THEORY OF OPERAT ION-MAINTENANCE

If you are new to high quality sound recording equip-

ment, you should become aware of the fact that high

quality sound requires high quality maintenance.

Recording studios that rent time by the hour are very

fussy about maintaining their equipment. Tape recorders

and other electronic gear in the studio are checked out

before every session. And, if necessary, adjusted to "spec"

by an "in house" service technician. He is usually

prepared to correct any problem from a minor shift in

circuit performance to

a

major breakdown n amotor. He

has a full stock of spare parts and al1 the est equipment

he needs.

Now that you are running your own "studio" you will

have to make some decisions about maintaining it, and

your 80-8. You will have to become your own "in house"

service technician. Well, what about the test gear and the

spare parts? A stock of spare parts and a super deluxe

electronic test bench can easily cost many times the price

of the recorder. Fortunately. the most frequently needed

adjustments use the least expensive equipment, and the

very costly devices are only needed for major parts

replacements such as drive and rewind motors or head

assemblies. Replacing parts cannot be considered "daily

maintenance" by any means, so we suggest that you leave

the major mechanical and electrical repair to the Dealer

Service Center. That's what it's for

Adjustments to the motors

-

back tension and brake

torque are not required often and can safely be left to

dealer service. The adjustments for wow and flutter

require severa1 thousands of dollars of testgear toperform.

It's not practical to consider doing these adjustments

yourself unless you have fifty machinesto service. Then it

might pay to buy the test gear.

In order to help you make plans about the more routine

adjustments to your 80-8, we have made this maintenance

section of the owners manual as easy to understand as

technology will allow. It's a short course in tape recorder

theory as well as a list of adjustmentsand will help you to

understand what

is

going on inside when you record. Read

the manual, decide what test equipment you can afford

(although it

is

not violently expensive, it

is

not free) and

determine what service you can do yourself.

Cleaning

The first thing-youwill need for service

is

definitely the

least expensive

-

Cleaning fluids and swabs. The whole

outfit,

2

fluids and al1 the cotton swabs you'll need for

months cost less than one roll of high quality tape. We

can't stress the importance of cleaning too much. Clean

up before every session. Clean up after every session.

Clean up every time you take a break in the middle of a

session (we're serious). How come? Well there are two

good reasons we can think of right off the top:

1.

Any dirt or oxide buildup on the heads will force the

tape away from the gaps that record and playback.

This will drastically affect the response. Even so small a

layer of dirt as one thousandth of an inch will cause big

troubles. All the money you have paid for high

performance will be wiped out by abit of oxide. Wipe

itoff with headcleaner and get back to normal.

2.

Tape and tape oxide act very much the same as fine

sandpaper. The combination will grind down the tape

path in time. If you don't clean off this abrasive on a

regular basis, the wear will be much more rapid and,

what's worse, it will become irregular. Even wear on

8

E'

A=

IOMILS

i

O

O.

2

0.4 0.6 O.

