Team Assocciated RC10B6.1 Dirt Light Team Kit User manual

2

:: Introduction

:: RC10B6.1DL KIT Features

:: Additional

:: Other Helpful Items

Thank you for purchasing this Team Associated product. This assembly manual contains instructions and tips for building and

maintaining your new vehicle. Please take a moment to read through the manual and familiarize yourself with the steps.

We are continually changing and improving our designs; therefore, actual parts may appear slightly different than the illustrations.

New parts will be noted on supplementary sheets located in the appropriate parts bags. Check each bag for these sheets before

you start to build.

• Easy access ball differential

• Differential height adjustment with 0, 1, 2, & 3mm insert included

• New slipper assembly for better weight balance and shock clearance

• 3-gear Lay Down Stealth® transmission for lower and more rearward CG

• Heavy-duty V2 routed graphite front shock tower with tower guard

• Heavy-duty V2 routed graphite rear tower, LONG

• Heavy-duty V2 rear axle with 67mm bones

• V2 springs for a more reactive and nimble feel

• Innovative rear arm with molded inserts for ultra-fine lower shock mount adjustment

• Molded spur gear guard to help protect body from damage

• +1 steering block arms optimize feel on dirt tracks

• Battery strap allows the use of optional turnbuckle based braces

• Machined pistons included for better fit and smoother operation

• Aluminum rear clamping hex and front axle with laser etching

• Rear hubs feature large bearings and the easy-insert system to adjust camber link position and rear axle height

• One piece shock bushing to make assembly easier

• Aluminum C and D arm mount included for large range of anti-squat and toe adjustment

• Lightweight aluminum top shaft

• Factory Team upgraded ball bearing kit included (now oiled instead of greased for less drag)

• JConcepts B6 Light weight clear body and wing included

• Cyanoacrylate glue (CA)(#1597)

• Thread locking compound (#1596)

• Tires and Inserts, Fronts and Rears

• Wheels w/12mm Hex

Front Wheels#9690, #9691, #91572, #91573

Rear Wheels #9695, #9696, #91570, #91571

Tools included:

• Allen wrenches 1.5mm, 2.0mm

• #1113 12mm Shock Tool

• Multi-wrench

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.RC10.com · http://twitter.com/Team_Associated · http://www.instagram.com/teamassociatedrc/ · http://www.facebook.com/TeamAssociated/

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Your new B6.1DL Team Kit comes unassembled

and requires the following items for completion

(refer to catalog section for suggestions):

• R/C two channel surface frequency radio system

• AA-size batteries for transmitter (#302 alkaline)

• Electronic Speed Control, ESC (#27002, 27003, 27004, 27005)

• Steering servo (#27106, #27107)

• R/C electric motor

• Pinion gear (48P), size determined by type/wind of motor

• Battery charger (a peak detection charger, or LiPo compatible charger)

• 2 cell LiPo battery pack (#27318, 27322, 27323, 27324)

• Polycarbonate specific spray paint

• Silicone Shock Fluid (Refer to catalog for complete listings)

• Body Scissors (AE Part # 1737) • FT Body Reamer (#1499) • Shock Pliers (#1675)

• FT Hex/Nut Wrenches (AE Part # 1519) • FT Ballcup Wrench (#1579) • FT Universal Tire Balancer (#1498)

• Green Slime shock lube (AE Part # 1105) • FT Dual Turnbuckle Wrench (#1114) • Calipers or a Precision Ruler

• Soldering Iron • Hobby Knife • Wire Cutters

• Needle Nose Pliers

3

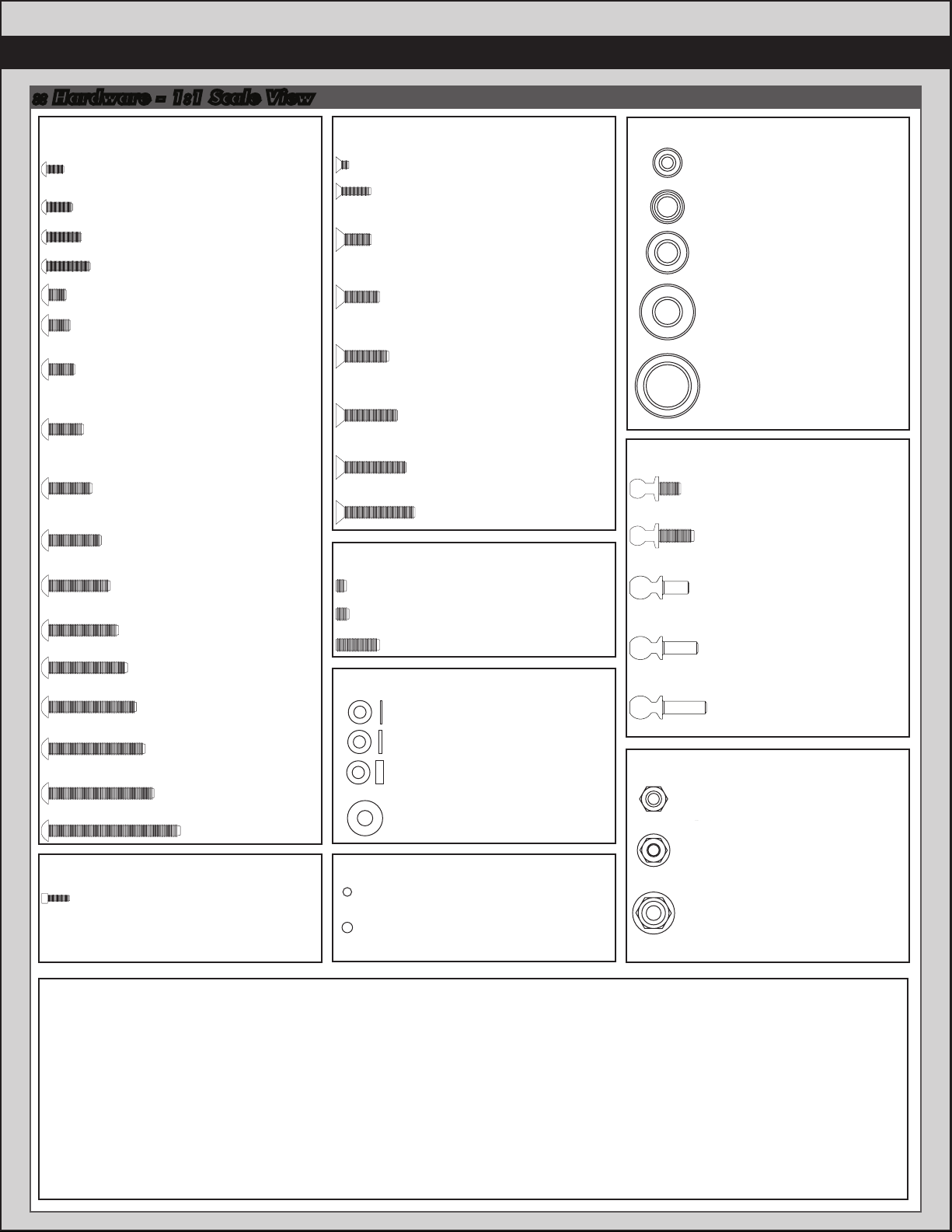

:: Hardware - 1:1 Scale View

2x3mm (91743)

2.5x8mm (31448)

3x8mm (25201)

Aluminum (8553)

Titanium (91592)

3x10mm (25202)

Aluminum (8555)

Titanium (91593)

3x12mm (25203)

Aluminum (8556)

Titanium (91594)

3x14mm (89208)

Aluminum (8567)

Titanium (91595)

3x16mm (25204)

Titanium (91596)

3x18mm (89209)

Titanium (91597)

Flat Head (fhcs)

2x4mm (31510)

Aluminum (8545)

2.5x6mm (31520)

2.5x8mm (31521)

2.5x10mm (31522)

3x4mm (91158)

3x5mm (31530)

3x6mm (31531)

Aluminum (8550)

Titanium (91580)

3x8mm (31532)

Aluminum (8552)

Titanium (91581)

3x10mm (25211)

Aluminum (8554)

Titanium (91582)

3x12mm (89202)

Titanium (91583)

3x14mm (25187)

Titanium (91584)

3x16mm (89203)

Titanium (91585)

3x18mm (2308)

3x20mm (25188)

Titanium (91587)

3x22mm (25189)

Titanium (91588)

3x24mm (89204)

Titanium (91589)

3x30mm (91478)

Button Head (bhcs) Ball Bearings

3x7x3mm (91475)

5x8x2.5mm (31400)

5x10x4mm (91560)

6x13x5 (91562)

10x15x4 (91563)

3x2.5mm (31500)

3x3mm (25225)

3x10mm (4671)

Set Screws

5.5x0.5mm (31381)

5.5x1.0mm (31382)

5.5x2.0mm (31383)

3x8mm Washer (89218)

Shims and Washers

Notes:

5/64 Diff Thrust Balls (6574)

3/32 Carbide Diff Balls (6581)

3/32 Ceramic Diff Balls (6584)

Diff Balls

M3 Nut (91477)

M3 Alum. Locknut, Blue (31550)

M3 Locknut, Black (25215

M3 Locknut w/Flange (25612)

FT 3mm Locknuts, Blue(25392)

M4 Locknuts:

Serrated Steel (Silver)(91826)

Flanged (Black) (91148)

FT Aluminum (Blue) (31551)

Serrated Aluminum (Black) (91738)

Nuts (lock/plain)

Cap Head (shcs)

1.6 x 5mm (91611)

Ballstuds

Silver 5mm long (31283)

Ti Nitride 5mm long (31291)

Silver 8mm long (31284)

Ti Nitride 8mm long (31292)

HD 6mm (91047)

Ti Nitride HD 6mm (91118)

Ti HD 6mm (91751)

HD 8mm (91048)

Ti Nitride HD 8mm (91119)

Ti HD 8mm (91752)

HD 10mm (91049)

Ti Nitride HD 10mm (91120)

Ti HD 10mm (91753)

