YARWAY OPERATING AND SAFETY INSTRUCTIONS

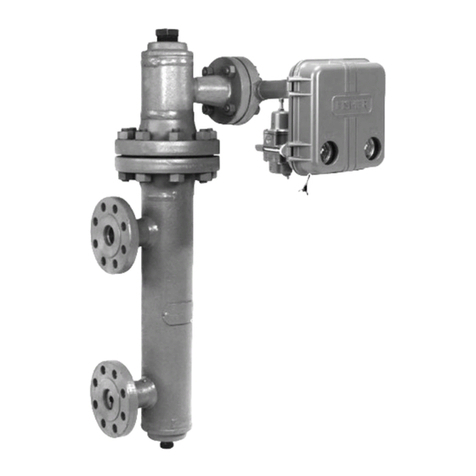

Pneumatic actuator

WARNING

For safety reasons, it is important to take the

following precautions before you start work

onthePDA*:

1. Read all labels fitted to the PDA* and

this sheet before installation, operation

ormaintenance.

2. Use PDA* for the intended purpose

(accordingcontract/specification).

3. Remove the PDA* carefully from its packaging,

lifting by means of straps (heavy weight)

around the body or use the hoisting lug.

4. The hoisting lug is for the actuator only,

notforthe total assembly!!!

5. For installation of the PDA* use bolting

material (2 half-couplings and lock nut; parts

of the Desuperheater) and free of 'forces,

moments and torques'.

6. Additional mounting/modifications on PDA's*

are not allowed without approval from Yarway.

7. The line must be depressurized, drained,

vented and cooled down before installation.

8. Handling of all PDA's *, with or without

accessories must be carried out by personnel

trained in all aspects of manual, mechanical

handling/lifting techniques and standard

safety procedures, in case of doubt, consult

your supervisor and/or safety officer.

9. Yarway do not accept liability for site work

performed under supervision of others.

10. Each PDA* air supply line should be protected

with its own air filter regulator.

11. Please, follow the procedure as detailed

intheIOM**.

12. Warning: high spring loaded assembly

(useextended bolts for dismantling).

13. The surface temperature as defined

in 2014/34/EC Annex II 2.2.1.2 of the

Desuperheater is a function of the system

it is built into. When installed, the surface

temperature cannot be controlled by the

manufacturer.

Before installation these instructions must be fully read and understood

!! Read all warning labels fitted to the PDA*

beforeoperation or maintenance !!

Never open, dismantle or modify the assembly

whilst under pressure/temperature or other

hazardous conditions.

NOTE

PDA* = Pneumatic diaphragm actuator

IOM** = Installation, Operation and Maintenance

Manual

© 2017 Emerson. All Rights Reserved.Emerson.com/FinalControl VCOSI-03350-EN 18/03

INSTALLATION

1. Place the PDA* with its yoke flange onto

thebonnet of the Desuperheater and fixed

itwith the lock nut.

2. Assemble the 2 half-couplings (upper and

lower) through the screws.

3. Installation may be in vertical or horizontal

piping (use support in case of heavy weight).

4. For installation of the positioner and

the air filter regulator, following the

manufacturer's recommendations.

5. Connect the lever of the positioner to the

stem coupling (mechanical linkage) and

adjust, if necessary, set points for air filter

regulator, and valve positioner, following

themanufacturer's recommendations.

6. Connection of electrical supplies and/or

air piping should be in accordance with

themanufacturer's instruction manual.

7. When satisfactory coordination between

signals and temperature are attained,

adjustment of the set-point can be made

and the system transferred to automatic

operation.

8. Ensure easy access of the operating

mechanism (actuator, positioner,

handwheel, etc.) if applicable.

CATEGORY

PDA's* are manufactured in accordance with

2014/68/EC - category I - gas group2.

Pressure/temperature limits are indicated:

# on the PDA* nameplate