TE 2305570-1 User manual

Instruction Sheet

1 of 5

© 2018 TE Connectivity Ltd. family of companies.

All Rights Reserved.

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product, and/or company names may be trademarks of their respective owners.

PRODUCT INFORMATION

1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com.

408-35037

01 MAR 18 Rev A

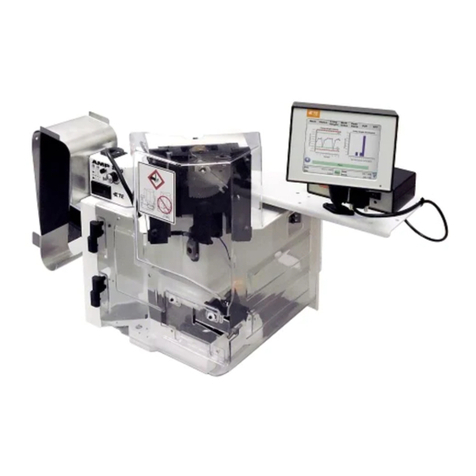

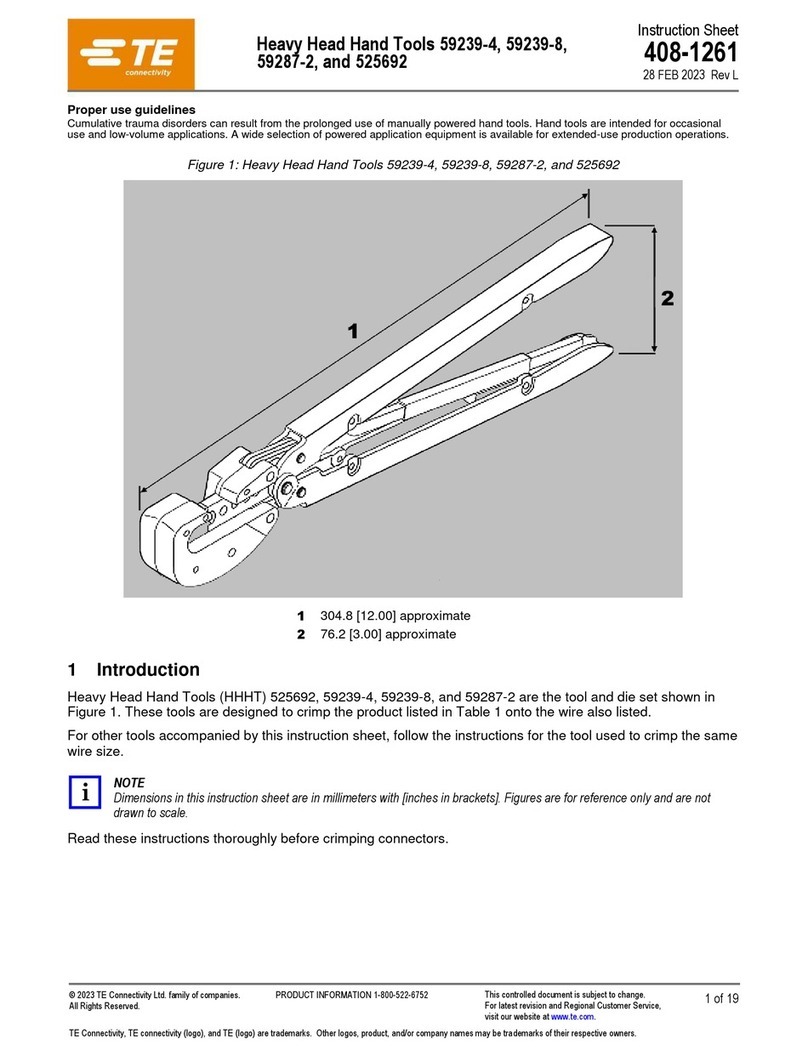

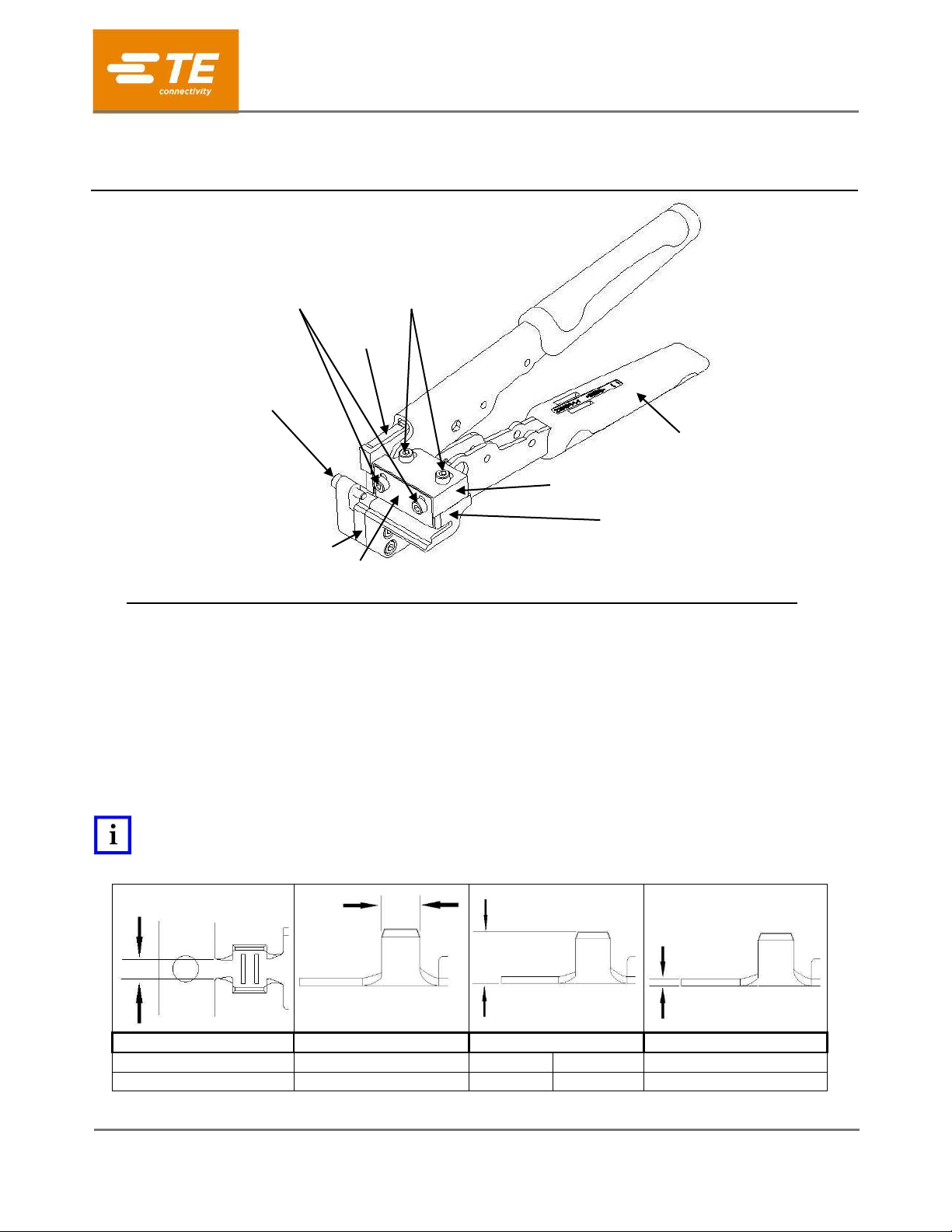

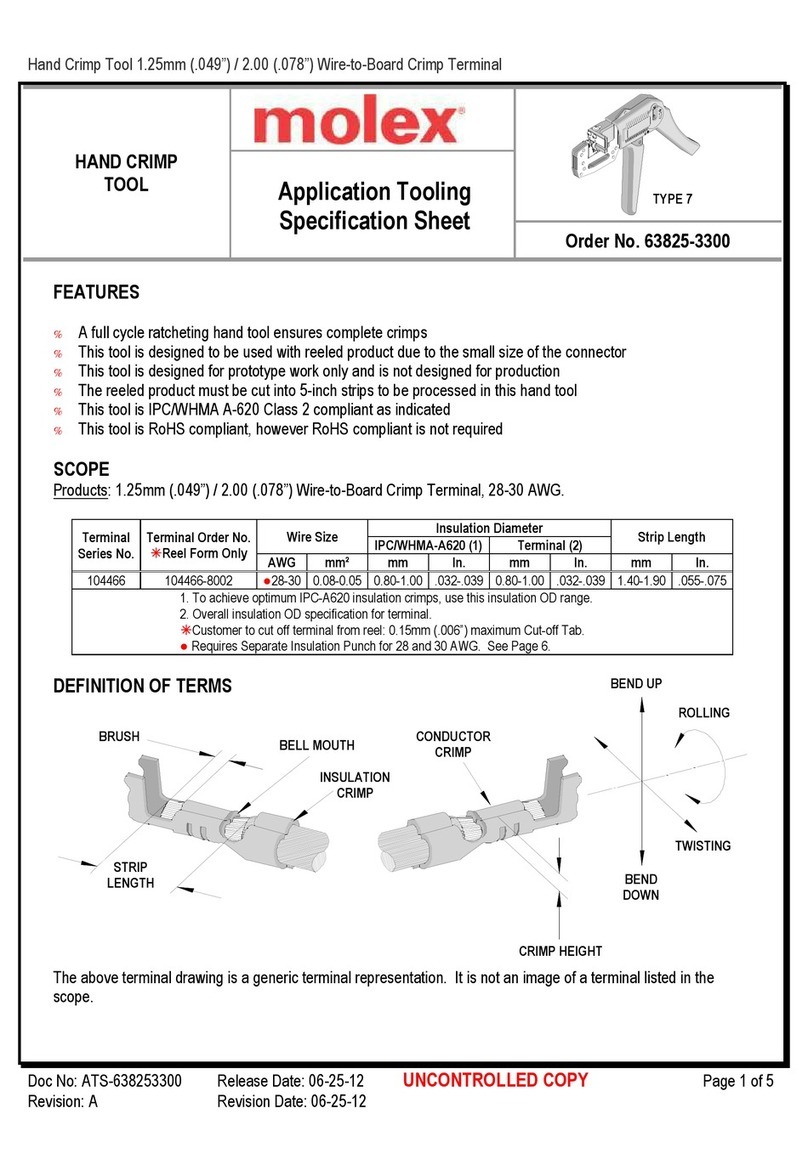

Figure 1

1. INTRODUCTION

The Light Duty Side Feed Terminal Cutter (PN 2305570-1) is designed to loose piece (cut) side-feed, front-

carrier terminals from the carrier strip.

2. DESCRIPTION

The tool is comprised of a Handle Assembly, Cut-off Anvil, Cut-off Shear, Strip Guide, Horizontal

Adjustment Block, Vertical Adjustment Plate, and Terminal Stop (reference Figure 1).

The tool adjustment specifications are presented in Figure 2.

NOTE

Dimensions in this Instruction Sheet are in inches [with millimeters in brackets]. Figures are not drawn to scale, but only for

reference.

