove external lubricators).

NOTE

Throughout this manual, the term “air” is used to

designate the motor drive medium. Unless other wise

stated, "air" means either compressed air or natural

gas.

1.2 BASIC OPERATION

TURBOTWIN T100-MS air starters is a simple turbine

driven, gear reduced air motors, with the following key

differencesvs. other typesofmotorscommonlyusedin

related applications:

Unlike electric motors, power output and

operating speeds correspond (and vary

widely) depending on the dynamic operating

pressures supplied to the motor inlet and the

load imposed. (see performance data).

Unlikevane-type or rotaryscrew-type (positive

displacement)motors, turbine type air motors,

if unloaded/under loaded will operate at much

higher free-speeds.

Turbinetype motors mustbe properly selected

and regulated to operate efficiently, at a

required loaded speed, rather than over a

wide range of inlet supply pressures.

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T1-795

Issued: August 1, 2008 Page 3

The basic operation of the motor is as follows:

Pressurized air or natural gas is admitted to the motor

via the inlet port. The air expands through the two-

stage turbine, which produces shaftrotation and motor

output.

Upon a successful engine start (or cycle), turn the air

off to the motor immediately. Minimizing the time the

motor is operating, especially unloaded, will maximize

motor life

IMPORTANT

To attain maximum product life, it is important to

properly match the motor inlet supply pressure,

output and motor speed to required load.

Attain (regulate) starter to the lowest possible

supply pressure required to start the engine.

Minimizing starter back pressure will extend

the life of air motor. Back pressure should not

exceed 15 psig.

1.3PRODUCT IDENTIFICATION

The identification nameplate(s) attached to motor

housing should indicate the following information:

Model designation

P/Ns(OEM &/or aftermarket p/ns may be

present)

Serial Number (date of manufacture)

Maximum Operating (Inlet) Supply Pressure

Direction of Rotation

PART NUMBER IDENTIFICATION TABLE

TDI Part Number Solar Part Number

T115-60034-MSL-1-90 1078362-100

T115-60G34-MSL-1-90 1078362-200

NOTE

Direction of Rotation is either left hand (LH) rotation

(CCW)or right hand(RH) rotation (CW)viewed looking

into the output (shaft) end of the motor.

CAUTION

Exceeding the Maximum Operating Pressure rating

shown on starter nameplate may result in damage

to the motor or damage to the driven equipment.

NOTE

Maximum Operating Pressure is indicated on the

nameplate. This can (should) be measured at the

pressure check port below starter inlet port, and

dynamically (while the motor is in operation).

IMPORTANT

Optimum(correct) Maximum OperatingPressure isnot

necessarily the dynamic motor supply pressure

recommended for your application. Starter supply

pressure regulation, byapplication, has beenproven to

maximize the service life and reliability ofthe starter(s)

in most all applications. (See section 1.2)

NOTE

Proof Pressure, if shown on the nameplate, indicates

the maximum static pressure rating at which starter

turbine motor housing(s) will not burst in operation.

1.4STARTER MOTOR OUTPUT AND

PERFORMANCE

Please refer to specific Performance Graphs of the

model being applied which illustrate:

StarterOutput (shaft HP/Torque)over range of

dynamic supply pressures, 0 RPM (stall) to

maximum free speed.

AirConsumption Rates over rangeof dynamic

supply pressures (consumption is constant at

dynamic inlet pressures indicated on

performance charts).

Starter output & operating speed vary

considerably on DIFFERENT drive mediums

(e.g. air vs. methane gas).

Onmethane gas, starterproduces significantly

more HP, at higher speeds, so inlet supply

pressuresmayneed to be reduced (regulated)

to prevent excessive engine cranking speeds

(flame out).

In all cases, indicated performance assumes

exhaust routed to a safe location, through

system & piping that minimizes back

pressure not to exceed 15 psig.