4

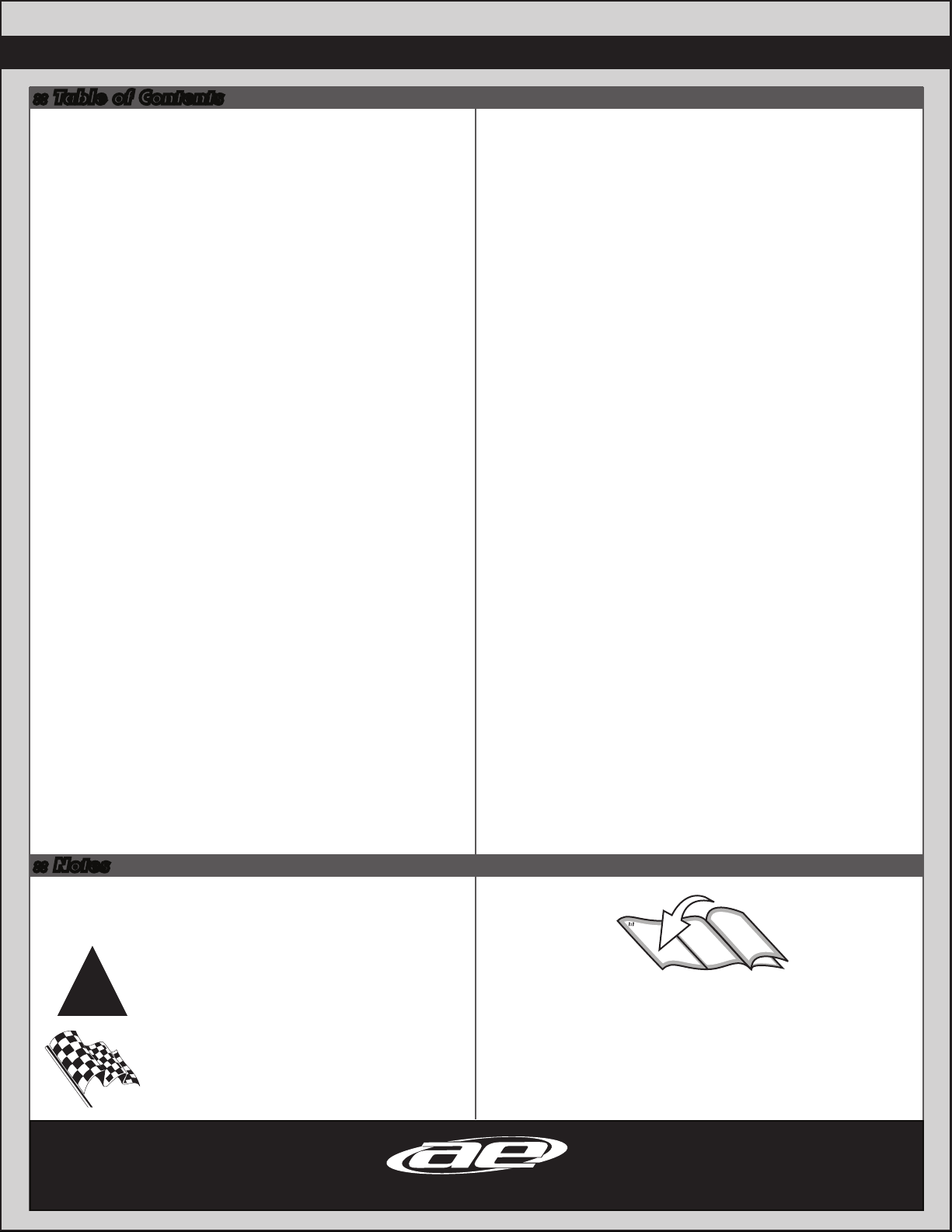

:: Table of Contents

:: Notes

This symbol indicates a special

note or instruction in the manual.

This symbol indicates a Racers Tip.

1................... Cover

2................... Introduction

3...................1:1 Hardware “Fold Out”

4................... Table of Contents

5....................Bag 1

5 - 8..............Bag 2

8 - 9..............Bag 3

9 - 10...........Bag 4

10 - 11.........Bag 5

11 - 13........Bag 6

13 - 14........Bag 7

14 - 15........Bag 8

15 - 16........Bag 9

17 - 19........Bag 10

19 - 21....... Tuning Tips

22 - 30.......Catalog

31................ Notes / Contact Info

32................Setup Sheet “Kit Setup”

33................Setup Sheet “Blank”

34................Back Cover

!There is a 1:1 hardware foldout page in the

front of the manual. To check the size of a part,

line up your hardware with the correct drawing

until you find the exact size. Each part in the

foldout has a number assigned to it for ordering

replacement parts.

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.RC10.com · http://twitter.com/Team_Associated · http://www.instagram.com/teamassociatedrc/ · http://www.facebook.com/TeamAssociated/

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

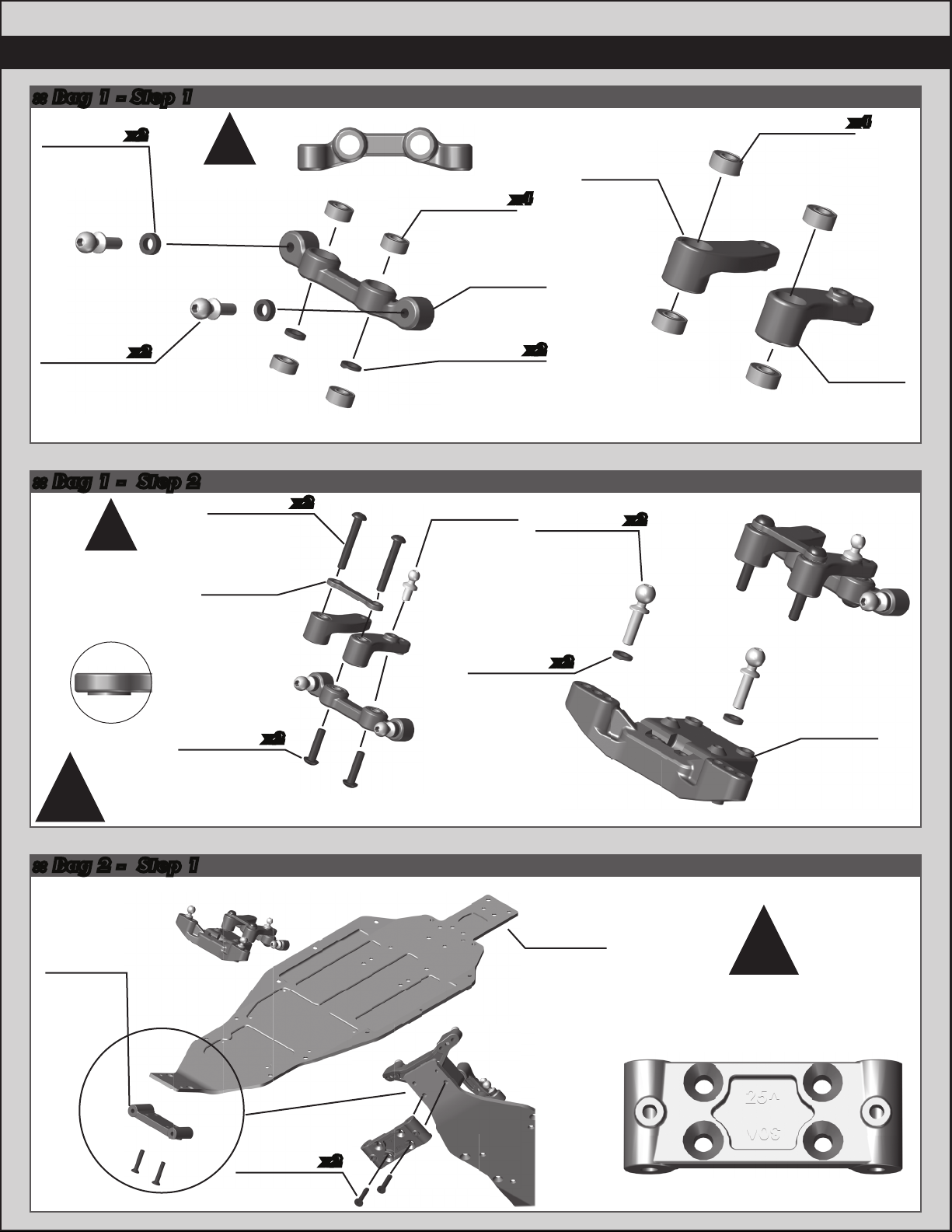

:: Bag 1 - Step 2

:: Bag 2 - Step 1

5

:: Bag 1 - Step 1

4/19

91667

Steering

Bellcrank

Brace

x2

91678

M3 x 20mm

BHCS

Shouldered

Do not overtighten steering bolts. Make sure

there is free movement in the steering rack.

91475

3 x 7 x 3

Ball Bearing

91475

3 x 7 x 3

Ball Bearing

91667

Steering

Rack

91667

Steering

Bellcrank

(Right)

Front

91667

Steering

Bellcrank

(Left)

x4

x4

x2

x2

x2

91048

Heavy-duty

Ballstud,

8mm

31382

FT Ballstud

Washer,

Aluminum

(1mm)

31382

FT Ballstud

Washer,

Aluminum

(1mm)

!

x2

89202

M3 x 12mm

BHCS

31283

5mm Ball

Stud, Long

Note orientation

of steering rack.

!

The steering

bellcrank brace

has offsets on one

side. They should be

installed towards

the bearings.

!x2

x2

91049

Heavy-duty

Ballstud,

10mm

31382

FT Ballstud

Washer,

Aluminum

(1mm) 91766

Front

Ball Stud

Mount

x2

25204

M3 x 16mm

FHCS

91656

Bulkhead

91765

Chassis,

B6.1 There are two bulkhead settings

(25 °, 30 °). 25 °is the standard used.

The arrow should point

forward for the desired setting.

!

