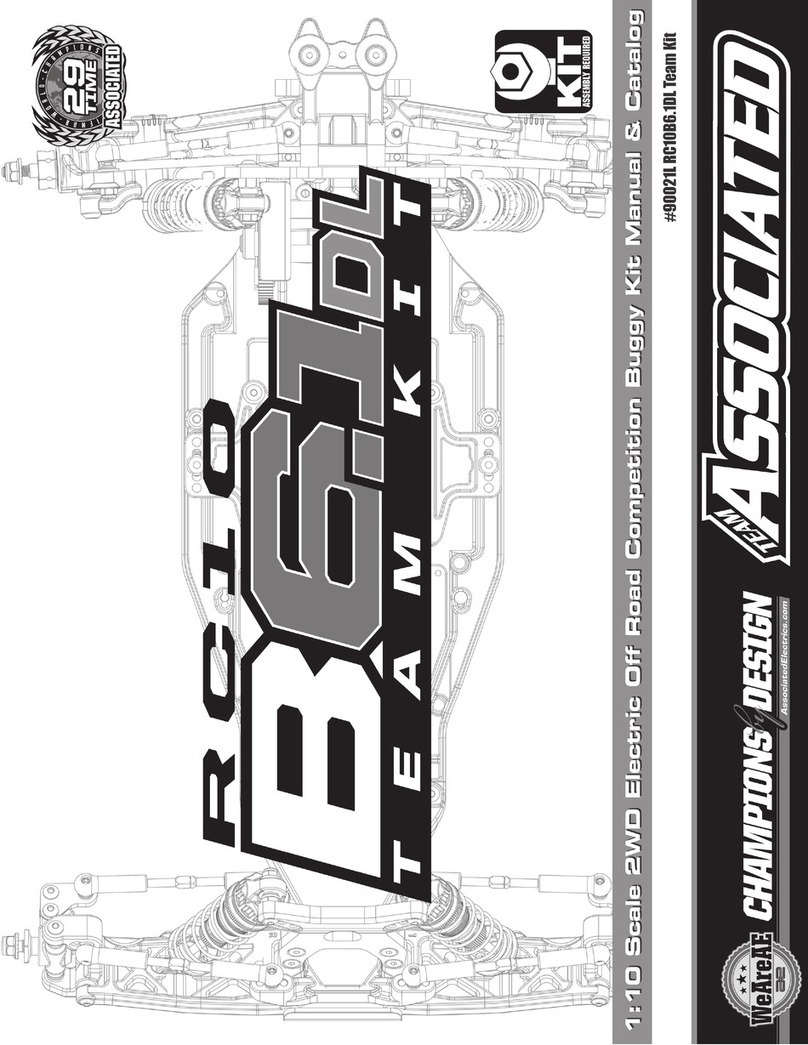

Team Assocciated RC10 B3 Factory Team Installation instructions

T E A M K I T S P O R T K I T B A S I C K I T

Shocks: Hard anodized, PTFE-

coated gray.

Rear Axles: MIP CVD's.

Also includes:

Ball bearings

throughout.

Shocks: Gold shocks.

Rear Axles: Associated dogbones &

stub axles.

Also includes:

Mechanical speed

control and motor. Bushings

throughout.

Shocks: Gold shocks.

Rear Axles: Associated dogbones &

stub axles.

Also includes:

Bushings

throughout.

All kit versions include:

2.40:1 transmission foreffortless power handling.

Molded composite chassis for better rigidity and Lexan B3 racing body.

Quadra-symmetric suspension for greater stability and handling.

Optimized front end geometry improves steerging and increases rigidity.

Adjustable battery placement for fine tuning of traction or steering.

2.2" one-piece front and rear wheels.

Pro-Line 4 Rib M2 front tires and Pro-Line "Holeshot" M2 rear tires.

F A C T O R Y T E A M

Shocks: Hard anodized, PTFE-

coated gray.

Rear Axles: MIP CVD's.

Also includes:

Factory Team

parts, ball bearings throughout.

2

YOU WILL NEED THESE TOOLS

TO ASSEMBLE YOUR KIT

Phillips screwdriver #2.

1/8" flat head screwdriver.

5/16" driver or glow plug wrench.

Needlenose pliers.

Super glue (cyanoacrylic glue).

Hobby knife

WARNING!

This knife

cuts plastic and fingers with equal

ease, so be careful.

Precision ruler.

WARNING! Always use hand and eye

protection with cyanoacrylic glue!

for the

B3 Basic+ kit #9003

R/C two channel surface

frequency radio system

with one servo.

Battery pack (6 cell).

