Team Assocciated SC10B RS RTR User manual

10/12

2

:: Introduction

:: RTR Features

:: Additional Items Needed: :: Items Included:

:: Other Helpful Items

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

Thank you for purchasing this Team Associated product. This assembly manual contains instructions and tips for building and

maintaining your new SC10B RS RTR. Please take a moment to read through this manual to help familiarize yourself with these

steps. We are continually changing and improving our designs; therefore, actual parts may appear slightly different than the

illustrations. New parts will be noted on supplimentary sheets located in the appropriate parts bags. Check each bag for these

sheets before you start your build.

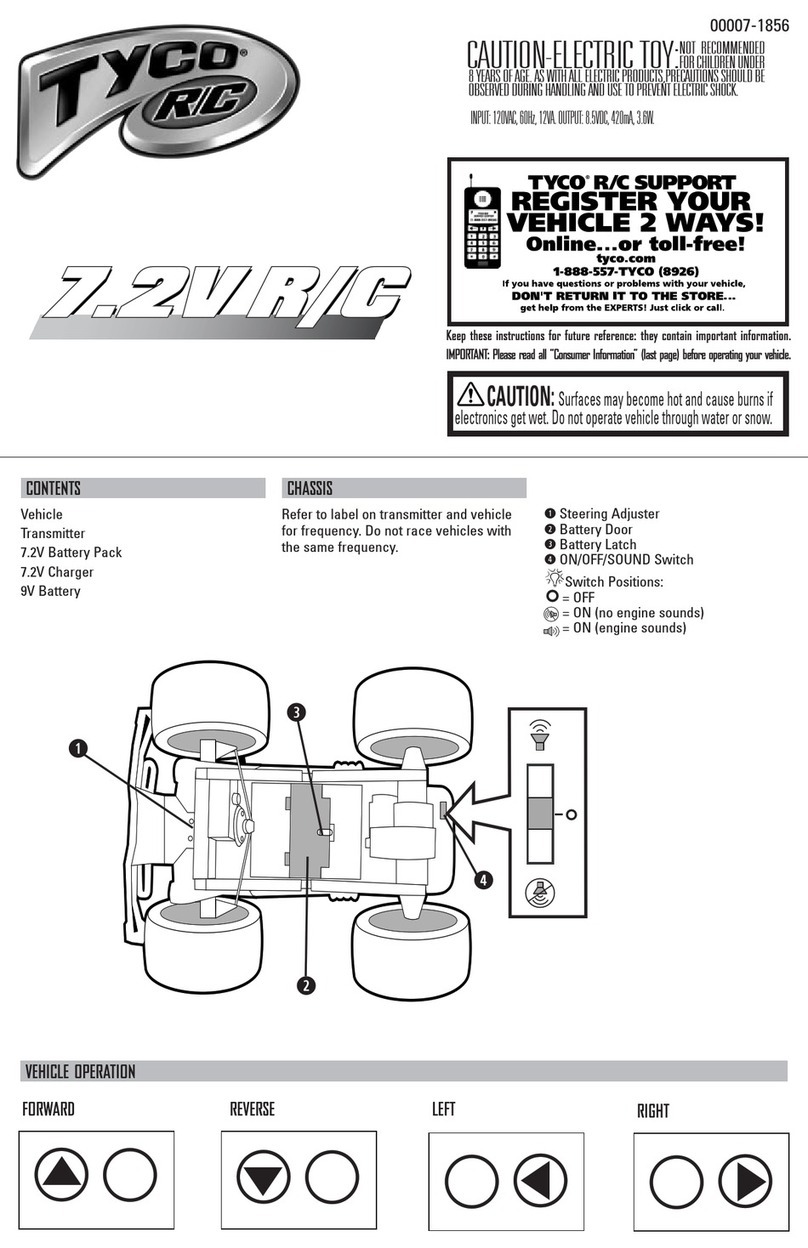

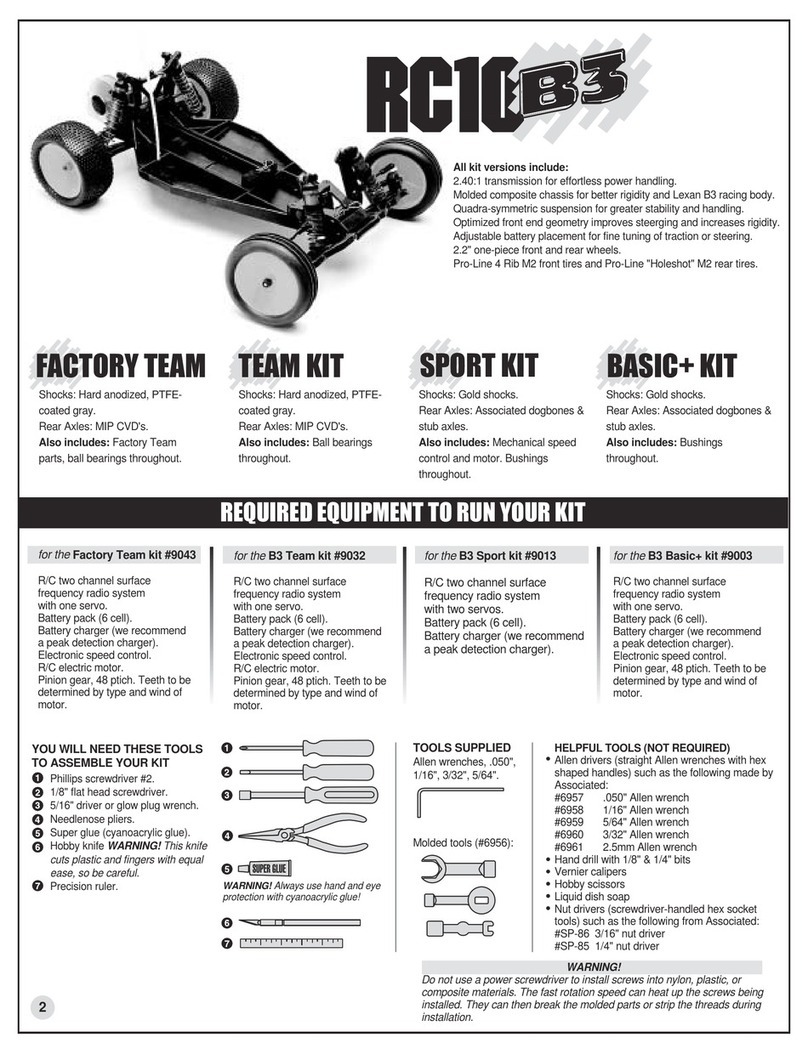

Features of the SC10B RS RTR:

• Fully assembled 2wd short course buggy based on the multi-time National Champion SC10 truck

• Full roll cage with window nets and integral nerf bars

• Water-resistant Brushless Speed Control with reverse

• XP 2.4GHz radio system with metal gear steering servo

• Powerful Reedy 540 sized brushless motor

• Factory finished body with authentic short course graphics

• Cockpit underbody with driver figure

• KMC replica hex drive wheels and aggressive short course tires with new narrow fronts

• Blue anodized aluminum V2 coil-over shock absorbers

• Sealed gear differential with heavy-duty gears