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T1-795

Issued: August 1, 2008

Page 4

2.0 INSTALLING THE MOTOR

TDI T100-MS starters feature a turbine type

air motor that does not require lubrication in

the supply air. This is a separate

consideration from the lubrication of the

starter motor gearbox, a discrete oil sump

which requires oil maintenance (oil fill,

checks & changes).

If a vane-type starter motor is being replaced

by a TDI turbine type starter, TDIrecommends

removal of in-line/mist type lubricators to

minimize their inherent flow restriction to the

starter and eliminate this maintenance item.

CAUTION

All T100-MS/CS motors should be installed with the

inlet either straight down (6o’clock or180 degrees)or

straight up (0 degrees or 12 o’clock). In all cases,

orientation of gearbox sight glass must be just

below the motor/starter centerline, toinsure proper

indication/maintenance of gearbox oil level (see

section 2.1).

Model: T115-MS Performance Curve

15 Nozzles, Natural Gas 9.0:1

0

100

200

300

400

500

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500

Output Speed - RPM

0

30

60

90

120

150112

90

68

45

22

0

POWER

HP KW

TORQUE

Nm LB.FT

408

680

272

544

136

0

90 Psig

60 Psig

150 Psig Inlet Flow

Pressure (Scfm) (Nm3/h)

150 Psig 2307 3921

120 Psig 1886 3206

90 psig 1466 2493

60 Psig 1047 1779

120 Psig

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T1-795

Issued: August 1, 2008 Page 5

2.1 PROPER INSTALLATION, ORIENTATION & OIL LEVEL MAINTNENACE

SOLAR P/N: 1078362-100 SOLAR P/N1078362-200

Motor/Starter Gearbox must be filled w/ (150ML) of Approved Oil Type** & Level Maintained

** Oil Type Recommended: Spec MIL-L-7808H, MIL-L-23699 (or equivalent synthetic grade turbine oil)

OIL FILL PORT

½”-14 NPT

OIL LEVEL

SIGHT GLASS

ORIENTATION

Viton O-ring

seal beneath 2”

NPT inlet flange

Viton O-ring seal

beneath 3”

exhaust adapter

flange

NOTE: PROPER INSTALLATION -

OIL LEVEL SIGHT GLASS

POSITIONED PARALEL TO

GROUNDLINE & BELOW

STARTER/MOTOR CENTERLINE

Starter

Output Shaft

& Mating

Spline

Engine Aux.

Gearbox

Splash-lube

Gearbox

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T1-795

Issued: August 1, 2008

Page 6

NOTE

TDI recommends synthetic grade oil (turbine oil) is

used in the starter gearbox sump. Use of either

improper synthetic or mineral based oils may

compromiseunit service life, manufacturer’s warranty,

and will increase the frequency of maintenance

intervals required.

WARNING

Donot operate this starter unless gearbox has been

filled to the proper oil level and maintained at this

level.

WARNING

Do not operate this starter unless it is properly

connected to an engine or load (see below).

2.2 SUPPLY LINE & EXHAUST LINE

INSTALLATION

WARNING

Be sure to either bleed the pressurized air reservoir

and/or safety the system such as closing all air/gas

supply valves, prior to installing motor or a new

supply line.

T100 TURBOTWIN T100-MS starter motors come

standard with a 2" NPT female pipe thread adapter for

theinlet connection port& various 3”exhaust adapters.

Various flange or thread adapters may be utilized at

these joints. Supplied adapters are sealed to the

motor housing with Viton O-rings (see section 2.1).

Hard piping may be used on supply/exhaust lines. A

section of flexible tubing may also be use/installed at

the starter inlet/outlet, to prevent leaks or wobble out

due to vibration.

The supply line consists of the line from the air/gas

supply source (via a pressure regulator when

necessary) through filters, manual and/or automatic

relay valves, to the starter inlet.

The exhaust line consists of the line from the motor

exhaust to a “safe” location. Turbine exhaust (air) is

typically plumbed away from the engine area.