Battery charger (we recommend

a peak detection charger).

Electronic speed control.

Pinion gear, 48 ptich. Teeth to be

determined by type and wind of

motor.

R E Q U I R E D E Q U I P M E N T T O R U N Y O U R K I T

for the

B3 Sport kit #9013

R/C two channel surface

frequency radio system

with two servos.

Battery pack (6 cell).

Battery charger (we recommend

a peak detection charger).

for the

B3 Team kit #9032

R/C two channel surface

frequency radio system

with one servo.

Battery pack (6 cell).

Battery charger (we recommend

a peak detection charger).

Electronic speed control.

R/C electric motor.

Pinion gear, 48 ptich. Teeth to be

determined by type and wind of

motor.

TOOLS SUPPLIED

Allen wrenches, .050",

1/16", 3/32", 5/64".

Molded tools (#6956):

for the

Factory Team kit #9043

R/C two channel surface

frequency radio system

with one servo.

Battery pack (6 cell).

Battery charger (we recommend

a peak detection charger).

Electronic speed control.

R/C electric motor.

Pinion gear, 48 ptich. Teeth to be

determined by type and wind of

motor.

HELPFUL TOOLS (NOT REQUIRED)

Allen drivers (straight Allen wrenches with hex

shaped handles) such as the following made by

Associated:

#6957 .050" Allen wrench

#6958 1/16" Allen wrench

#6959 5/64" Allen wrench

#6960 3/32" Allen wrench

#6961 2.5mm Allen wrench

Hand drill with 1/8" & 1/4" bits

Vernier calipers

Hobby scissors

Liquid dish soap

Nut drivers (screwdriver-handled hex socket

tools) such as the following from Associated:

#SP-86 3/16" nut driver

#SP-85 1/4" nut driver

WARNING!

Do not use a power screwdriver to install screws into nylon, plastic, or

composite materials. The fast rotation speed can heat up the screws being

installed. They can then break the molded parts or strip the threads during

installation.

7211

6273, qty 2

ball end

7210, qty 2

front block carrier,

30° caster 6272, qty 4

dust cover

7220, qty 2

front steering

block

6951, qty 2

4-40 set screw

6299, qty 2

E-clip

s t e p 1

ASSEMBLE STEERING BLOCKS

Assemble parts #7220, 6273 and 6272.

Push #7221 (7221B*) axle into the #7220 steering

block, lining up holes.

Push the #7211 kingpin through both to clear any

burrs. Then remove the kingpin.

ASSEMBLE BLOCK CARRIERS

Note location of L and R on #7210 block carriers and

#7220 steering blocks.

Align holes of #7220 (L) inside #7210 (L). Add

one #4187 spacer to #7211 kingpin and insert

#7211 through block and axle. Add a #6272

dust cover to the ball end as shown.

Insert one #4187 spacer and then one #6299

E-clip to the bottom of #7211 kingpin.

Add screw locking compound such as Loctite® (not

included in kit) to #6951 set screw and tighten into

#7221 (7221B*).

Now assemble right side.

L E F T S I D E

7210

6273

6299

"L" = left side

"R" = right side

B A G A

REMOVE THESE

PARTS FOR:

Step 1

.050

1:1

1:1

1:1 1:1

7221, 7221B*

6272

(foam)

3

T O O L S U S E D

Match this number

to the text to find

your way faster

Align this hole

with hole in #7220

7220

6951

6272

(foam)

4187

4187

"L" = left side

"R" = right side

7221

, 7221B*

, qty 2

front axle

7211, qty 2

kingpin ball end

4187, qty 4

1/32" thin plastic

washer

1:1

R E A C H I N G U S

ASSOCIATED ELECTRICS, INC.

3585 Cadillac Ave.

Costa Mesa, CA 92626-1401

USA

http://www.rc10.com

CUSTOMER SUPPORT

(714) 850-9342

Fax (714) 850-1744

http://www.rc10.com/help

http://www.rc10.com/kits

R E A D T H I S B E F O R E B U I L D I N G

READ THE MANUAL!

This manual is for four different B3 kits and will help you

assemble and set up each one. Read the manual before

starting your kit and before contacting us for help.

"Hello,

Associated, I need some help." "Did you read the manual?"

OPEN THE BAGS IN ORDER

The assembly is arranged so that you will open and finish that

bag before you go on to the next bag. Sometimes you will

have parts remaining at the end of a bag. These will

become part of the next bag. Some bags may have a large

amount of small parts. To make it easier to find the parts, we

recommend using a partitioned paper plate for spreading out

the parts so they will be easier to find.

