TE TE3112 User manual

PB

Service Manual

TE3124/TE3112.

Thermal Transfer Printer

2 2

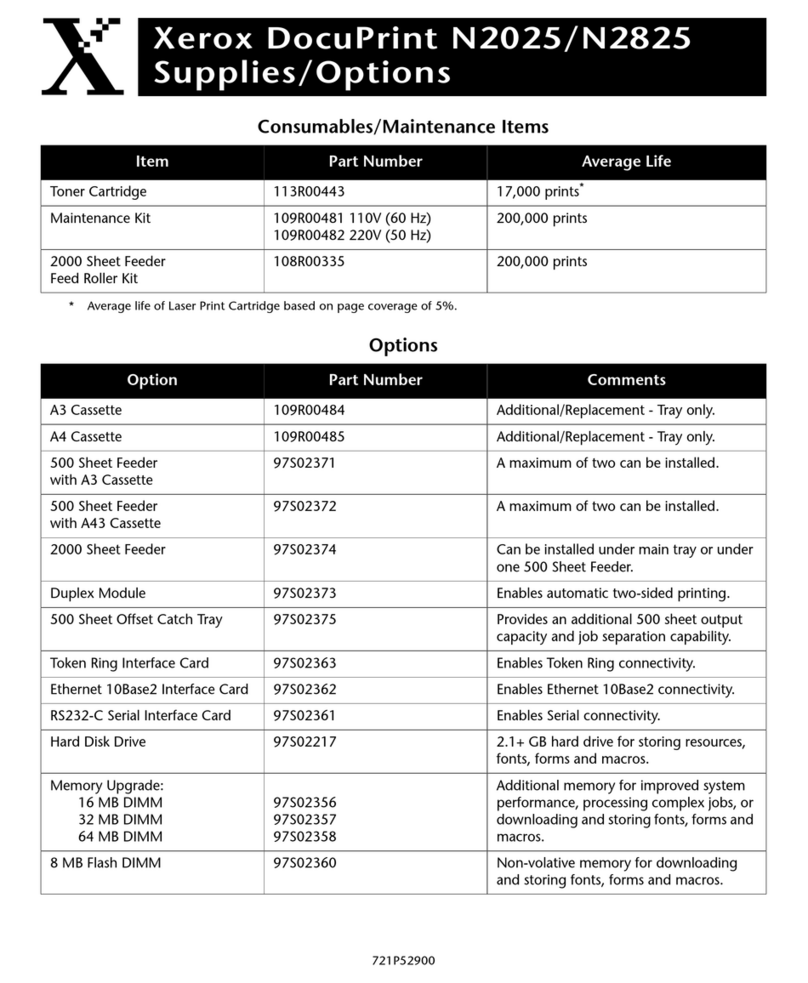

Description Part number

TE3124-PRINTER CC9352-000

TE3112-PRINTER CR2120-000

TE Connectivity document number:

412-121032 issue 1

Related Documents

412-121024, TE3124 Operators Manual.

412-121026 TE3112 Operators Manual.

411-121020 Thermal transfer cleaning instructions.

411-121018 Printhead setup for the TE3124/TE3112/

T6112DS.

Copyright

This documentation as well as translation hereof are property of TE

Connectivity.

The replication, conversion, duplication or divulgement of the whole

manual or parts of it for other intentions than its original intended purpose

demand the previous written authorization by TE Connectivity.

Trademark

Centronics®is a registered trademark of the Data Computer Corporation.

Microsoft®is a registered trademark of the Microsoft Corporation.

Windows 2000®, 2003®, XP®are registered trademarks of the Microsoft

Corporation.

TrueTypeTM is a registered trademark of Apple Computer, Inc.

Editor

Regarding questions or comments please contact TE Connectivity.

Topicality

Due to the constant further development of our products discrepancies

between documentation and product can occur.

Please check

http://www.te.com/commerce/DocumentDelivery/DDEController for the

latest update.

Terms and conditions

Deliveries and performances are effected under the General conditions of

sale of TE Connectivity.