Both supply & exhaust lines and components should

bedry-fitted for proper alignment/location,priortofinal

assembly.

All pipe threaded joints should be sealed with Loctite

Pipe Thread Sealant (TDI P/N 9-94085) or equivalent,

for leak tight joints prior to final assembly. Be sure to

tighten all joints to proper torque after final assembly.

The installation of the motorusingnatural gasis similar

to the air installation except all fittings, piping, valves

and regulators must be compatible with natural gas.

WARNING

When using natural (or combustible) supply gas

(e.g.methane gas) must be piped to a safe location,

routed and terminated according to industry codes

and local regulations.

NOTE

If the supply line is longer than 40 feet, the line piping

size may need to be increased to 2" diameter, to

minimize dynamic flow losses through piping and

ensure specified output. Similarly, if exhaust piping is

longer than 40 ft. in length, it may be necessary to

increase its diameter from 3” to 4” to minimize motor

exhaust back pressure and insure specified output.

On T115-MS applications, valves or regulators on the

supply side, having a Cv of 40 or higher, are

recommendedfor starter having15 nozzles (T115-MS)

Care must be taken to insure all inlet supply line piping

& components are capable of passing the required air

flow needed to produce specified power levels (motor

output).

See motor performance chart for specific

flow rates.

WARNING

Be sure that any/all piping &/or tubing used, meets

applicable requirements and that no leaks are

present following line installation or thereafter.

CAUTION

Although the light weight of these motors is easily

supported by their mounting flange designs, TDI

recommendsproperly bracing allrigid piping attached

to the motors… to eliminate axial strain on motor &

motormounting flanges. High axialloads (“over-hung

bending”) will greatly reduce motor life.

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T1-795

Issued: August 1, 2008 Page 7

CAUTION

There is often weld slag, grindings, thread shavings,

hardened compounds and other heavy debris in new

packagepiping & at new site installations. Therefore,

at commissioning (before running motors), TDI

recommendsa “blow-down”proceduretopurgemotor

supply lines of all hard debris that may otherwise

damage the motor severely. While T100

TURBOTWIN motors are highly tolerant of

contamination in the air/gas supply, motor life can be

greatlyincreased by usinga coarse meshstrainer. At

sites where dirty supply air/gas is present, use &

maintenance of a #40 mesh Y-strainer, upstream of

the motors, is highly recommended.

NOTE

Expensive moisture abatement (air/gas drying) is not

required, as this has no effect on the motors.

2.3 MOTOR CONTROLS

A preferred motor supply control valve is typically a

pilot-operated type, which can be pneumatically or

electrically actuated. The valve should be located

relatively close to the motor inlet, to prevent motor

over-running at the end of the cycle (especially on

starter applications).

CAUTION

Proper supply pressure “matching” and over-speed

control is highly recommended on all installations of

Models T100MS (See section 2.5)

Do not use supply pressure indications only as a

method to properly set the motors’ supply pressure. A

pressure regulator is required, where dynamic air/gas

motor supply pressure is great enough to exceed the

motor operating pressure (at the inlet port) and/or

where a “default” supply pressure would produce

motor output speeds beyond what is specified for

the application.(Result is over-speed, not

necessarily an indicated over-pressure). Both

over-pressure & over-speed will reduce life of the

motor & wastes supply air/gas (increases

operating costs).

2.4 INLET PRESSURE CHECK PORT

(checking dynamic operating pressures)

A 1/4" NPT port is located on the motor housing, under

the air inlet. This port can be used to check the supply

pressure at the motor when the motor is operating. To

check dynamic pressure, remove the 1/4" NPT pipe

plug and save for later use. Install a pressure gauge to

read at this port. Using Loctite Pipe Thread Sealant or

equivalent, replace ¼” NPTpipe plug whendone. This

pressure monitoring line/gauge may also be

permanently installed. Alternately, a pressure

transducer may be installed at the pressure check port

and electrical lines routed to a digital display at the

operator's station.

