Intec CS4000 Assembly instructions

Version 2 |NOV 2015

Intec ColorSplash CS4000 and CS5000

Enhanced Print Production Envelope Feeder

Installation and Set Up Guide

CONTENTS

1. GETTING STARTED

1.1. ColorSplash EPP Envelope Feeder Components 3

1.2. Control Panel Components and Features 4

2. INSTALLATION GUIDE 5

2.1. Preparing the INTEC CS4000 / CS5000 Printer for use with your

Intec EPP Envelope Feeder 5

2.1.1. Removing the MPT Tray/Door 5

2.1.2. Removing the Outer Separation Pad 6

2.1.3. Installing Non-Reflective Aid for Envelope Feeders Optical Sensors 6

2.2. Assembly of the Intec ColorSplash Envelope Feeder 7

2.2.1. Assembly of Top Plate 8

2.2.2. Assembly of the Feeder Bridge 8

2.2.3. Fitting the Paper Hold Down Strap 9

2.2.4. Positioning the Envelope Buckle Separator 10

3. OPERATING GUIDE 11

3. Setting up the Feeder for envelopes 11

3.1. Setting the Hopper Paper Guides 11

3.2. Setting the Envelope (Buckle) Separator(s) 13

3.3. Setting up the Back Wedge 16

3.3.1. Purpose of the Back Wedge 16

3.3.2. Setting the Back Wedge for small / medium envelopes 16

3.3.3. Setting the Back Wedge for large envelopes 18

3.4. Setting the Acceleration Table Paper Guides 19

4. CHECKING YOUR FEEDER SETUP 21

5. DAILY OPERATION (Running envelopes with your printer) 22

5.1. Mounting/Connecting your Envelope Feeder 22

5.2. Envelope Feeder’s latch mechanism 23

5.3. Setting the Feeder’s speed control 24

5.4. Resume feeding switch /paper out sensor control 24

5.5. Paper jam or feeder out condition 25

5.6. Setting the Intec ColorSplash Envelope Feeder’s speed control 26

5.7. Removing the Feeder from the printer 26

6. TROUBLESHOOTING 27

6.1. Note on new ColorSplash printers 27

6.2. Common issues 27

2

1. GETTING STARTED

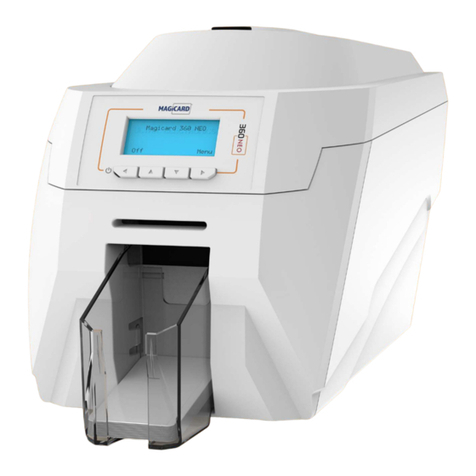

1.1. ColorSplash EPP Envelope Feeder Components

Back Wedge assembly

Paper guide assembly Bridge

Paper guide hopper

adjustment knob

Buckle separator assembly

Acceleration table

paper guide

Optical sensor

(RESTART envelopes)

Optical sensor (STOP envelopes)

Acceleration table

Envelope hold

down strap

Acceleration table

paper guide

Feed belts

IMPORTANT: Please familiarize yourself with the components shown above. These

components are referred to in the setup instructions contained in this manual.

