TE AMP 3K series Reference guide

1 of 31

© 2016 TE Connectivity family of companies

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product, and/or company names may be trademarks of their respective owners.

TOOLING ASSISTANCE CENTER

1-800-722-1111

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com.

Customer Manual

409-32034

16 SEP 16 Rev D

SAFETY PRECAUTIONS

READ THIS FIRST!

.............................................................2

1. INTRODUCTION ..................................................................................................................3

2. DESCRIPTION .....................................................................................................................4

2.1. Functional Description.................................................................................................5

2.2. Electrical Description...................................................................................................6

2.3. Machine Guard (Figure 7) ...........................................................................................8

3. RECEIVING INSPECTION AND INSTALLATION ...............................................................9

3.1. Receiving Inspection ...................................................................................................9

3.2. Installation ...................................................................................................................9

3.3. Considerations Affecting Placement of Bench Machines..........................................10

4. OPERATION ......................................................................................................................11

4.1. Machine Operation ....................................................................................................11

4.2. Crimp Quality Monitor II (CQM II)..............................................................................11

4.3. Applicator Installation ................................................................................................14

4.4. Setup.........................................................................................................................14

4.5. Mode Selection and Operation..................................................................................15

4.6. Crimp Height Adjustment ..........................................................................................17

4.7. End-Feed/Side-Feed Applicator Conversion.............................................................17

5. MACHINE FAULT CODES ................................................................................................17

6. PREVENTIVE MAINTENANCE .........................................................................................18

6.1. Cleaning ....................................................................................................................18

6.2. Lubrication.................................................................................................................18

7. ADJUSTMENTS.................................................................................................................19

7.1. Measuring the Shut Height........................................................................................19

7.2. Shut-Height Adjustment ............................................................................................20

7.3. Crimp Height Adjustment Using Precision Adjustment Mechanism ..........................21

7.4. Guard Insert Adjustment ...........................................................................................22

8. MACHINE OPTIONS AND INSTALLATION......................................................................24

8.1. Installation of Work Light Assembly Kit .....................................................................24

8.2. Installation of the Work Light Assembly Kit ...............................................................26

8.3. Installation of Batch Counter Kit 1424267-1..............................................................27

8.4. Installation of Air Feed Kit 1424266-1 .......................................................................28

9. TROUBLESHOOTING .......................................................................................................31

10. RoHS INFORMATION........................................................................................................31

11. REVISION SUMMARY .......................................................................................................31

AMP 3K* Terminating Machine 1725950-[ ] and

AMP 5K* Terminating Machine 1725900-[ ]

ORIGINAL INSTRUCTIONS

409-32034

Rev D

2 of 31

SAFETY PRECAUTIONS —AVOID INJURY

Safeguards are designed into this application equipment to protect operators and maintenance personnel from

most hazards during equipment operation. However, certain safety precautions must be taken by the operator

and repair personnel to avoid personal injury, as well as damage to the equipment. For best results, application

equipment must be operated in a dry, dust-free environment. Do not operate equipment in a gaseous or

hazardous environment.

Carefully observe the following safety precautions before and during operation of the equipment:

Always wear approved eye protection while operating

equipment.

Always wear appropriate ear protection while using

equipment.

Moving parts can crush and cut. Always keep guard(s)

in place during normal operation.

Electrical shock hazard.

Always turn off the main power switch and disconnect

the electrical cord from the power source when

performing repair or maintenance on the equipment.

Never insert hands into installed equipment.

Never wear loose clothing or jewelry that may catch in

moving parts of the equipment.

Never alter, modify, or misuse the equipment.

TOOLING ASSISTANCE CENTER

CALL TOLL FREE 1-800-722-1111 (CONTINENTAL UNITED STATES AND PUERTO RICO ONLY)

The Tooling Assistance Center offers a means of providing technical assistance when required.

In addition, Field Service Specialists are available to provide assistance in the adjustment or repair of the

application equipment when problems arise which your maintenance personnel are unable to correct.

INFORMATION REQUIRED WHEN CONTACTING THE TOOLING ASSISTANCE CENTER

When calling the Tooling Assistance Center regarding service to equipment, it is suggested that a person

familiar with the device be present with a copy of the manual (and drawings) to receive instructions. Many

difficulties can be avoided in this manner.

When calling the Tooling Assistance Center, be ready with the following information:

1. Customer name

2. Customer address

3. Person to contact (name, title, telephone number, and extension)

4. Person calling

5. Equipment number (and serial number if applicable)

6. Product part number (and serial number if applicable)

7. Urgency of request

8. Nature of problem

9. Description of inoperative component(s)

10. Additional information/comments that may be helpful

409-32034

Rev D

3 of 31

PART

NUMBER

CAPACITY

(lbs)

STROKE

LENGTH

(mm)

CQM II

APPLICATOR

BASE

SHUT HEIGHT

(mm)

WORK

LIGHT

BATCH

COUNTER

SPECIAL

1725950-2

3000

41.25

No

Amp

135.79 ±0.025

Yes

Yes

---

1725950-3

3000

30

No

Amp

135.79 ±0.025

Yes

Yes

---

4-1725950-2

3000

41.25

Yes

Amp

135.79 ±0.025

Yes

Yes

---

4-1725950-3

3000

30

Yes

Amp

135.79 ±0.025

Yes

Yes

---

5-1725950-0

3000

30

No

Universal (Jam)

119.50 ±0.025

Yes

Yes

---

5-1725950-1

3000

30

Yes

Universal (Jam)

119.50 ±0.025

Yes

Yes

---

1725900-2

5000

41.25

No

Amp

135.79 ±0.025

Yes

Yes

---

1725900-3

5000

30

No

Amp

135.79 ±0.025

Yes

Yes

---

1-1725900-0

5000

30

No

Quick (Jam)

119.50 ±0.025

Yes

Yes

---

3-1725900-0

5000

41.25

No

Amp

135.79 ±0.025

Yes

Yes

Air

Feed/Overside

Guards

4-1725900-2

5000

41.25

Yes

Amp

135.79 ±0.025

Yes

Yes

---

4-1725900-3

5000

30

Yes

Amp

135.79 ±0.025

Yes

Yes

---

5-1725900-0

5000

30

No

Universal (Jam)

119.50 ±0.025

Yes

Yes

---

5-1725900-1

5000

30

Yes

Universal (Jam)

