T2 and Terminator Crimp Module

Doc. No: TM-638018500 Release Date: 11-26-12 UNCONTROLLED COPY age 2 of 39

Revision: A Revision Date: 11-26-12

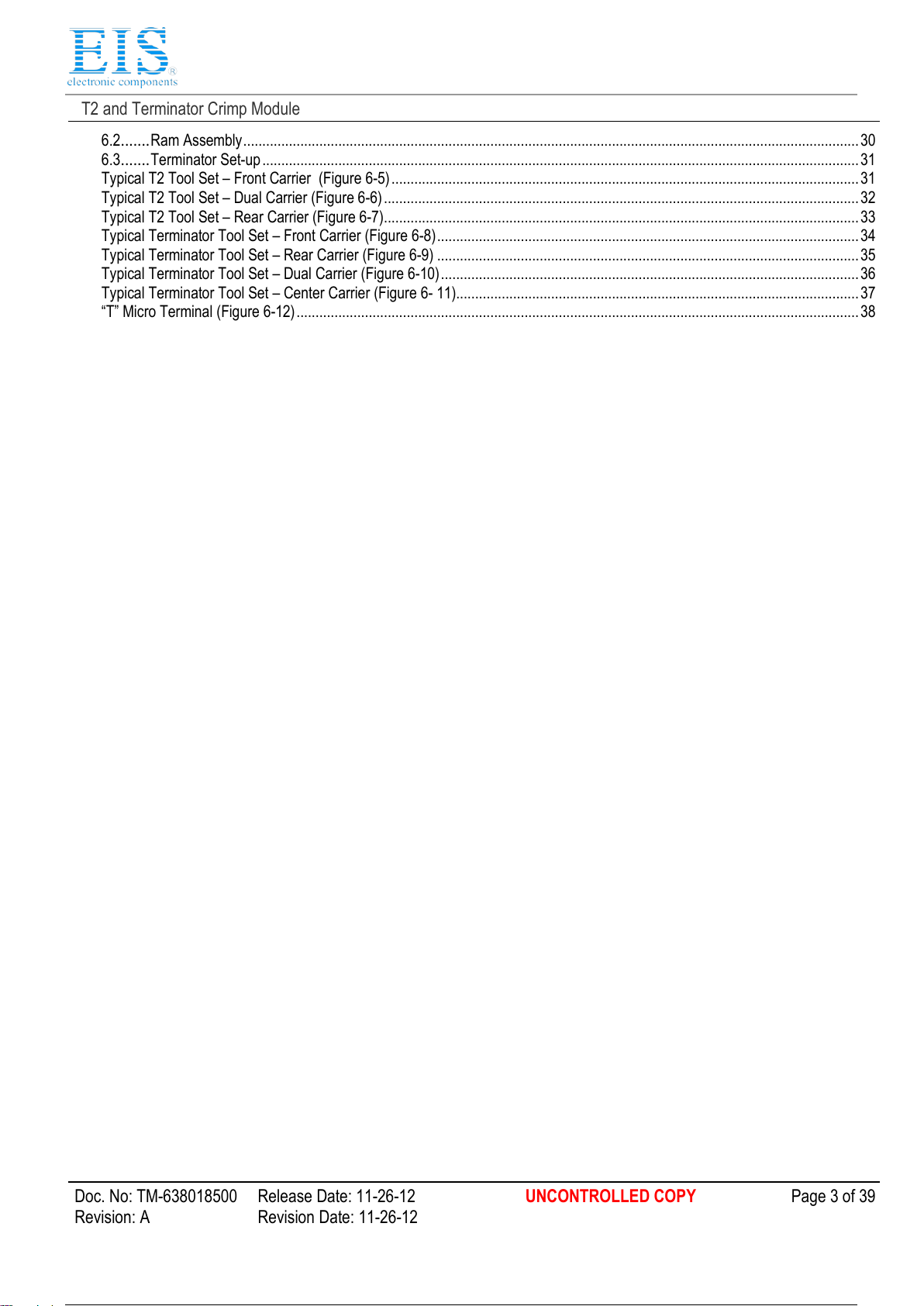

Table of Contents

Contents

T2™ and Terminator Crimp Module ......................................................................................................................................................... 1

Safety Warnings and Information.............................................................................................................................................................. 4

Tooling Technical Assistance ................................................................................................................................................................... 5

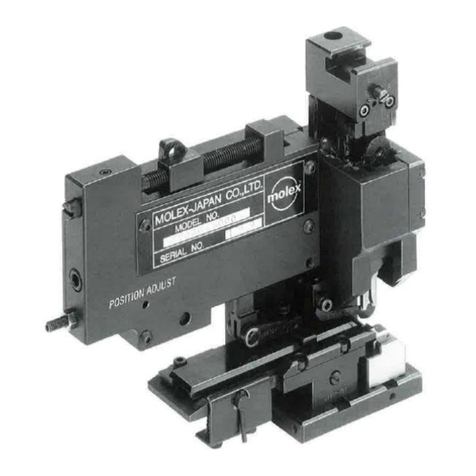

rincipal Mechanical arts of the Crimp Module ...................................................................................................................................... 6

Section 1 ............................................................................................................................................................................................... 7

General Description ......................................................................................................................................................................... 7