SUPPLEMENTAL SHEETS

We are constantly updating parts to improve our kits. These

changes, if any, will be noted in supplementary sheets located

in a parts bag or inside the kit box. Check the kit box before

you start and each bag as it is opened. When a supplement is

found, attach it to the appropriate section of the manual.

MANUAL FORMAT

The following explains the format of these instructions.

The beginning of each section indicates:

1Which bag to open ("BAG A") and which steps you'll be using

those parts for ("FOR STEPS 1-3").

2Which parts you will use for those steps. Remove only the

parts shown. "1:1" indicates an actual size drawing; place your

part on top and compare it so it does not get confused with a

similar part.

3Which tools you should have handy for that section.

4An asterix ( * ) next to a part number indicates the part used in

the Factory Team B3 kit. (You can use those numbers to

upgrade your B3 kits to Factory Team specs.)

5The instructions in each step are ordered in the order you

complete them, so read the words AND follow the pictures. The

numbers in circles are also in the drawing to help you locate

them faster.

6When we refer to left and right sides of the buggy, we are

referring to the driver's point of view inside the car.

8

Asterix ( * ) denotes Factory Team part number.

Use this number if you have the Factory Team kit.

©2000 Associated Electrics, Inc.

ball cups thread on in opposite directions

1:1

REMOVING BALL CUPS

Hold the cup next to the ball

with your pliers and twist the

cup off

.

9142, 9143*, qty 1

front shock tower

REMOVE SUSPENSION ARMS

Twist the #9107 (9108*) suspension arms

from the mold runners (shown in gray)

with your pliers, and trim away remaining

molding with your hobby knife. Do not cut

off the antiroll mounting balls. Carefully trim

balls so they are perfectly smooth.

ARMS TO BULKHEAD

Attach the block carrier assembly to the #9107 (9108*)

suspension arm with its #9115 hinge pin and #6299 E-clips.

Align the #9125 bulkhead with the #9107 suspension arm

hinge pin holes as shown. Install #6299 E-clip to one end of

#9110 hinge pin. Next hold the #9120 front cross brace in

front of the suspension arm while sliding the #9110 hinge

pin through the assembly. Install #6299 E-clip to other end

of pin. Assemble the other side the same way.

SHOCK TOWER TO BULKHEAD

Attach the shock screws and hardware #7413,

6936 and 6295. Do other side.

Attach the #9145 ball ends and #7260 nuts

through middle holes.

Attach the shock tower to the bulkhead with

the three #6924 screws.

Twist #7230 ball cups onto the #6263 (-

(1406*) turnbuckle until you get the

dimension shown.

Connect ball ends with the turnbuckle ball

cups as shown, using your needlenose

pliers.

7413, qty 2

4-40 x 3/4 6936, qty 2

#4 washer

6295, qty 2

4-40 nut 6924, qty 3

4-40 x 3/8

9145, qty 2

ball end 7230, qty 4

large ball cup

6263, 1406*, qty 2

2.06" turnbuckle

9110, qty 2

front inner hinge pin 9115, qty 2

front outer hinge pin

6299, qty 8

E-clip

9120, qty 1

cross brace

steel

9125, qty 1

front bulkhead

s t e p 2

L E F T S I D E

B A G A

7260, qty 2

4-40 nut

3/32"

1:1

1:1 1:1

1:1

1:1

1:11:11:1

1:1 1:1

1:1

T O O L S U S E D

COMPLETED FRONT ASSEMBLY

4

9107, 9108*, qty 2

front suspension arm

V I E W E D F R O M R E A R

REMOVE THESE

PARTS FOR:

Step 2

9107,

9108*

9115

9125

9145

9145

6924

7230

9120

7260

6295

6936

6924

7230

9110

6299

6299

6299

7260

7413

9107, 9108*

6299

HOW TO USE THE

TURNBUCKLE WRENCH

2 3/4" (2.75" or 69.9mm)

6924

6263, 1406*

DO NOT CUT OFF BALLS.

REMOVE FLASHING SO BALLS

ARE PERFECTLY SMOOTH.

9107, 9108*

6263, 1406*

KICKUP TO CHASSIS

Add screw locking compound such as

Loctite© (not included in kit) to the three

#9215 screws and attach the #9210 (9210B*)

aluminum kickup (nose plate) to the #9200

(9199*) chassis.

Place the two #9160 servo saver/bell crank

mounting pins in the locating holes.

9215, qty 3

6-32 x 3/16

s t e p 1

9160, qty 1

mounting pin,

right hand

9160, qty 1

mounting pin,

left hand

SERVO SAVER

Push one #9155 servo saver

bushing into each end of the

#9158 (9156B*) aluminum

tube.