• Molded composite chassis and battery strap that accommodates NiMH or LiPo battery packs

• Water-resistant enclosed receiver box

• Realistic front and rear bumpers designed to absorb impacts

Your new SC10B RTR comes factory assembled including radio

gear, motor, and ESC. However, there are some items you will

need to complete your new kit.

Items needed:

• AA-size batteries for transmitter (x6)

(#302, 303 recommended)

• Battery charger (peak detection charger recommended)

(#610 NiCd/NiMH)(#604, LRP41281, LRP41555 LiPo/LiFe)

• 6 cell NiMH battery pack or 2S LiPo battery pack

w/Deans® Ultra Plug® connector

(#683, 684 NiMH)(#730, 731, 732, 734 LiPo)

Tools included:

• Allen wrenches #6950 (.050”, 1/16”, 5/64” , 3/32”)

• 1.5mm allen wrench

• Molded tools #6956

• Camber gauge #1719

Optional parts and accessories to maintain your SC10B:

• Green Slime shock lube (AE Part # 1105)

• Cyanoacrylate glue (AE Part # 1597)

• Thread Locking Compound (AE Part # 1596)

• Silicone Shock Fluid (Refer to catalog for

complete listings)

• Silicone Diff Fluid (Refer to catalog for

complete listings)

• Body Scissors (AE Part # 1737)

• 8 Piece Hex Driver Set (AE Part # 1655)

• FT Hex Wrenches (AE Part # 1541)

• Hobby Knife

• Needle Nose Pliers

• Wire Cutters

• Soldering Iron

• Calipers or a Precision Ruler

• Reamer / Hole Punch

• FT Nut Driver Set (AE Part # 1561)

3

:: Table of Contents

:: Notes

This symbols indicates a

special note or instruction

in the manual.