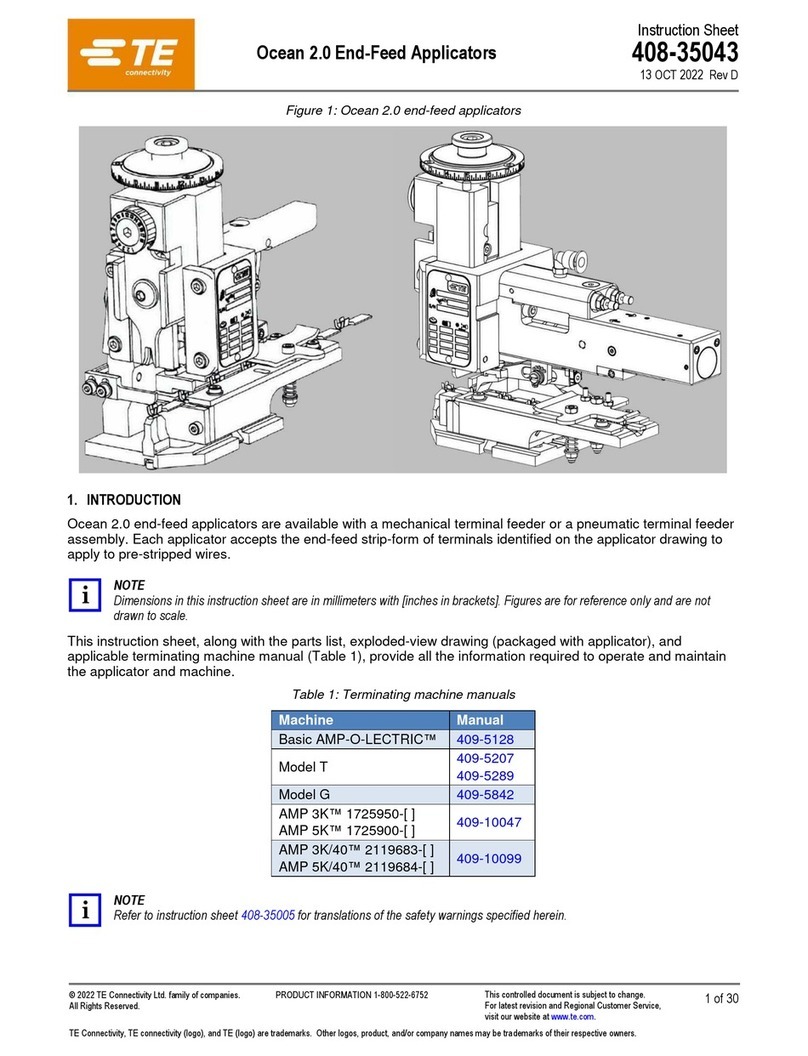

Tab Width

Barrel Width

Barrel Height

Stock Thickness

(Max)

(Max)

(Min)

(Max)

(Max)

.130 [3.30]

.175 [4.45]

.050 [1.30]

.325 [8.30]

.024 [0.61]

Figure 2

PROPER USE GUIDELINES

Cumulative Trauma Disorders can result from the prolonged use of manually powered hand tools. Hand tools are intended for occasional use and low

volume applications. A wide selection of powered application equipment for extended-use, production operations is available.

Side Feed Terminal Cutter,

Light Duty, PN 2305570-1

Horizontal

Adjustment

Screws (2)

Cut-off

Shear

Terminal Stop

Handle

Assembly

Horizontal Adjustment Block

Strip Guide

Vertical Adjustment Plate

Cut-off Anvil

Vertical

Adjustment

Screws (2)