Slide the two #9155 servo

saver arms onto the tube.

Slide the spring and adjusting

nut on the tube. Tighten the

nut until 1/32" of the tube

threads are exposed.

Add three #6270 ball ends

where shown and three #6272

foam dust covers onto them.

BELLCRANK

Install the two #9155 (9162*)

bushings or 9162* bearings

into the bell crank.

Add two #6270 ball ends

where shown and two #6272

foam dust covers onto them.

6270, qty 5

ball end 6272, qty 5

dust cover 9155, 9162*, qty 2

left hand servo

saver bushing

9155, qty 1

servo saver arm 9155, qty 1

servo saver

arm

9155, qty 2

bell crank

bushing

9158, 9156B*, qty 1

tube,

aluminum

9158, 9156B*, qty 1

adjusting nut 9158, qty 1

servo saver

spring

9155, qty 1

bell crank

9165, qty 1

drag link

DRAG LINK

Install the #9165 drag link

over the two ball ends with

your needlenose pliers.

1:1 1:1

1:1 1:1 1:11:1

1:1 1:1

9210, 9210B*, qty 1

kickup

T O O L S U S E D

s t e p 2

5

s t e p 3 P R O F I L E

IFMAR 2WD World Champion

Masami has a long string of wins for

Associated 2WD and Yokomo 4WD

cars. Masami drove the fastest car at

the '97 World's with his RC10B3

buggy, and took top honors in the

4WD category.

At the '99 Worlds in Finland Mark

Pavidis (left) TQ'd with his RC10B3

and Masami (right) was crowned as

World Champion driving his B3.

REMOVE THESE

PARTS FOR:

Steps 1-3

9210,

9210B*

9160

9215

9160

9200,

9199* 9215

9215

6272

6272

(foam)

6272

(foam)

9155

9155

9158, 9156B*

9155

9155

9155,

9162*

9155,

9162*

9155

6272

6270

6270

6270

6270

6270

9158, 9156B*

9158

6272

9165

B A G B

9162*, qty 2

bell crank

ball bearing

1:1

Masami in 1997

Mark Pavidis

TQ

Masami Hirosaka

2WD World Champion

I F M A R W O R L D C H A M P I O N S H I P S 1 9 9 9

T h e R C 1 0 B 3 T Q ' d a n d w o n t h e

1 9 9 9 I F M A R W o r l d C h a m p i o n s h i p

SERVO SAVER TO CHASSIS

Place the servo saver assembly over the

pins.

TOP PLATE TO CHASSIS

Line up the #9130 (9131*) front top plate

with the servo saver pins and screw holes.

Bolt down the top plate with two #6923

screws tightly,

then back off both screws

one full turn.

This will allow us to

accomplish step 5 below.

6292, qty 2

4-40 x 3/8

B A G B

9130, 9131*, qty 1

front top plate

6923, qty 2

4-40 x 3/4 9220, qty 1

front bumper

7673, 6933*, qty 2

4-40 x 5/16

1:1 1:1 1:1

BUMPER TO CHASSIS

Use two #6922 (6934*)

screws to secure the top plate

to front bulkhead.

FRONT END TO CHASSIS

Slip front end under top plate, then

push rearward over kickup.

T O O L S U S E D

s t e p 4

1/16"

s t e p 5

6

s t e p 6

REMOVE THESE

PARTS FOR:

Steps 4-6 6922, 6934*, qty 2

4-40 x 1/2

1:1

6922,

6934*

9130, 9131*

6923

6923

under top plate

6292 6292

9220

7673,

6933*

over kickup

Secure front bulkhead to kickup plate

with two #6292 screws.

Go back and tighten the two #6923

screws from Bag B, step 4.

Bolt on the #9220 bumper with the two

#7673 (6933*) screws.

3

6922,

6934*

7673,

6933*

B A G B

6263, 1406*, qty 2

2.06" turnbuckle

7230, qty 4

large ball cup

1:1 1:1

TURNBUCKLES

Add #7230 ball cups to two

#6263 or 1406* turnbuckles to

the dimension shown.

Pop on the turnbuckles. Do both

sides.

T O O L S U S E D

s t e p 7

7

P R O F I L E

Ranch Pit Shop

The RC10B3 TQ'd as the fastest car in the World's on this track

in Pomona, California, site of the 1997 IFMAR Off Road World

Championships. The B3 was driven by Masami Hirosaka, multi-

World Champion from Japan.