3

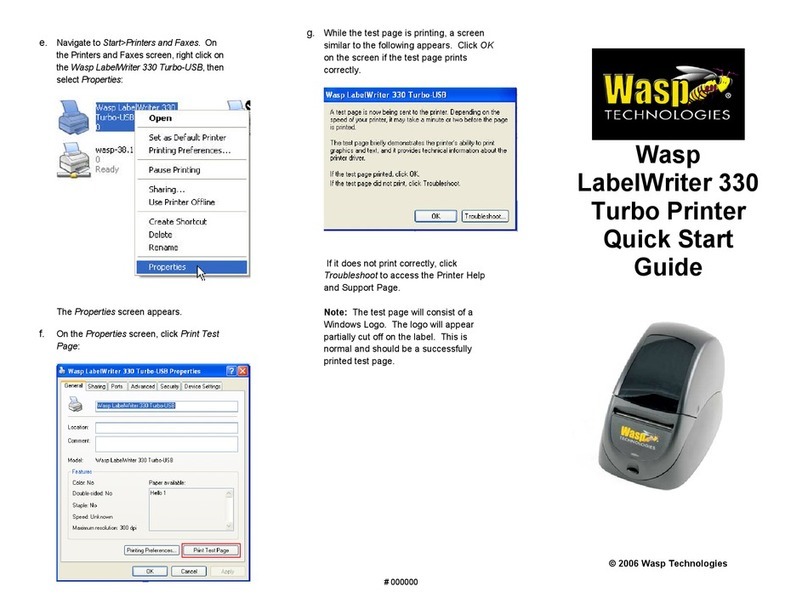

1.2. Control Panel Components and Features

Timeout reset / Jog button*

24 VDC power input jack Fuse holder (5 amp fuse)Ready/Feed switch Speed adjust knob

Mains power switch

The ColorSplash’s EPP Envelope Feeder

features a timeout function. During

operation, if the optical sensor mounted at

the exit end of the acceleration table (the

STOP Envelope Sensor) does not detect

an envelope for 4 seconds, the feed motor

will be paused. This is to ensure that the

motor does not ‘run on’ in the event the

feeder runs out of envelopes, or a jam

occurs in the feeder.

The Reset / Jog button shown above is

used to reset the timer and allow the motor

to restart running after a timeout occurs.

If you press and hold this button in,

the motor will run continuously until an

envelope covers the optical stop sensor.

The variable speed control can be

adjusted to accommodate different size

envelopes. As a general rule, most small

envelopes will require approximately 50%

maximum speed or more. For envelopes

150mm (6" long) in the running direction or

longer, higher speeds will be required for

consistent operation.

The feeder utilizes a low voltage 24 VDC\5

amp external power supply. An on board

5 amp fuse is included for electrical

component protection. This fuse can be

accessed by unscrewing the fuse cap in

the lower right corner of the control panel.

*TIMEOUT FEATURE

4

2. INSTALLATION GUIDE

The Intec ColorSplash’s EPP Envelope Feeder is designed to operate with the new Intec ColorSplash digital production

printers. This guide will show the proper way to prepare the printer for the envelope feeder and installation and operation

of the feeder.

2.1. Preparing the INTEC CS4000 / CS5000 Printer for use your Intec EPP

Envelope Feeder

2.1.1. Removing the MPT Tray/Door

Step 4. Remove the left side of the door in the same

fashion and remove the door from the printer.

Step 3. Press inward on the pivot point of the

door on the right side to remove it

from the printer housing.

Step 2. Press inward on the right side hinge

of the door to release it from the slot.

Step 1. To prepare the ColorSplash CS4000/

CS5000 printer for the feeder, you must

first remove the door from the manual

feed tray. First, open the manual feed

tray door on the right side of the printer.

5

1

3

2

4

2.1.2. Removing the Outer Separation Pad

Step 6. With the right side door fully open,

lift the feed roller assembly to gain

access to the feed roller and sheet

separator area.

Step 7. Pinch the two upper corners of the

sheet separator assembly (rubber

pad) and remove the assembly from

the printer.

Remove the separator assembly

NOTE: The envelope feeder is equipped with paper sensors positioned just to the left of

the printer’s manual feed tray feed roller and in the centre of the floating delivery table. It is

possible for the sensors to detect the white plastic housing just to the left of the feed roller,

and reflective silver housing above the middle sensor, which can cause erratic feeding.

It is very important to place the black tape or Velcro™ (included with feeder) in these 2 positions.

Note: This tape will not affect the printer and can be left in place, even when not using envelope feeder

Place black

tape

in these areas

6

Step 5. Open the right side cover on the printer by

pulling on the latch shown here:

5

6

7

2.2. Assembly of the Intec ColorSplash Envelope Feeder

Step 1. After removing the feeder from the shipping container, carefully place the feeder

and cabinet in the upright position.