408-35037

Rev A

2 of 5

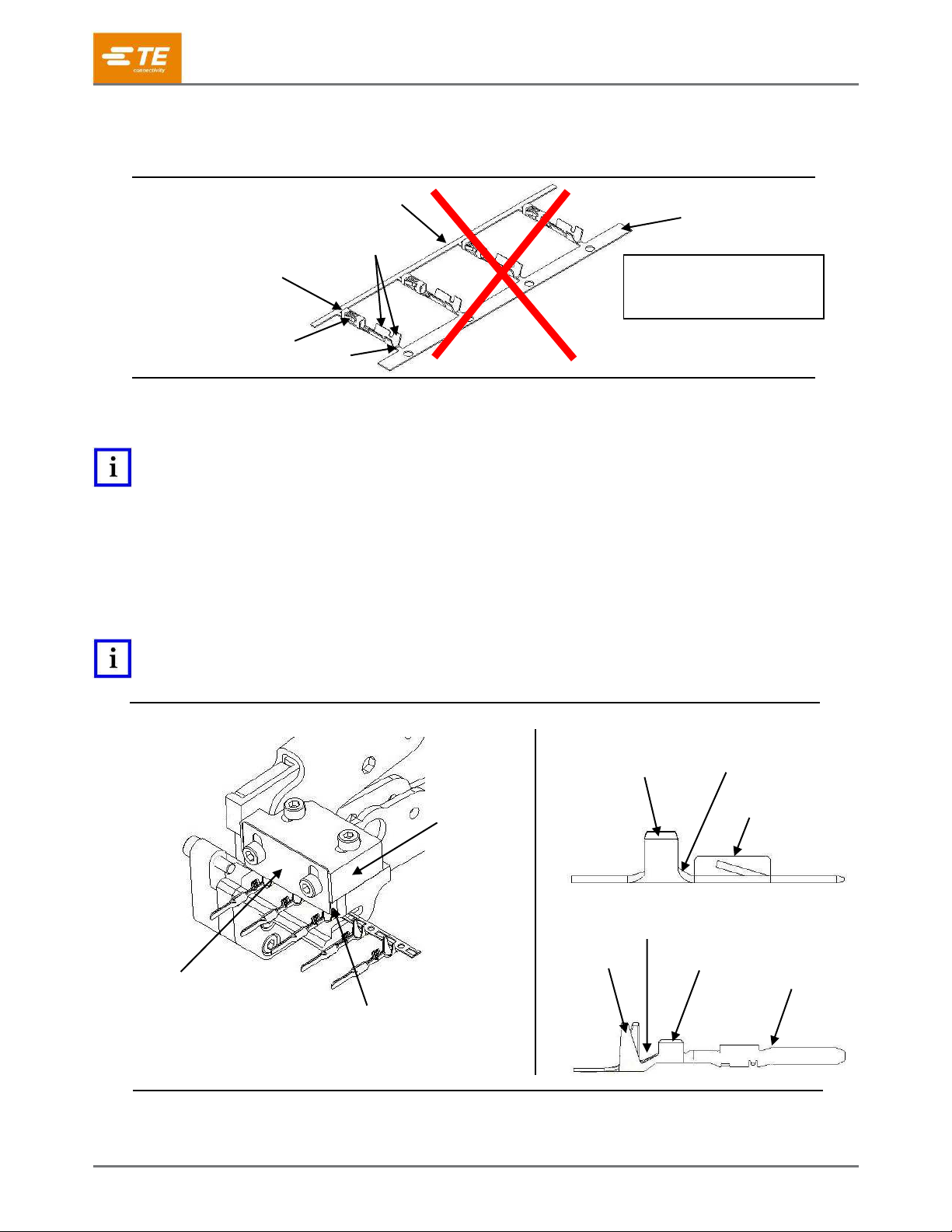

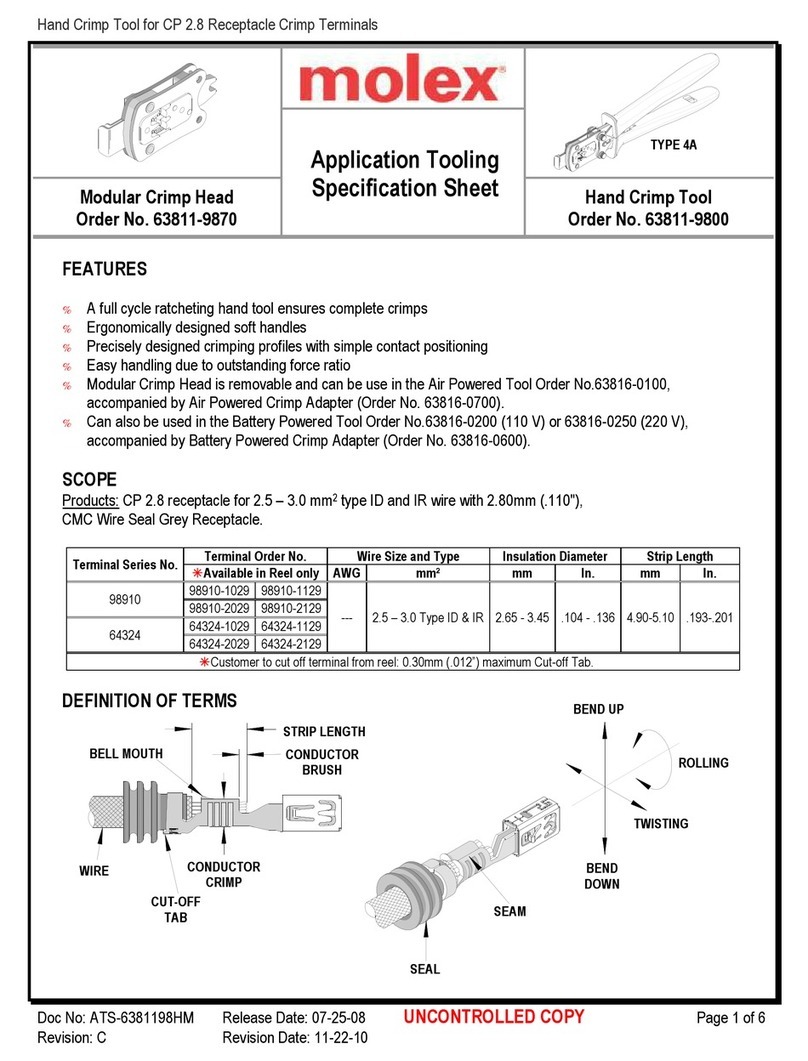

3. TERMINAL DESCRIPTION

NOTE

This tool is designed specifically to loose piece side-feed front-carrier terminals. Tool is not designed to loose piece end-

feed, center-carrier or dual-carrier terminals.

3.1. Side-Feed Front-Carrier Terminals

Terminal consisting of a contact body, crimp barrels, tab and single-carrier strip located adjacent to the crimp

barrels.

Figure 3

3.2. End-Feed Terminals

Terminal consisting of a contact body, crimp barrels and tab. The tab is located between the contact body

and crimp barrels of the next terminal in sequence.

Figure 4

3.3. Center-Carrier Terminals

Terminal consisting of a contact body, crimp barrels (or other style termination feature) and tab. The tab is

located between the contact bodies of the terminals.

Figure 5

Contact Body

Tab

Carrier Strip

Crimp Barrels

Contact Body

Crimp Barrels

Tab

Tab

Crimp Barrels (or Other

Style Termination Feature

Contact Body

This Style of Terminal

CANNOT

Be Used with the Cutter

This Style of Terminal

CANNOT

Be Used with the Cutter

408-35037

Rev A

3 of 5

3.4. Dual-Carrier Terminals

Terminal consisting of a contact body, crimp barrels, a tab and carrier strip adjacent to the crimp barrels of

the contact, and, a tab and carrier strip adjacent to the contact body portion of the contact.