The B3 was later to come back to TQ and win at the very next

'99 World's at Finland!

REMOVE THESE

PARTS FOR:

Step 7

ball cups thread on in opposite directions

2 47/64" (2.74 or 69.5mm)

1:1

TRIM SUSPENSION ARMS

Twist the #9257 (9258*) suspension arms

from the mold runners (shown in gray) with

your pliers, and trim away the remaining

molding with your hobby knife.

s t e p 2

L E F T S I D E

REAR PLATE TO CHASSIS

Attach the two #9267 (3-3) rear suspension arm mounts to the #9241

(9241B*) chassis plate with two #9269 5-40 x 1/2 screws and a single

#6936 washer as shown.

These mounts are marked L3-3 (left) and R3-3 (right). The coding

stands for 3° toe in and 3° anti-squat.

NOTE: by using the #4 washer,

your anti-squat is effectively reduced to 1.5°.

Fasten the chassis plate to the bottom of the chassis with four #6292

screws.

Add two #6273 ball ends to the inside holes of the chassis, then thread

on the #7260 nuts to the ball ends. Then add the #6272 foam dust

covers.

SUSPENSION ARMS TO MOUNTS

Attach the #9257 (9258*) left suspension

arm to the #9267 left mount with the #9260

hinge pin and #6299 E-clips.

Now do the right side.

s t e p 1

8

s t e p 3

L E F T S I D E

9257, 9258*, qty pr

rear suspension arm

9267, qty 2

rear suspension mount, 3-3

(3° toe-in, 3° anti-squat)

9260, qty 2

rear inner hinge pin 9241, 9241B*, qty 1

rear chassis plate

7260, qty 2

4-40 nut 6272, qty 2

dust cover

1:1 1:1 1:1

6273, qty 2

ball end

1:1

6299, qty 4

E-clip

1:1

9269, qty 4

5-40 x 1/2

1:1

6292, qty 4

4-40 x 3/8

1:1

T O O L S U S E D

1/16", 5/64"

6936

1:1

6936, qty 2

#4 washer

9241,

921B*

6299

9260

6299

9260

9257,

9258*

9241,

9241B*

9267 6272

(foam)

6272

(foam)

6273

6273

6292

6292

9269

7260

7260

6292

6292

REMOVE THESE

PARTS FOR:

Steps 1-3

9267

Make sure the

arm outer rib

is facing down

9257, 9258*

B A G C

9257, 9258*

9269

2

SET UP DIFF GEAR

Add a generous amount of #6591 diff lube to the

#9365 diff gear ball holes and push in the twelve

#6581 diff balls. Then push in the lube that was

pushed out.

Insert one #6597 bushing or #6589 bearing into the

gear.

B A G D

9365, qty 1

diff gear

1:1

6581, qty 12

diff balls

carbide

6591, qty 1

diff lube

6597, qty 1

5/32 x 5/16

bushing

T E A M &

F . T .

1:1

9365

6581

1:1

6589, qty 1

5/32 x 5/16

ball bearing

9370, qty 1

left diff

outdrive hub

6582, qty 1

diff spring

6575, qty 1

T-nut

6573, qty 2

diff thrust

washer

6574, qty 6

diff thrust

ball

6575, qty 1

2-56 diff bolt

9375, qty 1

right diff

outdrive hub

6575, qty 1

diff thrust bolt

cover, nylon

9367, qty 2

diff drive ring

6588, qty 1

black grease

B A S I C &

S P O R T

1:11:1 1:1 1:1 1:1 1:1

T O O L S U S E D

s t e p 1

5/64"

REMOVE THESE

PARTS FOR:

Steps 1-5

6591

9367

RIGHT OUTDRIVE HUB

Insert one #6597 bushing or #6589 bearing

into the #9375 right hub.

Add a

light

coat of #6591 diff lube to right

hub where shown.

Place a #9367 diff drive ring and then the

gear assembly on the hub.

ASSEMBLE THE HUBS

Add a

light

coat of #6591 diff lube to left

hub where shown.

Place a #9367 diff drive ring on the hub.

Push the #9370 hub over the diff bolt and

center the hub.

CHECK ALIGNMENT OF HUBS

Tighten the diff with your 5/64" Allen

wrench, but not completely.

Rotate the diff hubs several times as you

are tightening the bolt to check for proper

alignment of the parts.

We'll adjust the diff on the next page.

9367

9375

9370

6597, qty 1

5/32 x 5/16

bushing

1:1 1:1

6589, qty 1

5/32 x 5/16

ball bearing

9

6591

6591

s t e p 4

RIGHT

LEFT

T E A M &

F . T .