119.50 ±0.025

Yes

Yes

---

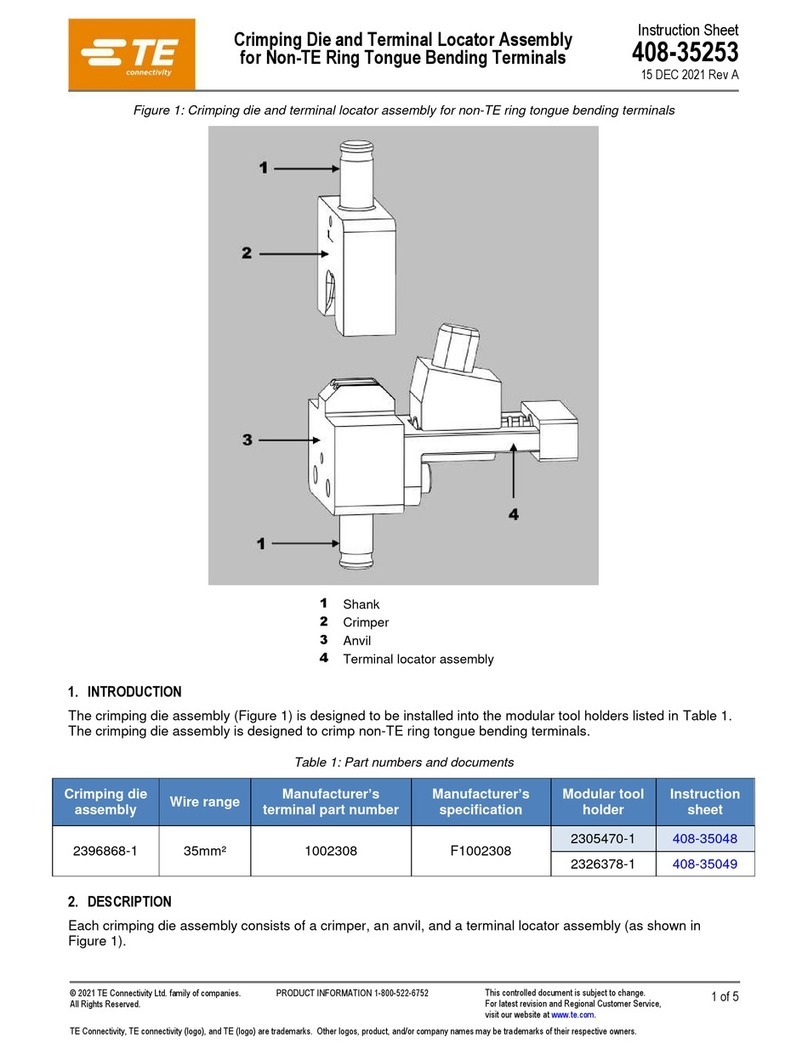

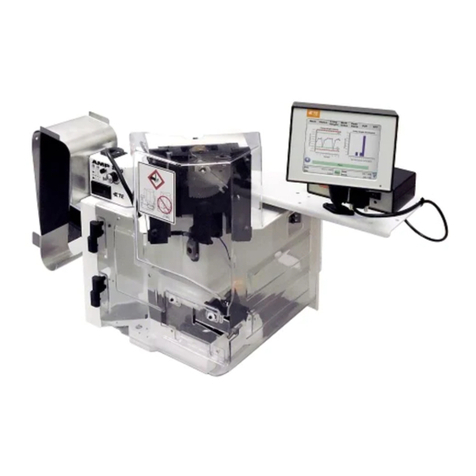

Figure 1

1. INTRODUCTION

This manual contains information on operation, preventive maintenance, and adjustments of the AMP 3K and

AMP 5K Terminating Machines 1725950-[ ] and 1725900-[ ] respectively. See Figure 1.

Both series machines (AMP 3K and AMP 5K) are equipped with precision crimp height adjustments and a

guard interlock.

Descriptions in this manual pertain to the controls and adjustments on the AMP 3K and AMP 5K machines

only.

When reading this manual, pay particular attention to DANGER, CAUTION, and NOTE statements.

409-32034

Rev D

4 of 31

The specifications and requirements for the AMP 3K and AMP 5K Terminating Machines are as listed below:

Deflection

0.13 mm [.0046 in.] Maximum per 4,448 Newtons [1,000 lb] Crimp Force

Noise (Model 3k Series):

Less than 76 dBa Typical at operator position with standard mechanical feed applicator

Noise (Model 5k Series):

Less than 80 dBa Typical at operator position with standard mechanical feed applicator

Weight

68.86 Kilograms [143 lb]

Height

510 mm [20 in.] without reel supports

Electrical

100-240 Vac, 50/60 Hz, Single-Phase Current

Air

620-760 kPa [90-100 psi], 2.83 liters/sec (6 scfm) When required for use with air-feed applicators

Physical Environment:

Temperature: 4.4° to 40° C [40° to 104° F]

Relative Humidity: Less than 95% (non-condensing)

Transportation and Storage: Store in a clean, dry environment after coating all surfaces lightly with a rust

preventing oil.

Various TE applicators can be used in the AMP 3K and 5K terminating machines. Applicator instructions sheets

are packaged with each applicator. The applicator instruction sheets provide information on applicator

installation, care, and adjustment.

When reading this manual, pay particular attention to DANGER, CAUTION, and NOTE statements

DANGER

Denotes an imminent hazard that may result in moderate or severe injury.

CAUTION

Denotes a condition that may result in product or equipment damage.

NOTE

Highlights special or important information.

NOTE

Dimensions in this customer manual are in metric units [with U.S. customary units in brackets]. Figures are not drawn to scale.

2. DESCRIPTION

The AMP 3K and AMP 5K Terminating Machines were designed to be used as stand-alone semi-automatic

bench units. They are assembled with metric hardware.

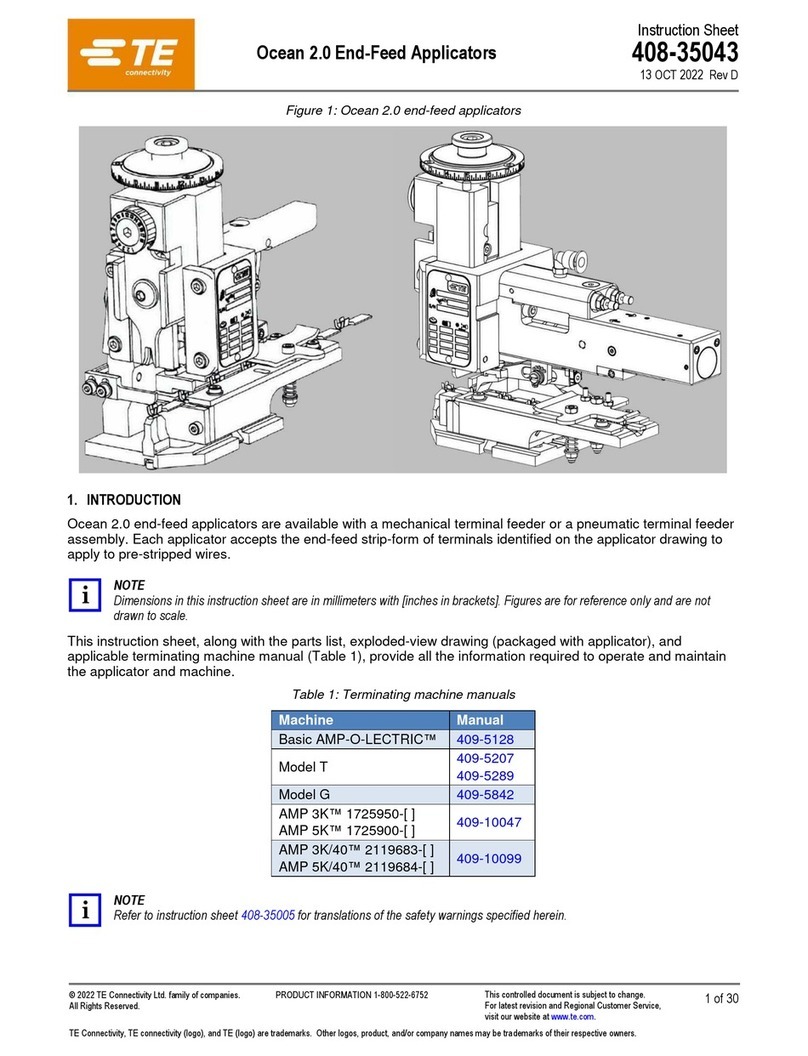

These machines accept a wide variety of miniature (mini) quick-change applicators (including the TE Ocean

Applicator), thus providing a great selection of terminals for many applications.