Figure 6

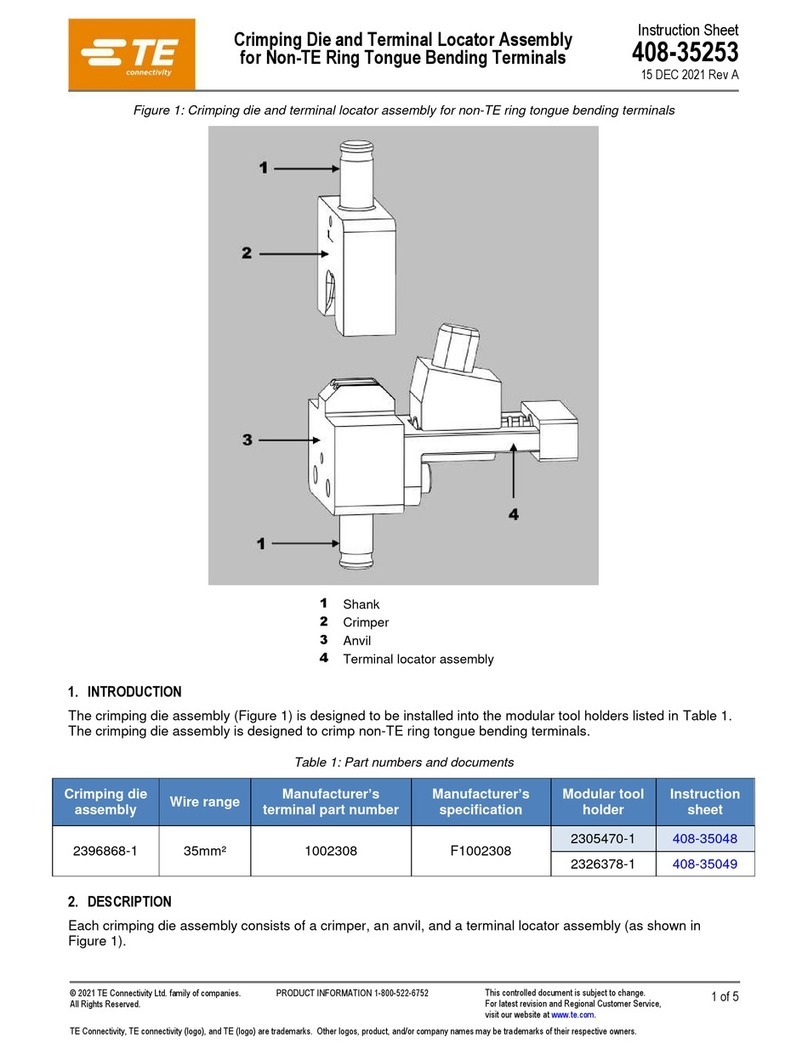

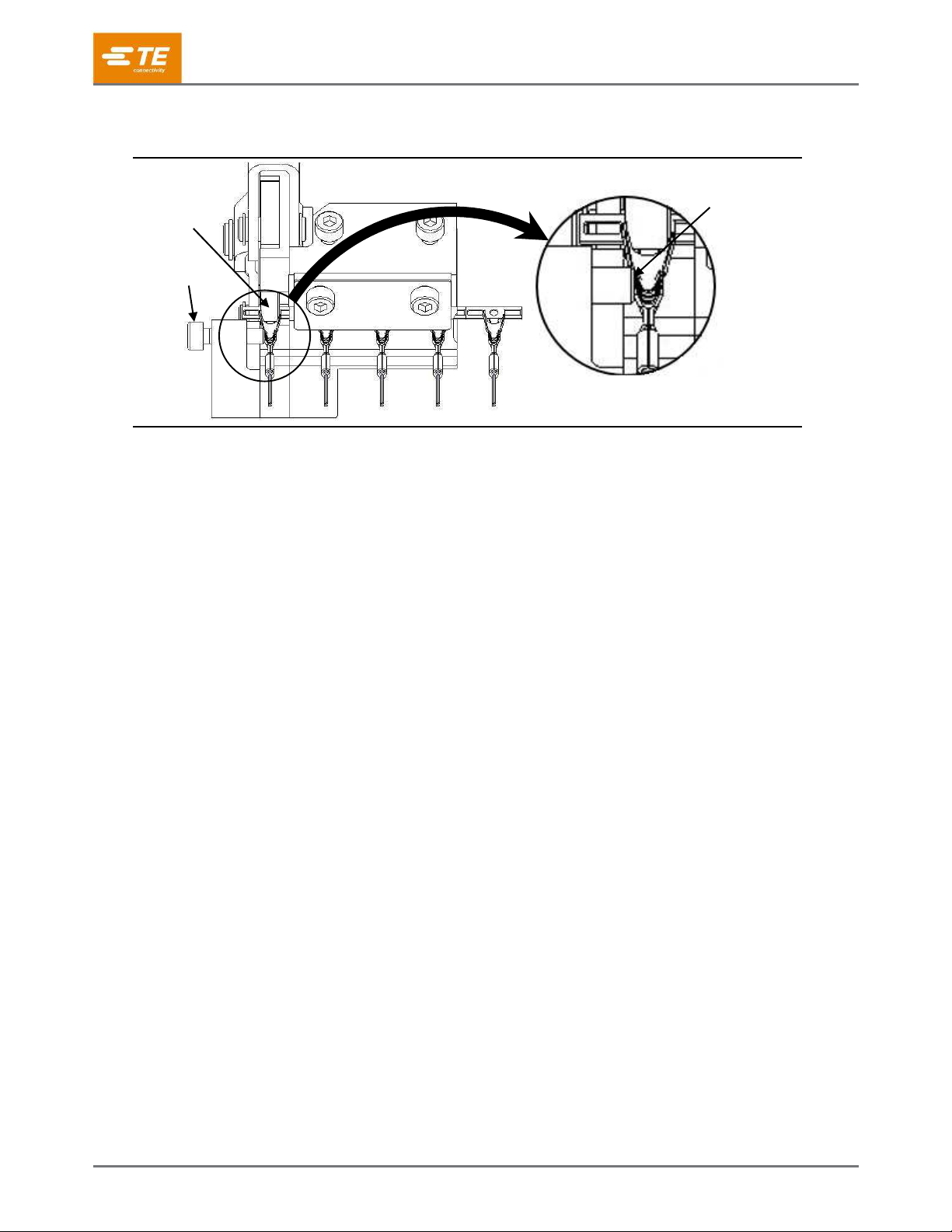

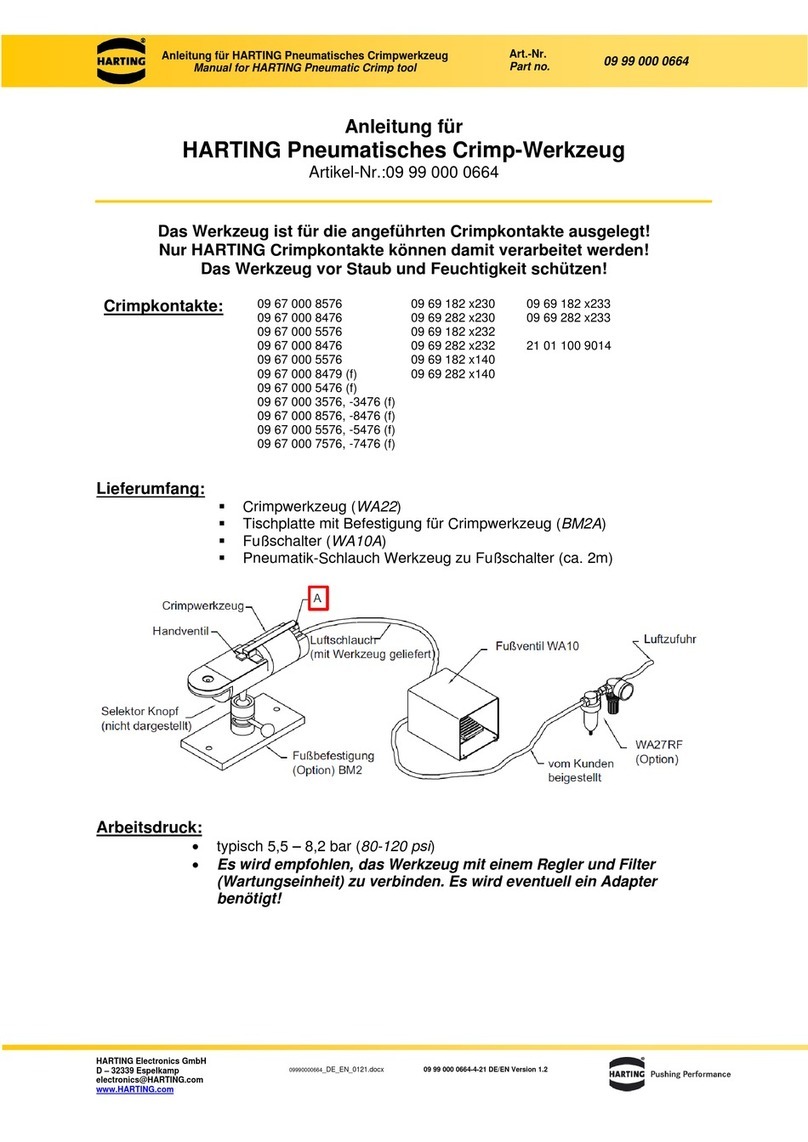

4. ADJUSTMENT PROCEDURE [FIGURE 7]

NOTE

The adjustment procedure is performed most easily with a small strip of terminals - approximately 4 to 5.

1. Loosen the Vertical and Horizontal Adjustment Screws just enough to allow the Vertical Adjustment

Plate and Horizontal Adjustment Block to move.

2. Move the Vertical Adjustment Plate and Horizontal Adjustment Block so the terminal strip can be

inserted into the Strip Guide; positioning the contact barrel against the Strip Guide surface indicated

(see Figure 7).

3. Lower the Vertical Adjustment Plate into the transition area between the Insulation Barrel and the

Wire Barrel of the terminal.

NOTE

Some terminals do not have an Insulation Barrel –in that case, use the transition area between the Wire Barrel and the

Contact Body to set up the tool (see Figure 7; Contact Details).

Figure 7

Wire Barrel

Transition Area

Contact Body

Contact Body

Wire Barrel

Transition Area

Insulation

Barrel

Vertical

Adjustment

Plate

Locate Terminal Against

Strip Guide Surface

Horizontal

Adjustment

Block

Contact Details

Tab

Crimp Barrels

Contact Body

Tab

Carrier Strip

This Style of Terminal

CANNOT