!There is a 1:1 hardware foldout page in the back

of the manual. To check the size of a part, line

up your hardware with the correct drawing until

you find the exact size. Each part in the foldout

has a number assigned to it for ordering

replacement parts.

1....................Cover

2....................Introduction

3....................Table of Contents

4 - 5..............Steering System

5 - 8..............Front Suspension

8 - 10...........Transmission

11 - 12........Rear Suspension

13.................Rear Hubs

14 - 15........Shocks

16 - 19........Electronics

19 - 23........Roll cage

24.................Wheels and Tires

25 - 26.......Tuning Tips

27 - 38........Catalog

38.................Contact Information

39................Setup Sheet “RTR Setup”

40.................1:1 Hardware “Fold Out”

41.................Setup Sheet “Blank”

42................Back Cover

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

4

:: Steering System

:: Steering System (cont.)

:: Steering System (cont.)

Remove bolt and

washer, continue

assembly per

instructions.

* With supplied wrench, tighten

servo sacer bolt completely, until it

hits bottom. Do not overtighten.

* With supplied

wrench, tighten servo

sacer bolt completely.

Do not overtighten.

!

!

!

9659

Servo saver

(lower)

9659

Servo saver

(lower)

9659

Servo saver

(upper)

9659

Servo saver

(lower)

9610

Servo saver

bolt

9610

Servo saver

bolt

9610

Servo saver

washer

(upper)

9610

Servo saver

washer

(upper)

black grease

#6588

9610

Servo saver

washer

(lower)

9659

Block

carrier

bushing

2221

4-40 x 7/16

bhcs

9659

Bellcrank

6272

Dust cover

foam

9659

Steering

rack

6276

Ballstud

.20 short

(silver)

6276

Ballstud

.20 short

(silver)

6272

Dust cover

foam

9610

Servo saver

washer

(upper)

9610

Servo saver

bolt

9657

Heavy duty

servo saver

spring

x2

x2

x2

x2

x2

5

:: Steering System (cont.)

:: Front Suspension

:: Front Suspension (cont.)

Align the C clip on

the front axles

with the D shape

inside the steering

blocks.

Install the C clip on

the groove shown

below.

Do not overtighten steering

bolts. Make sure there is free

movement in the steering rack.

!

!

!

6272

Foam

dust

cover

3977

3/16 x 3/8

bearing

3977

3/16 x 3/8

bearing

9882

C clip

(3/16”)

7369

1/16”

universal

roll pin

9883

Wheel hex

adapter

(thin)

4449

4-40 x 3/16

aluminum

locknut

9880

Steering

blocks

hex style

(left, right)

4187

.030 washer

(nylon)

3856

Steering

rack bushing

6925

4-40 x 1/2

shcs

6915

4-40 x 5/8

fhcs

6277

Ballstud

.30 long

(silver)

9640

Steering

bolt

(left)

9659

Steering

brace

9881

Front axle

(hex style)

7368

3/16” axle

shim

x2

x4

x3

x2

Build left and

right sides!

Build left and

right sides!

!

!

9640

Steering

bolt

(right)

9563

Front

bulkhead

9823

SC10

chassis

9566

Top plate

6

:: Front Suspension (cont.)

:: Front Suspension (cont.)

:: Front Suspension (cont.)

9622

Outer

hinge pin

9621

Inner

hinge pin

6277

Ballstud

.30 long

(silver)

6292

4-40 x 3/8

fhcs

91202

SC10B

front shock

tower

4334

2-56 x 5/16

bhcs

9645

2-56 x 1/8

bhcs

9645

2-56 x 1/8

bhcs

9580

Spacer

7260

4-40

small

plain nut

7922

Caster

block 30˚

(left, right)

9622

Kingpin

x2

x2 x2

x2

x2

x2

x2

x2

x2

Build left and

right sides!