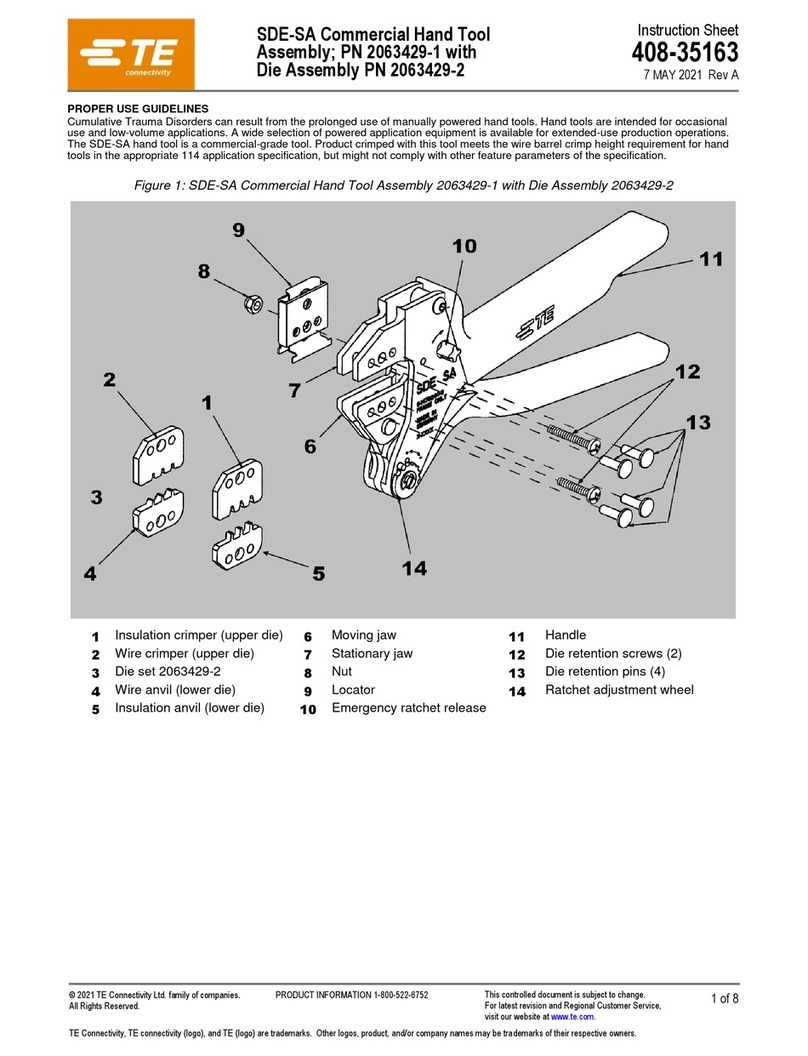

Older TE applicators use different feed cams depending on the machine stroke. Refer to Figure 2 for

changeover cams required to run 1 1/8-in. stroke cams (for AMP-O-LECTRIC* Model "K" terminating

machines) and 1 5/8-in. stroke cams (for Model "T" and Model "G" Terminating machines) in the machines.

409-32034

Rev D

5 of 31

ORIGINAL APPLICATOR

FEED TYPE

CHANGEOVER CAMS FOR THE MACHINES

1 5/8-in. [41.25 mm]

Stroke Machines

1 1/8-in. [30 mm]

Stroke Machines

1 1/8-in. Stroke Applicator for

Model “K" Terminating Machine

Pre-Feed

690602-6

---

Post-Feed

690501-4

---

1 5/8-in. Stroke Applicator for

Model “T" and Model “G"

Terminating Machines

Pre-Feed

---

690602-5

Post-Feed

---

690501-3

Heavy-Duty Industrial (HD-I)

Applicator

Pre-Feed/Post-Feed

Refer to the HD-I Applicator customer drawing for part numbers.

Figure 2

2.1. Functional Description

These machines provide the force required to crimp terminals in the applicator. A terminal is attached to the

wire by placing the wire in the crimp area and pressing the footswitch. The machine consists of four functional

areas:

1. The motor group includes a dc motor which drives a crankshaft. The motor is activated each cycle

and rotates the crankshaft one full revolution. A 6 mm hex key placed in the recess located on the end

of the motor, can be used to cycle the motor manually. See Figure 3.

2. The crankshaft-ram group converts the motor’s rotational motion into the up-and-down action of the

ram for driving the applicator during the crimping cycle.

Figure 3

Crankshaft

DC Motor

Hex Key

Location for

Manual

Cycling

Power Cord

Receptacle

409-32034

Rev D

6 of 31

Figure 4

3. The base plate provides the mounting surface on which the applicator is installed. The quick-release

latching feature on machines with the AMP style base plate permits fast, easy installation and removal

of the applicator. Machines with the Universal style base plate do not include the quick-release

latching feature. See Figure 4.

4. The crimp height adjustment group uses an eccentric located in the ram linkage, along with

detented stops in the mechanism to adjust the crimp height. Indexing the mechanism in either

direction will change the crimp height in increments of approximately 0.013 mm [.0005 In.] per step.

Refer to Figure 4 for the Precision Crimp Height Adjustment Mechanism.

2.2. Electrical Description

The 1725950-[ ] and 1725900-[ ] machine electrical components consist of the operator control panel, the

motor, and the CPU/motor controller package. The machine operates on 100/240 Vac, 50/60 Hz, single-phase

current with ground. The machine will automatically detect the supply voltage and adjust the controller

accordingly.

The operator control panel (Figure 5) is mounted on the left side of the machine frame. The control panel

consists of two indicator lights, one jog button, and one speed control knob, with icons depicting each function.

See Figure 9 for control panel operation.

Precision Crimp Height

Adjustment Mechanism

Mounting Hole

AMP Style Applicator

Base Plate

Quick-Release

T-Handle

Universal Style

Applicator Base Plate

Base Plate for JAM

Style Applicators

Alternate Rear Stop

Mounting Position

Swing Handle

409-32034

Rev D

7 of 31

Figure 5

A main power switch/circuit breaker (Figure 6) is located on the back of the machine. This switch connects ac

power to the control system. The CPU/motor controller is located behind the back cover of the machine. It is a

modular unit that contains all of the electronics necessary to operate the machine. See Figure 6.

Machine

Ready Icon

Green

Indicator

Guard Open

Icon

Yellow

Indicator

Jog

Button

Speed

Control

Knob

Speed

Control

Icon

Fault Icon

Batch

Counter

(Optional)

Guard

Disable

Icon

Jog

Button

Icon

409-32034

Rev D

8 of 31

Figure 6

2.3. Machine Guard (Figure 7)

A guard is installed to provide protection for the operator while maintaining proper visibility of the work area.

The guard swings open to allow easy access for applicator installation and setup. A safety interlock on the

guard prevents the machine from cycling if the guard door is open during production operation.