B A S I C &

S P O R T

7

8

9

LEFT OUTDRIVE HUB

Push in the #6582 spring and

#6575 T-nut.

6582

9370 6573

6575

6574

6573

9375

6575

s t e p 2 s t e p 3

6575

6588

RIGHT OUTDRIVE HUB

Slide one #6573 washer onto the #6575

bolt. Apply a generous amount of #6588

black grease to the washer on the side

facing away from the bolt head.

Stick six #6574 balls into the grease against

the bolt and washer. Add the other #6573

washer. The grease will hold the balls in

place during assembly.

Slide all this into the #9375 right outdrive

hub, being careful not to lose any of the

balls.

Insert the #6575 bolt cover.

B A G D

9352, qty 1

right tranny case 9352, qty 1

left tranny case

3976, qty 2

3/8 x 5/8

unflanged bearing

3977, qty 2

3/16 x 3/8

unflanged bearing

6598, qty 2

3/8 x 5/8

bushing

6599, qty 2

3/16 x 3/8

bushing

1:1

6571, qty 1

drive shaft/gear 7669, qty 2

drive shaft

spacer

9360, qty 1

idler gear

ADD BUSHINGS OR BEARINGS TO

THE CASE HALVES

Cut the two #9352 transmission case

halves and the three #9352 spacers

from the runner.

Add bushings or bearings to each

case half.

1:1

9361, qty 1

idler gear shaft

6928, 6935*, qty 3

4-40 x 1

6572, qty 1

drive shaft

roll pin

6292, 6934*, qty 1

4-40 x 3/8

1:1 1:1 1:1

1:1

1:1

ADJUST THE DIFFERENTIAL

As you tighten the diff bolt, you will notice the T-

nut ears moving closer to the bottom of the diff hub

slot. This compresses the spring behind the T-nut.

The spring should be fully compressed at the same

time the T-nut reaches the end of the slot.

Caution:

Pay close attention to feeling when

the spring is fully compressed.

Do not overtighten the

bolt.

When you feel the spring fully compressed, loosen

the diff bolt 1/8 of a turn. No more, no less. Your diff

should now operate very smoothly when turning the

hubs in opposite directions. After you have driven the

car once, recheck the diff adjustment. Never adjust the

diff any other way.

INSIDE THE TRANNY

Install the right side diff assembly into the right case.

(Page 9, Step 3 will show you which diff hub is the right

side.)

Add the #7669 spacer to the #6571 drive shaft and put

both into the case.

Install the two bushings or bearings in the #9360 gear,

followed by the #9361 shaft. Insert the assembly into

the case.

Add the other #7669 spacer to the #6571 shaft and put

the case halves together.

OUTSIDE THE TRANNY

Screw the halves together with one

#6292 (6934*) bolt.

Insert the #6572 roll pin into the shaft

hole with your needlenose pliers.

Push the three #6928 (6935*) bolts

through, each with its own #7337 washer.

s t e p 5

T O O L S U S E D

1/16", 3/32"

s t e p 6

s t e p 7

10

1:1

center pin about shaft

9352 9352

9352

RIGHT LEFT

6599, qty 2

3/16 x 3/8

bushing

1:1

9352

7669

6571

3977, qty 2

3/16 x 3/8

unflanged bearing

1:1

6572

9361 7669

6292

6928, 6935*

LEFT

RIGHT

7337, qty 3

washer, gold

1:1

7337

7337

7337

9360

REMOVE THESE

PARTS FOR:

Steps 6-7

T E A M

&

F . T .

B A S I C &

S P O R T

T E A M

&

F . T .

B A S I C &

S P O R T

6928, 6935*

6928, 6935*

REMOVE THE BACKING

Remove the backing and

center from the #7373

gasket.

B A G D

INSTALL THE MOTOR PLATE

Center the #7373 gasket around the

large round hole of the 9245 (9245B*)

plate.

Install the three #9352 spacers.

Line up the #9245 (9245B*) plate and

fasten with the three #6928 (6935*)

screws.

7373, qty 1

motor plate gasket

foam

1:1

9352, qty 3

motor plate

spacer

9245, 9245B*, qty 1

motor plate

INSTALL THE ASSOCIATED TORQUE CLUTCH (ATC)

Add the #9251 inner hub to the shaft, lining up the notch with the roll

pin.

Install the #9253 clutch disc into the inner hub, then add the #9252

outer hub and #6599 bushing.

Install parts in the following order: #6594 (thin), 6594 (thick), 6594

(thin), 6587 black spring, 6629 locknut.