Build left and

right sides!

6272

Foam

dust

cover

6272

Foam dust

cover

9630

Ballstud

washer,

aluminum

(.030”)

6927

4-40 x 3/4

shcs

6295

4-40 plain

nut

6917

4-40 x 3/8

bhcs

91212

SC10B front

body mount

91200

SC10B

front bumper

(upper)

9564

Front

hinge pin

brace

3983

Ballstud

.30 short

(black)

91201

Front arm

(left, right)

7

:: Front Suspension (cont.)

:: Front Suspension (cont.)

:: Front Suspension (cont.)

91200

SC10B

front bumper

(lower)

91200

SC10B

skid plate

7230

Ball cup

(large)

7230

Ball cup

(large)

7253

2.62

turnbuckle

7101

2.80

turnbuckle

3.48”

(88.3mm)

3.30”

(83.9mm)

7230

Ball cup

(large)

7230

Ball cup

(large)

91220

4-40 x 1 5/8

shcs

6924

4-40 x 3/8

shcs

6915

4-40 x 5/8

fhcs

2221

4-40 x 7/16

bhcs

x4

x2

x2

6915

4-40 x 5/8

fhcs

4-40 x 7/16

x2

x2

x2

x2

Orient the notch to the left throughout

the vehicle. It indicates which end of the

turnbuckle has the left hand threads.

!

Build left and

right sides!

8

:: Front Suspension (cont.)

:: Transmission

:: Transmission (cont.)

Align pin with

groove in

sun gear

!

black grease

#6588

black grease

#6588

black grease

#6588

black grease

#6588

black grease

#6588

black grease

#6588

9765

4-40 x 7/16

fhcs

9828

Diff gear

cover

9828

Diff gear

52T, 48P

9888

0.5mm gear

diff shim

9888

0.5mm gear

diff shim

9830

2x8mm

round end

pin

9830

2x8mm

round end

pin

x4

x2

x2

x2

91205

SC10B

roll cage

bracket

9831

3.6x0.7mm

o-ring

9831

4.7x1.42mm

o-ring

9831

4.7x1.42mm

o-ring

9830

Outdrive

cup

9829

Sun gear

Build left and

right sides!

Build two!

9

:: Transmission (cont.)

:: Transmission (cont.)

:: Transmission (cont.)

Align pin with

groove in

sun gear

!

black grease

#6588

black grease

#6588

black grease

#6588

9829

Planet gear

shims

9829

Planet

gear

9602

Top shaft

spacer

9601

Top

shaft

4675

2.5x6mm

fhcs

x4

x4

x2

x4

9829

Sun gear

9829

Cross pin

Use the 1.5mm allen

wrench to tighten the

2.5x6mm fhcs on the

diff gear cover

Align flat

spots

Ensure free outdrive

rotation before

installation!

!

!

!

!

spacer

9601

Top

shaft

9826

Transmission case

(left, right)

x2

3977

Ball bearing

3/16 x 3/8

3977

Ball bearing

3/16 x 3/8

6919

4-40 x 5/16

bhcs

6925

4-40 x 1/2

shcs

9630

.030 alum.

ballstud

washer

9819

Motor

guard

9832

Ball bearing

10 x 16mm

6928

4-40 x 1

shcs

x2

x2

x2

x2

x3

x3

9831

Diff gear

seal

9360

Idler

gear

9361

Idler gear

shaft

10

:: Transmission (cont.)

:: Transmission (cont.)

:: Transmission (cont.)

9603

Slipper

pad

6915

4-40 x 5/8

fhcs

91203

SC10B

engine bay

side panel

(left, right)

91203

SC10B rear

bumper

6932

4-40 x 5/16

shcs

6924

4-40 x 3/8

shcs

7486

V2 slipper

washer

6913

4-40 x 1 1/4

shcs

x2

x4 x2 x2

x2

x2

x2

91203

SC10B rear

bumper brace

(left, right)

9600

Motor

plate

x2

thread lock

#1596

thread lock

#1596

Compress

spring !

* Install locknut until even with end of

shaft. Then tighten 3 turns for kit

slipper setting. Recheck after initial run. !