8

1.0

SPACING

-

MILS

W

>

0.05

u

J

W

a

0.02

O O

1

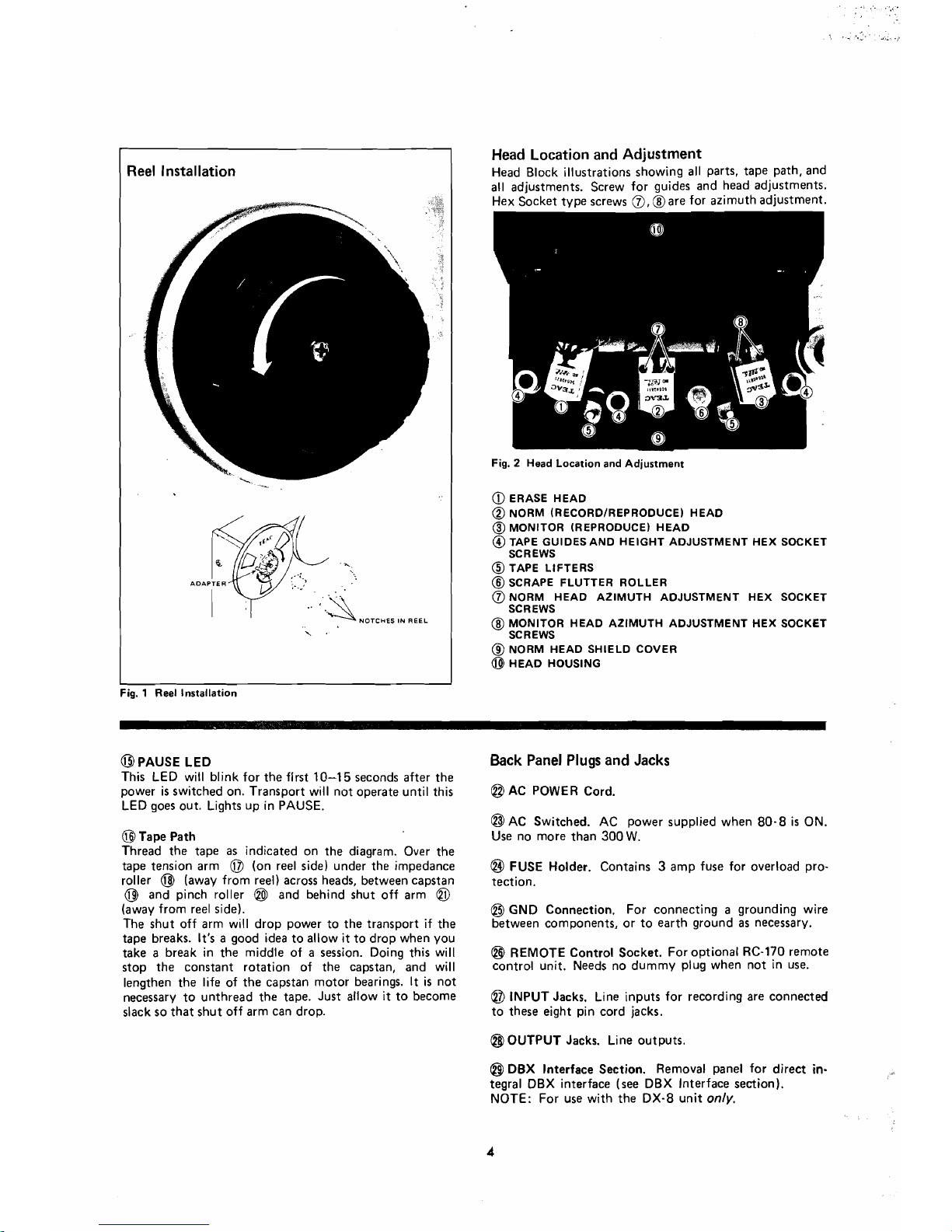

Fig.

3

Curves showing fall-off of reproduced signals versus spacing

from reproducer head.

(Courtesy, Minnesota Mining and Manufacturing Co.)

A-

I

MIL

SPACING

-

MILS

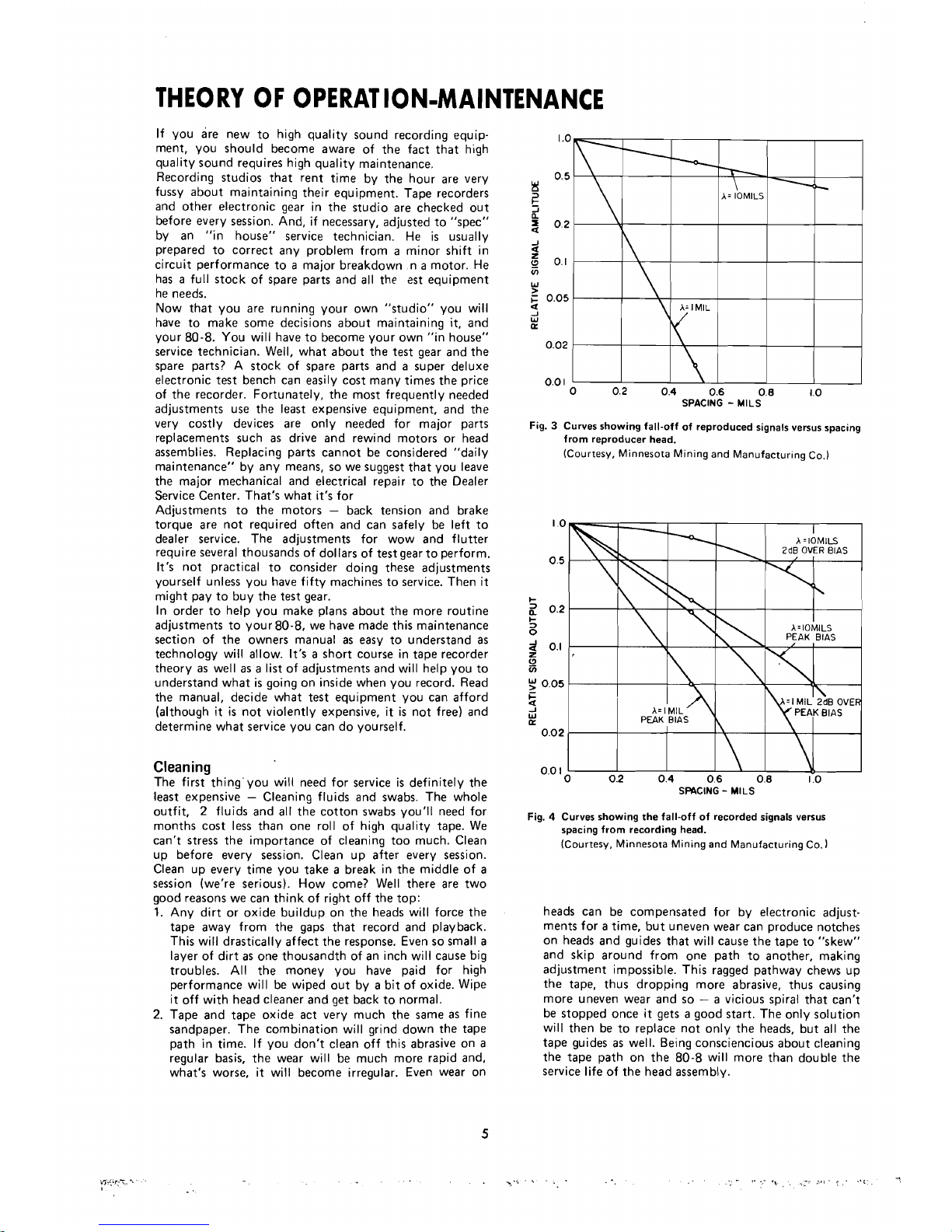

Fig.

4

Curves showing the fall-off of recorded signals versus

spacing from recording head.

(Courtesy, Minnesota Mining and Manufacturing Co.

heads can be compensated for by electronic adjust-

ments for atime, but uneven wear can produce notches

on heads and guides that will cause the tape to "skew"

and skip around from one path to another, making

adjustment impossible. This ragged pathway chews up

the tape, thus dropping more abrasive, thus causing

more uneven wear and so

-

a vicious spira1 that can't

be stopped once it gets agood start. The only solution

will then be to replace not only the heads, but al1 the

tape guides as well. Beingconscienciousabout cleaning

the tape path on the 80-8 will more than double the

service life of the headassembly.