Be Used with the Cutter

Carrier Strip

408-35037

Rev A

4 of 5

4. Rotate the tool in a vertical orientation.

a. Slide the Horizontal Adjustment Block towards the tool handles, allowing the Vertical Adjustment

Plate to rest on the appropriate crimp barrel.

b. Position the Vertical Adjustment Plate in the transition area of the terminal, allowing clearance

between the Vertical Adjustment Plate and the transition area to prevent the terminal from

binding in the tool.

c. Tighten the Vertical Adjustment Screws.

d. With the Vertical Adjustment Plate resting on the appropriate crimp barrel, tighten the Horizontal

Adjustment Screws.

CAUTION

Do not over-tighten any of the adjustment screws, as damage to the tool may occur.

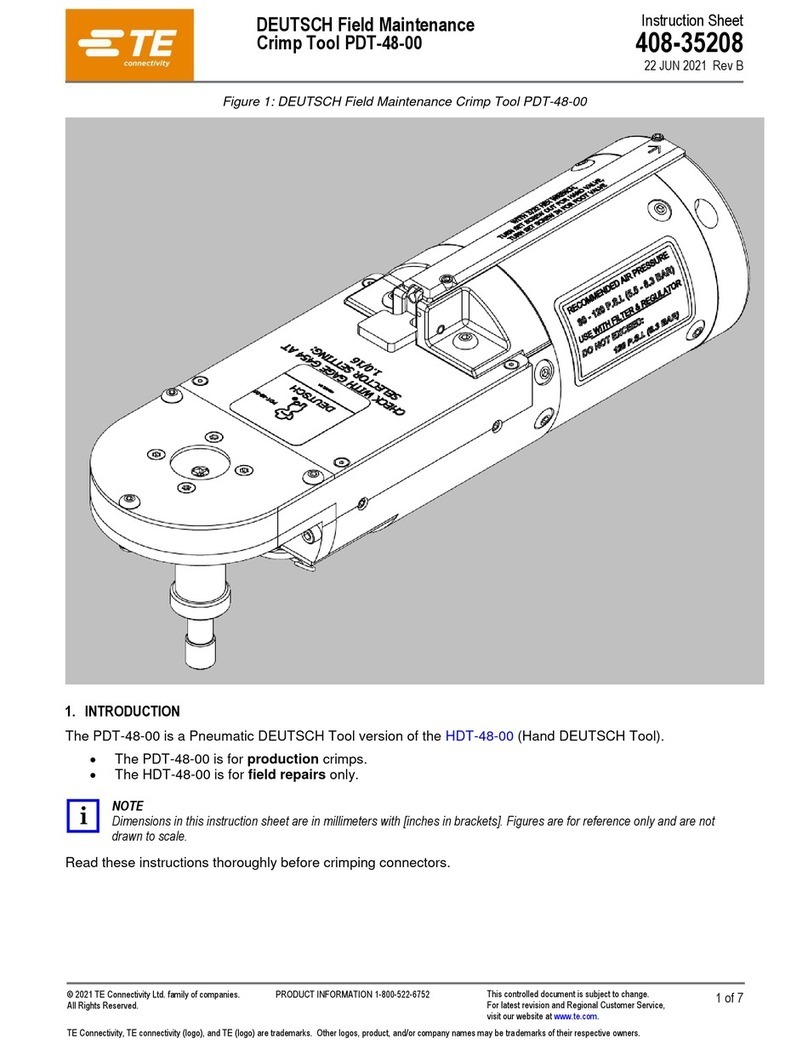

Figure 8

5. Test the adjustments by sliding the terminal strip left and right. If the terminal strip is tight and does

not slide easily, loosen the Horizontal Adjustment Screws and slide the Horizontal Adjustment Block

towards the contact body to allow more clearance between the contact barrels and Strip Guide.

CAUTION

The terminal strip should have minimal clearance between the Insulation or Wire Barrel and the Strip Guide. Excessive

clearance may allow tab length to exceed the TE requirement for the specific terminal being cut.