!

7485

V2 slipper

hub

9654

Spur gear

(87T, 48P)

6629

5-40

locknut

7486

V2 slipper

spring

x2

11

:: Rear Suspension

:: Rear Suspension (cont.)

:: Rear Suspension (cont.)

9645

2-56 x 1/8

bhcs

x2

x2

x2

9621

Hinge pin

(rear, inner)

9818

Rear chassis

plate

7487

Anti squat

shim

(2 degrees)

7487

Rear arm

mount

(3.5 degrees)

7448

Rear A-arms

(left, right)

x2

x2

9269

5-40 x 1/2

fhcs

6272

Dust cover

foam

6277

Ballstud

.30 long

(silver)

9269

5-40 x 1/2

fhcs

9630

.030 alum.

ballstud

washer

9564

Rear chassis

brace

9643

5-40 x 7/16

shcs

x2

x2

x2

x4

x2

x2

12

:: Rear Suspension (cont.)

:: Rear Suspension (cont.)

:: Rear Suspension (cont.)

9643

5-40 x 7/16

shcs

7260

4-40 small

plain nut

9824

Rear shock

tower

x2

x2

9644

5-40 x 9/16

shcs

6927

4-40 x 3/4

shcs

x2

x2

6928

4-40 x 1

shcs

91212

SC10B rear

body mount

x2

6922

4-40 x 1/2

fhcs

6924

4-40 x 3/8

shcs

x2

x2

13

:: Rear Hubs

:: Rear Hubs (cont.)

:: Rear Hubs (cont.)

LEFT SIDE

SHOWN

6272

Dust cover

foam

7369

1/16

universal

roll pin

9670

Rear axle

3977

Ball bearing

3/16 x 3/8

5407

O-ring 9622

Hinge pin

(rear, outer)

4187

Spacer

7377

Bearing

spacer

7368

3/16 axle

shim

9883

Wheel hex

adapter

9584

Rear hub

carrier

(left, right)

x2

x2

x2

3983

Ballstud

.30 short

(black)

7462

Dogbone

9645

2-56 x 1/8

bhcs

7101

2.80

turnbuckle

7230

Ball cup

(large)

7230

Ball cup

(large)

7260

4-40 small

plain nut

Orient the notch to the left

throughout the vehicle.

It indicates which end of

the turnbuckle has the left

hand threads.

!

!

!

Build left and

right sides!

Build left and

right sides!

Build left and

right sides!

3.58”

(90.9mm)

14

:: Shocks

:: Shocks (cont.)

:: Shocks (cont.)

Piston

Front

Shock

Front

Shock

Front

Shock

Rear

Shock

Rear

Shock

Rear

Shock

Remove

spurs

7217

Pivot

ball

7217

Pivot

ball

7217

Eyelet 7217

Eyelet

6466

Downstop

thin

1/32”

6466

Downstop

thin

1/32”

Piston number here

Use #3 = front shocks

Use #1 = rear shocks

5407

Red

o-ring

6465

Shock

piston

#3

6465

Shock

piston

#1

6299

E-clip

6299

E-clip

6299

E-clip

6299

E-clip

5407

Red

o-ring

9884

V2 RTR

front shock

body 1.02”

stroke

(blue)

9885

V2 RTR

front shock

body 1.39”

stroke

(blue)

7484

Shock

internal

spacer

6459

Shock

shaft

1.02”

stroke

6458

Shock

shaft

1.32”

stroke

7484

Shock

internal

spacer

6469

Shock

cap

o-ring

6469

Shock

cap

o-ring

7484

Lower shock

seal cap

7484

Lower shock

seal cap

x5 x2

15

:: Shocks (cont.)

:: Shocks (cont.)

:: Shocks (cont.)

* Shock Bleeding Steps:

1. Pull shock shaft down.

2. Fill shock body 3/4 full with silicone fluid.

3. Slowly move the shock shaft up and

down to remove air from under piston.

4. Wait for bubbles to come to surface.

5. Fill shock body to top with silicone fluid.

6. Place several drops of oil in the cap and

on cap threads.

7. Install cap and tighten completely.

8. Slowly compress shaft all the way to

the top. If there is pressure at the top

of the stroke, there is too much oil or air.