Reel Support Hole

DC Motor

Power

Receptacle

Back Cover

CPU/Motor Controller

(Behind Back Cover)

Terminal

Strip Guide

Power

Switch/Circuit

Breaker

409-32034

Rev D

9 of 31

Figure 7

3. RECEIVING INSPECTION AND INSTALLATION

3.1. Receiving Inspection

These machines are thoroughly inspected during and after assembly. A final series of inspections is made to

insure the proper machine functioning before packaging and shipping.

To protect against damage that may have occurred during shipment, remove the machine from the crate

(Paragraph 3.2.) and carefully inspect the machine for damage. If damage is evident, file a claim against the

carrier and notify TE immediately.

3.2. Installation

Remove all mounting bolts securing the machine to the shipping pallet. Install lift ring (see Figure 7) on top of

the machine.

NOTE

Lift ring (M1220 eye bolt) is customer supplied.

NOTE

Install the lift ring carefully. A 19.05-mm [.75-in.] thread length engagement is required for the lift ring to support the machine.

Attach a suitable hoist to the lift ring, lift the machine, and place it in the selected operating location.

Insert the reel support post into the appropriate hole on top of the machine (Figure 6) until the roll pin engages

a groove in the machine frame.

Hole for Customer

Supplied Lift Ring

Precision Crimp Height

Adjustment Mechanism

Safety Interlock

Machine

Guard

Quick Release T-Handle

with AMP Style Base Plate

409-32034

Rev D

10 of 31

Attach the terminal strip guide included with the machine with the two thumbscrews supplied. Mount the guide

on the left guard for side-feed applicators. Mount the guide on the right guard for end-feed applicators.

Connect the power cord to a suitable electrical supply.

NOTE

The machine will automatically detect the supply voltage and adjust the controller accordingly.

3.3. Considerations Affecting Placement of Bench Machines

The location of the machine in relation to the operator's position is extremely important in terms of both safety

and maximum efficiency. Studies have repeatedly shown that operator fatigue will be reduced, and greater

efficiency achieved, if:

1. The bench is of appropriate height, preferably with sound-deadening rubber mounts.

2. The machine is properly located on the bench with ample work areas on both sides to facilitate work

flow.

3. The operator uses a swivel chair with padded seat and back rest which are independently adjustable;

and

4. The footswitch, on machines so equipped, is placed on a rubber mat to maintain its movability, while

preventing it from sliding unintentionally.

Figure 8 illustrates proper machine location and operator position and the following:

Bench

The bench to be used should be of sturdy construction, preferably with rubber mounts to minimize noise. A height of 762 to 812.8

mm [30 to 32 in.] is the most suitable for operator comfort and convenience. This height allows the operator to rest both feet on

the floor, thereby providing for the shifting of weight and leg position.

Machine Mounting and Location on Bench

The machine should be located near the front of the bench with the “target area" (tooling area where the product is applied) not

more than 152.4 to 203.2 mm [6 to 8 in.] -- minimum 50.8 mm [2 in.] from the front edge. This location will eliminate unnecessary

operator motion and help to avoid back strain and fatigue.

Orientation of the machine should be such that the “target area" is facing the front of the bench and is parallel to the front edge

(access to the back of the machine MUST also be provided).

DANGER

Machines should be securely bolted to the bench using the machine mounting hole(s) shown in Figure 4. Hardware is

customer supplied. Machines should not extend beyond the front of the bench.

Operator's Chair

The operator's chair should swivel, and should have independent seat height and back rest adjustments. The seat and back rest

should be padded, and the back rest should be large enough to provide support both above and below the waist line.

In use, the chair should be far enough under the bench so that the operator's back is straight and is supported by the back rest.

Footswitch

When the operator is correctly positioned in front of a machine equipped with a footswitch, the foot should rest on the switch

comfortably. The footswitch should be movable, so that its location can be readily changed when the operator shifts position to

minimize fatigue. Placing the switch on a rubber mat keeps it movable while preventing unintentional sliding.

The preferred footswitch location varies to some extent among operators. Some operators prefer the switch located so that their

foot rests on the switch when their feet are in the natural sitting position (calf of leg perpendicular to the foot). Others prefer the

leg to be slightly in front of the natural position. The important thing to remember is that the foot should be at approximately 90°

(right angle) to the calf when resting on the switch. Those operators who prefer the footswitch slightly in front of the natural

position may require a wedge-shaped block placed under it.

409-32034

Rev D

11 of 31

Figure 8

Scrap Removal

A suggested method of scrap removal: place a tray on the right side of the machine, under the cast slot in the frame, to capture

the scrap chips.

4. OPERATION

4.1. Machine Operation

The machine is operated by the footswitch, the jog button, and the speed control knob. The jog button and the

speed control knob are located on the control panel. The control panel features are described in Figure 9.

4.2. Crimp Quality Monitor II (CQM II)

The AMP 3K / AMP 5K machine must have software version 3.2.1 or later to interface with the monitor.

The software version can be checked by pressing and holding the footswitch when the green and yellow lights

start to blink while the terminator is powering up.

The yellow light will flash three times, and then the green light will flash the software version. For example,

three yellow flashes followed by three green flashes, a pause, two green flashes, a pause, and one green flash

would indicate version 3.2.1.

Refer to Customer Manual 409-10100 for detailed instructions regarding the use of the CQM II. This manual is

included in the machine’s documentation package.

Machine Power Up

During power up, the machine looks to see if the monitor’s interface cable is connected. Specifically, it looks to see if the jumper

from J10–3 to J10–4 is installed on the CPU/Motor Controller Board.

If the jumper is seen, the green and yellow lights will alternately flash a couple of times on power up. If the jumper is not detected,

the green and yellow lights flash together a couple of times.

After seeing the jumper, the machine looks to see if the monitor is ready to accept a crimp by looking at the monitor’s output

relay, Relay 2. Relay 2 is a normally open relay that is closed when the monitor is ready for a crimp.

If Relay 2 is not closed when the machine is powered up, it will flash both lights seven times (Monitor Not Detected Fault).

This “fault” can be cleared by holding down the footswitch until the lights stop flashing.

409-32034

Rev D

12 of 31

Cycling the Machine

When the footswitch is pressed to cycle the machine, the machine looks at the monitor’s output relays, Relay 1 and Relay 2. The

indicator light, DS2, on the machine’s CPU/Motor Controller Board indicates the status of Relay 2. The light will be turned on

when Relay 2 is closed.

If Relay 2 is not closed, the green and yellow lights will flash together three times (Monitor Not Ready Fault). If Relay 1 is not OFF

(open) the green and yellow light will flash together six times (Good Crimp Signal Fault).

Both of these faults can be cleared by holding down the footswitch until the lights stop flashing.

Bad Crimp Fault (After the Machine Cycles)

After the machine has been cycled, the machine looks at the monitor’s output relays, Relay 1 and Relay 2. If the Relay 1 is

pulsed and Relay 2 remains closed, the machine will be ready for the next crimp cycle.

If the Relay 1 is not pulsed and Relay 2 is open, the monitor has detected a BAD crimp and both the green and yellow light will be

flashed four times (Bad Crimp Fault).

The fault can be cleared by holding down the footswitch until the lights stop flashing.

Crimp Analysis Fault (After the Machine Cycles)

If the Relay 1 pulse is not detected and Relay 2 remains closed (after the machine has cycled), the green and yellow light will be

flashed five times (Crimp Analysis Fault).