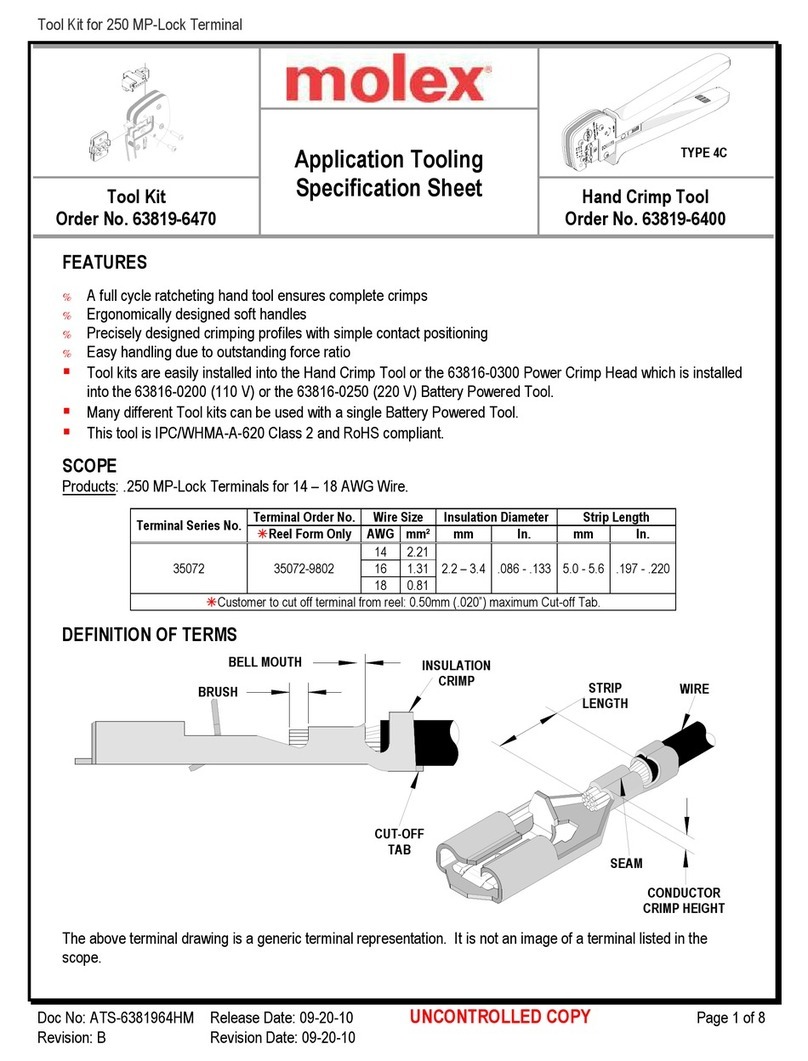

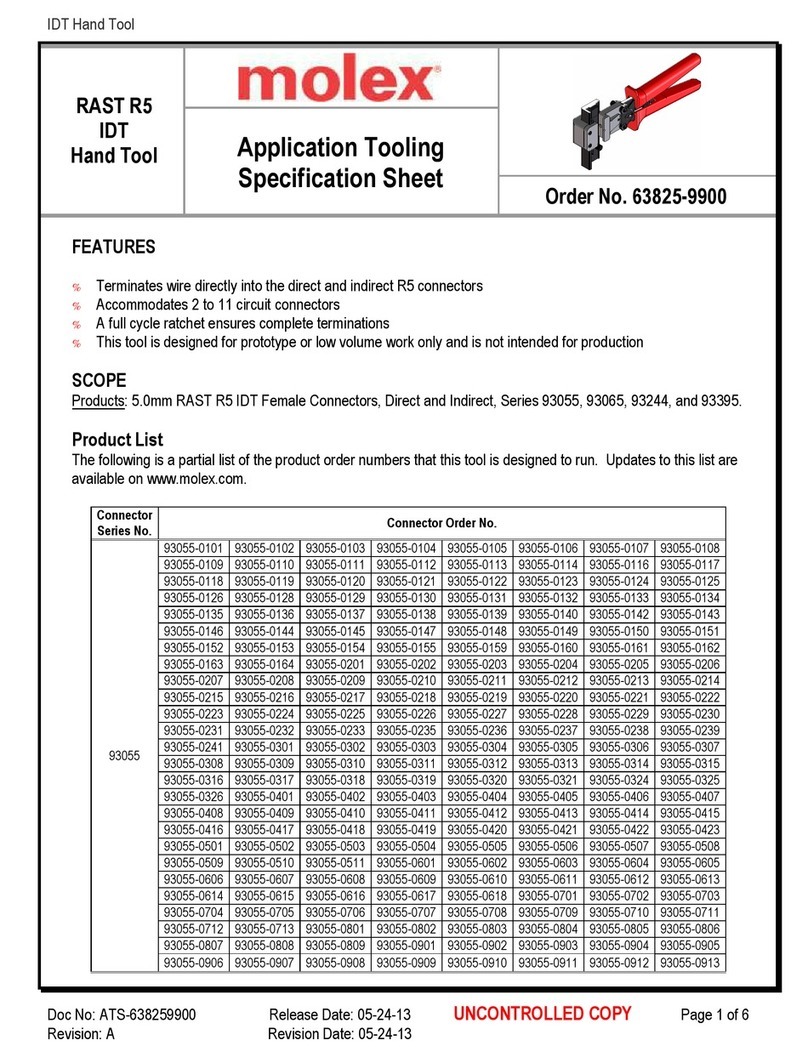

1.1 ....... Description .......................................................................................................................................................................... 7

1.2 ....... Features .............................................................................................................................................................................. 7

1.3 ....... Technical Specification ....................................................................................................................................................... 7

1.4 ....... Delivery Check .................................................................................................................................................................... 7

1.5 ....... Crimp Tooling Accessories (optional) ................................................................................................................................. 7

1.6 ....... Tools ................................................................................................................................................................................... 7