Step 2. Open the door on the rear of the cabinet and remove the accessories box.

Step 3. Carefully remove the contents of the accessories box and set them on a table.

Ensure that all of the components listed below are accounted for before discarding the packaging.

Additional items included in the accessories box include:

• Extra sheet separator

• Envelope buckle device

• Black Velcro™ patches for printer

• 24 VDC power supply

• Narrow back wedge assembly

Hold down strap and shoulder screw

Top plate and back wedge assembly

Bridge

1/8" Allen wrench

7

5

7

8

9

2.2.1. Assembly of Top Plate

Step 4. Using the included 1/8" Allen wrench, remove

the four button head screws from the top of

the back plate of the feeder.

Step 5. Attach the top plate to the feeder

using the four button head screws

removed in Step 4.

Step 6. Tighten the screws holding the top

plate securely.

Step 7. Using the 1/8" Allen wrench, remove the two flat

head screws from each end of the bridge.

Step 8. Carefully position the bridge between the

side plates of the feeder and line up the

attaching holes.

2.2.2. Assembly of the Feeder Bridge

Step 9. Attach the bridge to the feeder using

the four flat head screws removed

from the bridge in Step 7.

Step 10. Tighten all four bridge screws.

Do not tighten any of the screws until

all four are in place.

Be careful on steps 4 & 5 not to drop

the screws into the feeder.

8

4

2.2.3. Fitting the Paper Hold Down Strap

Step 11. Remove the shoulder screw from the paper hold down strap pivot block.

Step 12. Place the end of the hold down strap (opposite pivot

block end) underneath the acceleration table cross bar

and on top of the transport belt.

Step 13. Position the hold down strap pivot block next to the

mounting block (on the right side) on the bridge and

insert the shoulder screw into the pivot block.

Step 14. Attach the pivot block to the mounting block on the

bridge using the 1/8" Allen wrench to tighten securely.

The hold down strap assembly should

pivot at the shoulder screw and should lie

flat on the transport belt.

The steel weights on the strap apply downward

pressure on the envelopes to ensure consistent

movement of the envelopes by the transport belt.

Strap weights

Pivot block for paper

hold down strap

Shoulder screw

9

12

13

14

15

16

17

2.2.4. Positioning the Envelope Buckle Separator

Step 15. Loosen the locking knob holding the envelope buckle

separator in position on the bridge.

Step 16. Slide the buckle separator to the

center of the feeder and position the

yellow tip at the bottom between

the two center feed belts as shown

in the photo.

Step 17. Lock the separator

in position with the

locking knob.

10

2

3. OPERATING GUIDE

IMPORTANT: It is recommended that you set up the feeder for your envelopes before moving

the feeder into position with the printer. This will ensure complete access to the paper guides

on the acceleration table and make testing the feeder easy.

The ColorSplash’s EPP Envelope Feeder can feed a variety of envelope sizes and types into the printer via the printer’s

manual feed tray. The following instructions illustrate the proper setup of the feeder.

Note: The feeder can be setup for your envelopes away from the printer and then easily placed in line with the printer

after setup is complete.

Setting up the Feeder for Envelopes

Setting the feeder for your envelopes consists of the following basic steps:

1. Setting up the hopper paper guides

2. Setting up the sheet separator(s)

3. Setting the back wedge (envelope stack support)

4. Setting the delivery table paper guides

5. Testing the feeder

6. Moving the feeder into position alongside the printer

3.1. Setting the Hopper Paper Guides

Step 1. Ensure that the main power switch on the feeder’s

control panel is in the OFF position and plug the 24

VDC power supply, included with the feeder, in the

power jack on the control panel.

Step 2. Rotate the paper guide adjusting knob on the bridge

to position the paper guides outward toward the side

plates of your feeder.

24 VDC power input

11

1

3

6 7

Step 3. Loosen the locking knobs on the acceleration table

paper guide blocks and slide the acceleration table

paper guides outward. Grasp the paper guide

block to move the guides.