25

30

>

>

TOP

6

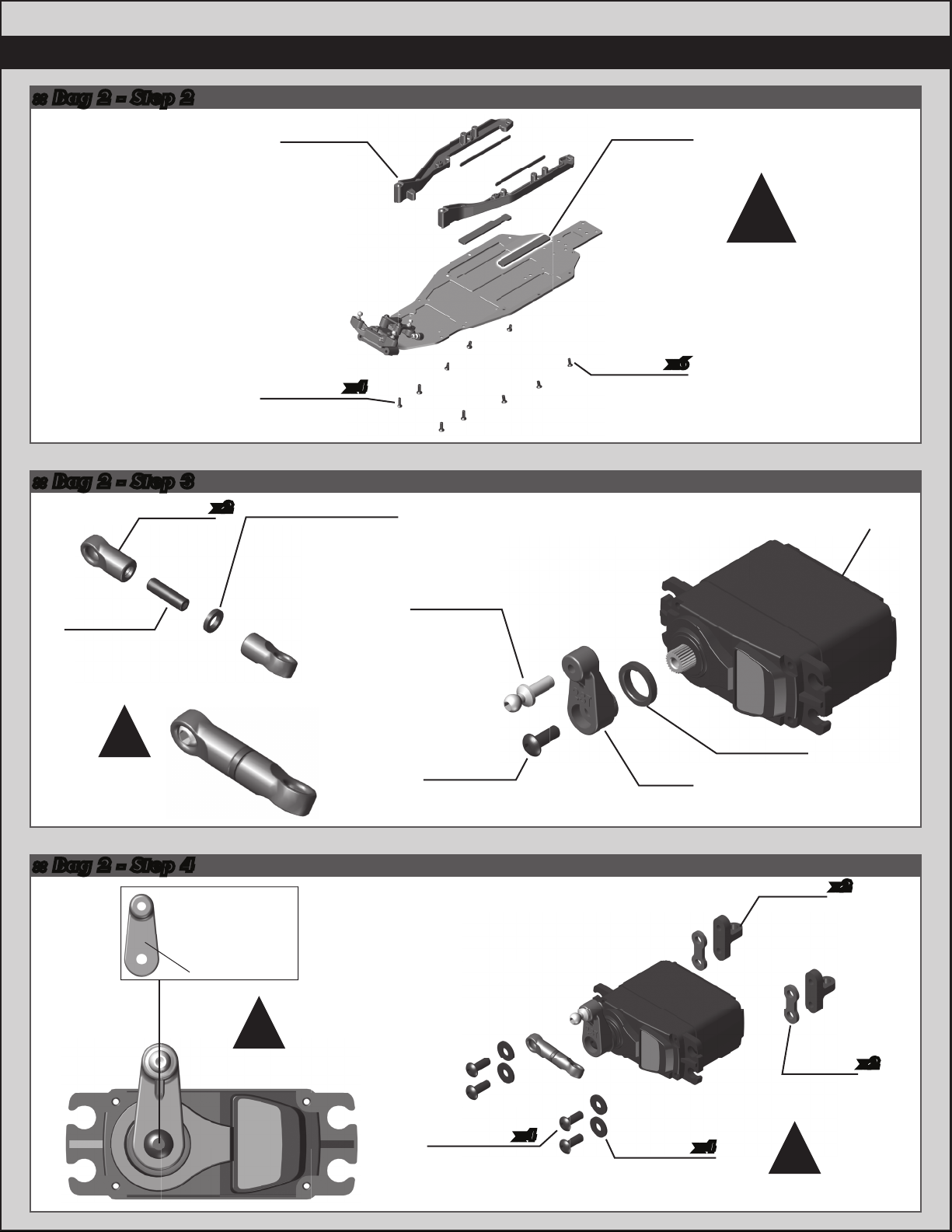

:: Bag 2 - Step 2

:: Bag 2 - Step 4

A - Airtronics

F - Futaba

H - Hitec

J - JR

Printed here

:: Bag 2 - Step 3

4671

M3x10mm

Set Screw

91820

Steering

Link, B6.1

31382

FT Ballstud

Washer, aluminum

(1mm)

Tighten the

steering link ball

cups all the way

until snug.

!

Align the servo

horn 90 degrees

!

91728

Servo Horn

Ring

31284

8mm Ball

Stud, Long

91728

Servo

Horn

Servo not

included!

x2

31532

M3 x 8mm

BHCS

x4

x6

25202

M3 x 10mm

FHCS

91652

Side Rails

(L & R)

25201

M3 x 8mm

FHCS

91734

Battery

Foam, B6

#91734 - Battery Foam

There are two thickness

options to accomodate

any battery size.

!

#91728 - Servo Spacers

are not required for all servos.

!

89218

M3 x 8mm

Washer

91719

Servo

Mount

91728

Servo

Spacers

31532

M3 x 8mm

BHCS

x4

x2

x2

x4

7

:: Bag 2 - Step 7

:: Bag 2 - Step 6

:: Bag 2 - Step 5

The front hinge pin

brace has a sharp

edged side, and a

rounded edge side.

Mount the sharp

edge side towards

the bulkhead.

!

25211

M3 x 10mm

BHCS

x2

91766

Top Plate,

B6

25187

M3 x 14mm

BHCS

x2

25211

M3 x 10mm

BHCS

x2

31510

M2 x 4mm

BHCS

91673

Front Arms,

Gull-Wing, B6

91656

Front Hinge

Pin Brace,

B6

x2

x2

91670

Hinge Pin

(front, Inner)

25225

M3 x 3mm

Set Screw

x2

x2 25204

M3 x 16mm

FHCS

91685

Front

Bumper

x2

:: Bag 3 - Step 2

:: Bag 3 - Step 1

8

:: Bag 2 - Step 8

Build 2 (1 left, 1 right)

x2

31531

M3 x 6mm

BHCS

91560

5 x 10 x 4

Bearing

91682

Front Axle

91677

Steering

Block

(4mm)

#1596

thread lock

25188

M3 x 20mm

BHCS

25202

M3 x 10mm

FHCS

91815

Shock

Bushing,

10mm

91768

Front Shock

Tower,

Gull-Wing

91771

Front Shock

Tower Cover,

Gull-Wing

x2

x4

x2

Build 2 (1 left, 1 right)

91049

Heavy-duty

Ballstud,

10mm

25215

M3 Locknut,

black

91675

Caster

Block Insert

(+5°)

There are three caster

block inserts included

(0°, +/- 2.5 °, +/- 5 °).

+5 ° is the standard

insert used.

Tab up =positive caster

Tab down =negative caster

There are two sets of steering

blocks included with your kit, a 3mm

and a 4mm. The 4mm steering

blocks are used for the kit setup.

!

!

91675

Caster

Block

You can install an

optional #31520 screw

to use as a steering

stop setting.

You can install an

optional #4670 set

screw to better hold

the caster block inserts

and hinge pin.

Total

Caster

25°25°30°20°2 7. 5 °22.5°

0 2.5 up 5 up2.5 down 5 down

30°30°35°25°32.5°2 7. 5 °

Bulkhead

Orientation

Caster Block Insert

Bearing

Bearing

There are two sets of steering

There are two sets of steering

blocks included with your kit, a 3mm

blocks included with your kit, a 3mm

and a 4mm. The 4mm steering

and a 4mm. The 4mm steering

4L

25215

M3 Locknut,

black

91680

Steering

Block Arm

(+1)

91048

Heavy-duty

Ballstud,

8mm

31382

FT Ballstud

Washer,

Aluminum

(1mm)

optional #31520 screw

31532

M3 x 8mm

BHCS

x2

25202

M3 x 10mm

FHCS

x4x4

:: Bag 4 - Step 2

:: Bag 4 - Step 1

9

:: Bag 3 - Step 3

Build 2 (1 left, 1 right) Build 2 (1 left, 1 right)

91777

Rear

Arms (L&R)

91777

Rear Arm

Threaded

Insert

x2

x2

91685

Rear

Bumper

91688

Aluminum

Arm Mount, D

91670

Hinge Pin

(rear, Inner)

92014

Arm Mount

Inserts

(up, 0.5°)

x2

x2

25187

M3 x 14mm

BHCS 91676

Caster Hat

Bushing

Top: 2mm

Bottom: 1mm

x2

31510

M2 x 4mm

BHCS

91675

Caster Block

Spacer

91670

Hinge Pin

(front, Outer)

x2

91772

Aluminum

Arm Mount,

C

92014

Arm Mount

Inserts

(up, 0.5°)

x2

31541

M3 x 6mm

FHCS

x2

#91670 - Hinge Pin will be

tight in the caster blocks,

but should rotate freely

in the front arms.

!

BCD A

Install the rear arm threaded

insert in the same position for

the left and right side arms!

See page 10 for

pill chart tips

!

!

Center 0.5° Up

Center 0.5° Up

10

:: Bag 5 - Step 2

:: Bag 5 - Step 1

:: Bag 4 - Step 3

#6588

black grease

6573

Diff thrust

washer

6574

5/64 diff

thrust

balls

6573

Diff thrust

bolt

x2

x6

31400

5 x 8 x 2.5mm,

Bearing

x2

6581

3/32 carbide

diff balls

91419

Diff Gear,

52T

91701

Ball Diff

Outdrive

91701

Ball Diff

Outdrive

7666

Diff Drive

Ring

7666

Diff Drive

Ring

x14

#6591

diff lube

#6591

diff lube

#6591

diff lube

Anti-SquatToe-In

3°

Kit Setup

1°

Kit Setup

3° 2°

3° 1°

The (#91772) C and (#91688) D aluminum arm

mounts allow for a large amount of setup

combinations when using the (#92014) 0.5°

and 1°arm mount inserts.