2.5 MATCHING MOTOR OUTPUT (SPEED)

TO LOAD

A hand held tachometer should be used to double-

check motor output speeds. Motor supply pressure

should be set at the minimum pressure required to

insure the motor runs the speed/load required by the

application.

It is recommended that all starters be installed with a

discrete supply pressure regulator. Do not use supply

pressure only, (such as the default fuel gas pressure

onthe package) as indicators ofmotor speed &output,

which typically do not account for:

Varyingfuel gas pressures (on variousturbine

engine models)

Varying compressor loads during start-up

Varying site conditions (temperatures, etc…)

Varying turbine engine ramp-up speeds (&

time) required.

NOTE

Starter motor over pressure (even where starter

supply pressure minimally exceeds that needed for

proper ramp-up speeds/times) may result in engine

turning too fast, too quickly… a.k.a. “flame-out.” In

these cases simply reducing starter supply

pressure will generally correct this.

3.0 MOTOR OPERATION

WARNING

Do not operate the TDI TURBOTWIN starter at

dynamic supply pressures greaterthan the pressure

rating on the nameplate. This dynamic pressure is

measured at the motor inlet while the motor is

running.

Static (non-flowing) supply pressure will

always be higher than theoperating (dynamic)

pressure.

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T1-795

Issued: August 1, 2008

Page 8

The maximum pressure limit (proof pressure)

that the TDI TURBOTWIN motor housings may

be subjected to is 600 PSIG (42 BAR).

Where system static pressure may exceedthe

600 PSIG (42 BAR) limit, in addition to

pressure reducing device, it a pressure relief

valveset below 600 PSIG (42 BAR) should be

used.

Where operating supply pressure exceeds

motors’ maximum operating pressure ratings,

or produces outputs above required by the

application, a pressure reducing device

(regulator) must be used.

All appropriate local pressure codes and pressure

limitations on other system components must be

adhered to and supersede the guidelines given in this

manual.

4.0 PREVENTIVE MAINTENANCE

IMPORTANT

All TURBOTWIN T100-MS/CS starter motors use

new oil-sump lubrication of the drive end (gearbox)

which must be properly maintained.

Severe Service ** & Required Field

Maintenance Procedures,to be performed

as preventative maintenance include:

oUtilize only oil types recommended

by the manufacturer (TDI), in the

starter gearbox.

oProperly orient the motors/starters

as described herein, to insure proper

oil levels can be easily maintained in

the starter gearbox (See section 2.1)

MAINTENANCE SCHEDULE

INTERVAL CHECKS MAINTENANCE

2,000

operating

hours (or

quarterly)

Check Oil

Level

Check oil

condition,

change oil if

using oil other

than

recommended

synthetic types

4,000

operating

hours (semi-

annually)

Check Oil

Level

Check oil

condition,

change oil if

using oil other

than

recommended

synthetic types

8,000

operating

hours

(annually)

Check Oil

Level Change Oil

(regardless of

type being used)

** Severe Service:is where motor(s) are cycled

longer than one (1) hour continuously or wherever

motor(s) can/may become unloaded for periods

longer than 30 seconds during cycle.

Repair technicians or un-authorized/un-trained service

organizations, without TDI TurboTech certification,

should not attempt to rebuildnor repair these products.

Proper maintenance, qualified maintenance repair of

your TDI TURBOTWIN starters & motors will assure

continued reliable and superior performance for many

years.

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T1-795

Issued: August 1, 2008 Page 9

5.0 TROUBLESHOOTING CHART

TROUBLE

PROBABLE CAUSE

SOLUTION

A. Valve not fully open.

A. Repair or replace valve.

1. Motor does not run;

small air flow from

exhaust.