Service Manual

for the following products

United States

Toll Free: 1-800-430-7226 x4

(East) or x5 (West)

Email:

United Kingdom

Toll Free: 0 800988 9177

*Phone is monitored in the

afternoon local time

Email:

Germany

+49(0)173-3169004

Email:

Ireland

Toll Free: 800-557-810

*Phone is monitored in the

afternoon local time

Email:

Rest of Europe

http://www.te.com/help

Email:

Asia

+86-21-33980184

Email:

Australia

Toll Free: 1-800-144-078

Email:

New Zealand

Toll free: 0800-TYCO-HELP

Email:

Representatives in other countries on request.

Global Identication Technical Contact Information

Printer & Software Technical Support:

Disclaimers

The information contained within this document is the

property of TE Connectivity. It is supplied in

confidence and the commercial security of the contents

must be maintained. It must not be used for any

purpose other than that for which it is supplied nor may

any information contained in it be disclosed to

unauthorised persons. It must not be reproduced in

whole or in part without obtaining written permission

from TE Connectivity.

While TE Connectivity has made every reasonable

effort to ensure the accuracy of the information in this

document, TE Connectivity does not guarantee that it is

error-free, nor does TE Connectivity make any other

representation, warranty or guarantee that the

information is accurate, correct, reliable or current.

Tyco Electronics reserves the right to make any

adjustments to the information contained herein at any

time without notice. TE Connectivity expressly

disclaims all implied warranties regarding the

information contained herein, including, but not limited

to, any implied warranties of merchantability or fitness

for a particular purpose. Specifications are subject to

change without notice. Consult TE Connectivity for the

latest dimensions and design specifications.

2

3

Table of Contents

1 Important Information............................................................................................................................ 4

1.1 General Safety Instructions...................................................................................................................... 4

1.2 Protective Devices ................................................................................................................................... 4

1.3 Handling Electricity .................................................................................................................................. 5

1.4 Procedure in Case of Accidents .............................................................................................................. 5

2 Cleaning .................................................................................................................................................. 6

2.1 Cleaning by the Operator ......................................................................................................................... 6

2.2 Cleaning the Label Sensor ...................................................................................................................... 7

3 Replacing Assembly Units .................................................................................................................... 8

3.1 Tools......................................................................................................................................................... 8

3.2 Removing and Installing the Plastic Cover............................................................................................... 8

3.3 Replacing the Printhead........................................................................................................................... 9

3.4 Replacing the Printhead .......................................................................................................................... 9

3.5 Replacing the Slipping Clutches .............................................................................................................11

3.6 Replacing the Label Sensor ................................................................................................................... 13

3.6.1 Replacing Standard Label Sensor.................................................................................................... 13

3.6.2 Replacing Label Sensor ................................................................................................................... 14

3.7 Replacing the PCB CPU ........................................................................................................................ 15

3.8 Replacing the Power Supply Unit........................................................................................................... 16

4 Adjustments ......................................................................................................................................... 17

4.1 Measuring and Adjusting the Winding Torques ...................................................................................... 17

4.1.1 Measuring the Winding Torques ....................................................................................................... 17

4.1.2 Adjusting the Winding Torques ......................................................................................................... 20

4.2 Adjusting the Printing Mechanism.......................................................................................................... 21

4.2.1 Preparing the Printer for Adjustment ................................................................................................ 21

4.2.2 Adjusting the Printhead Position....................................................................................................... 22

4.2.3 Adjusting the Printhead Pressure..................................................................................................... 23

4.2.4 Adjusting the Transfer Ribbon Feed Path......................................................................................... 24

4.2.5 Final Test .......................................................................................................................................... 24

4.3 Adjusting the Belt Tension at the Main Drive Motor ............................................................................... 25

Adjusting the Head Switch ..................................................................................................................... 26

5 Troubleshooting and Error Correction............................................................................................... 27

5.1 Failure of Device Functions.................................................................................................................... 27

5.2 Hardware Faults..................................................................................................................................... 28

Block Diagram ...................................................................................................................................... 29

7 Layout Diagram PCB CPU............................................................................................................. 30, 31

8 Index...................................................................................................................................................... 32

4 4

1 Important Information

1.1 General Safety Instructions

This service manual is intended for use by qualied service and maintenance personnel. For more operation and

conguration information, refer to the user or conguration manual.