The fault can be cleared by holding down the footswitch until the lights stop flashing.

409-32034

Rev D

13 of 31

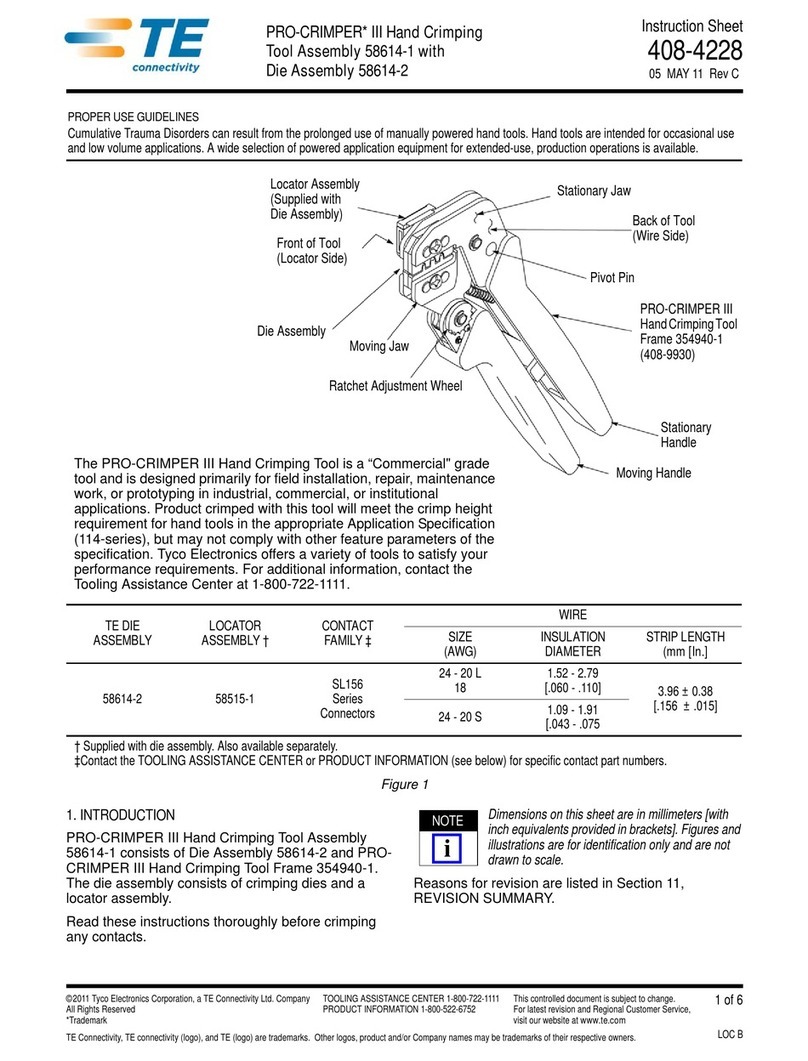

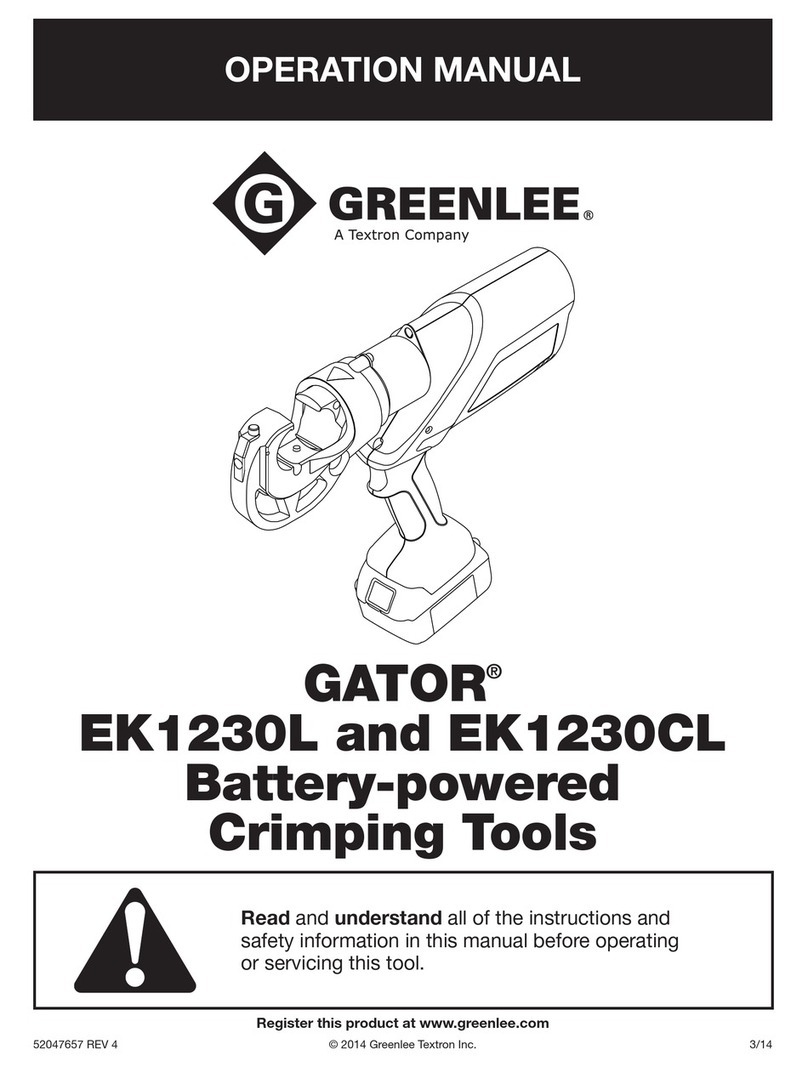

Figure 9

Yellow Indicator

Jog Button

Speed Control

Knob

Speed Control

Icon

Green Indicator

Machine Ready

Icon

Fault Icon

Jog Button

Icon

Optional Batch Counter

Guard Open

Icon

Guard Disabled Icon

The green and yellow indicators on top of the control panel indicate the machine status.

When the green indicator is “on” and is not flashing, the machine is ready for operation.

When the green indicator is flashing by itself, a machine fault has been detected. When the green and yellow

indicators are flashing together a CQM fault has been detected. See Figure 10. To reset the fault indicator,

clear the problem area then hold down the footswitch, for approximately 5 seconds, until the indicator light

stops flashing. Some machines faults require AC power to be cycled using the rocker switch on the back panel.

Leave the machine powered off for approximately ten seconds before reapplying power.

When the yellow indicator is “on” and not flashing, the guard is disabled and the machine will only operate with

the Jog button.

When the yellow indicator is flashing by itself, the guard interlock switch is disabled and the machine will

only operate with the Jog button. When the green and yellow indicators are flashing together a CQM fault

has been detected. See Figure 10. To reset the fault indicator, clear the problem area then hold down the

footswitch, for approximately 5 seconds, until the indicator light stops flashing. Some machines faults require

AC power to be cycled using the rocker switch on the back panel. Leave the machine powered off for

approximately ten seconds before reapplying power.