For a complete list of pill setup combinations, please

visit our website by using the link or QR code below.

https://www.teamassociated.com/pdf/cars_and_

trucks/RC10B6/B6_B6D_Pill-Chart.pdf

!D Plate

Center 0.5° Up

C Plate

Center 0.5° Up

D Plate

Center

C Plate

Center

D Plate

Center

C Plate

1° Up

Commonly used setups

11

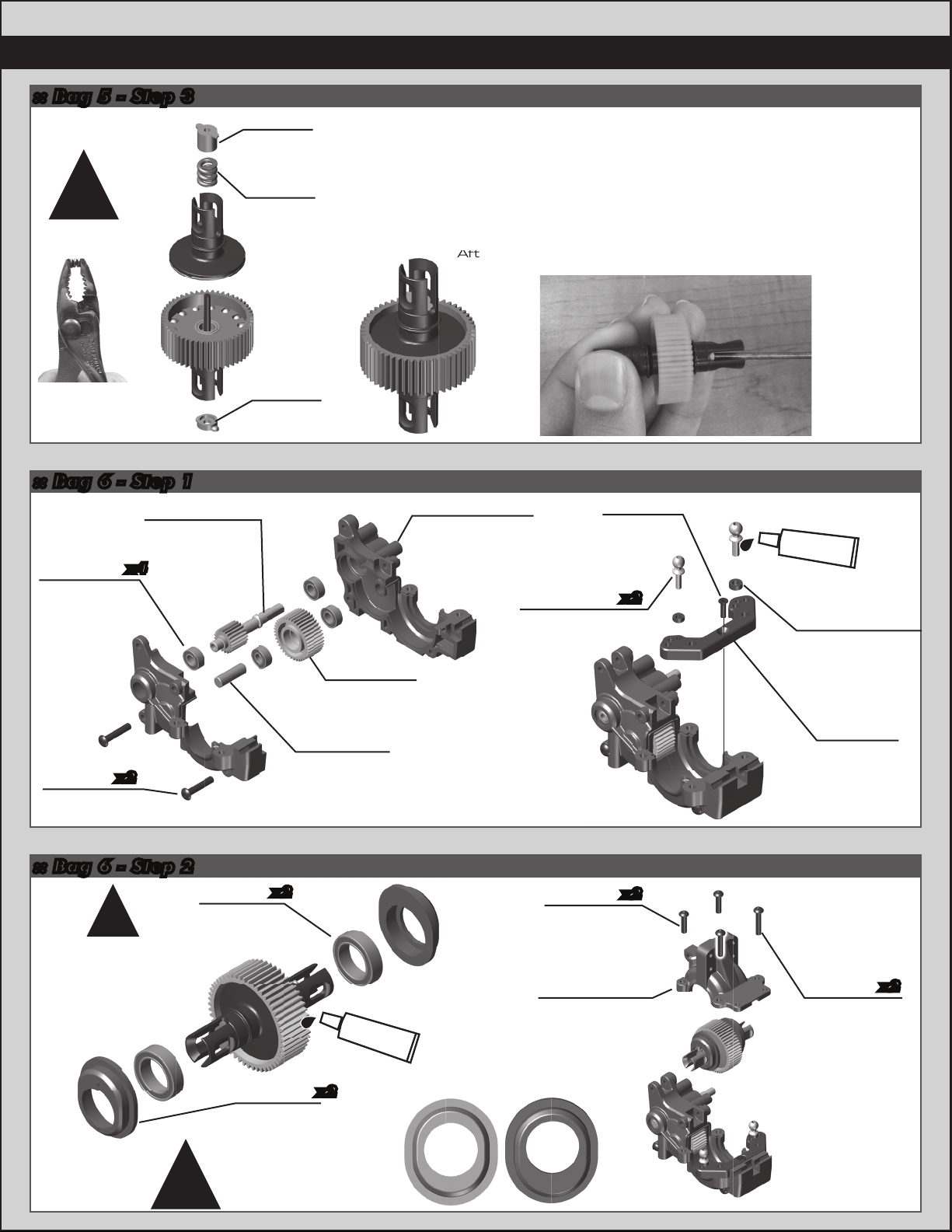

:: Bag 6 - Step 2

:: Bag 6 - Step 1

:: Bag 5 - Step 3

As you tighten the diff bolt, you will notice the T-nut ears moving

closer to the bottom of the outdrive slot. This compresses the

spring behind the T-nut. The spring should be completely

compressed at the time the T-nut reaches the end of the slot.

Caution! Pay close attention to the feeling when the spring is

completely compressed. Do not overtighten the bolt. When you

feel the spring completely compressed, loosen the diff bolt 1/8”

of a turn. Your diff should now operate smoothly but with

resistance as the outdrives move in opposite directions.

After you have driven the car once, re-check the diff setting.

After you have driven the car once, re-check the diff setting.

6575

Diff

cover

6575

Locking

t-nut

6582

Diff

thrust

spring

Compress

spring first.

!

#6591

diff lube

Add a drop of Diff

Lube (#6591) to

the teeth of the diff

gear, idler gear, and

top shaft.

!

91792

B6.1 Diff

Height Insert

91563

10x15x4

Bearing

x2

x2

!

2

1

3

0

Diff Height Inserts:

The number on top

is the setting.

Stock diff height is 0.

91791

B6.1 Laydown

Gearbox

(right & left)

91560

5 x 10 x 4,

Bearing

89203

3x16mm

BHCS

31448

2.5x8mm

FHCS

91716

Idler Gear

39T

91799

B6.1 Laydown

Top Shaft

91132

Idler Gear

Shaft,

Aluminum

x4

x2

91048

Heavy-duty

Ballstud, 8mm

x2

91775

B6.1 Rear

Ballstud

Mount,

Aluminum

31383

Ballstud

Washers,

5.5x2.0mm,

Blue Aluminum

89202

3 x 12mm

BHCS

91791

B6.1 Laydown

Gearbox Top

89203

3 x 16mm

BHCS

x2

x2

#1596

thread lock

12

:: Bag 6 - Step 5

:: Bag 6 - Step 4

:: Bag 6 - Step 3

91811

B6.1 Spur

Gear, 78T

91799

B6.1 Top

Shaft Screw

91799

B6.1 Top

Shaft Pin

x2

9611

Slipper

Pad, V2

91803

B6.1 Slipper

Hub, Inner

91804

B6.1 Slipper

Hub, Outer

25202

M3 x 10mm

FHCS

x6

Set nut

flush with

top shaft.

See page 20 for gear

mesh, and slipper clutch

setting instructions!

!

!

25204

M3 x 16mm

FHCS

x2

91801

Slipper Spring

Adapter, Inner

91801

Slipper Spring

Adapter, Inner

91801

Slipper

Spring

25215

M3

Locknut

!

#91811 spur gear

walls should point

away from gear box.

25202

3 x 10mm

FHCS

91813

B6.1 Gear

Guard 91795

B6.1 Laydown

Motor Plate

x3

91819

B6.1 Shock

Pivot Ball

91709

Lay-Down

Chassis

Brace

89203

3 x 16mm

BHCS

25188

3 x 20mm

BHCS

There’s also a

72T, 48P spur

gear (#91809)

included for

stock motor use!

!

13

:: Bag 7 - Step 2

:: Bag 7 - Step 1

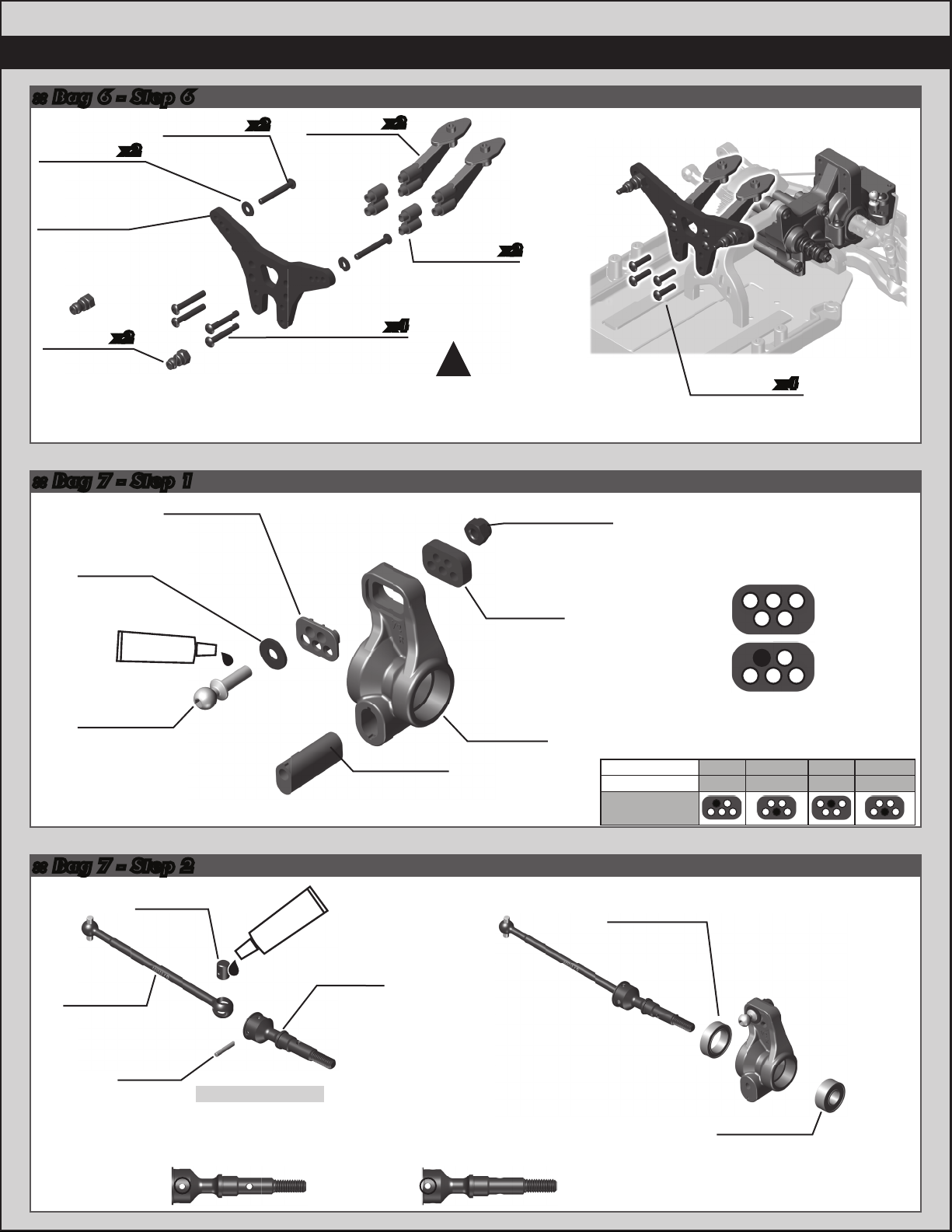

:: Bag 6 - Step 6

Build x2 (right and left side)

Rear Hub Link Setting

(Right Side Shown):

(Right Side Shown):

Up A

E

C

C

E

A

B

D

D

B

Down

Insert 0/3 up

0 (low) + 3mm + 1mm + 2mm

1/2 up0/3 down 1/2 down

Recommended

Ballstud location

Axle Height

Build x2 (right and left side)

25189

M3 x 22mm

BHCS

x2 x2

x2

91718

Rear Wing

Mount

91718

Rear Wing

Mount Spacer

25188

M3 x 20mm

BHCS

89218

M3 x 8mm

Washer

91816

Shock

Bushing,

12mm

91770

Rear Shock

Tower, B6.1

(Long)

x4

x2

x2

#1596

thread lock

25215

M3 Locknut,

black

91698

Rear Hub

Link Nut

91779

Rear Hub

Link Insert

91779

Rear Hub

B6.1

91049

Heavy-duty

Ballstud,

10mm

89218

3 x 8mm

Washer

91563

10 x 15 x 4

Bearing

91562

6 x 13 x 5

Bearing

There is an optional wing mount spacer included

in your kit. If you do not use the optional wing

mount spacer, use #89202 3 x 12mm BHCS

instead of the #25188 3x20mm BHCS.