Follow the general safety rules below:

• Keep the area around the device clean at all times!

• Work with safety in mind.

• Parts of device that are removed during the maintenance work must be put in a safe place.

• Avoid risks of tripping over.

Danger!

Danger to life and limb from increased current ow through metal parts in contact with the device.

XDo not wear clothing with metal parts.

XDo not wear jewelry.

XDo not wear spectacles with metal frames.

!

Warning!

Items of clothing drawn into the device by moving parts can lead to injuries.

XDo not wear any items of clothing which could get caught by moving parts.

1.2 Protective Devices

!

Warning!

There is a risk of injury if protective devices are missing or defective.

XReplace all protective devices (covers, safety notices, grounding cables etc) after maintenance work

has been completed.

XReplace parts that have become defective or unusable.

Wear protective goggles for:

• Knocking pins or similar parts in or out with a hammer.

• Using spring hooks.

• Inserting or removing springs, retaining rings or grip rings.

• Using solvents, cleansers or other chemicals.

4

5

1 Important Information

1.3 Handling Electricity

The following work may only be done by trained and qualied electricians:

• Work on electrical components.

• Work on an open device still connected to the mains supply.

General precautions before starting maintenance work:

• Find out where the emergency and power switches are so that they can be quickly operated in an emergency.

• Disconnect the current supply before carrying out the following work:

- Installing or removing power units.

- Working in the immediate vicinity of open power supply components.

- Mechanical check of power supply components.

- Modifying circuits in the device.

• Test the zero potential of the device parts.

• Check the working area for possible sources of danger, such as wet oors, defective extension cables, defective

protective conductor connections.

Additional precautions in the case of exposed voltages:

• Ask a second person to remain near the working site. This person must know where the emergency and power

switches are, and how to switch the current off if danger arises.

• Only use one hand to work on electric circuits of devices that are switched on. Keep the other hand behind your

back or in your pocket.

This prevents electricity from owing through your own body.

1.4 Procedure in Case of Accidents

• Act calmly and with great care.

• Avoid danger to yourself.

• Switch off power.

• Request medical assistance.

• Give rst aid, if qualied.

6 6

2 Cleaning

2.1 Cleaning by the Operator

The following cleaning work is described in the “Thermal Transfer Printer cleaning instructions“ TE document number:

411-121020.

• cleaning the device

• cleaning the printhead

• cleaning the print roller

• cleaning the label sensor

Danger!

Risk of death via electric shock!

XBefore opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

XAny electrical work must be carried out by a fully trained and qualied Electrical Engineer.

6

7

2.2 Cleaning the Label Sensor

1

5

2423

Fig. 1 Cleaning the label sensor Fig 2 Removing the label sensor

Danger!

Risk of death via electric shock!

XBefore opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

1. Remove media from the printer.

2. Remove the Allen key (5) from its retainer.

3. Remove the rear cover of the printer.

4. Unscrew knurled thumb screw (1).

5. Unplug the cable (3) from the plug on the rear end of the label sensor (2).

6. Push the label sensor (2) so deep as possible into the guide prole toward the chassis.

7. Slide out the label sensor assembly (2) toward the back side cover.

8. Clean label sensor and sensor units (2) with brush or cotton swab soaked in pure alcohol.

9. Push label sensor back toward the print head side of printer so you can see the hole in the label sensor over the

long hole in the prole (guide).

10. Connect the cable (3) to the label sensor (2).

11. Attach knurled thumb screw (1).

12. Pull the label sensor (2) via knurled thumb screw (1) so far as possible toward cover side. This prevents the cable

(3) from being pinched when installing the rear cover.

13. Install the rear cover of the printer.

14. Adjust label sensor operators manual.

15. Insert the Allen key (5) into its retainer.

2 Cleaning

8 8

3 Replacing Assembly Units

3.1 Tools

XDo not use any worn of damaged tools.