409-32034

Rev D

14 of 31

4.3. Applicator Installation

NOTE

These instructions apply to machines that have an AMP style base plate with the quick release feature. Machines with the

Universal style base plate, do not have a quick release feature and require a hex wrench to install an applicator. Machines

with the JAM style base plate use a swing handle to release applicators. Removal is in the reverse order of installation.

Install the proper applicator in the quick-change mounting base as follows:

CAUTION

Make sure that the precision adjustment lever has been returned to the "0" position before installing the applicator. Be sure

that the applicator has the proper feed cam prior to installation.

NOTE

Applicators from AMP-O-LECTRIC Model "K" terminating machine and Model "T" terminating machine can be used in these

machines by using a special replacement cam. Refer to Figure 2.

1. Loosen the quick-release T-handle (see Figure 5) and slide the applicator base clamp down.

2. Place the applicator on the quick-change base plate, then slide it back until the two notches in the

applicator base engage the stops at the back of the quick-change base plate. At the same time, guide

the ram post into the ram post adapter.

3. Slide the applicator base clamp UP and re-tighten the quick-release T-handle to secure the applicator

in place.

NOTE

When using Applicator 567200-2 (originally intended for use with AMP-O-LECTRIC Model "K" terminating machine), loosen

the quick-release T-handle, slide down the applicator base clamp, and remove the rear stop located on the left side of the

base plate. Install the rear stop (PN 354561-1), supplied with the air feed kit, at the alternate mounting position on the base

plate. See Figure 4.

4. Set the crimp height and insulation crimp discs so that the letters and numbers on the applicator pad

align with the front pad on the ram post adapter.

5. If the applicator is an air-feed type, connect the airlines to the valves located on the back of the

machine.

NOTE

Quick Disconnect Coupling 23238-1 is required to run air-feed applicators.

6. Adjust the reel support for side-feed or end-feed product, depending on the applicator being used.

7. Mount the terminal strip guide on the left sheet metal guard for side-feed product, or on the right sheet

metal guard for end-feed product, depending on the applicator being used.

8. Mount the terminal reel on the reel support. Thread the terminal strip through the guard and into the

applicator according to the instruction sheet included with the applicator. If necessary, adjust the

lubricator bowl.

9. Align the product reel to the applicator by adjusting the reel flanges.

10. Close the guard.

NOTE

The guard door must be closed in order to operate the machine, unless you are in the Jog (With Guards Disabled) Mode. See

Paragraph 4.4.C.

4.4. Setup

Install a miniature applicator and terminals according to Paragraph 4.3.

1. Turn on the main power using the switch located on the back of the machine.

2. Jog the machine (as described in Paragraph 4.5.B.) through a complete crimp cycle.

409-32034

Rev D

15 of 31

NOTE

Machine should be able to jog through the terminal and wire at maximum jog speed.

3. Inspect the crimped terminal to verify that the terminal is being positioned properly within the

applicator.

4. Correct for any positioning errors according to the applicator instruction sheet, and repeat Steps 2

and 3 until a terminal is properly positioned.

5. Place a prepared wire in the crimp area and press the footswitch.

6. Inspect the completed crimp and make adjustments as necessary.

4.5. Mode Selection and Operation

The three basic modes of operation for these machines include: Full-Cycle, Jog, and Jog (With Guards

Disabled).

Full-Cycle Mode

Depressing the footswitch (with the guard closed) causes the crankshaft to be rotated (at a speed defined by the speed control

knob), through a complete revolution. This completes one full machine cycle.

The speed control knob in Figure 9 ALSO adjusts the air feed timing. Normally the air feed timing is set at 280 ms. When the

speed control is set at less than 50% of its maximum setting (pointing straight down or counterclockwise from pointing straight

down, the air feed timing changes to 440 ms. This is done to accomodate applicators that have longer than normal air cylinders.

Jog Mode (Figure 9)

Pressing the Jog button causes the crankshaft to be rotated at a default reduced speed in the forward direction until the Jog

button is released or the crankshaft completes the machine cycle. If the Jog button is released in mid–cycle, the crankshaft will

stop turning. Press the Jog button again and the crankshaft will continue to rotate in the forward direction and complete the

machine cycle.

The ram may drift downward if the Jog Button is released in mid-cycle.

If while jogging, the machine stalls and cannot complete a full cycle, release the jog button. Before continuing, verify that there is

not an interference problem in the crimping area. To complete the cycle, either press the footswitch or jog at a faster speed. The

jog speed can be temporarily increased by following the “Adjusting the Jogging Speed Using the Speed Control Knob” procedure

described below.

If the Jog button is held down for longer than five seconds and the machine cycle is not completed, the machine will “err” and the

green indicator light will flash a fault code. To clear the error, hold down the footswitch for five seconds. If the machine stalled

because of an interference problem, “power down” the machine, clear the problem, and then “power up” the machine again. It

may be necessary to manually cycle the machine to clear an interference problem. Refer to the CAUTION and DANGER

statement below for the proper manual cycling procedure.

The green flashing status indicator flashes a specific number of times to represent a corresponding fault. For example, the green

status indicator will flash two times (each followed by a one second pause) to indicate that the machine guard opened while the

machine was running. Refer to Figure 10.

CAUTION

While in the Jog mode, attempting to complete a crimp cycle with terminals and wire in the applicator may cause the motor to

stall. Although the machine can terminate some smaller terminals and wire, it may be necessary to turn "off" the machine and

manually cycle the machine to the home position. The machine can be manually cycled by turning off the machine,

disconnecting the power cord plugged into the receptacle mounted to the motor end plate (Figure 6), and inserting a 6mm hex

key into the recess located in end plate of the motor. Rotate the hex key to manually rotate the motor.

DANGER

The hex key must be removed from the recess before the power cord can be plugged back into the receptacle. To avoid

personal injury, be sure to remove the hex key before operating the machine under power.

409-32034

Rev D

16 of 31

Adjusting the Jogging Speed Using the Speed Control Knob

The default speed of the machine, when jogging, is set to a minimum value which is not defined by the initial

position of the speed control knob. Adjusting the speed upward enables jogging at speeds greater than the

default in case greater speeds are required to complete a cycle.

To cause the machine to run at a jog speed other than the default speed, perform the following:

1. Rotate the speed control knob completely counterclockwise.

2. Rotate the speed control knob to the desired speed.

3. Within three seconds, press the jog button. The machine will run at the speed set by the speed control

knob.

4. If the jog button is released and pressed again within three seconds, the machine will run at the set

speed. If the jog button is pressed after three seconds the machine will run at the default speed.

5. If the jog button is released, the speed control knob is adjusted to a different position, and the jog

button is pressed within three seconds, the machine will jog at the newly adjusted speed.

6. If the jog button is not pressed for three seconds, repeat Steps 1, 2, and 3 to set the jog speed to a

setting other than the default jog speed.

Jog (With Guards Disabled) Mode (Figure 9)

NOTE

The footswitch will NOT initiate cycling in this mode.

DANGER

To avoid personal injury, be very careful of moving mechanisms when jogging the machine with the guards open.

This mode allows maintenance and setup personnel to cycle the machine with the guard door open using the

jog button. To activate this mode, turn "off" power, and open the guard door. Turn the power back "on" and,

immediately after the machine ready and guard disable indicators flash "on", press and hold the Jog button.

The guard disable indicator will flash at a rate of two flashes per second, indicating that the guard has been

disabled.

