Page 2 of 21

Document Number: DS-000358

Revision: 1.0

TABLE OF CONTENTS

General Description ..................................................................................................................................................................... 1

Functional Block Diagram ............................................................................................................................................................ 1

Applications ................................................................................................................................................................................. 1

Features ....................................................................................................................................................................................... 1

Ordering Information................................................................................................................................................................... 1

Table of Contents.................................................................................................................................................................................... 2

Specifications .......................................................................................................................................................................................... 4

Table 1. Acoustical/Electrical Characteristics – General.............................................................................................................. 4

Table 2. Acoustical/Electrical Characteristics – High Quality Mode ............................................................................................ 4

Table 3. Acoustical/Electrical Characteristics – Low-Power Mode.............................................................................................. 5

Table 4. Digital Input/Output Characteristics .............................................................................................................................. 5

Table 5. PDM Digital Input/Output.............................................................................................................................................. 6

Timing Diagram............................................................................................................................................................................ 6

Absolute Maximum Ratings.................................................................................................................................................................... 7

Table 6. Absolute Maximum Ratings ........................................................................................................................................... 7

ESD Caution ................................................................................................................................................................................. 7

Soldering Profile........................................................................................................................................................................... 8

Table 7. Recommended Soldering Profile*.................................................................................................................................. 8

Pin Configurations And Function Descriptions ....................................................................................................................................... 9

Table 8. Pin Function Descriptions............................................................................................................................................... 9

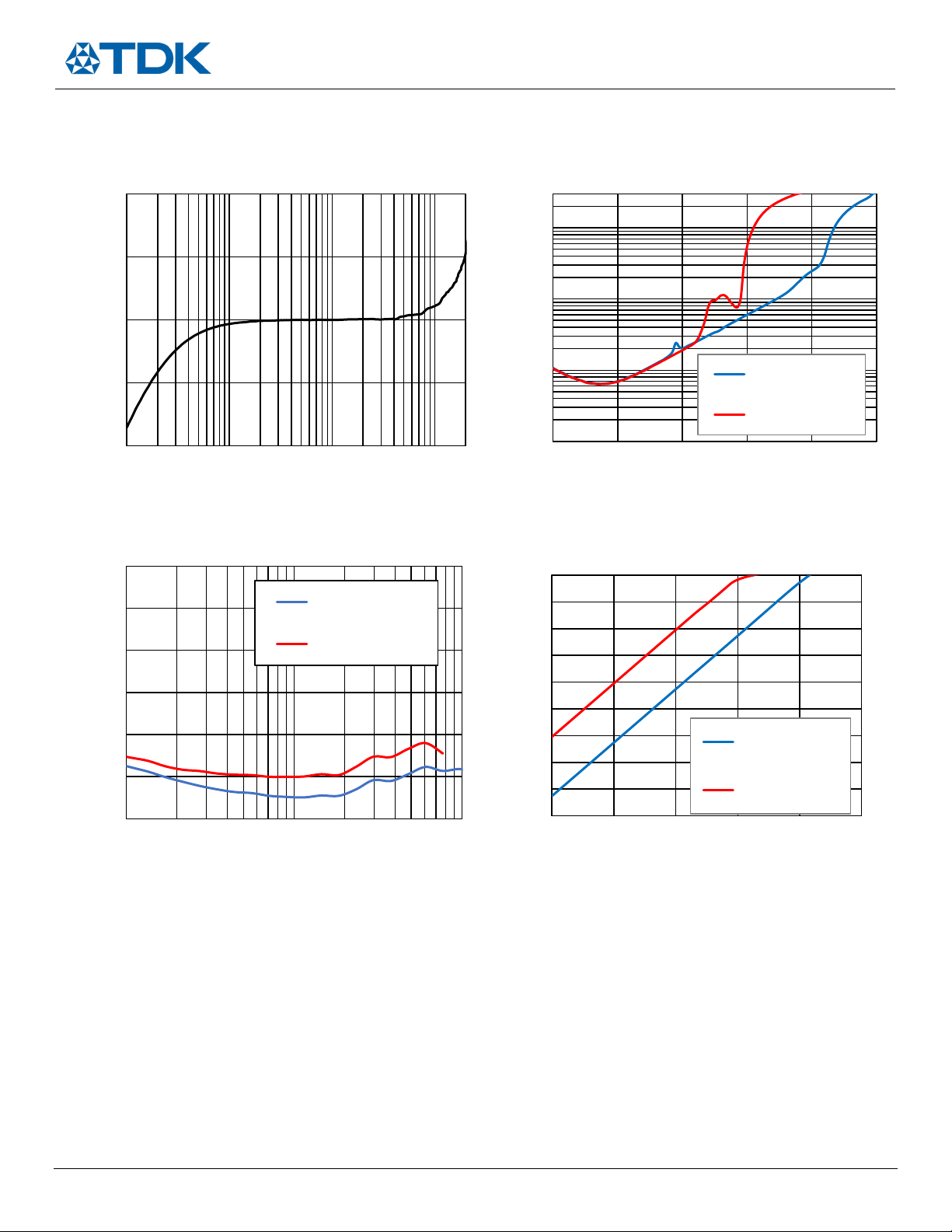

Typical Performance Characteristics..................................................................................................................................................... 10