XOnly use tools and testing devices that are suitable for the task at hand.

special tools:

• Test collar for transfer ribbon winder (5534199)

Standard tools:

• Phillips-head screwdriver, size 1

• Allen key 1,5 mm

• Screw driver Torx, size TX 20

• Snap ring pliers ZGG 0

• Cylindrical dynamometer (spring scale), 0 - 10 N

• Cylindrical dynamometer (spring scale), 0 - 25 N

• Jaw wrench 8 mm

3.2 Removing and Installing the Plastic Cover

!Attention!

The plastic cover can be damaged via careless handling.

XDo not use force.

XDo not twist the plastic cover when removing it or pressing it on.

Fig. 3 Removing and installing the plastic cover

Removing the plastic cover :

1. Swivel the plastic cover up 90° and hold it in this position with both hands.

2. Carefully pull the hinges of the plastic cover out of the front mount and then the rear mount.

3. Put the plastic cover in a safe place.

Installing the plastic cover :

1. Place the hinges of the plastic cover onto the mounts with the open side downward.

2. First carefully press the rear hinge onto the respective mount and then do the same with the front hinge.

3. Swivel the plastic cover closed.

8

9

3 Replacing Assembly Units

3.3 Replacing the Printhead

3.4 Replacing the Printhead

The printhead of the printer can be replaced without the need for ne adjustment. The printhead must be replaced if

worn or when switching to a printhead with higher or lower resolution. For better identication, the print heads have a

label stating the printer type and resolution.

1

2

3

4

6

7

4

6

5

1 Head plate

2 Plug connection

3 Plug connection

4 Screw

5 Printing line

6 Pins

7 Printhead

Fig.4 Structure of the printhead

!Attention!

The printhead (7) is adjusted on a head plate (1) and precisely aligned at the factory. Do not loosen the

screws (4) under any circumstances.

!Attention!

The printhead can be damaged by static electricity discharges and impacts!

XSet up printer on a grounded, conductive surface.

XGround your body, e.g. by wearing a grounded wristband.

XDo not touch contacts on the plug connections (2, 3).

XDo not touch printing line (5) with hard objects or your hands.

5

8

9

10

11

3

6

6

2

1

4

74

Fig. 5 Removing and installing the printhead

Note:

Location of item

11 has moved

on more recent

printer models

10 10

3 Replacing Assembly Units

Removing the printhead

1. Turn lever (10) counterclockwise to lift the printhead.

2. Remove labels and transfer ribbon from the printer.

3. Remove Allen key (11) from its retainer.

4. Lightly keep printhead mounting bracket (9) on the print roller with one nger and screw out screw (8) with the

Allen key and remove it and the washer.

5. Swivel printhead mounting bracket (9) upward.

6. Remove printhead from the printhead mounting bracket (9) if necessary.

7. Loosen both plug connections (2, 3) on the printhead and set printhead down on a clean, soft surface.

Installing the printhead

1. Attach plug connections (2, 3).

2. Position printhead in printhead mounting bracket (9) in such a way that the pins (6) are secured in the corre-

sponding holes in the printhead mounting bracket (9).

3. Lightly keep printhead mounting bracket (9) on the print roller with one nger and check for correct positioning of

the printhead mounting bracket (9).

4. Screw in screw (8) with washer with the Allen key and tighten it.

5. Reload labels and transfer ribbon.

10

11

3.5 Replacing the Slipping Clutches

The rewinder for the transfer ribbon and the internal rewinder are coupled to slipping clutches in the main drive. The

supply hub of the transfer ribbon is braked with a slipping clutch during printing.

Change the slipping clutch when it can no longer be set 4.1 on page 18. Removal and installation of the slipping

clutch is also required for replacement of a winder.

1

2

3

1 Transfer ribbon supply hub: brake

2 Transfer ribbon take up hub: coupling

3 Internal rewinder: coupling

Fig. 6 Slipping clutches

Danger!

Risk of death via electric shock!