!

91762

HD CVA

Axle, V2

91438

CVA Pin

#6588

black grease

91438

CVA

Coupler

91434

CVA Bone,

67mm

CVA Axle Holes

There are two hole locations on the #91762 CVA axle.

One is used for the included 67mm CVA bones, and

one for the optional 65mm CVA bones.

Use the inner hole for the included 67mm CVA bones.

67mm hole

location

65mm hole

location

91779

Rear Hub

Insert (0/3)

Kit Setup: Tab up (0mm)

89202

M3 x 12mm

BHCS

x4

14

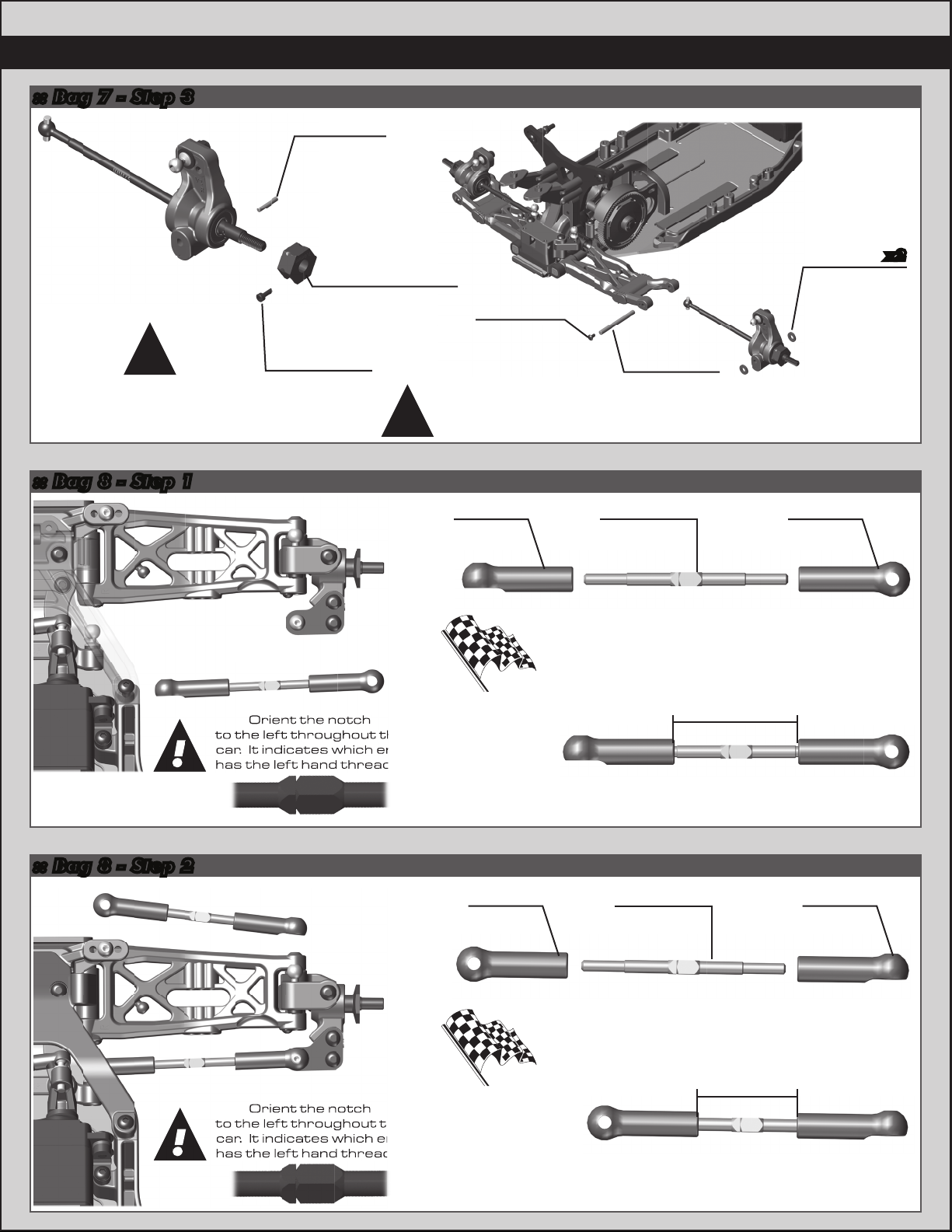

:: Bag 8 - Step 2

:: Bag 8 - Step 1

:: Bag 7 - Step 3

91722

Ball Cup

91722

Ball Cup

91723

Turnbuckle

3x48mm

Racers Tip:

Use black grease

(#6588) on the

threads of the

turnbuckles for

easier ball cup

installation!

Orient the notch

to the left throughout the

car. It indicates which end

has the left hand threads!

!

Build x2 (right and left side)

Front Camber Turnbuckle

23.00mm

91722

Ball Cup

91722

Ball Cup

91723

Turnbuckle

3x48mm

28.50mm

Steering Turnbuckle

Build x2 (right and left side)

Racers Tip:

Use black grease

(#6588) on the

threads of the

turnbuckles for

easier ball cup

installation!

Orient the notch

to the left throughout the

car. It indicates which end

has the left hand threads!

!

Build x2 (right and left side)Build x2 (right and left side)

Orient the notch

to the left throughout the

car. It indicates which end

has the left hand threads!

!

Orient the notch

to the left throughout the

car. It indicates which end

has the left hand threads!

!

91779

Rear Hub

Spacer

91670

Hinge Pin

(rear, outer)

31510

M2 x 4mm

BHCS

x2

91611

M1.6 x 5mm

SHCS

91436

CVA Wheel

Hex Pin

91610

Clamping Wheel

Hex, 7mm Offset

(rear)

Do not overtighten the

1.6 x 5mm SHCS into the

Clamping wheel hex.

!

#91670 - Hinge Pin will be

tight in the rear hub, but

should rotate freely

in the rear arms.

!

15

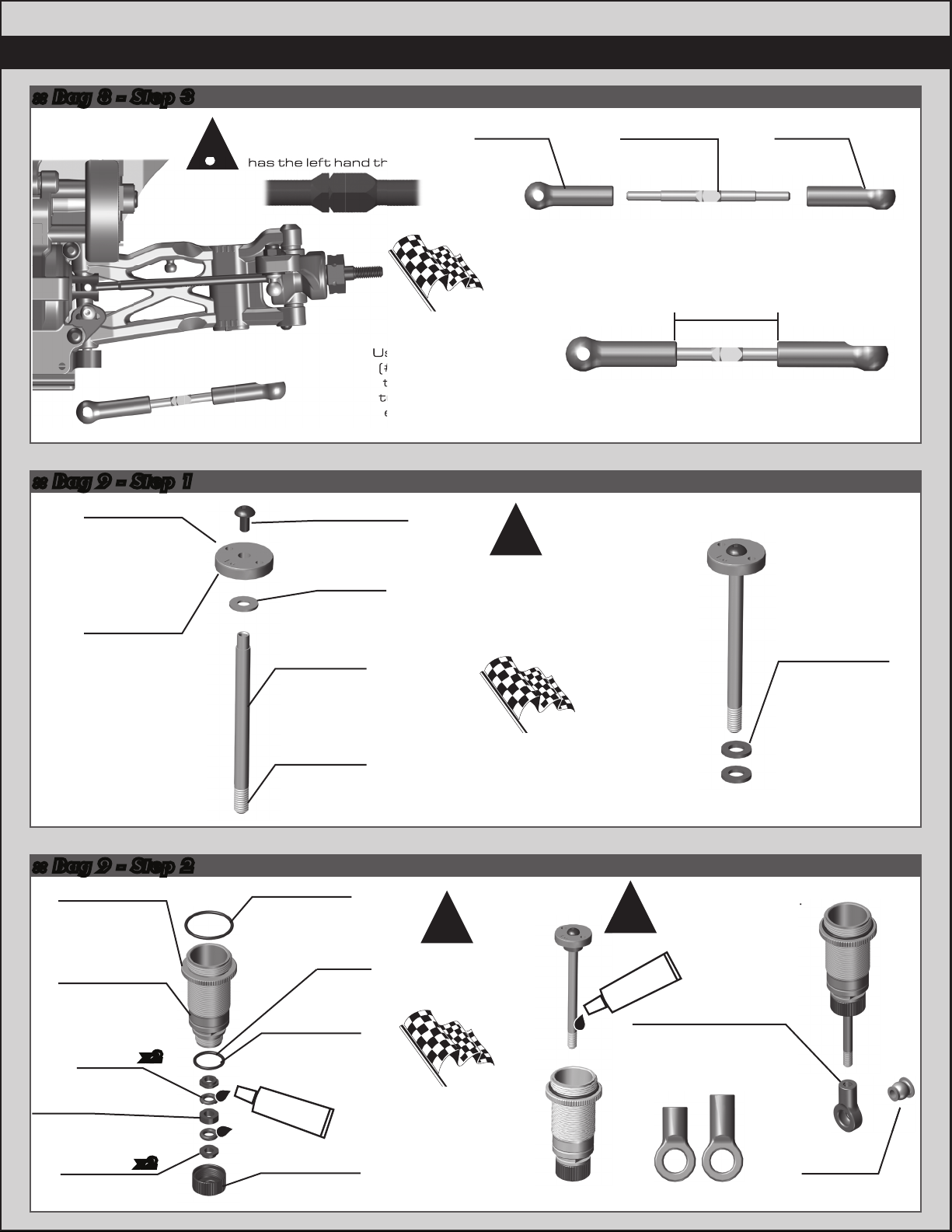

:: Bag 9 - Step 2

:: Bag 9 - Step 1

4187

Nylon Spacer,

(.030)

Front:

2 spacers

Rear:

1 spacers

:: Bag 8 - Step 3

Racers Tip:

Use a marker over the

numbers on the pistons to

make them easily visible!