You must bleed it out.

9. Slowly pull shaft down.

10. Unscrew the cap 3/4 turn and tilt the

shock at a slight angle.

11. Slowly compress the shaft to push out

excess oil and air. You should see

bubbles coming out from under the cap.

12. With the shaft compressed, tighten the

cap and re-check for pressure at the top

of the stroke. If there is still pressure,

repeat steps 9 thru11.

Step 7Step 5-6Step 3-4Step 1-3

7425

Front

spring

(gold)

3.70lb

6480

Rear

spring

(green)

1.90lb

6475

Spring

collar

6475

Spring

collar

8846

Preload

spacers

6927

4-40 x 3/4

shcs

6472

Shock

mount nut

6473

Shock

bushing

6473

Shock

bushing

8846

Preload

spacers

6441

Shock

cap

(molded)

6475

Spring

cup

6475

Spring

cup

Shock fluid

30wt #5422

Shock fluid

30wt #5422

Front

Shock

Rear

Shock

Front x2 Rear x2

6925

4-40 x 1/2

shcs

6472

Shock

mount nut

Build left and

right sides!

!

.02

x1

.25

x2

.12

x1

x1

.02

x1

.12

x1

.03

16

:: Electronics

:: Electronics (cont.)

:: Electronics (cont.)

6917

4-40 x 3/8

bhcs

7336

Servo

spacers

7336

Servo

mount

7337

Gold

washer

9170

Servo

link

3981

Ballstud

.20 short

(black)

6272

Dust cover

foam

x4

x2

x2

x4

8255

18T 48P

pinion gear

w/setscrew

9180

Servo horn

Servo

See page 40 for

correct servo

horn on the

servo chart

Screw supplied

with servo

!

See page 40 for

correct servo

spacing on the

servo chart

Leave a

1/16 gap

!

!6292

4-40 x 3/8

fhcs

x2

6285

4-40 x 1/4

shcs

31531

M3 x 6mm

bhcs

6936

Washer #4

aluminum

7460

Gear cover

w/button

(black)

x2

x2

x2

Motor

See page 25 for

gear mesh setting

instructions.

!

17

:: Electronics (cont.)

:: Electronics (cont.)

:: Electronics (cont.)

!

!

!

!

9877

Receiver

box

(bottom)

9643

5-40 x 7/16

shcs

6727

Servo

tape

Speed Control

(ESC)

9878

Wire

grommet

plug

Receiver

9878

Receiver

box

grommet

Receiver grommet plug

can be removed if you use

a personal transponder!

Install the ESC and servo

wires into the wire

grommet before installing

the grommet into the

receiver box!

You may need to reposition

the receiver in order to

geit it to fit with the plugs

installed and the receiver

box lid installed.

Once you find a good fit,

use #6727 servo tape to

install your receiver.

18

:: Electronics (cont.)

:: Electronics (cont.)

9815

foam

spacer

9643

5-40 x 7/16

shcs

9879

4-40 x 1/2

setscrew

9879

Thumb

knob

3862

5-40 x 1/8

setscrew

6338

Antenna

and cap

9879

Battery

strap

Batttery

(Not included)

9878

Receiver

box seal

x2

x2

x2

9877

Receiver

box (top)

Leave

no gap!

You can trim the foam

to move the battery

pack and adjust the

weight balance of the

vehicle!

To install the battery

strap, slide the back

section in between

the top of the battery

and the bottom of the

shock tower!

!

!

!

!

!

9146

2-56 x 3/16

bhcs

x3

91214

SC10B

body, clear

Install left and

right sides!

19

:: Electronics (cont.)

:: Rollcage

Unlocked Locked

To remove your battery pack from the vehicle, twist the thumb knobs to the

unlocked position, remove the battery strap, and then remove the battery.

When you install the battery, make sure the thumb knobs are locked before

operation.

You may need to adjust the height of the thumb knobs and/or the set

screws that the thumb knobs are attached to for your specific battery

pack type.

6919

4-40 x 5/16

bhcs

x2

9146

2-56 x 3/16

bhcs

6927

4-40 x 3/4

shcs

x2

x2

91204

SC10B

roll cage

side panel

(left, right)

91204

SC10B

roll cage

rear panel

(left, right)

91208

SC10B

window

nets

Build left and

right sides!