Pressing the Jog button causes the crankshaft to be rotated at a default reduced speed in the forward direction

until the Jog button is released or the crankshaft completes the machine cycle. If the Jog button is released in

mid–cycle, the crankshaft will stop turning. Press the Jog button again and the crankshaft will continue to rotate

in the forward direction and complete the machine cycle.

If while jogging, the machine stalls and cannot complete a full cycle, release the jog button. Before continuing,

verify that there is not an interference problem in the crimping area. To complete the cycle, either press the

footswitch or jog at a faster speed. The jog speed can be temporarily increased by following the “Adjusting the

Jogging Speed Using the Speed Control Knob” procedure described below.

If the Jog button is held down for longer than five seconds and the machine cycle is not completed, the

machine will “err” and the green indicator light will flash a fault code. To clear the error, hold down the

footswitch for five seconds. If the machine stalled because of an interference problem, “power down” the

machine, clear the problem, and then “power up” the machine again. It may be necessary to manually cycle the

machine to clear an interference problem. Refer to the CAUTION and DANGER statement below for the proper

manual cycling procedure.

The machine will exit the Jog (With Guards Disabled) Mode whenever the guards are closed or the power is

turned "off."

The ram may drift downward if the Jog Button is released in mid-cycle.

The green flashing status indicator flashes a specific number of times to represent a corresponding fault. For

example, the green status indicator will flash two times (each followed by a one second pause) to indicate that

the machine guard opened while the machine was running. Refer to Figure 10.

409-32034

Rev D

17 of 31

4.6. Crimp Height Adjustment

Refer to Paragraph 7.3. for procedures to adjust the crimp height using the machine precision adjustment

feature.

4.7. End-Feed/Side-Feed Applicator Conversion

When changing from an end-feed applicator to a side-feed applicator (or from a side-feed applicator to an end-

feed applicator), the reel support assembly must be moved to the opposite side of the machine. With the

terminal reel removed, lift and rotate the reel support bar to the opposite side of the machine. Mount the

terminal reel on the reel support and load the terminal strip into the applicator. Remove the metal terminal lead-

in and thumbscrews and move to the opposite side of the machine. Move the machine lubricator bowl to the

opposite side of the machine as required.

NOTE

Lubricator Bowl Assembly 354550-3 is an optional accessory. When using an Ocean Side-Feed or End-Feed applicator, the

lubricator assembly part numbers are 2119955-1 and 2119955-2, respectively.

5. MACHINE FAULT CODES

INDICATOR LIGHTS

(Number of Consecutive

Green Flashes)

INDICATOR LIGHTS

(Number of Consecutive

Yellow Flashes)

MACHINE FAULT

2

---

Guard switch opened while motor was running.

3

---

Guard switch not closed. Close the guard to close the guard switch.

4

---

Top Dead Center (TDC) switch fault; machine motion not detected. The switch

was not unmade within the allotted time, 175 ms.

5

---

Top Dead Center (TDC) switch fault: complete machine cycle not detected. The

switch was not made within the allotted time. The allotted time for the Run

mode is 1.5 seconds. The allotted time for Jog mode is six seconds.

6

---

Motor control circuit fault. A bad transistor (PWM IGBT) was detected. The

CPU/Motor Control Board assembly must be replaced.

7

---

Jog Push Button Fault. During power up, the jog button pressed input was

detected.

8

---

Footswitch fault. During power up, the footswitch pressed input was detected.

9

---

Jog button detection circuit fault; DC bus relay turned on during power up. The

CPU/Motor Control Board assembly must be replaced

10

---

Jog enable input circuit fault was detected. The CPU/Motor Control Board

assembly must be replaced.

11

---

Not applicable to this machine.

12

---

J9 Input fault; Input on during power up. Note that this fault in not applicable to

this machine. If it occurs, the CPU/Motor Control Board assembly must be

replaced.

3

3

Crimp Quality Monitor Not Ready Fault (Refer to Paragraph 4.2.B.)

4

4

Bad Crimp Fault (Refer to Paragraph 4.2.C.)

5

5

Crimp Analysis Fault (Refer to Paragraph 4.2.D.)

6

6

Good Crimp Signal Fault (Refer to Paragraph 4.2.B.)

7

7

Monitor Not Detected (Refer to Paragraph 4.2.A.)

Figure 10

409-32034

Rev D

18 of 31

6. PREVENTIVE MAINTENANCE

Preventive maintenance will keep the machine in good working order and ensure maximum reliability and

service from all of its components.

DANGER

To avoid personal injury, electrical and pneumatic power MUST be DISCONNECTED at the source prior to maintenance.

6.1. Cleaning

Clean debris from the applicator area daily.

DANGER

Compressed air used for cleaning must be reduced to less than 207 kPa [30 psi] and effective chip guarding and personal

protective equipment (including eye protection) must be used.

If an air feed assembly is installed, check and replace the air filter element, if necessary.

Wipe off the guards with a clean, soft cloth.

CAUTION

DO NOT USE A SOLVENT TO CLEAN THE GUARDS. Solvent could damage the guards.

6.2. Lubrication

The moving parts of the machine require regular lubrication to ensure reliable service and long life. The

preferred greases are Chevron Ultra-Duty EP NLGI 2, Chevron Ulti-Plex EP NLGI 2, and Caltex Ultra-Duty EP

NLGI 2.

NOTE

Contact TE Engineering for 2nd choice alternates.

CAUTION

It is important to only use Lithium-based grease with extreme pressure (EP) additives.

NOTE

For operation in temperatures below 10° C [50° F], it will be necessary to use a No. 1 grease.

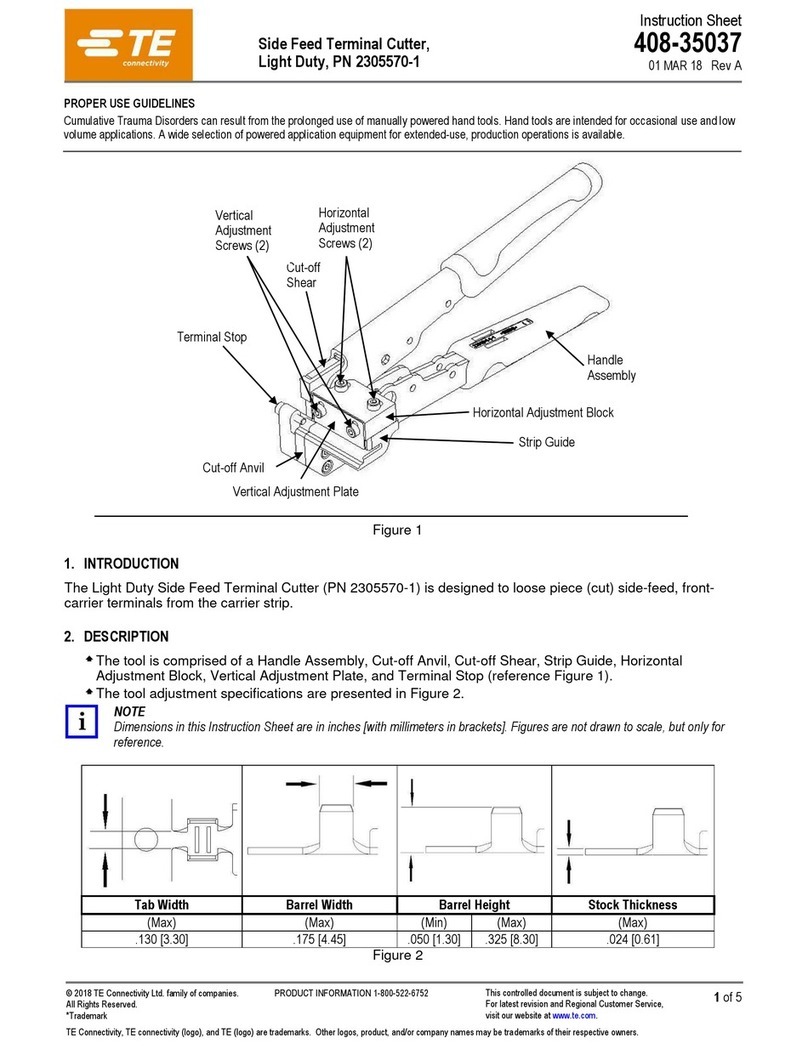

Using a grease gun, apply grease every 250,000 cycles to the fittings at the following locations and as shown