XBefore opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

Removing the slipping clutch

1. Unplug the printer from the electrical outlet.

2. Remove the rear cover of the printer.

3. Remove the snap ring (1).

4. Pull coupling or brake (2) from the winder axis (Item 5 in Fig. 7) or (Item 9 in Fig. 8).

5. Ensure that the pin (Item 11 in Fig. 8) remains on the winder axis when pulling the brake off. Reattach the pin to

the winder axis if it has been pulled off. The axis prole is shaped in such a way that the pin only ts on the winder

axis in one way.

3 Replacing Assembly Units

12 12

Installing the slipping clutch on the rewinders

8765

4

4 Snap ring

5 Slipping clutch

6 Coupling disks

7 Winder axis

8 Collar of the belt wheel

Fig. 7

Slipping clutch on the rewinders

1. Slide coupling (5) onto the winder axis (7).

2. Align grooves in the coupling disks (6) with the guides in the collar of the belt wheel (8).

3. Slide coupling further until it stops.

4. Secure the snap ring (4).

5. Adjust the coupling 4.1 on page 19.

6. Pull the label sensor toward the cover side as far as possible and install the rear cover of the printer.

Installing the brake on the transfer ribbon supply hub

12 711 9

4

10

4 Snap ring

7 Winder axis

9 Brake

10 Lever

11 Pin

12 Spring

Fig. 8 Brake on transfer ribbon supply hub

1. Slide the brake (9) onto the winder axis (7) in such a way that it ts on the hexagonal prole of the pin (11).

2. Ensure that the lever (10) grasps between the two ends of the spring (12).

3. Secure the snap ring (4).

4. Adjust the coupling 4.1 on page 19.

5. Pull the label sensor toward the cover side as far as possible and install the rear cover of the printer.

3 Replacing Assembly Units

12

13

3.6 Replacing the Label Sensor

iNotice!

Contamination of the label sensor can also cause malfunctions. Before replacing the label sensor, check

whether it is soiled and clean it if necessary..

Danger!

Risk of death via electric shock!

XBefore opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

3.6.1 Replacing Standard Label Sensor

2 1

3

4

6

5a

1

5b

5c 7

Fig. 9 Replacing the standard label sensor

Removing the label sensor

1. Remove media from the printer.

2. Remove the Allen key (6) from its retainer.

3. Remove the rear cover of the printer.

4. Slide the label sensor assembly onto the tab (4) toward the rear cover until it stops.

5. Unplug the cable (2) from the plug on the rear end of the label sensor (1).

6. Unscrew the screws (5) with an Allen key and remove the side plate (7).

7. Pull out the label sensor (1) via the tab (4) toward the cover side.

Installing the label sensor

1. Insert the label sensor (1) into the guide from the cover side and slide it onto the tab (5) toward the rear cover until

it stops.

2. Remount the side plate (7) with the screws (5) by tightening the screws in order, i.e. a, b then c.

3. Connect the cable (2) to the label sensor (1).

4. Pull the label sensor (1) via the tab (4) as far as possible toward the cover side.

This prevents the cable (2) from being pinched when installing the rear cover.

5. Install the rear cover of the printer.

6. Insert the Allen key (6) into its retainer.

7. Adjust the label sensor Conguration Manual.

3 Replacing Assembly Units

14 14

3.6.2 Replacing Label Sensor

1

5

2423

Fig. 10 Replacing the label sensor

Danger!

Risk of death via electric shock!

XBefore opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

Removing the label sensor

1. Remove the Allen key (5) from its retainer.

2. Remove the rear cover of the printer.

3. Unscrew knurled thumb screw (1).

4. Unplug the cable (3) from the plug on the rear end of the label sensor (2).

5. Push the label sensor (2) so deep as possible into the guide prole toward the chassis.

6. Slide out the label sensor assembly (2) toward the back side cover.

Installing the label sensor

1. Push label sensor back toward the print head side of printer so you can see the hole in the label sensor over the

long hole in the prole (guide).

2. Connect the cable (3) to the label sensor (2).

3. Attach knurled thumb screw (1).

4. Pull the label sensor (2) via knurled thumb screw (1) so far as possible toward cover side. This prevents the cable

(3) from being pinched when installing the rear cover.