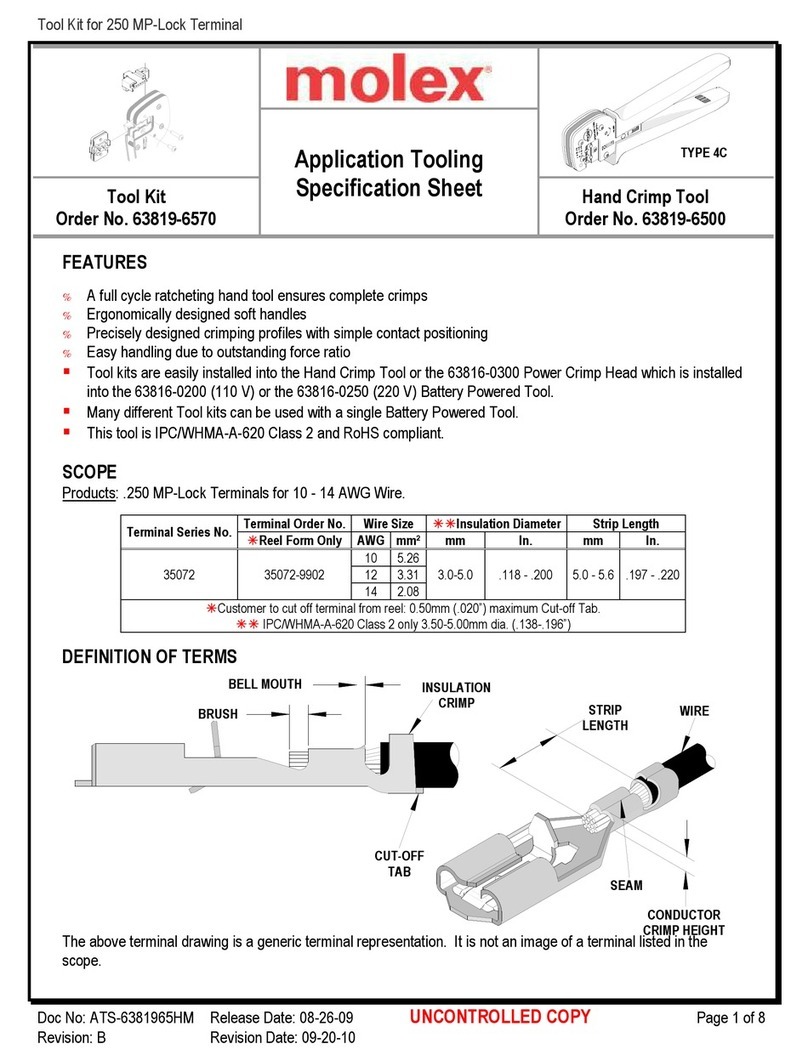

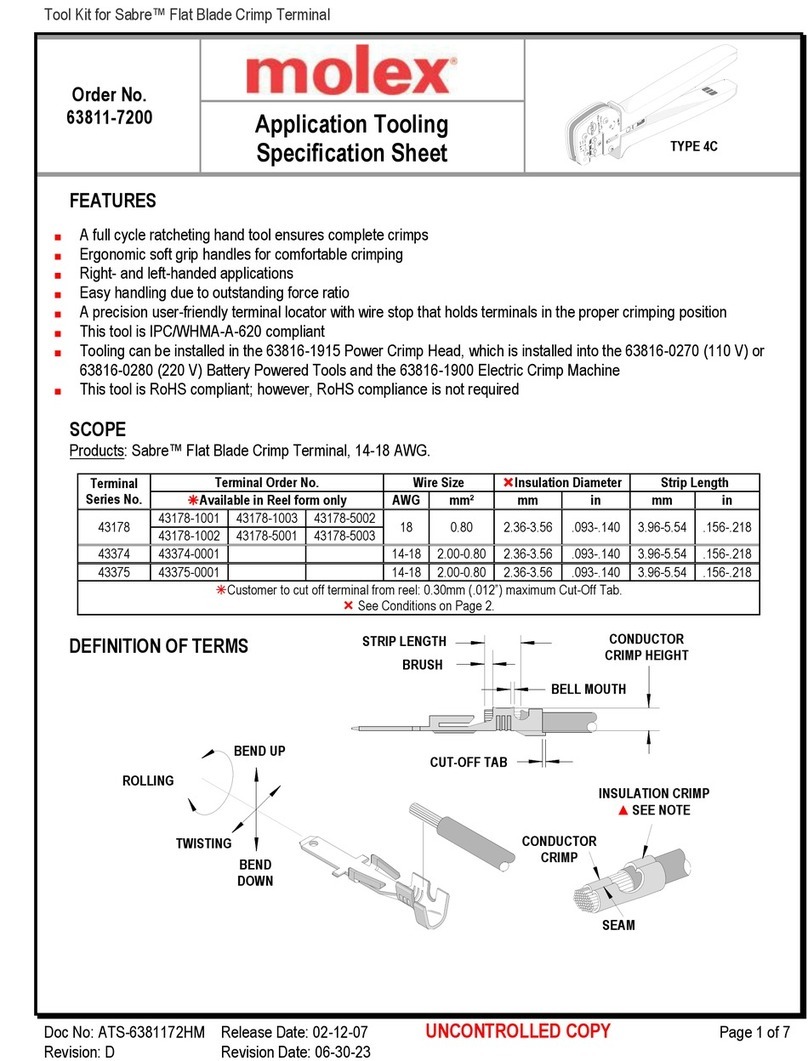

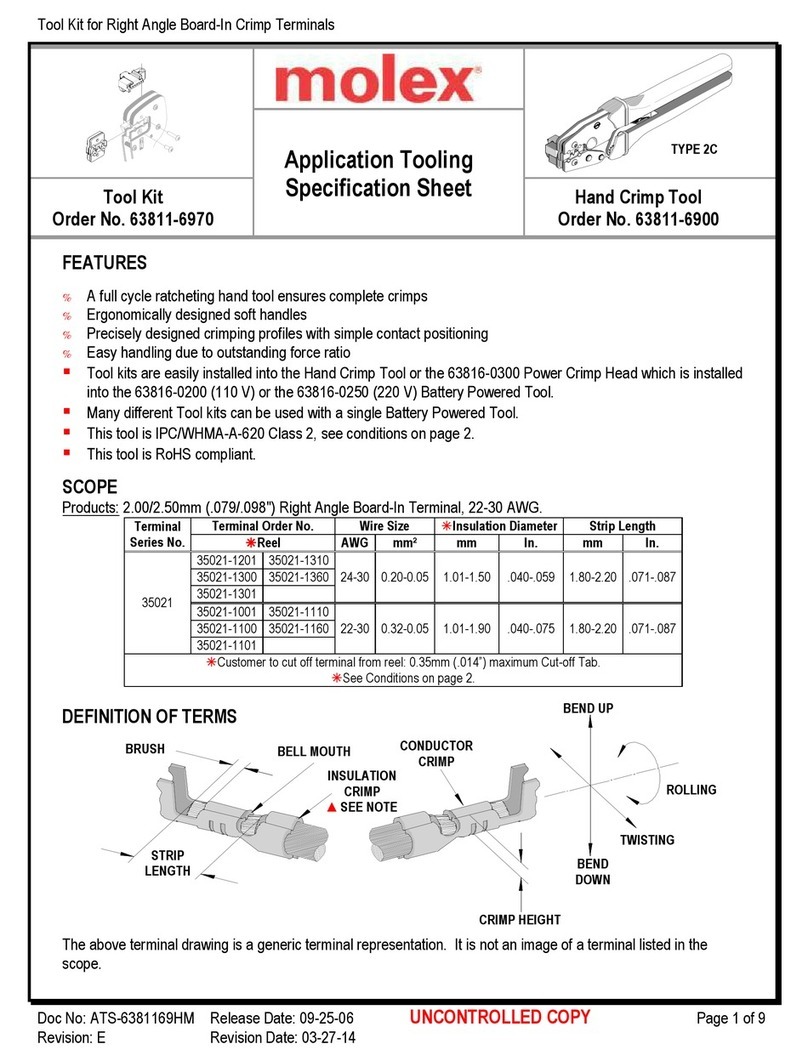

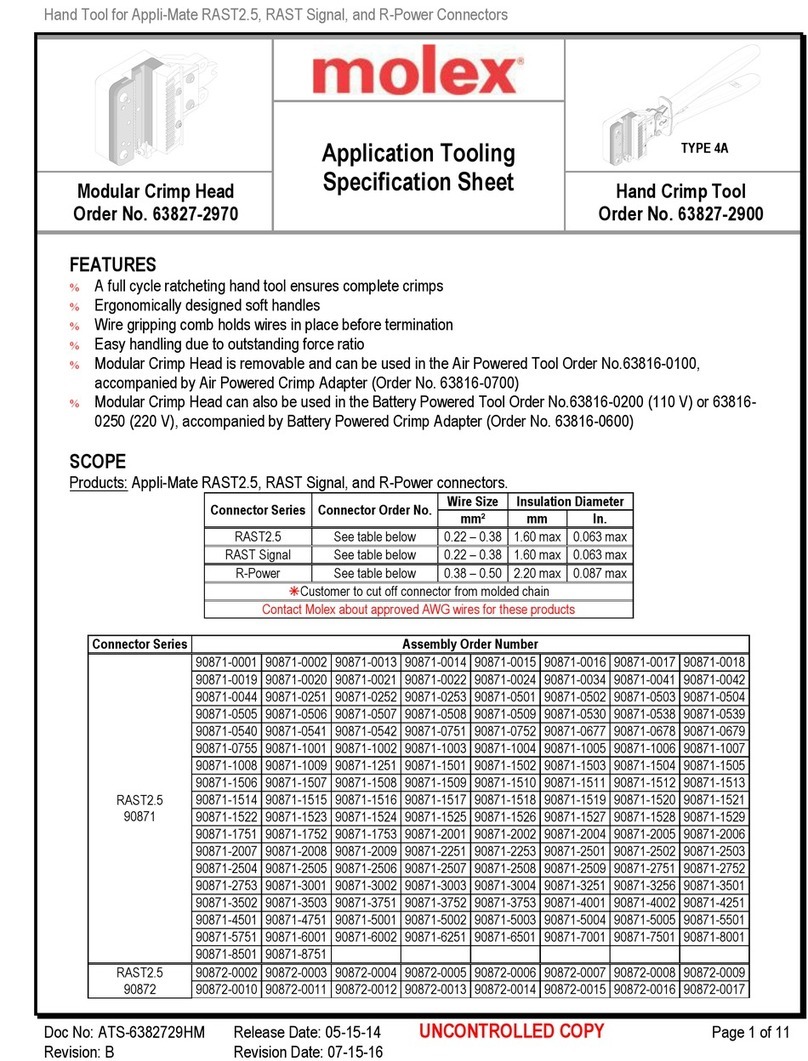

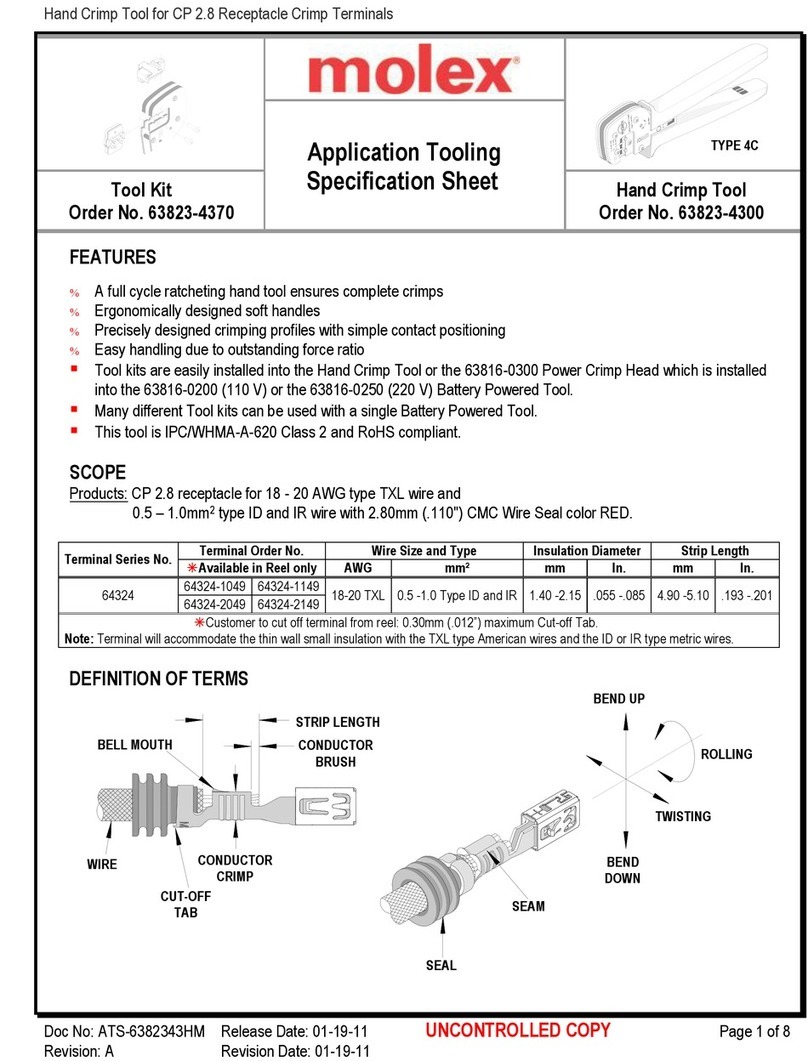

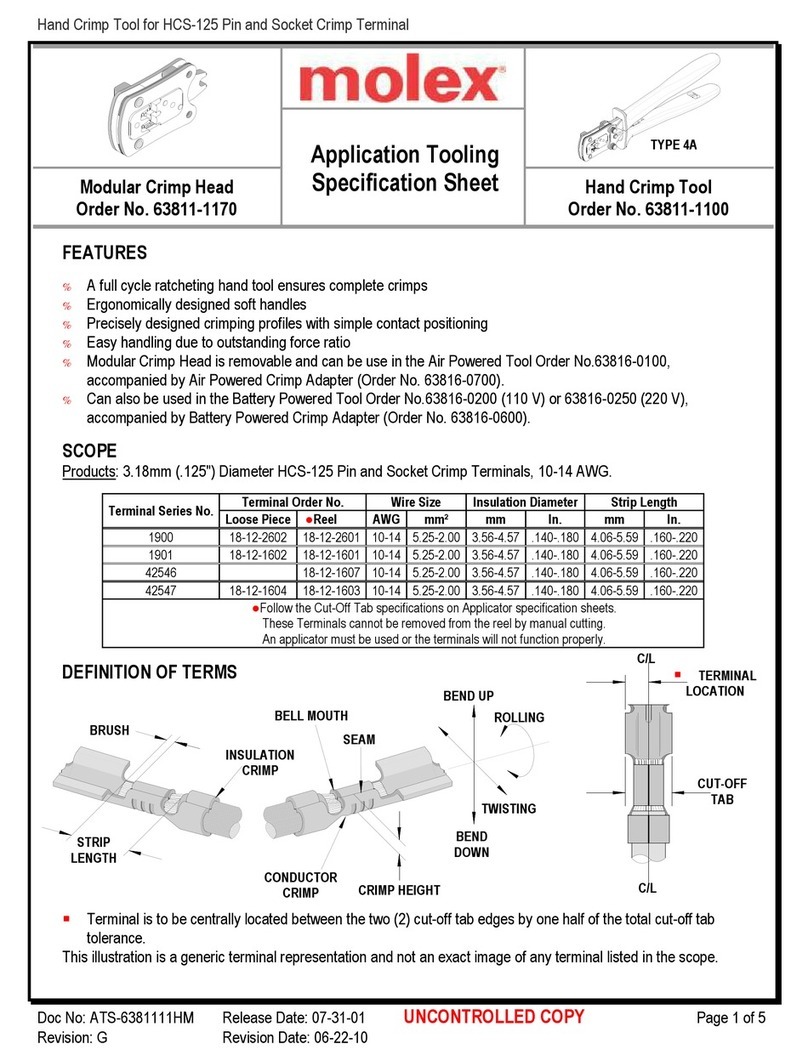

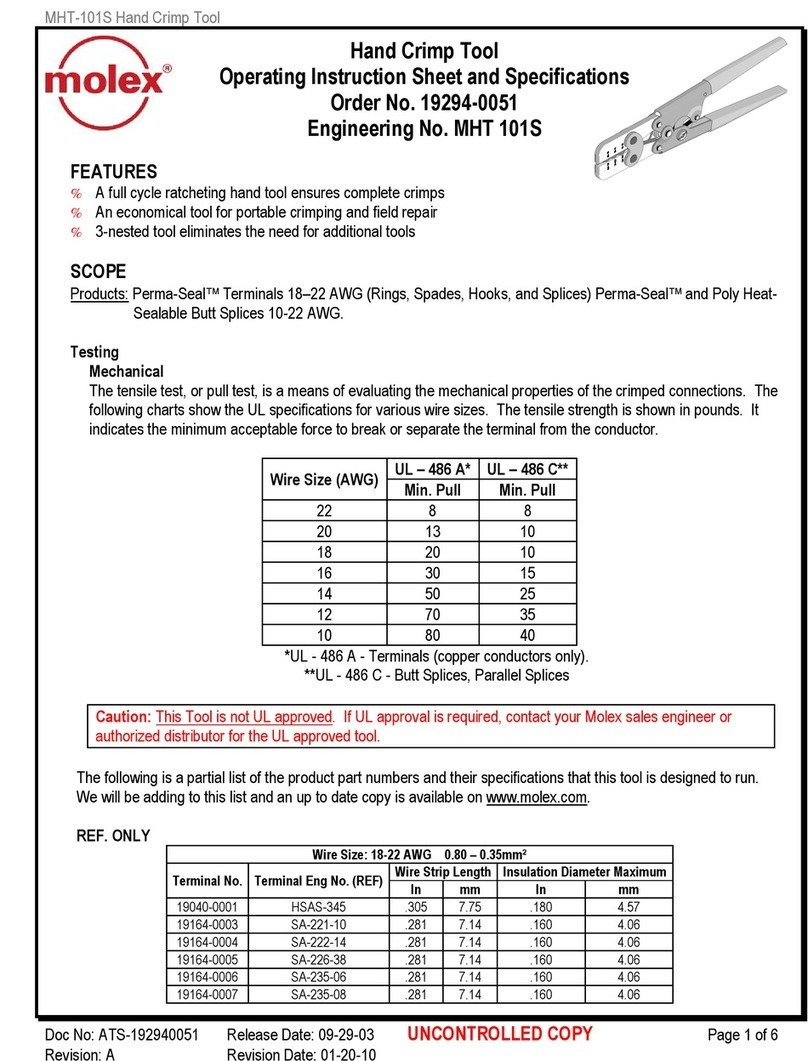

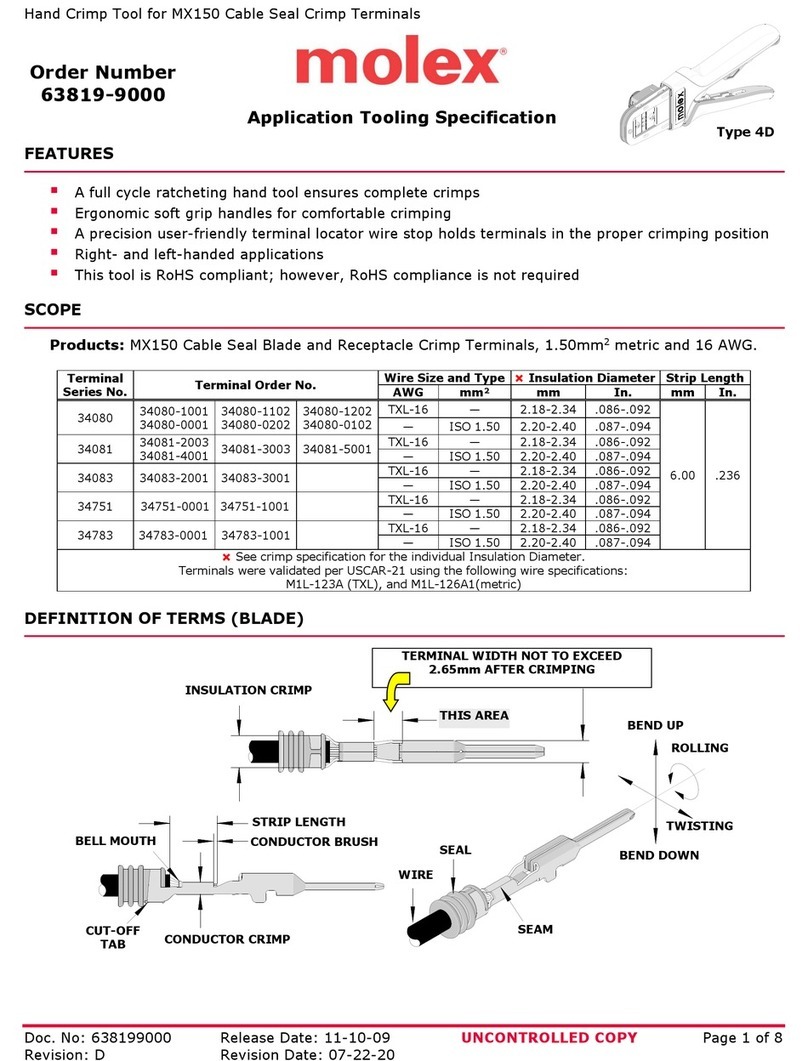

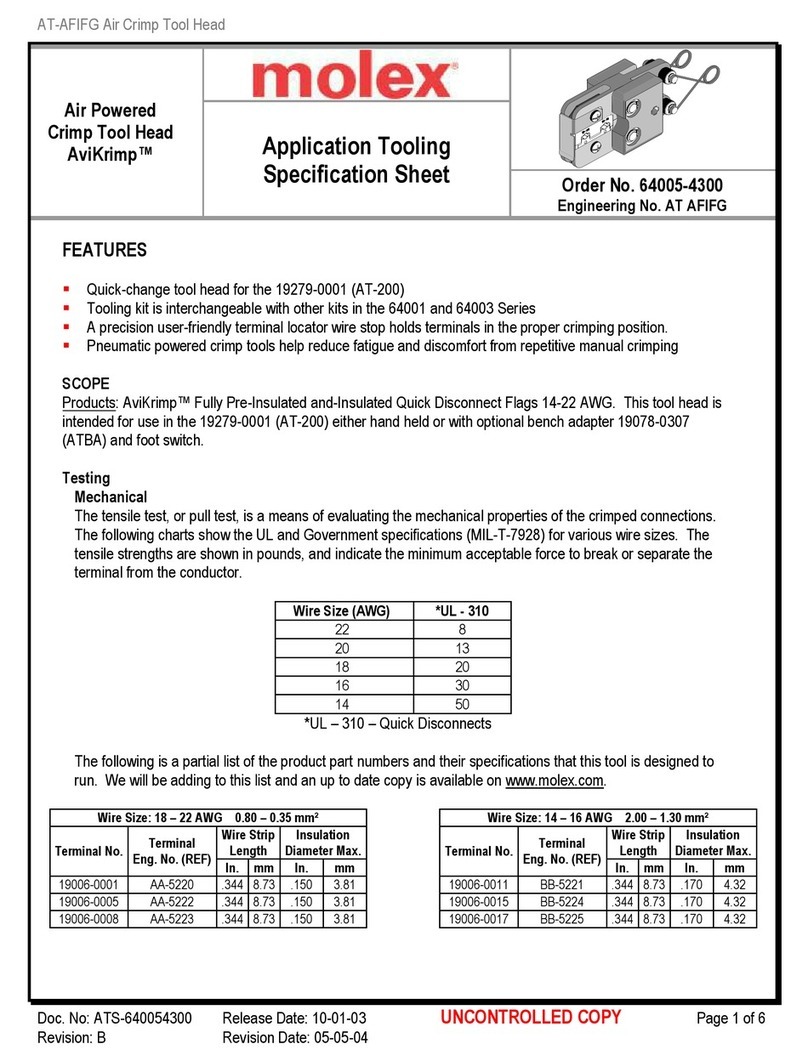

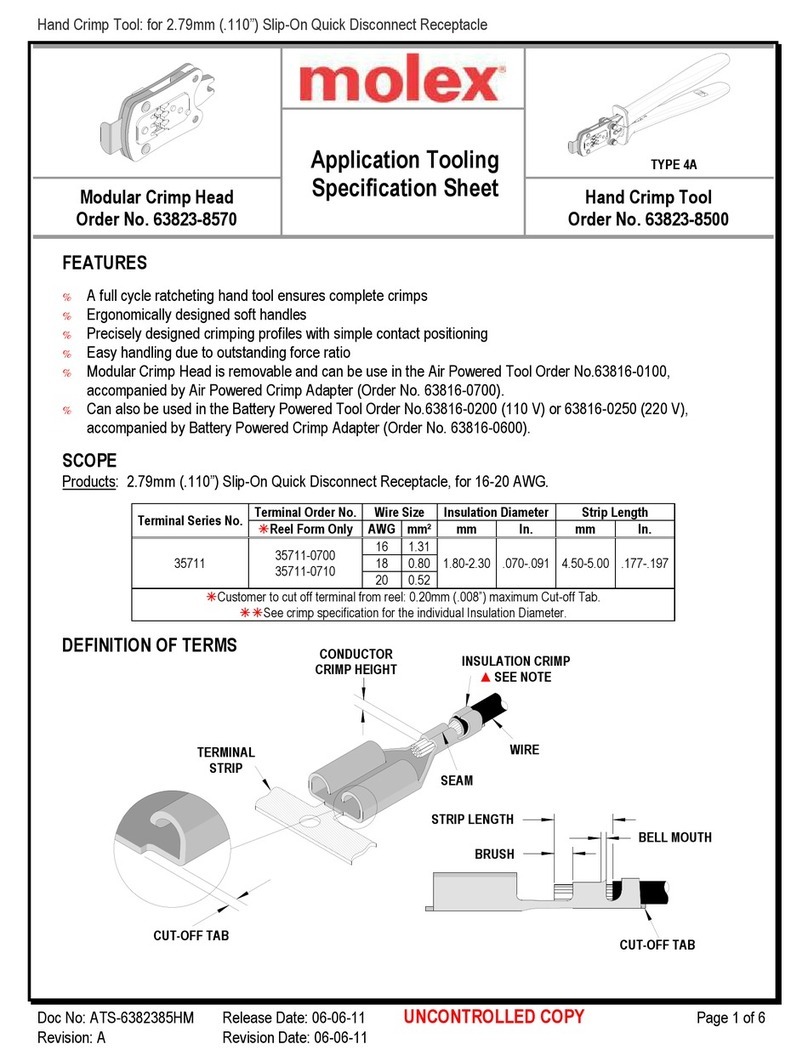

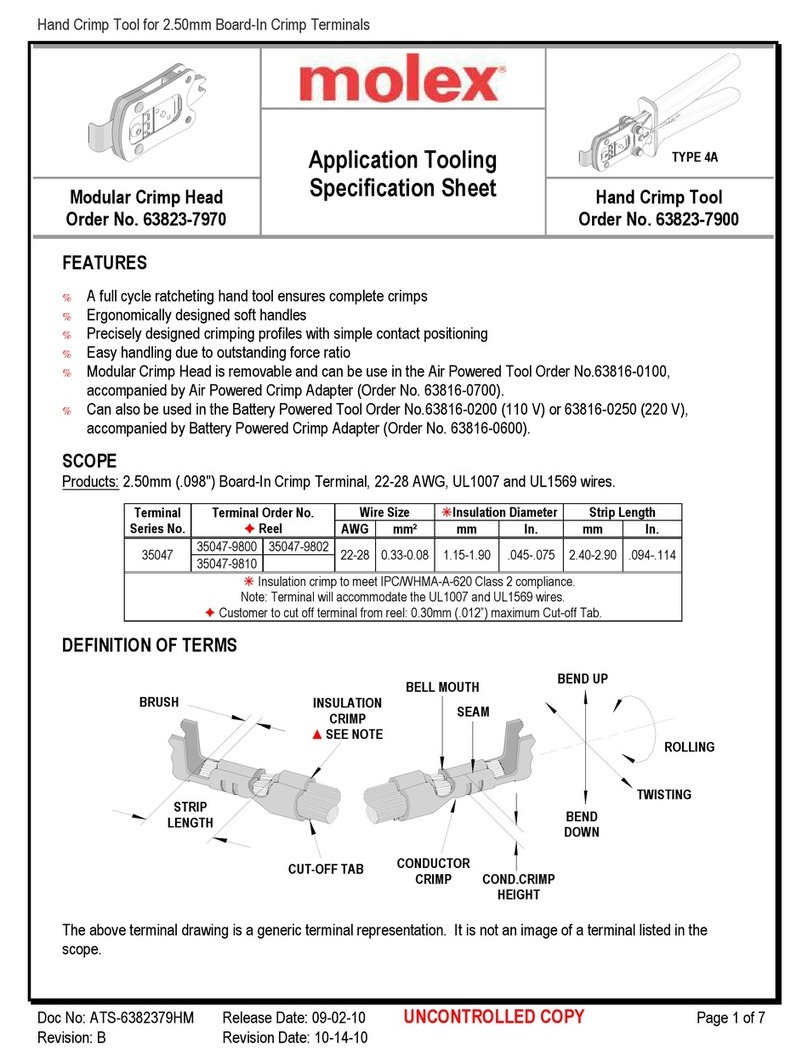

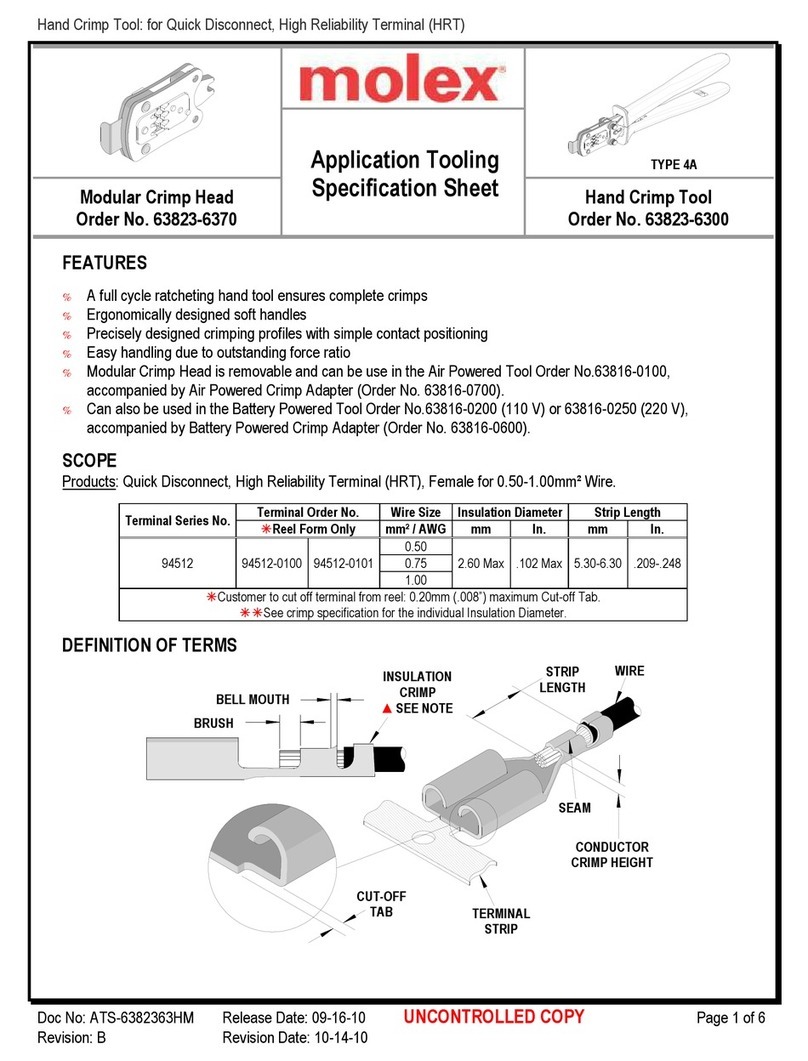

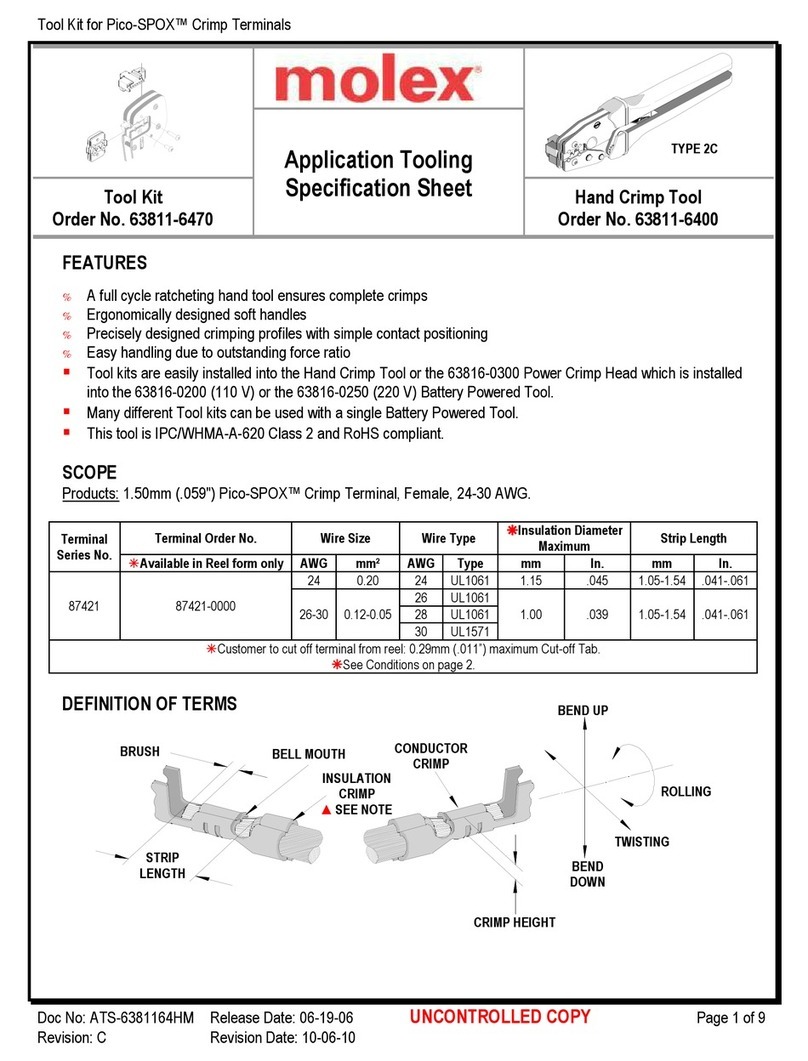

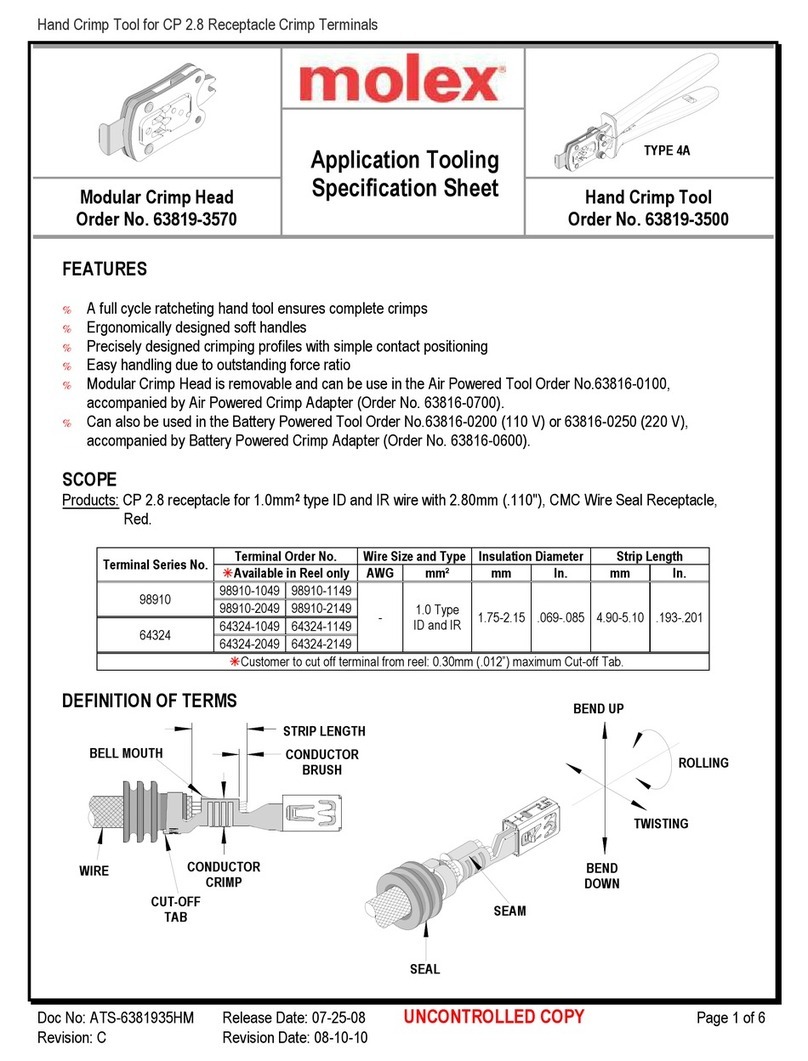

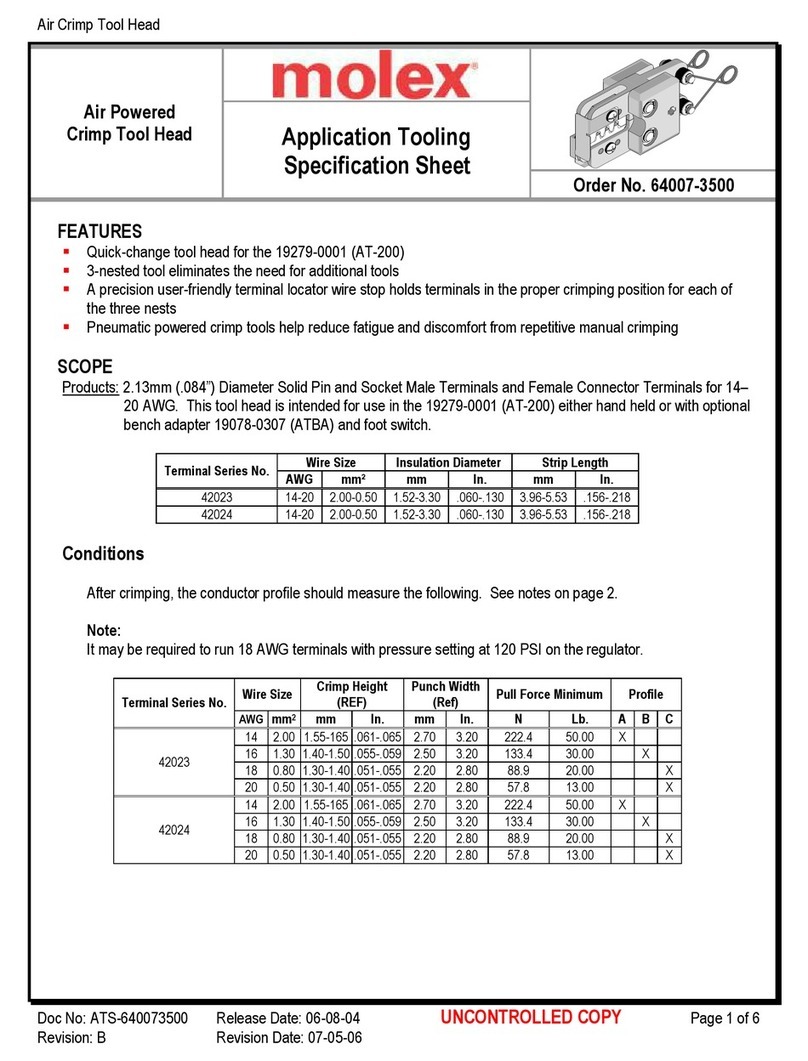

1.7 ....... Application Tooling Specification Sheets ............................................................................................................................ 7

Section 2 ............................................................................................................................................................................................... 9

Set-Up and Operation ...................................................................................................................................................................... 9