B. Nozzle blockage.

B. Remove blockage or obstruction from nozzles.

A. Broken turbine rotor.

A. Replace all damaged parts.

B. Broken gear train.

B. Repair or replace gear train.

2. Motor does not run;

normal air flow from

exhaust.

C. Damaged motor drive.

C. Repair or replace motor drive.

A. Inlet air pressure too low.

A. Increase air pressure in 10 PSIG (0.6 BAR)

increments; DO NOT EXCEED OPERATING LIMIT.

B. Inlet supply piping too small.

B. Supply piping must be a minimum of 1.5" diameter.

C. Pressure regulator orifice too

small.

C. Increase orifice size or replace pressure regulator

D. Inlet supply line valve (ball,

gate, relay, plug) too small.

D. Install larger valve.

E. In line lubricator installed in

supply line.

E. Remove lubricator.

F. Y-Strainer in supply line

clogged.

F. Clean strainer.

G. Excessive back pressure;

exhaust restricted.

G. Clean exhaust piping or increase size to at least the

minimum diameter recommended.

H. Damaged turbine nozzle.

H. Replace turbine nozzle.

J. Wrong rotation motor.

J. Replace with motor or proper rotation.

3. Reduced Motor

output power.

K. Wrong size motor.

K. Check the Application Guide for the correct motor.

A. Motor Inlet air pressure too

high.

A. Decrease air pressure in 10 PSIG (0.6 BAR)

increments.

OR

If there is a manual shut-off valve in the supply line,

partially close it.

OR

Install a restriction orifice in the inlet supply line.

4. Engine cranks too

fast (flameout).

B. Wrong size motor.

B. Check the Application Guide for the correct motor.

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T1-795

Issued: August 1, 2008

Page 10

6.0 WARRANTY

TDI TURBOTWIN ENGINE MOTOR WARRANTY

Tech Development (TDI) warrants to the original user of the TDI TURBOTWIN™ air starters to be free from defects in material

and workmanship for a period of one year (6 month for remanufactured units) from the date of installation. The warranty period

shall not extend beyond two years (12 months forfactoryremanufacturedunits) from thedate the unit was manufactured. (i.e.:a

unit with a manufactured date of July 1999 (SN: 9907-101) will not be covered under warranty after July2001). The conditions

of this warranty are: a) TDI is notified within this period by return of such product to TDI or its authorized distributor/dealer,

transportation prepaid by user; b) the starter has been installed according to TDI’s specifications; c) the starter has not been

misused, abused, or improperly maintained by user; d) the defect is not the result of normal wear and tear; e) the starter has

been repaired with parts manufactured or authorized by TDI; and f) TDI installation and repair procedures as outlined in the

appropriate manual were properly followed.

Tech Development will repair, or at its option, replace the unit during the warranty period at no charge to the customer,

provided it is returned to TDI with the proper return procedure.

Tech Development makes no other warranty, and implied warranties including any warranty or merchantability or fitness for a

particular purpose are hereby disclaimed.

This warranty constitutes the entire obligation of Tech Development relating to the sale and use of such product and TDI’s

maximum liability is limited to the purchase price of such product at the date of purchase. In no event shall TDI be liable for

incidental, indirect, consequential, or special damages of any nature arising from the sale or use of such engine starter

product.