Note placement of window net tab!

Note placement of window net tab!

20

:: Rollcage (cont.)

:: Rollcage (cont.)

:: Rollcage (cont.)

6925

4-40 x 1/2

shcs

6927

4-40 x 3/4

shcs

6927

4-40 x 3/4

shcs

6924

4-40 x 3/8

shcs

6924

4-40 x 3/8

shcs

91204

SC10B roll cage

rear body

mount bar

6927

4-40 x 3/4

shcs

6927

4-40 x 3/4

shcs

91206

SC10B

rollcage

roof

91204

SC10B

roll cage

front panel

(left, right)

91204

SC10B

roll cage

hood

x2

6925

4-40 x 1/2

shcs

x2

6925

4-40 x 1/2

shcs

x2

Table of contents

Other Team Assocciated Motorized Toy Car manuals

Team Assocciated

Team Assocciated TEAM ASSOCIATED RC10T4 User manual

Team Assocciated

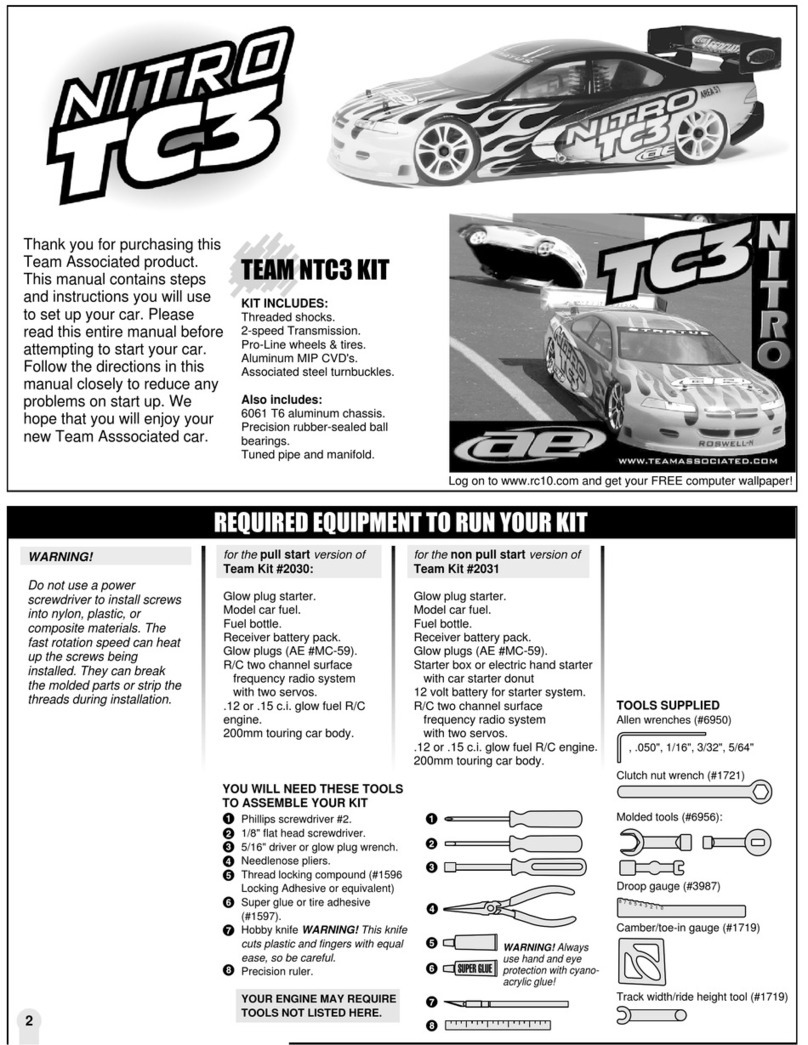

Team Assocciated Nitro TC3 User manual

Team Assocciated

Team Assocciated RC10B6.1 Dirt Light Team Kit User manual

Team Assocciated

Team Assocciated RC104T4.1 User manual

Team Assocciated

Team Assocciated RC 12L User manual

Team Assocciated

Team Assocciated Factory Team TC4 User manual

Team Assocciated

Team Assocciated RC10 B3 Factory Team Installation instructions