Vertical Adjustment

Screws (2)

Allow Clearance Between

Vertical Adjustment Plate

and Transition Area

Allow Vertical Adjustment

Plate to Rest on Crimp Barrel

Horizontal

Adjustment

Screws (2)

408-35037

Rev A

5 of 5

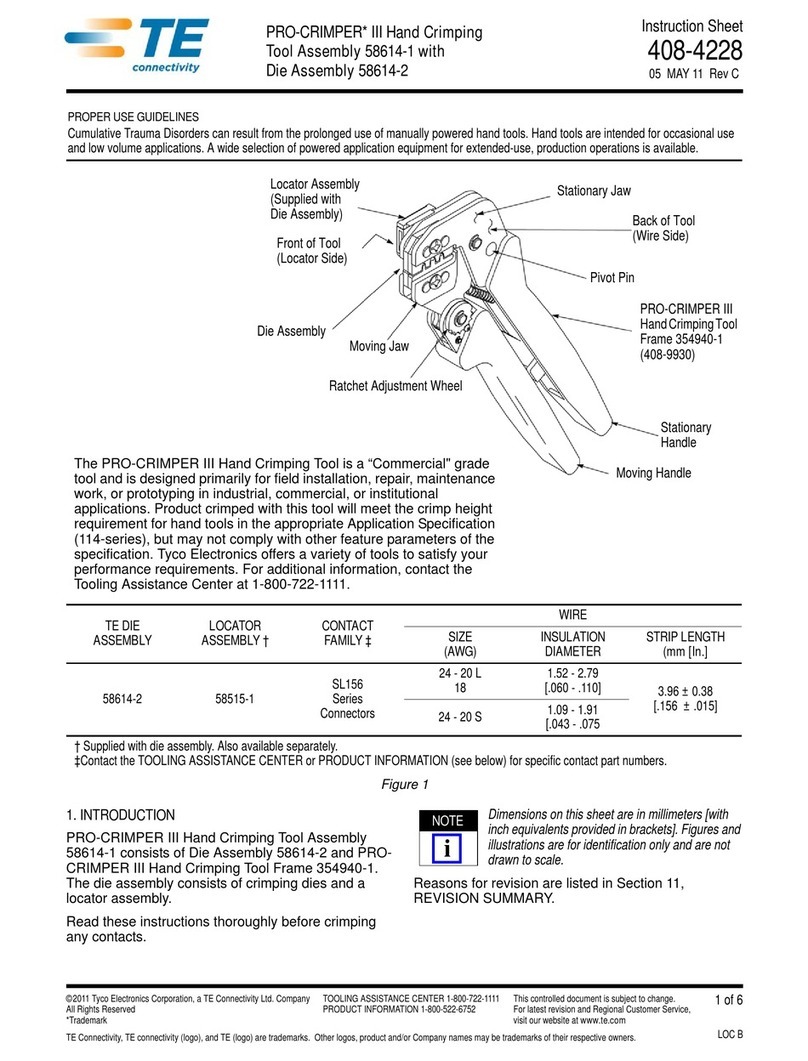

6. Slide the terminal strip into the tool until the terminal contacts the Terminal Stop.

Adjust the Terminal Stop to position the tab in the center of the Cut-off Shear (see Figure 9)

Figure 9

5. CUTTING PROCEDURE

1. Insert strip terminals into the Strip Guide until the Terminal Stop is reached.

2. Cycle the hand tool to shear the terminal from the carrier strip.

Measure the cut-off tab length to confirm it is within TE specification for the specific terminal being

cut. Note: If cut-off tab does not meet the TE specification, repeat set-up procedure in Section 4.

3. When cut-off tab length meets the TE requirement, advance terminal strip to position the next

terminal against Terminal Stop and cycle tool. Additional loose-piecing of terminals may commence.

6. TOOL MAINTENANCE AND INSPECTION

6.1. Maintenance

Remove any debris with a clean, soft brush. Ensure that the tool is clean by wiping it with a clean, soft

cloth. DO NOT clean with objects that could damage any components.

6.2. Visual Inspection

1. Inspect the tool on a regular basis to ensure excessive wear or any damage does not exist.

If damage or abnormal wear is evident, the tool must be replaced (refer to Section 7).

2. Inspect the Cut-off Anvil and Cut-off Shear for chipped, worn, or broken areas –if evident, refer to

Section 7.

7. REPLACEMENT

If the Cut-off Anvil and/or Cut-off Shear are damaged or worn excessively, the tool must be replaced. Order a

new tool through your TE representative; call 1-800-522-6752, send a facsimile of your purchase order to

717-986-7605, or write to:

CUSTOMER SERVICE (038-035)