Other manuals for TURBOTWIN T100-MS

1

Table of contents

Other TDI Controllers manuals

Popular Controllers manuals by other brands

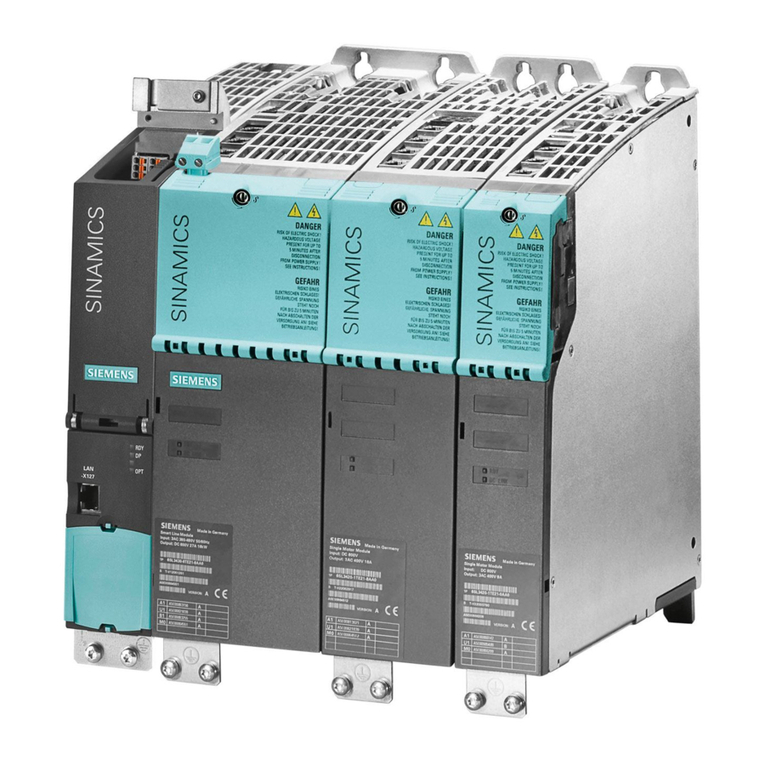

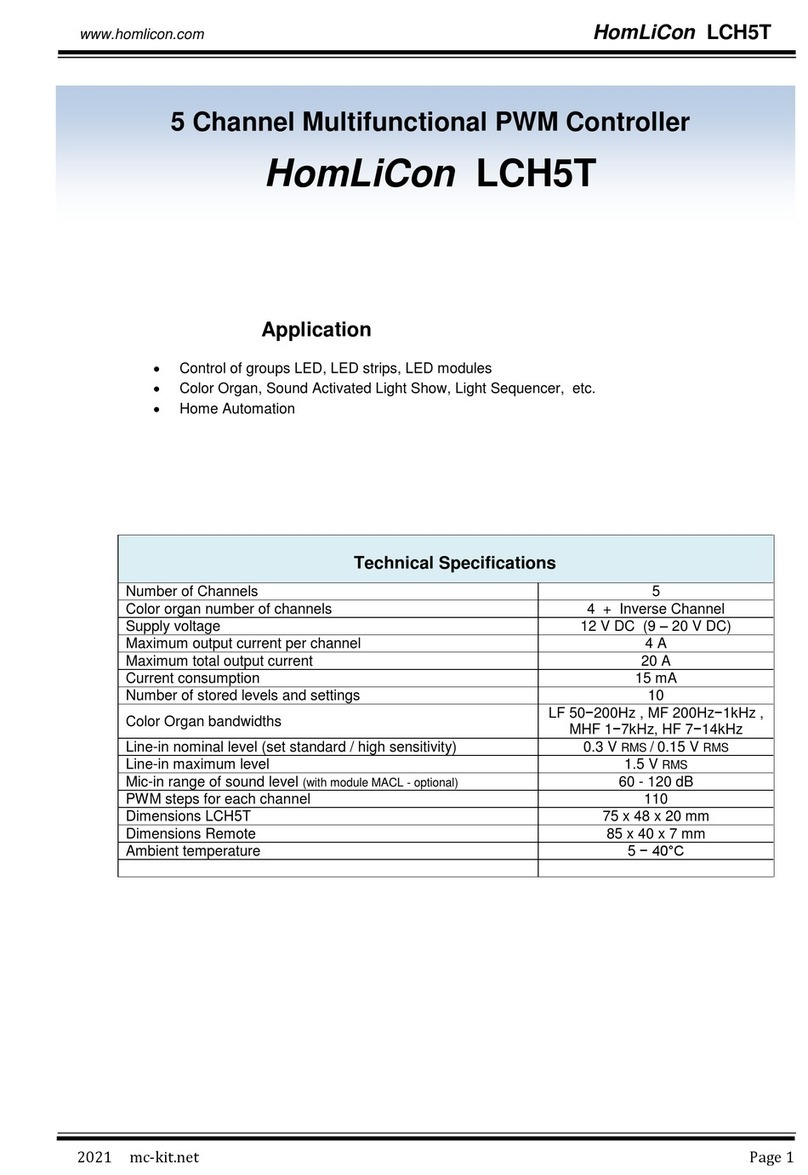

HomLiCon

HomLiCon LCH5T quick start guide

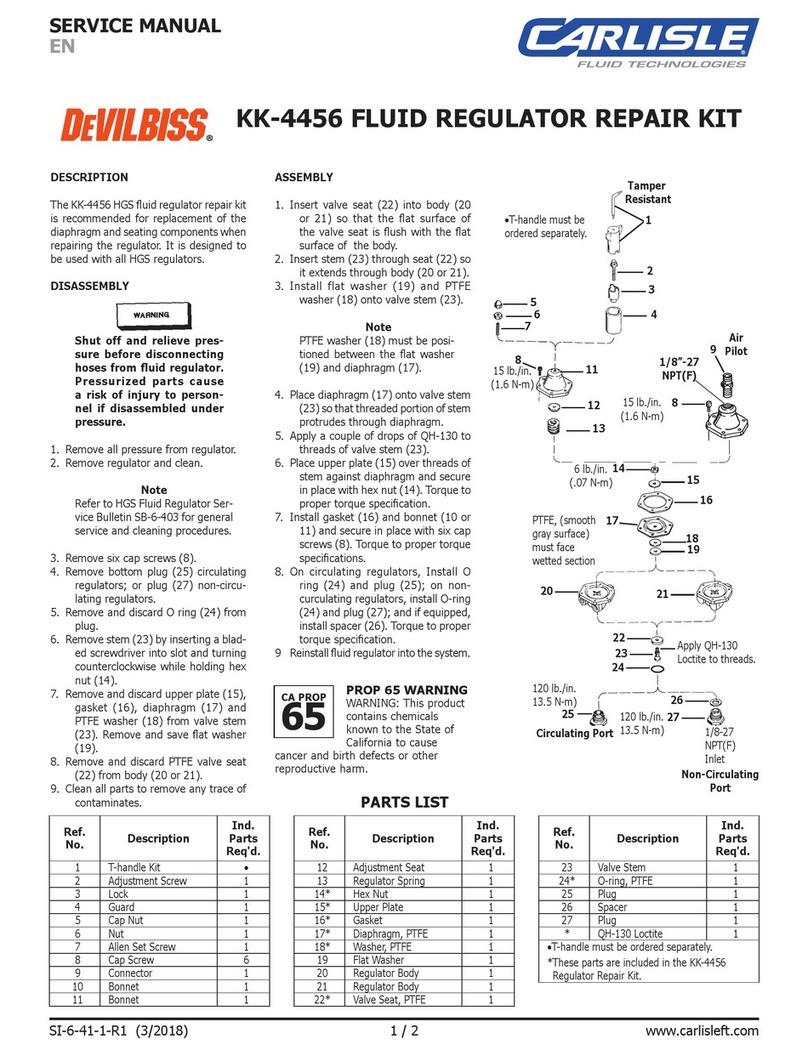

DeVilbiss

DeVilbiss KK-4456 Service manual

New Focus

New Focus LB1005 operating manual

Mitsubishi Electric

Mitsubishi Electric MELSERVO-J5 MR-J5-G Series user manual

HANA CONTROL ENGINEERING

HANA CONTROL ENGINEERING HN 3200 SERIES user manual

Multiplex

Multiplex MULTIcont BL-50 SD operating instructions