Orient the #6693 spur gear side facing out as shown and mount to

#9252 with two #6568 screws.

Tighten the #6629 locknut so the end of the shaft is flush with the end of

the nut. This is a good initial adjustment. For further info on the torque

clutch, see the tuning section on page 27.

MOUNT THE TRANSMISSION

Mount the #9380 brace with two #7874 (7873*) screws.

Mount the tranny with the two #6292 (6934*) screws from below,

lining up the motor plate holes as shown.

Bolt the motor plate to the rear chassis with two #6568 screws.

6587, qty 1

torque control

spring

6629, qty 1

5-40 locknut

1:1

6594, qty 2

thrust bearing

washer (thin)

6594, qty 1

thrust bearing

(thick gold)

6599, qty 1

3/16 x 3/8

bushing

1:1

6693, qty 1

81T 48 pitch

spur gear

9251, qty 1

inner torque

clutch hub

9252, qty 1

outer torque

clutch hub

9253, qty 1

clutch disc

9380, 9381*, qty 1

rear transmission

brace

7874, 7873*, qty 2

4-40 x 7/16

1:1

6568, qty 4

4-40 x 3/16

6292, 6934*, qty 2

4-40 x 3/8

1:1

1:1

1:1

1:1

1:1

T O O L S U S E D

s t e p 8

s t e p 1 1

L E F T S I D E

1/16", 3/32"

s t e p 9

s t e p 1 0

11

7373

9352

9245, 9245B*

9352

9352

9251

9252

9253

6587

6629

6693

6568

6568

6599 bushing

6292, 6934*

6568

6568

7874, 7873*

9380

6594

silver color

6594

gold color

REMOVE THESE

PARTS FOR:

Steps 8-11

1:1

6928,

6935*

7874, 7873*

6292, 6934*

s t e p 1

L E F T S I D E

12

6370

6372

6374

6273

6272

7260

7360

7360

6388

6374

6375

6466

1/16"

6273, qty 2

ball end

B A G E

1 : 1

1:1

HUB CARRIERS TO REAR ARMS

(Upper left drawing:) Push the #9273 spacer into the outdrive of the

transmission.

(Upper left drawing:) Insert the dogbone pins into the stub axle and

outdrive hub as shown.

Place the hub carrier between the arm holes as shown and add two

#6466 spacers where shown.

Add one #6299 E-clip to the end of the #9263 hinge pin, insert it as

shown, then add the other #6299 E-clip.

Now install the axle assembly for the right side.

ASSEMBLE REAR HUB CARRIERS

Note that the #7366 hub carriers are marked for left and right.

Insert #7360 bushings into each side of the left hub carrier.

Install the #6374 stub axle as shown.

Insert #6388 cone washer as shown, raised outer edges facing

out. Add #6375 roll pin.

Insert the #6372 spring into the stub axle.

Thread on the #6273 ball end and add the #7260 nut to the

other side.

(When you do the other hub carrier, thread the ball

end into the other side so both will point to the front when

assembled.)

Add a #6272 dust cover to the ball end.

Follow the above for the right hub carrier.

6272, qty 2

dust cover

1:1 1:1

1:1 1:1

1:1

1:1 1:1

1:1

1:1

6299, qty 4

E-clip

6466, qty 4

spacer, 1/16" 7260, qty 2

small nut 7366, qty 2

hub carrier

1:1

9263, qty 2

rear outer hinge pin

6375, qty 2

roll pin

9273, qty 2

dogbone spacer

3/32" (black)

6388, qty 2

cone washer 7360, qty 4

bushing

6370, qty 2

dogbone 6372, qty 2

dogbone spring

6374, qty 2

stub axle

T O O L S U S E D

9273

3/32" (black)

REMOVE THESE

PARTS FOR:

Basic: step 1

Sport: step 1

B A S I C & S P O R T K I T S O N L Y

B A S I C & S P O R T K I T S O N L Y

9257

6299

9263

6299

9263

R E A R

7366

6466

1/16", 2

make sure window

faces front

5

7366

10

T O O L S U S E D

HUB CARRIERS TO REAR ARMS

Place the left hub carrier between the arm holes as shown and

add two #6466 spacers where shown.

Add a #6299 E-clip to the #9263 hinge pin insert it as shown,

then add an E-clip at the other end of the hinge pin.

Insert the universal dog bone into the slots of the outdrive hub.

Now install the axle assembly for the right side.

ASSEMBLE THE #9276 MIP CVDTM

(Constant Velocity Drive

TM

)

Spread some Associated #6588 black grease inside the #7380 axle hole where shown, then on

the #7381 coupling, and insert the coupling into the axle.