Locking knobs

Step 4. Loosen the back wedge assembly locking knob

and slide the back wedge back away from the feed

belts for easy access to the envelope hopper area.

Step 5. Place one of your envelopes between the hopper

paper guides above the feed belts.

Step 6. While holding the envelope with one hand, rotate the paper guide adjusting knob to move the

paper guides in until they are alongside the edges of your envelope.

Do not pinch the envelope with the Hopper paper guides.

12

4

5

The ColorSplash EPP Envelope Feeder utilizes a patented technique for separating the bottom envelope from the stack

called 'buckle separation'. This unique method separates the envelopes by buckling them downward between feed

belts. This results in simple sheet separation and minimizes envelope scuffing and paper jams.

You will notice in the following instructions that the separator(s) are positioned between the

feed belts, not over them.

When in this position, the separators push down on the envelope as it is advanced from the bottom of the stack, forming

a downward 'buckle' in the envelope between feed belts.

This method is simple, effective, easy to set up and does not require a lot of fine tuning. The downward buckle breaks

the friction 'bond' between the bottom envelope and the stack, making it easier to pull the bottom envelope away.

This method of separation also reduces jams because with the separators pushing down on the envelope between,

rather than on top of, the feed belts, there is not a 'pinch point' created.

The EPP Envelope Feeder comes with two buckle separator assemblies. Most jobs only require the use of one

separator so we recommend trying a single one in the middle first as shown here:

3.2. Setting the Envelope (Buckle) Separators(s)

If you are not getting consistent results after some time and adjustments, you may wish to try two separators as

shown here:

Note that in both examples above, the separators are positioned between belts.

Single separator

(positioned between belts)

Separator locking knob

(loosen to reposition

separator(s))

Two separators.

Each positioned between

two feed belts

13

1

2

3

4

3.2 Setting the Envelope Separator(s) (continued)

Step 1. If using a single separator (recommended), ensure

that the buckle separator is positioned in the gap

between the two center feed belts.

Step 2. Rotate the separator height adjustment knob

clockwise several turns to raise the separator

tip up above the level of the feed belts.

Step 3. Place the lead edge of your envelope under the

buckle separator’s yellow tip as shown below.

Separator height adjustment knob

Separator tip (yellow)

Step 4. Slowly turn the separator height adjustment

knob counter-clockwise to lower the separator tip onto

the envelope.

14

5

Step 5. Continue to slowly lower the separator tip until the envelope is buckled downward between the

belts slightly (approx 2mm (1/16") to 3mm (1/8").

NOTE: Ensure that the separator tip is between feed belts so it does not 'pinch' the envelope.

Step 6. (optional) If you are using two separators, repeat the above steps for both.

NOTES: The separators do not need a lot of fine tuning, as a small buckle is all that is required.

Some experimentation is recommended to get the best results with your materials.

One or both separators can be used as desired, but be sure to position the separators between belts and buckle the

envelopes down slightly.

There is no specific configuration that you must use as this design offers tremendous flexibility. If one setup doesn’t

work, try moving the separators to different positions across the feeder bridge.

Lower the separator tip to 'buckle' the envelope down between belts

15

3.3. Setting up the Back Wedge

Step 1. After setting the separator as shown in the

previous steps, leave one envelope in the

feeder, that you used for the separator setup.

Step 2. Carefully shingle out a small stack of envelopes so

that the bottom one will be the foremost envelope

in the stack as shown here.

Step 3. Place the stack in the hopper on top of the

envelope left on the belts from the separator

setup. Try to 'nudge' the envelopes a bit from the

back to help the stack conform to the curvature

of the paper guides at the bottom.

The back wedge, attached to the rear plate of the feed

hopper is a very important tool that must be set properly

to obtain the best results.

3.3.1. Purpose of the Back Wedge

The back wedge performs several important functions:

1. Supports the weight of the stack so that not all of the weight is on the belts.

2. Tilts the back end of the media stack up so the lead edge presses against the belts.

3. (most important) While the bottom envelope is getting pulled away from the stack by the feed belts, the

back wedge holds the other envelopes off the belts so they don’t advance too closely after the first one.