Mount the shock

pistons with the

number facing up!

!

91722

Ball Cup

91722

Ball Cup

91723

Turnbuckle

3x48mm

Racers Tip:

Use black grease

(#6588) on the

threads of the

turnbuckles for

easier ball cup

installation!

Orient the notch

to the left throughout the

car. It indicates which end

has the left hand threads!

!

Build x2 (right and left side)

Rear Camber Turnbuckle

23.75mm

Use black grease

(#6588) on the

threads of the

turnbuckles for

easier ball cup

has the left hand threads!

!

91480

12x23mm V2

Shock Bodies

(front)

91482

12x31mm

V2 Shock

Bodies (rear)

91495

V2 Shock

Hat Bushing

91495

V2 Shock

Spacer

91493

X-Ring

31327

VCS3 Shock

Bottom Cap

31327

VCS3 Shock

Bottom Cap

O-Ring

91491

12mm

Shock Cap

O-Ring

x2

x2

#1105

green slime

Lightly rub shock oil

on the o-ring before

installation!

There is a short and

long shock eyelet.

Front and rear

shocks use the

long eyelet.

Racers Tip:

Coating the o-rings

with green slime

(#1105) helps seal

& reduce o-ring

swell! Green slime

not included in kit!

!!

long shock eyelet.

#1105

green slime

91820

Shock Eyelet

Front Shocks - Long

Rear Shocks - Short

91819

Shock

Pivot Ball

Short / Long

91626

FT 12mm V2

Shock Piston,

2x1.6 flat

(front)

91627

FT 12mm V2

Shock Piston,

2x1.7 flat

(rear)

91615

V2 3 x 21

Shock Shaft

TiN (front)

31510

M2 x 4mm

BHCS

89278

2.5mm

Washer

91619

V2 3 x 27.5

Shock Shaft

TiN (rear)

16

:: Bag 9 - Step 5

:: Bag 9 - Step 4

:: Bag 9 - Step 3

Front Shock: 30 wt

#5422

Rear Shock: 30 wt

#5422

Shock fluid

Steps 9-10Step 8Steps 6-7Steps 4-5Steps 2-3

Shock Bleeding Steps:

1. Before assembly, get each bleed

screw and thread it 1-2 turns into

the shock cap, then remove the

screw. This will make it easier when

you are bleeding your shocks.

2. Pull shock shaft down.

3. Fill shock body 3/4 full with silicone

shock fluid.

4. Slowly move the shock shaft up and

down to remove air from under the

piston.

5. Wait for bubbles to come to surface.

6. Fill shock body to top with silicone

shock fluid.

7. Place a drop of oil in the cap and on

cap threads.

8. Install cap (without bleed screw) and

tighten completely.

9. Slowly compress shaft all the way to

bleed excess silicone shock fluid out

the hole in the cap (use rag around

shock to catch excess fluid).

10. Install M2x4mm button head

screw until snug while shaft is fully

compressed.

Rear Shock: 30 wt

91492

M2 x 4mm

BHCS

91814

12mm

Shock Cap

Stroke

Front: 20.5mm

Rear: 28mm

Stroke

Stroke

Shock fluid

91304

12mm

Threaded

Collar

91304

12mm

Threaded

Collar

O-ring

x4

x4

Threaded

91814

12mm shock

spring cup

(Front - 5mm

Rear - 5mm)

91831

12mm Front

Spring, White

(3.40lb)

91838

12mm Rear

Spring, White

(1.91lb)

Front:

3.00mm

Rear:

9.00mm

Build x2 front and x2 rear shocks

Racers Tip:

Use your finger to rub

shock oil on the o-ring for

smoother adjustment!

#91310 12mm Shock Spring Cups

0mm 5mm 9mm

Use outside

hole in

front arm!

!

25612

M3 Locknut

w/Flange

25612

M3 Locknut

w/Flange

25187

M3 x 14mm

BHCS

25188

M3 x 20mm

BHCS

Build x2 (right and left side)Build x2 (right and left side)

Make sure the

flange on the

shock pivot ball is

towards the rear

arm.

!

17

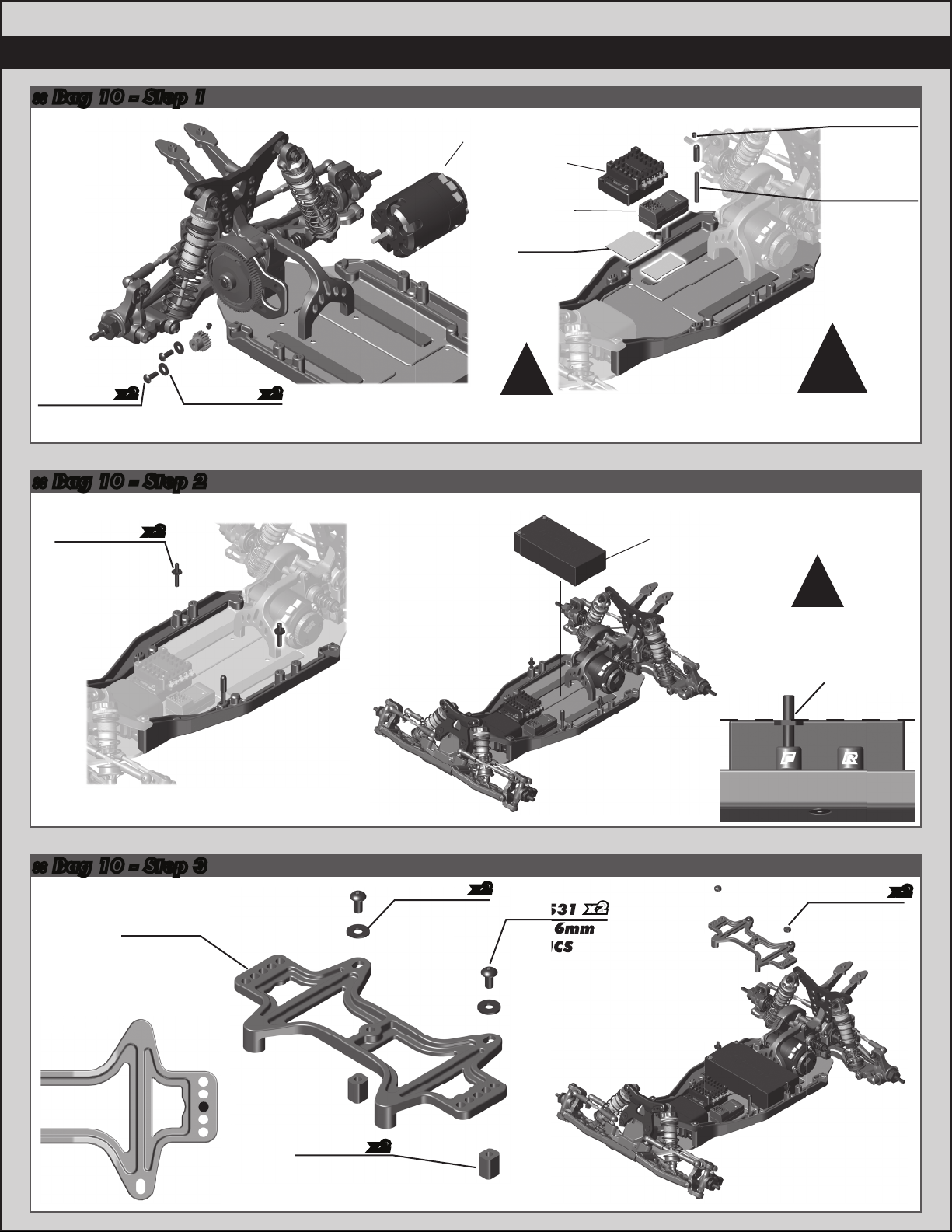

:: Bag 10 - Step 3

:: Bag 10 - Step 2

:: Bag 10 - Step 1

Make sure the

battery strap

shoulder screw is

flush with the top of

your battery pack!

!

RF

Battery

not included!

1

2

3

4

5

Front

31531

M3 x 6mm

BHCS

89218

3 x 8mm

Washer

x2

x2

x2

91731

Battery

Strap, B6

91731

Battery

Strap Nut,

B6

See page 20 for

gear mesh setting

instructions!

!

Motor not included!

Pinion / Setscrew

not included!

31532

M3 x 8mm

BHCS

x2

x2 89218

3 x 8mm

Washer

ESC not

included!

6727

Servo

Tape

There are two options

for mounting your

antenna.

!

Receiver not

included!

25225

M3 x 3mm

Set Screw

6338

Antenna

Tube & Cap

91730

Battery Strap

Shoulder

Screw

x2

31531

M3 x 6mm

BHCS

x2

x2

91729

Thumb

Screw, B6

x2

18

:: Bag 10 - Step 4

91718

Wing

Button

91741

Wing,

B6

91718

Wing

Mount

25202

M3 x 10mm

FHCS x2

x2

Mount

Mount

Pic 1: Pic 2: Pic 3:

Cut Line B

Cut Line A

Cut Line B

Cut Line A

Body Trimming / Mounting:

There are 3 body trimming options depending on what transmission and

shock position you choose to run.

Laydown (Pic 1): Laydown Transmission.

• Cut Line A is for shocks mounted in front of arm.

• Cut line B is for shocks mounted in rear of arm.

Layback (Pic 2): Layback Transmission.

• Cut Line A is for shocks mounted in front of arm.

• Cut line B is for shocks mounted in rear of arm.

Standup (Pic 3): 3 Gear Stand Up Transmission.