5. Install the rear cover of the printer.

6. Insert the Allen key (5) into its retainer.

7. Adjust label sensor.

8. Adjust the label sensor.

3 Replacing Assembly Units

14

15

3.7 Replacing the PCB CPU

Danger!

Risk of death via electric shock!

XBefore opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

3

12

1Removing the PCB CPU

1. If possible, save the printer conguration to a Compact-

Flash card.

2. Unplug the printer from the electrical outlet.

3. Detach all interface cables from the back of the printer.

4. Remove all memory cards from the slots.

5. Screw off the rear cover.

6. Unplug all side plug connections from the PCB CPU (2).

7. Remove the four xing screws (3) from the PCB CPU.

8. Remove the PCB CPU.

Fig. 11 Removing the PCB CPU

4

5

6

7

8

9

10

Fig. 12 Used connectors on the PCB CPU

4 Control panel

5 Peripheral port

6 Sensors

7 Printhead signals

8 Printhead power supply

9 Power supply unit

10 Stepper motor

Installing the PCB CPU

1. Place PCB CPU (2) onto the retainers (1).

2. Secure the PCB with four screws (3).

3. Insert all plug connections on the PCB.

4. Pull the label sensor toward the cover side as far as

possible and install the rear cover of the printer.

5. Restore all interface connections on the back of the

printer.

6. Connect the power cable at the rear of the printer.

7. Update the rmware if necessary.

8. Adjust the label sensor.

9. Load the printer conguration from the memory card if

possible. Otherwise, set the printer conguration via the

control panel.

3 Replacing Assembly Units

16 16

3.8 Replacing the Power Supply Unit

Danger!

Risk of death via electric shock!

XBefore opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

123

2

4

6

7

5

4

Removing the power supply unit

1. Unplug the printer from the electrical outlet.

2. Remove the PCB CPU 3.7 on page 15.

3. Remove the two screws (6) of the cover plate (5).

4. Remove the cover plate (5).

5. Unplug the plug at the power supply unit input (3).

6. Unplug the plug at the power supply unit output (1).

7. Remove the two screws on the back of the printer (7).

8. Hold the power supply unit rmly at the metal bracket (4)

and remove the two screws (2).

9. Remove the power supply unit.

Installing the power supply unit

1. Insert the power supply unit and secure the PCB with two

screws (2).

2. Secure the metal bracket (4) of the power supply unit to

the back of the printer with two screws (7).

3. Connect the power supply unit cable to the power supply

output (1).

4. Insert the power input cable (3).

5. Insert the cover plate (5) and secure it with the two

screws (6).

6. Install the PCB CPU.

Fig. 13 Replacing the power supply unit

3 Replacing Assembly Units

16

17

4 Adjustments

4.1 Measuring and Adjusting the Winding Torques

The rewinder for the transfer ribbon and the internal rewinder are coupled to slipping clutches in the main drive. The

supply hub of the transfer ribbon is braked with a slipping clutch during printing.

The correct setting of the torques of these slipping clutches is necessary for:

• precise conveyance of the transfer ribbon during label transport

• the prevention of wrinkles in the feed path of the transfer ribbon

• sufciently tight peel-off tension of the liner and thus easy peeling off of labels in peel-off mode

• a sufciently tightened label strip

The winding axes of the rewinder are not actively driven by the belts during label backfeed, but rather solely by the

pull of the print roller. The torque required to disengage the rewinder from the belt drive is implemented via a brake

in the winding reel, which works in both directions. The measured clockwise torque is the sum of the coupling torque

and the torque of the brake. Only the torque of the brake is measured when the winding axis is rotating counter-

clockwise. For this reason, measurement of the torques at the rewinders are required in both directions.

The method of measurement differs for the various types of slipping clutches:

• measurement of the winding torques at the transfer ribbon take up and supply hub page 18.

• measurement of the winding torque at the internal rewinder page 19.

If the winding torque differs from the set value, it must be adjusted. The procedures for adjusting the winding torques

of the transfer ribbon winders and the internal rewinder are identical 4.1.2 on page 20.