in Figure 11:

the left side of the ram assembly;

the right side of the ram assembly;

the left side of the frame just behind the ram assembly at two places; and

NOTE

Give one pump of grease while the ram is near the top of its stroke and one pump of grease while the ram is near the bottom

of its stroke for best distribution of grease around the bearing.

the crimp height adjuster pivot pin.

Chevron, Caltex, and Lithium are trademarks of their respective owners. NLGI is the National Lubrication and Grease Institute.

409-32034

Rev D

19 of 31

Figure 11

7. ADJUSTMENTS

The following adjustments are necessary to maintain the machine in operating condition, and to set up the

machine after replacing parts.

DANGER

To avoid personal injury, ALWAYS disconnect electrical and air supplies before performing adjustments.

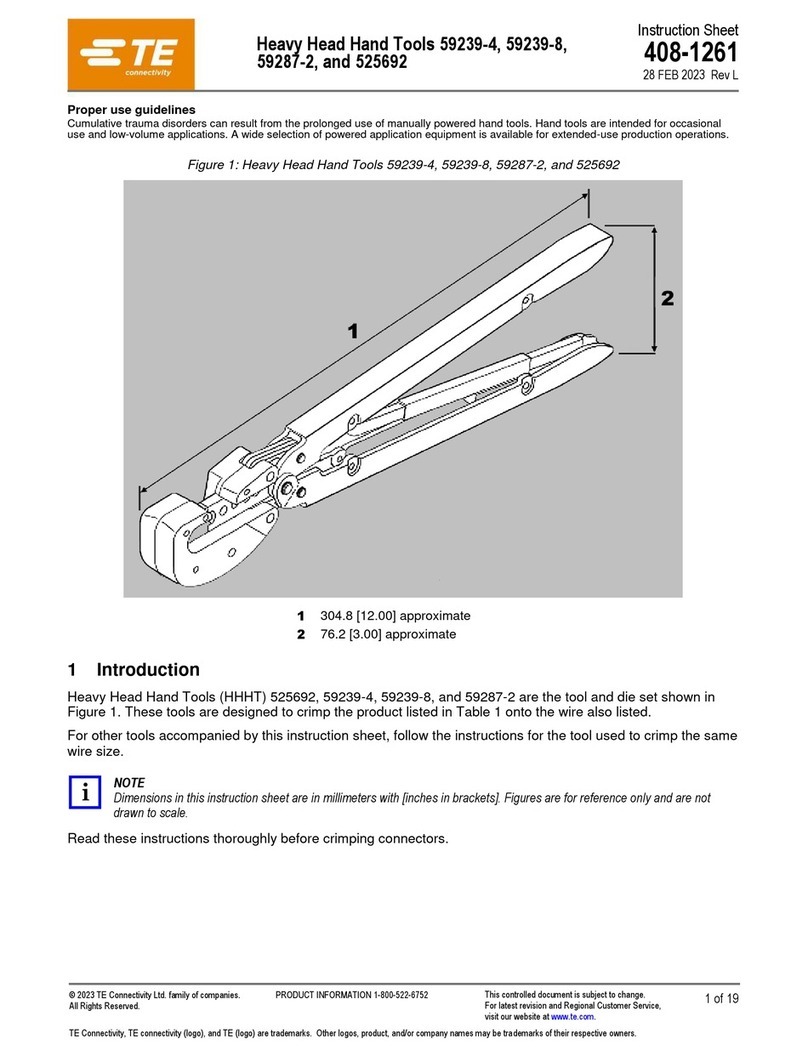

7.1. Measuring the Shut Height

The shut height is the distance between the bottom surface of the ram post adaptor and the top surface of the

machine base plate as shown in Figure 12.

NOTE

Shut Height Gage 679655-[ ] (see the table in Figure 12) is recommended for measuring the shut height (refer to 408-8535 for

instructions on use of the gage).

1. If installed, adjust the manual precision adjustment lever to the “0” crimp setting.

2. Turn off the machine and disconnect the power cord plugged into the receptacle mounted to the motor

end plate (Figure 6).

3. Insert a 6-mm hex wrench into the end of the motor until it completely engages the recess in the end

of the motor. Use the hex wrench to manually rotate the motor.

DANGER

Be sure to remove the hex wrench before operating the machine.

4. Follow the procedure for measuring the shut height as described in 408-8535.

5. Remove the hex wrench when finished and plug in the power cord.

Lubrication Points

Precision Crimp

Height Adjustment

Mechanism

Lubrication

Points

409-32034

Rev D

20 of 31

Figure 12

7.2. Shut-Height Adjustment

The shut height is pre-set at the factory and should not require further adjustment unless it is necessary to

replace parts. Before you make any changes to the machine, contact your local field service representative, or

call the Tooling Assistance Center at 1-800-722-1111.

CAUTION

NEVER attempt to adjust the shut height without FIRST trying an applicator that is known to produce terminations of the

correct crimp height. If this applicator produces correct terminations, the trouble is in the original applicator and the shut height

MUST NOT BE CHANGED.

If it is determined that the shut height must be adjusted, use the following procedure:

DANGER

To avoid personal injury, ALWAYS turn "off" the machine and disconnect the power supply to the machine before making any

adjustments. If applicator is an air-feed type, DISCONNECT air lines to valve located on the right side of the machine.

1. Check shut height as described in Paragraph 7.1.

2. If the shut height is incorrect, refer to Figure 13, and proceed as follows:

a. Remove the two socket head cap screws which secure the ram post adaptor. Remove the ram

post adaptor and shims. Change the shim thickness as required to adjust the shut height. Shims

contain .051-mm [.002-in.] peel-type laminations.

NOTE

If additional shims are required, they can be ordered using the numbers 1338618-1 (for 41.25 mm stroke machines) or

1424680-1 (for 30 mm stroke machines).

Precision Crimp

Height Adjustment

Mechanism

SHUT HEIGHT GAGE

PART NUMBER

SHUT HEIGHT

DIMENSIONS

BASE PLATE

STYLE

679655-2

135.79 mm ±0.025 mm

[5.346 ±.0010 in.]

AMP

UNIVERSAL

679655-3

119.50 ±0.025 mm

[4.7047 ±.0010 in.]

JAM

This manual suits for next models

1

Table of contents

Other TE Crimping Tools manuals