Theory Of Operation............................................................................................................................................................................. 11

PDM Data Format ...................................................................................................................................................................... 11

Table 9. T3903 Channel Setting ................................................................................................................................................. 11

PDM Microphone Sensitivity ..................................................................................................................................................... 11

Applications Information ...................................................................................................................................................................... 13

Low-Power Mode....................................................................................................................................................................... 13

Dynamic Range Considerations ................................................................................................................................................. 13

Connecting PDM Microphones.................................................................................................................................................. 13

Sleep Mode................................................................................................................................................................................ 15

Start-Up Time............................................................................................................................................................................. 15

Supporting Documents ......................................................................................................................................................................... 16

Application Notes – General ...................................................................................................................................................... 16

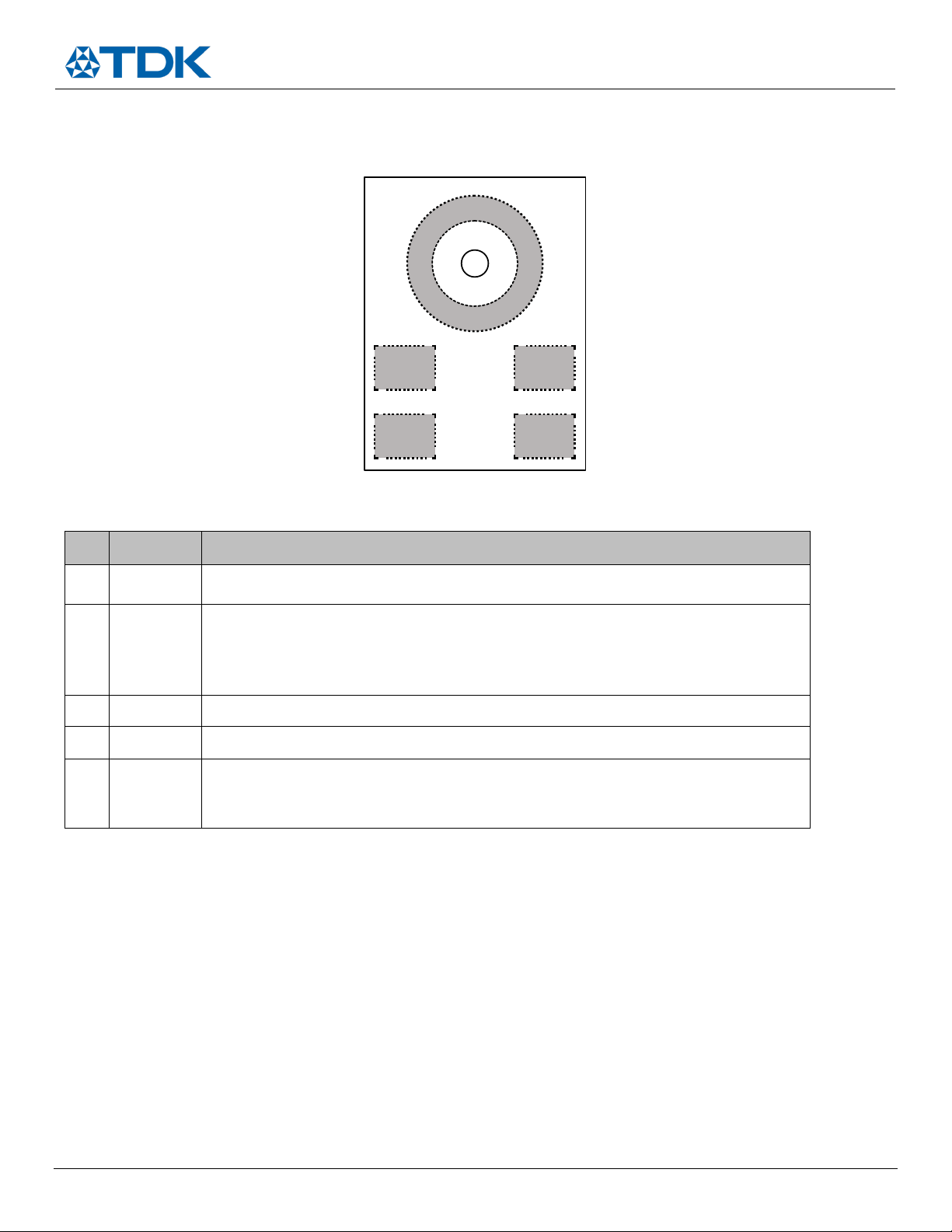

PCB Design And Land Pattern Layout ................................................................................................................................................... 17

PCB Material And Thickness ...................................................................................................................................................... 17

Handling Instructions............................................................................................................................................................................ 18

Pick And Place Equipment ......................................................................................................................................................... 18

Reflow Solder............................................................................................................................................................................. 18