16

1

2

3

Step 4. With one hand, raise the back end of the

envelope stack up and then slide the back

wedge into position underneath the back

end of the stack. Lock the wedge in place

with the locking knob.

As shown in the pictures above and left, the back wedge

should be in just far enough to hold the back edge of the

envelope stack up off the belts.

Step 5. The angle of the back wedge can be adjusted to

assist with different kinds of envelopes. To adjust

the angle, loosen the locking lever on the side of

the back wedge.

Step 6. The height of the back wedge ramp can also be

adjusted by loosening the round locking knob on

the back of the upright as shown here. For smaller

envelopes, the top of the ramp should be slightly

below the top of the upright.

Back wedge upright

Locking lever

17

4

5

6

As with the separators, some experimentation would be helpful to obtain the best results.

3.3.3. Setting the Back Wedge for large envelopes

In addition to setting the paper guides properly for large envelopes, the back wedge will need to be adjusted.

For larger (longer) envelopes, you will need to move the back wedge further away from the bridge.

Larger (longer) envelopes have a tendency to 'sag' downward in the middle, which can cause double feeding or

inconsistent gaps between envelopes. This 'sagging' can be remedied by lowering the angle of the back wedge

and moving it a bit more underneath the stack of envelopes as shown below.

Back wedge locking knob

The back wedge ramp can be used to lift the middle of the envelopes off

the belts

18

After setting these guides, remove the envelope.

Note: The acceleration table paper guides can be locked in to position by tightening the paper guide block

locking knobs.

1

2

3.4. Setting the Acceleration Table Paper Guides

The patented 'floating' or tilting delivery table on the ColorSplash EPP

envelope feeder is designed to advance the envelopes that the feed belts

deliver, one at a time, into the printer’s manual feed tray feed roller.

The acceleration table is equipped with self centering paper

guides, an envelope drive belt and a stop photo sensor at the

end. The photo sensor is used to stop each envelope in position

underneath the printer’s feed roller, for take-away by the printer.

An additional photo sensor is positioned a few inches back

from the stop sensor. This is the restart sensor. When the first

envelope is pulled away by the printer, the trail edge of that

envelope uncovers the start sensor, which starts the feeder

motor. Using the dual sensors allows the ColorSpalsh EPP

envelope feeder to run larger envelopes at higher speeds.

Step 2. Grasp the acceleration table paper guide block and

slide the paper guides inward until they are close to

the edges of your envelope.

Lift hold down strap to place envelope

underneath

Step 1. After the feeder portion of the machine has been

set for your envelopes as per the previous section,

position one of your envelopes over the exit end of

the acceleration table between the paper guides.

Paper guide locking knob

Do not set the guides tightly against

the envelope. Too tight will restrict the

envelope movement.

19

The feeder should advance the bottom envelope from your stack until it reaches the exit end of the

acceleration table. When the envelope lead edge blocks the stop photo sensor, the feeder motor will stop.

3

4

5

Step 3. Set the speed control knob on the control

panel to approximately 20% to test the feeder.

Step 4. With the green feed switch in the off position, turn on

the feeder power with the red power switch.

Step 5. Move the green feed switch to the 'resume feeding'

position to start the feeder.

Note: Due to the downward angle of the

acceleration table, if you are running short

envelopes, the first envelope may fall off the

end of the acceleration table after pausing the motor

for a moment. If this happens, the stop photo sensor

will become unblocked and the feeder will advance

the next envelope. This is normal and does not

indicate a problem.

Note: The feeder has a 4 second timeout

feature that is used to stop the motor in the

event of a paper jam or if the feeder runs

out of envelopes. If, during this setup procedure, the

machine is set to run very slowly the envelope may

not reach the stop photo before the 4 second timer

stops the motor. If this happens, simply press the

reset button on the control panel to reset the timer

and start the motor. Stop photo sensor (under envelope)

20

Other manuals for CS4000

2

This manual suits for next models

1

Table of contents

Other Intec Printer manuals