2.1 ....... Shut Height ......................................................................................................................................................................... 9

2.2 ....... How to Manually Cycle the ress ..................................................................................................................................... 10

2.3 ....... Crimp Module Installation and Removal ........................................................................................................................... 10

2.4 ....... Tool Set Removal and Installation .................................................................................................................................... 11

2.5 ....... A Quick Checklist rior To The First Crimp ...................................................................................................................... 13

2.6 ....... Conductor Crimp Height Adjustment ................................................................................................................................. 14

2.7 ....... Insulation Crimp Height Adjustment .................................................................................................................................. 14

Section 3 ............................................................................................................................................................................................. 15

Troubleshooting ............................................................................................................................................................................. 15

Section 4 ............................................................................................................................................................................................. 16

Adjustments ................................................................................................................................................................................... 16

4.1. ...... unch and Anvil Alignment ............................................................................................................................................... 16

4.2. ...... Wire Stop Adjustment ....................................................................................................................................................... 16

4.3 ....... Rear Cover Adjustments ................................................................................................................................................... 17

4.4 ....... Track osition Adjustment (T2 tools only) ......................................................................................................................... 18

4.5 ....... Feed Finger Alignment ...................................................................................................................................................... 18

4.7 ....... Terminal Forward Feed Adjustment (Centering the Terminal to the Anvils) ..................................................................... 20

4.8 ....... Back Stroke Feed Adjustments (Terminal pitch or spacing on the strip) ........................................................................... 20

4.9 ....... Crimp Tooling Installation and Removal ........................................................................................................................... 21

Section 5 ............................................................................................................................................................................................. 23

Maintenance .................................................................................................................................................................................. 23

5.1 ....... Cleaning ............................................................................................................................................................................ 23

5.2 ....... Lubrication ........................................................................................................................................................................ 23

5.3 ....... Spare arts ....................................................................................................................................................................... 24

5.4 ....... erishable arts ................................................................................................................................................................ 24

5.5 ....... Crimp Module Storage ...................................................................................................................................................... 25

Section 6 ............................................................................................................................................................................................. 26

6.1 ....... Main arts List .................................................................................................................................................................. 26

6.2 ....... Frame Assembly ............................................................................................................................................................... 28

6.2 ....... Feed Assembly ................................................................................................................................................................. 29