Front of Vehicle

0° - Mount under wing

3° - Mount on top of wing

6° - Mount under wing - KIT

Wing Mount

19

:: Tuning Tips

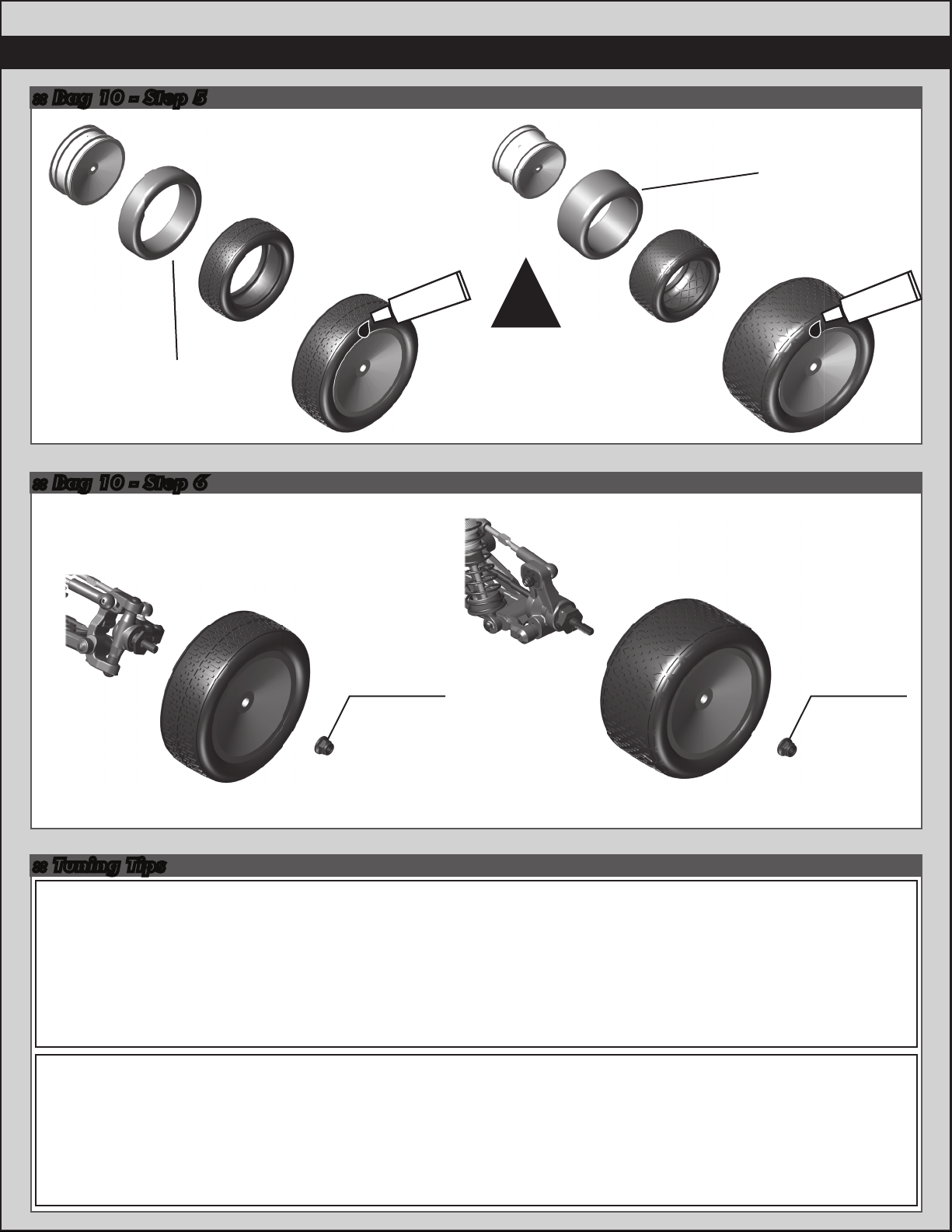

:: Bag 10 - Step 5

:: Bag 10 - Step 6

Tips for Beginners:

Before making any changes to the standard setup, make sure you can get around the track without crashing. Changes

to your vehicle will not be beneficial if you can’t stay on the track. Your goal is consistent laps. Once you can get around

the track consistently, start tuning your vehicle. Make only ONE adjustment at a time, testing it before making another

change. If the result of your adjustment is a faster lap, mark the change on the included setup sheet (make adddtional

copies of the sheet before writing on it). If your adjustment results in a slower lap, revert back to the previous setup and

try another change. When you are satisfied with your vehicle, fill in the setup sheet thoroughly and file it away. Use this

as a guide for future track days or conditions. Periodically check all moving suspension parts. Suspension components

must be kept clean and move freely without binding to prevent poor and/or inconsistent handling.

Painting:

Your Kit comes with a clear polycarbonate body. You will need to prep the body before you can paint it.

Wash the INSIDE thoroughly with warm water and liquid detergent (do not use any detergents with scents or added

hand lotion ingredients!). Dry the body using a clean, soft, lint-free cloth. Use the supplied window masks to cover the

windows from the INSIDE of the body (RC cars get painted on the inside). Using high quality masking tape, apply tape

to the inside of the body to create a design. Spray (use either rattle can or airbrush) the paint on the inside of the body

(preferably dark colors first, lighter colors last). NOTE: ONLY use paint that is recommended for (polycarbonate)

plastics. If you do not, you can destroy the body! After the paint has completely dried (usually after 24 hours), cut the

body along the trim lines. Make sure to drill or use a body reamer to make the holes for the antenna if needed! Use hook

and loop tape to secure the body to the side rails of the vehicle.

Wheels / Tires and

Inserts are

not included!

Wheels / Tires and

Inserts are

not included!

#1597

ca glue

#1597

ca glue

Carefully apply ca glue

(tire adhesive) to the tire

bead on the side. Do one

side at a time, allowing it

to dry before gluing the

other side!

CA glue not included!

!

Build x2 Build x2

Build 2 (1 left, 1 right) Build 2 (1 left, 1 right)

91826

M4 Steel

Serrated

Nut, with

Flange -

Silver

91826

M4 Steel

Serrated

Nut, with

Flange -

Silver

20

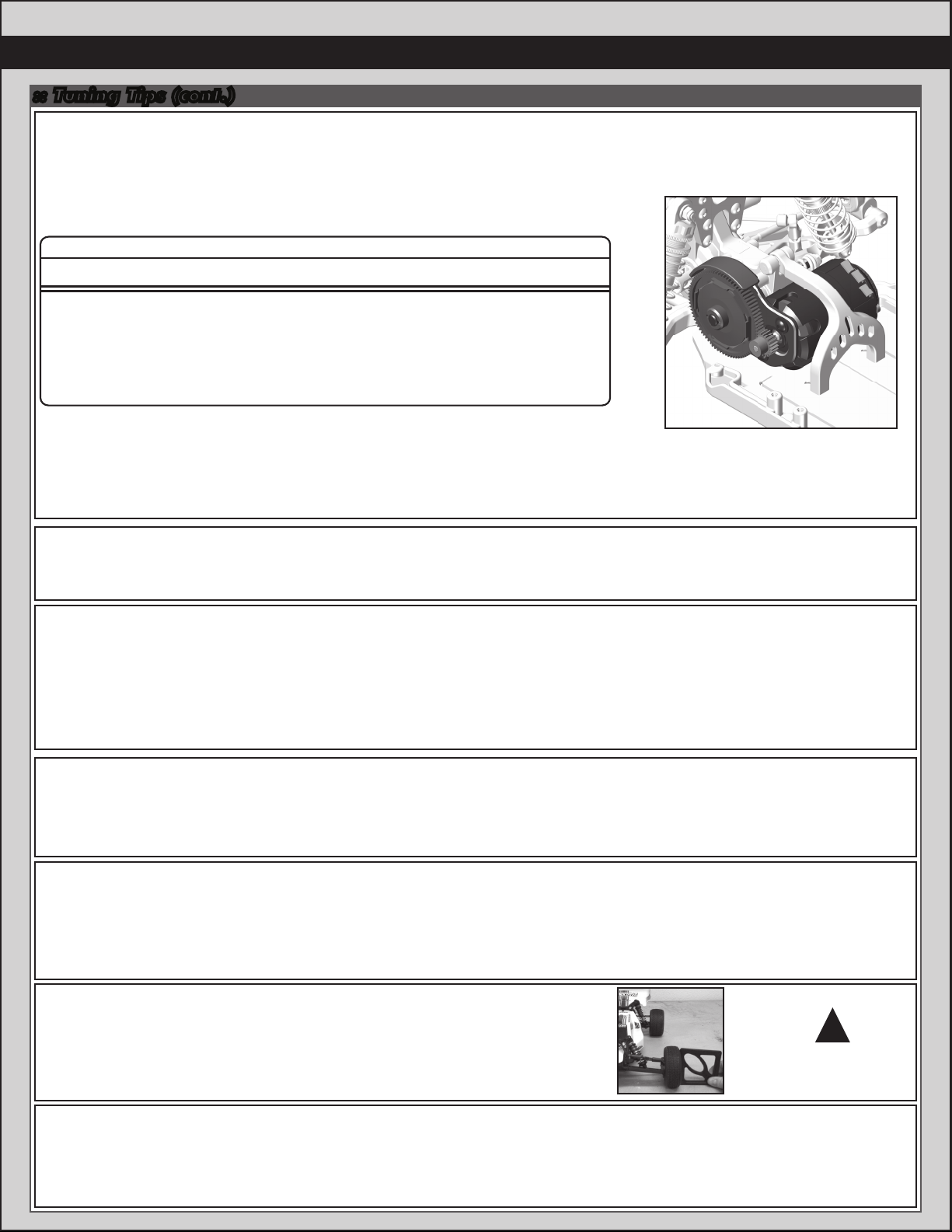

:: Tuning Tips (cont.)

Rear Camber:

Camber describes the angle at which the tire and wheel rides when looked at from the back. Negative camber means

that the tire leans inward at the top. A good starting camber setting is -1°. Adding a small amount of positive camber,

where the top of the tire is leaning out, will tend to improve straight-line acceleration on loose tracks.

Optional #1719 camber gauge can be used to more accurately set camber.

Slipper Clutch:

The assembly instructions give you a base setting for your clutch. Turn the nut on the shaft so that the end of the top

shaft is even with the outside of the nut. At the track, tighten or loosen the nut in 1/8 turn increments until you hear

a faint slipping sound for 1-2 feet on takeoffs. Another popular way to set the clutch is to hold both rear tires firmly in

place and apply short bursts of throttle. If the clutch is properly set, the front tires should lift slightly up off the surface.

Front Camber:

Camber describes the angle at which the tire and wheel rides when

looked at from the front. Negative camber means that the tire leans

inward at the top. A good starting camber setting is -1°. Positive camber,

where the top of the tire is leaning out, is not recommended.

Optional #1719 camber gauge can be used to more accurately set camber.