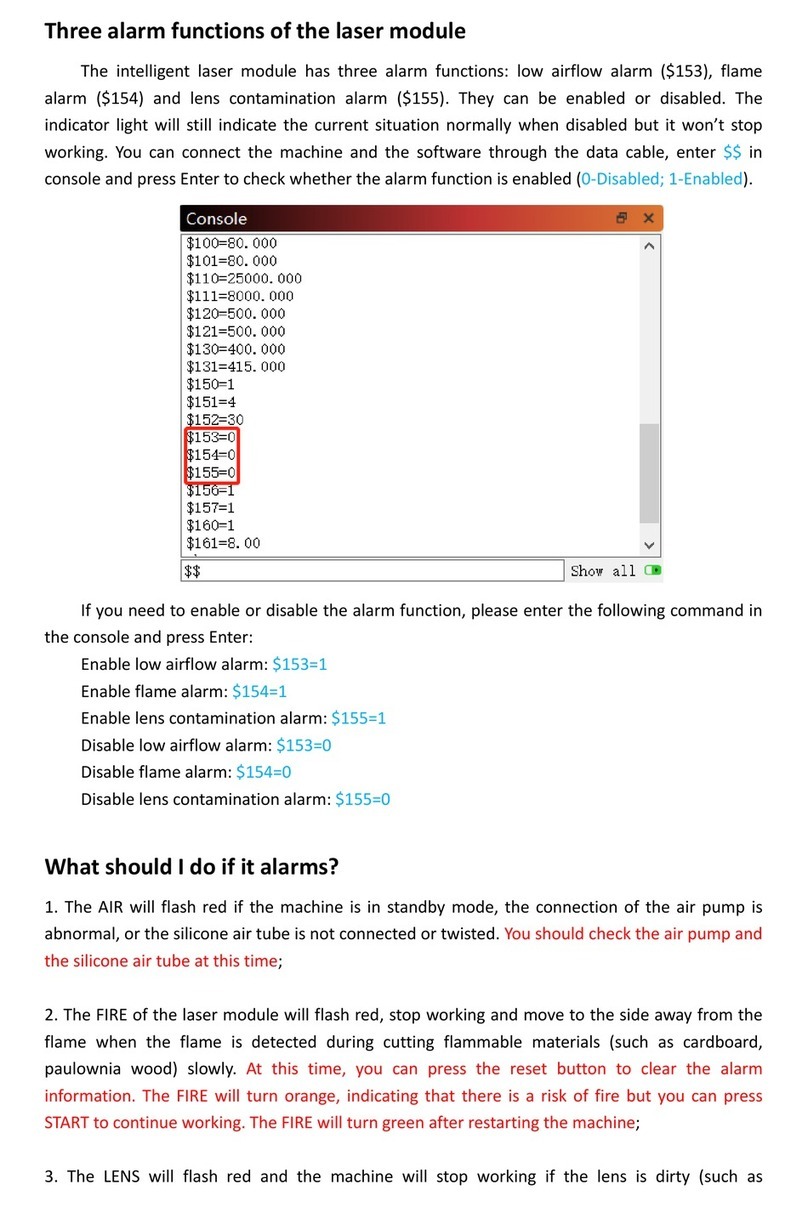

4.1.1 Measuring the Winding Torques

Transfer ribbon take up and supply hub

Measurement of the winding torque at the transfer ribbon take up and supply hub occurs by determining the pulling

forces on a test collar attached to the winder.

The physical relation between the torque and the pulling force is:

F= M / r

F: Pulling force [N],

M: Winding torque [Ncm],

r: Radius of the test collar (30 mm)

18 18

4 Adjustments

The set values for the winding torque and the resulting pulling force at the test collar are:

Slipping clutch on Direction of rotation Printer Winding torque M Pulling force F

Ribbon take up hub clockwise TE3124

TE3112

13.5 - 14.4 Ncm

13.5 - 14.4 Ncm

4.3 - 4.8 N

4.3 - 4.8 N

counterclockwise all 2.1 - 3.0 Ncm 0.7 - 1.0 N

Ribbon supply hub any TE3124

TE3112

3.6 - 4.5 Ncm

3.6 - 4.5 Ncm

1.2 - 1.5 N

1.2 - 1.5 N

Table 1 Winding torques at the transfer ribbon hubs

1

3

4

4

3

1 2

Fig. 14 Measuring the winding torque at the transfer ribbon take up hub (left) and supply hub (right)

Danger!