TE CONNECTIVITY CORPORATION

PO BOX 3608

HARRISBURG PA 17105-3608

8. REVISION SUMMARY

Initial Release

Cut-off

Shear

Terminal

Stop

Correct Setting

for Terminal Stop

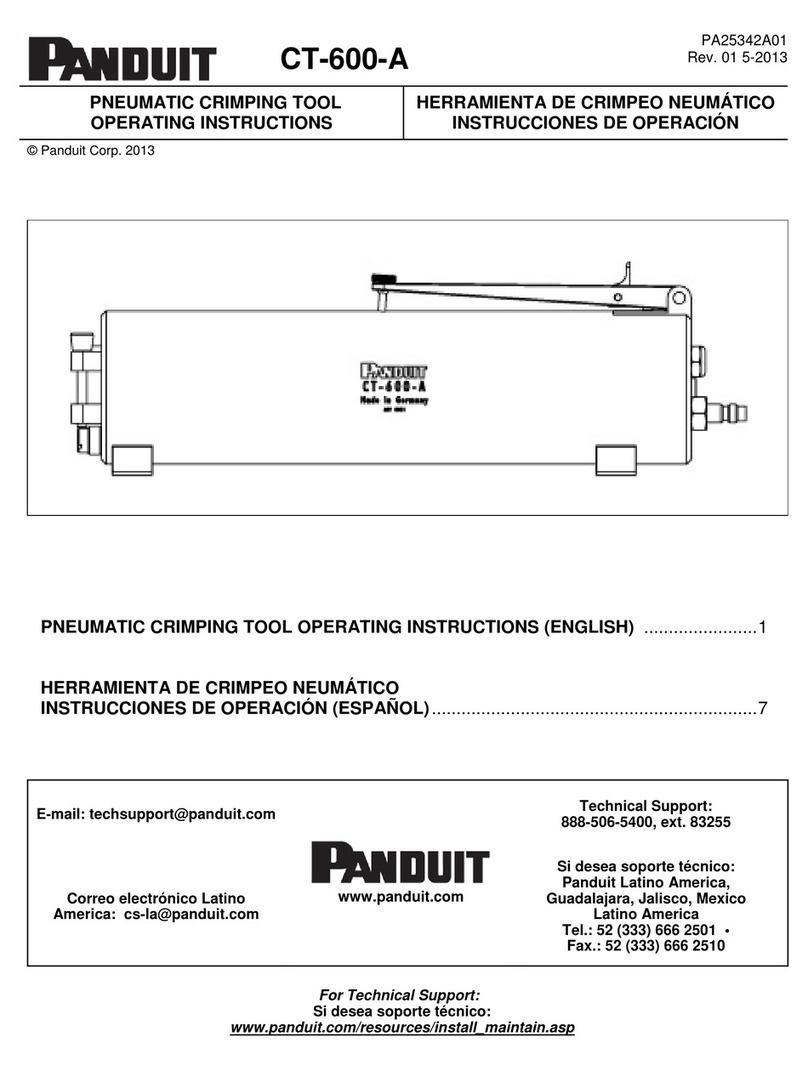

Table of contents

Other TE Crimping Tools manuals

Popular Crimping Tools manuals by other brands

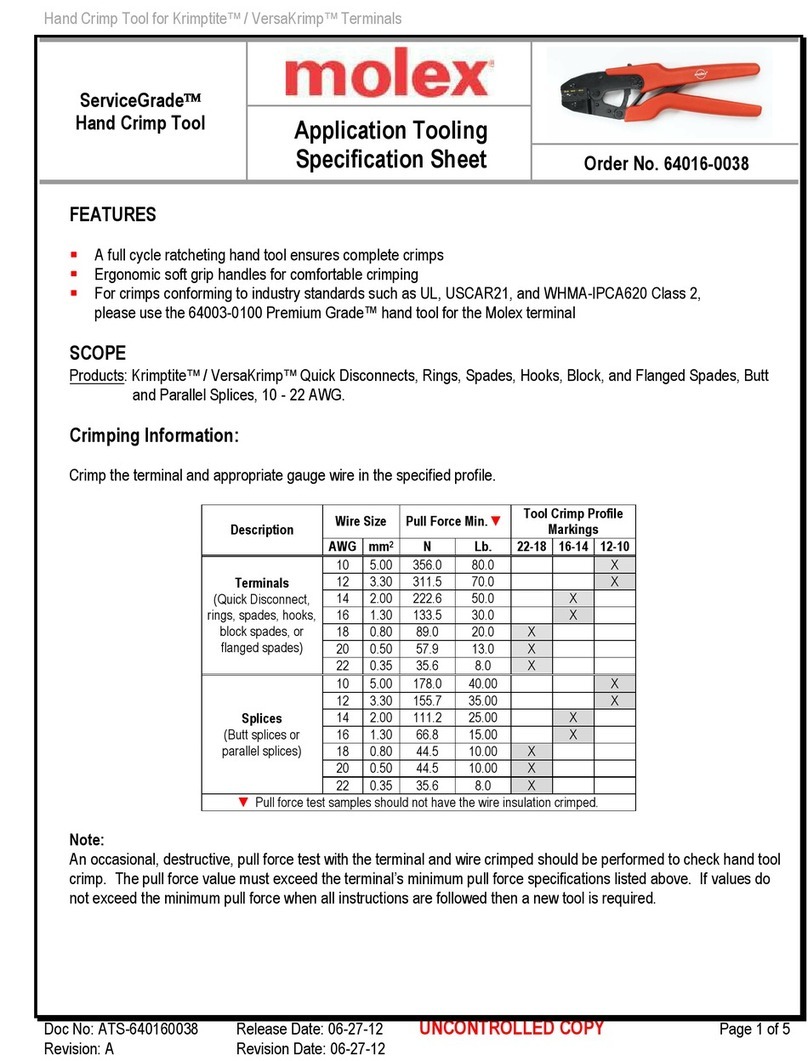

molex

molex 207129 Series Specification sheet

Cembre

Cembre B1500 Operation and maintenance manual

molex

molex 207129 Series Specification sheet

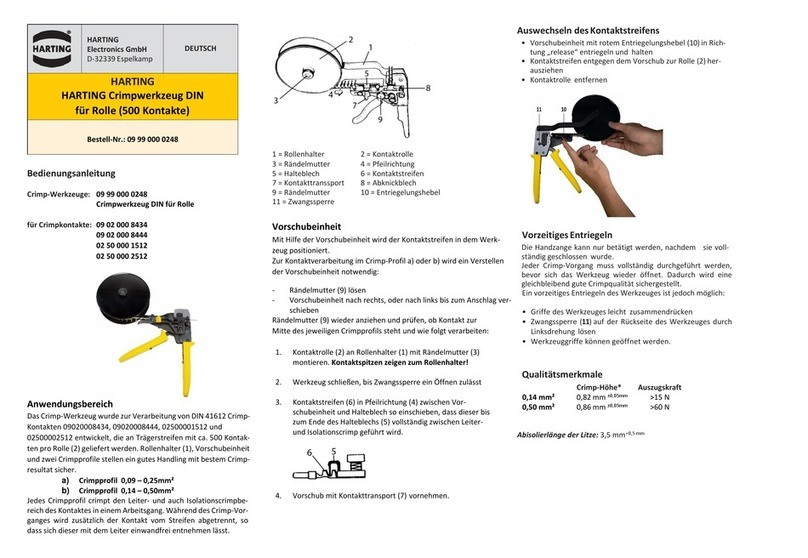

HARTING

HARTING 09 99 000 0664 instructions

Eastwood

Eastwood CRIMP-RIGHT WEATHER-TIGHT 31676 instructions

TE Connectivity

TE Connectivity PDT-48-00 instruction sheet