*Testing camber

with camber gauge

!

Gear Box Type:

Selecting the correct gear box is dependent on the type of track it will be used on. The optional 4 gear stand-up gear

box is for the lowest grip conditions. This gear box moves the weight towards the rear of the car and also uses the

rotation of the motor to transfer weight to the rear while on-power. The 3 gear stand-up gear box also moves the

weight towards the rear of the car, but in this configuration, the motor’s rotation helps with on-power steering.

The lay-down gear box is used on high grip conditions when on-power steering and stability are most important.

This gear box will change directions the quickest and generate the most steering. Layback is used for most indoor clay

track conditions.

Caster:

Caster describes the angle of the caster block as it leans toward the rear of the vehicle. Positive caster means the

kingpin leans rearward at the top. The kit includes three inserts to adjust caster angle at the caster block, 0°, 2.5°, and

+5°. The total caster angle is the sum of the kick-up angle and the caster block angle. Standard total caster angle for

the B6 is 30°, with 25°kick-up and +5°caster block angle.

For less entry steering and more exit steering, try 0°caster block angle.

Diff Height Adjustment:

The diff height adjustment is a good way to tune the car for grip level. On high grip with low ride heights, a higher diff

height will be a good option. On lower grip with higher ride heights, a lower diff height will be better.

Motor Gearing:

Proper motor gearing will result in maximum performance and run time while reducing the chance of overheating and

premature motor failure. The gear ratio chart lists recommended starting gear ratios for the most widely used

motor types. Gear ratios will vary depending upon motor brand, wind, and electronic speed control. Consult your

motor and electronic speed control manufacturers for more information.

Team Associated is not responsible for motor damage due to improper gearing.

Set The Gear Mesh:

You should be able to rock the spur gear back and forth in the teeth of the pinion gear without making the pinion gear

move. If the spur gear mesh is tight, then loosen the #31532 screws and move the motor away, then try again.

A gear mesh that is too tight or too loose will reduce power and damage the gear teeth.

29

27

24

23

22

21

20

Pinion

72

75

78

78

78

78

78

Spur

6.45:1

7.22:1

8.45:1

8.82:1

9.22:1

9.65:1

10.14:1

Final Drive Ratio

17.5 Reedy S-Plus Brushless

13.5 Reedy S-Plus Brushless

10.5 Reedy 540-M3 Brushless

9.5 Reedy 540-M3 Brushless

8.5 Reedy 540-M3 Brushless

7.5 Reedy 540-M3 Brushless

6.5 Reedy 540-M3 Brushless

Motor

B6 Gear Ratio Chart (Internal Gear Ratio 2.60:1)

Table of contents

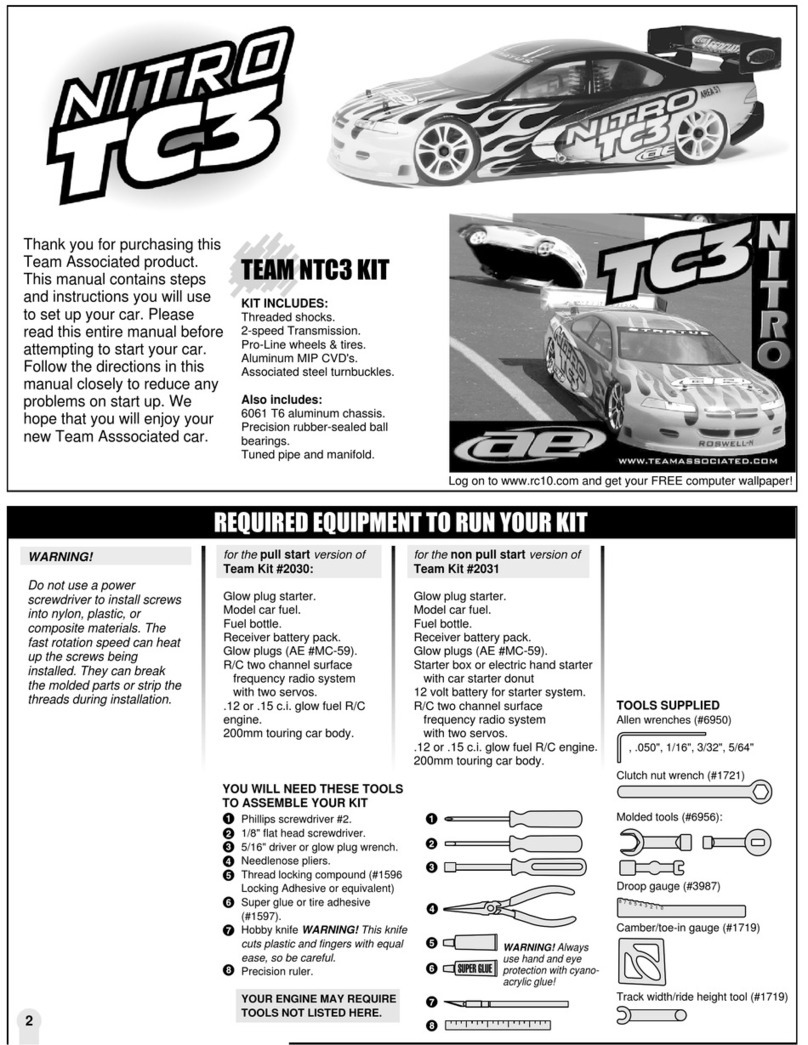

Other Team Assocciated Motorized Toy Car manuals

Team Assocciated

Team Assocciated SC10B RS RTR User manual

Team Assocciated

Team Assocciated Nitro TC3 User manual

Team Assocciated

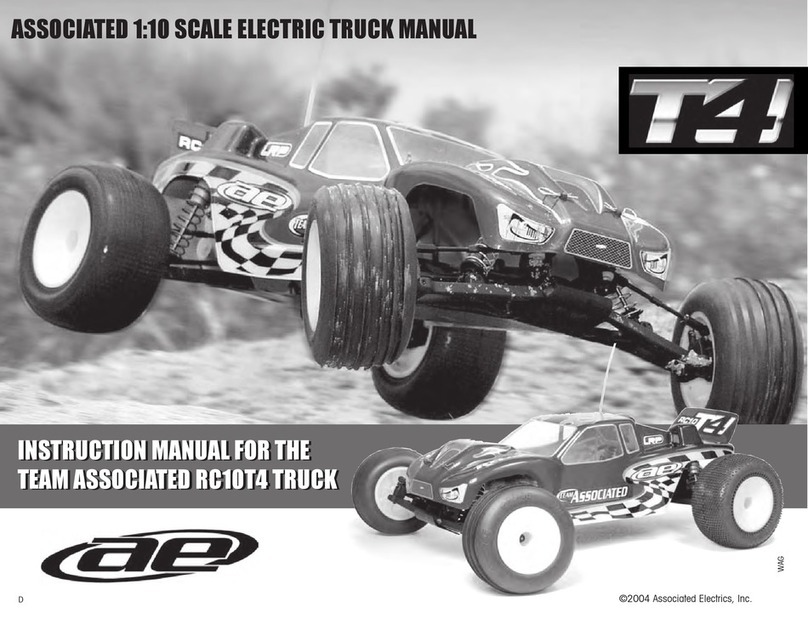

Team Assocciated TEAM ASSOCIATED RC10T4 User manual

Team Assocciated

Team Assocciated RC 12L User manual

Team Assocciated

Team Assocciated Factory Team TC4 User manual

Team Assocciated

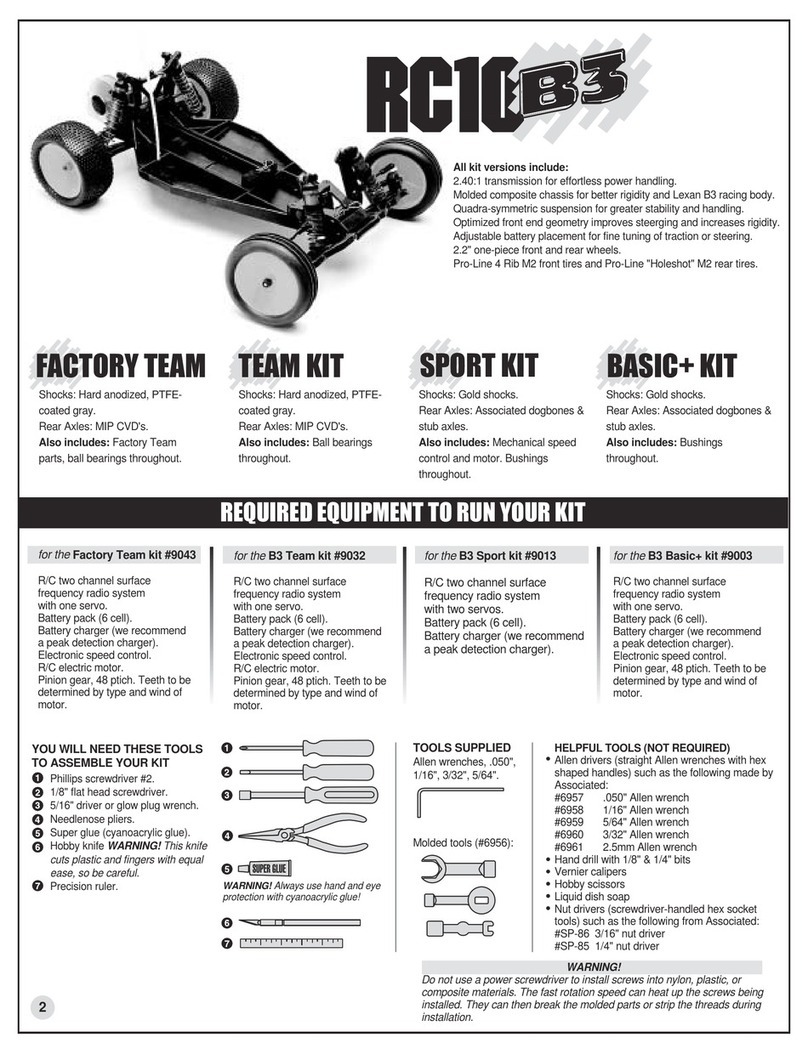

Team Assocciated RC10 B3 Factory Team Installation instructions

Team Assocciated

Team Assocciated RC104T4.1 User manual