Risk of death via electric shock!

XBefore opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

1. Unplug the printer from the electrical outlet.

2. Remove the rear cover.

3. Remove the transfer ribbon from the printer.

4. Attach the test collar (3) to the winder (4).

5. Turn the knurled nut counterclockwise to clamp the test collar.

6. Wind the cord attached to the test collar around the test collar several times.

7. Secure spring scale [10 N] (1) at the end of the cord.

8. Move the spring scale upward vertically until the winder begins turning.

9. If the drive belt at the rewinder is also moving, hold it in place during the measurement. Otherwise, the

measurement is not accurate.

10. Allow the cord to unwind from the test collar at least one full turn and read the pulling force F on the spring scale

at the same time.

11. Determine the pulling force at the transfer ribbon take up hub in the same manner, except in the opposite rotation

direction (2).

12. If the winding torque differs from the set value, it must be adjusted 4.1.2 on page 20.

18

19

4 Adjustments

Internal rewinder

Measurement of the winding torque at the internal rewinder occurs by determining the pulling forces with a cord

wrapped around the rewinder.

The physical relation between the torque and the pulling force is:

F= M / r

F: Pulling force [N],

M: Winding torque [Ncm],

r: Radius of the internal rewinder (20 mm)

The set values for the winding torque and the resulting pulling force at the test collar are:

Slipping clutch on Direction of rotation Printer Winding torque M Pulling force F

Internal rewinder clockwise TE3124/TE3112 28 - 32 Ncm 14 - 16 N

counterclockwise TE3124/TE3112 8 - 12 Ncm 4 - 6 N

Table 2 Winding torques at the internal rewinder

Danger!

Risk of death via electric shock!

XBefore opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

3

1

2

4

1. Unplug the printer from the electrical outlet.

2. Remove the rear cover.

3. Remove the label media from the printer.

4. Push the cord (2) under a bracket of the internal

rewinder (3) and wind it around the rewinder.

5. Secure spring scale [25 N] (1) at the end of the cord.

6. Move the spring scale (1) upward vertically until the

winder begins turning.

7. If the drive belt is also moving, hold it in place during

the measurement. Otherwise, the measurement is

not accurate.

8. Allow the cord to unwind from the test collar at least

one full turn and read the pulling force F on the

spring scale at the same time.

9. Determine the pulling force in the same manner,

except in the opposite rotation direction (4).

10. If the winding torque differs from the setpoint, it must

be adjusted 4.1.2 on page 20.

Fig. 15 Measuring the winding torque at the internal rewinder

20 20

4 Adjustments

4.1.2 Adjusting the Winding Torques

The winding torque of a winder can be changed at the knurled ring of the respective slipping clutch. The numbers on

the knurled ring stand for the value of the winding torque:

• 1: Lowest winding torque

• 7: Highest winding torque

The current value is indicated by the number located at the positions of the two locking tabs.

Danger!

Risk of death via electric shock!

XBefore opening the housing cover, disconnect the device from the mains supply and wait at lease one

minute until the power supply unit has discharged.

2

1

1. Unplug the printer from the electrical outlet.

2. Remove the rear cover.

3. Press the knurled ring (1) of the slipping clutch

toward the housing wall.

The lock (2) of the knurled ring is released.

4. Turn the knurled ring while pushing it and release it

in the desired position.

5. Ensure that the tabs of the lock are located

completely in the grooves of the setting value.

6. Measure the winding torque again and compare it to

the set value.

Transfer ribbon hubs page 18

Internal rewinder page 19

7. Repeat the adjustment until the measured winding

torque is within the tolerance range.

8. Pull the label sensor toward the cover side as far as

possible and install the rear cover of the printer.

Fig. 16 Adjusting the winding torque

This manual suits for next models

1

Table of contents

Other TE Printer manuals