Slide the axle into the #9278 dogbone, aligning the cross holes.

Insert the #7381 cross pin, making sure it is evenly spaced on both sides of the #9278 bone.

Add the #9276 MIP thread lock to the #7381 set screw. Angle and turn the MIP CVD

TM

so the

set screw can be screwed in with the Allen wrench.

Assemble the other axle.

7368

6272

6273

3977 7260

7366

7369

3977 7380

6466

1/16"

Be careful not to damage

the indented shields of the

ball bearings when pushing

them in.

6273, qty 2

ball end

B A G E

1 : 1

1:1

6272, qty 2

dust cover

1:1 1:11:1 1:1 1:1

6299, qty 4

E-clip 6466, qty 4

spacer, 1/16" 7260, qty 2

small nut

9263, qty 2

rear outer hinge pin

1:1

7377, qty 2

rear axle

bearing spacer,

aluminum

1:1

7368, qty 6

3/16" axle shim,

steel

7369, qty 2

axle spring

pin

1:1 1:1

T E A M & F A C T O R Y T E A M K I T S O N L Y

s t e p 1

L E F T S I D E

13

7377

3977, qty 4

3/16 x 3/8

ball bearing

REMOVE THESE

PARTS FOR:

Team: step 1

Factory Team:

step 1

7366, qty 2

hub carrier

9257,

9258*

6299

9263

6299

9263

R E A R

7366

REAR HUB CARRIERS

Note that the #7366 hub carriers are marked left and right. Slide one of

the thin #7368 3/16" axle shims onto the axle.

Install one #3977 bearing, then the #7377 bearing spacer.

NOTE: You

MUST use the bearing spacer.

Slide the axle assembly into the hub

carrier from the rear.

Install the second #3977 bearing into hub carrier and onto the axle,

followed by the #9276 thick spacer and two #7368 thin spacers. Insert

the #7369 roll pin into axle.

Thread on the #6273 ball end into the hole shown and add the #7260 nut

to the other side.

(When you do the other hub carrier, thread the ball end

into the other side so both ball ends will point to the front when

assembled.)

Add a #6272 dust cover to the ball end.

Follow the above for the right hub carrier.

7381

cross pin

9278

9276

7381

7381

coupling

7380

6588

6588, qty 1

black grease

9276, qty 1

MIP threadlock

9278, qty 2

CVD dog bone 7380, qty 2

CVD axle 3438, qty 2

8-32 locknut

1:1 1:1

7381, qty 2

CVD coupling

1:1

7381, qty 2

CVD cross pin

1:1

7381, qty 2

CVD set screw

.050"

9276, qty 2

3/16" axle shim

MIP thick, steel

1:1

6466

1/16", 2

7368

9276

7380

T E A M & F A C T O R Y T E A M K I T S O N L Y

make sure window

faces front

5

9

5

6292,

6934* 6292,

6934*

6915

6915

9270,

9279,

9280*

7413

7260

7413

7260

ball cups thread on in opposite directions,

and face in opposite directions

2 1/2" (2.50" or 63.5mm)

1:1

7230

T O O L S U S E D

B A G E

REMOVE THESE

PARTS FOR:

Steps 2-3

6292, 6934*, qty 2

4-40 x 3/8 6915, qty 2

4-40 x 5/8

1:1

BASIC & SPORT ONLY

9270, qty 1

rear shock tower

MOUNT THE REAR SHOCK

TOWER

Orient the tower outward as

shown and mount to bulkhead

with #6292 (6934*) screws.

Fasten the tower to the

transmission brace with the #6915

screws.

Add two #7413 screws in the

middle holes at top, then thread

on #7260 nuts.

1:1

7413, qty 2

4-40 x 3/4

1:1

7260, qty 2

4-40 nut

14

s t e p 2

L E F T S I D E

R E A R V I E W

1/16", 3/32"

A L L K I T S

COMPLETED REAR ASSEMBLY

s t e p 3

ADD TURNBUCKLES

Twist #7230 ball cups onto the

#6262 (1403*) turnbuckle until

you get the dimension shown.

Ball cups will face in opposite

directions.

Connect ball ends with the

turnbuckle ball cups as shown,

using your needlenose pliers.

Assemble both right and left

sides.

7230, qty 4

large ball cup

6262, 1403*, qty 2

1.65" turnbuckle

1:11:1

7230

6262, 1403*

TEAM & F.T. ONLY

9279, 9280*, qty 1

rear shock tower

1:1

6465

B A G F

REMOVE THESE

PARTS FOR:

Steps 1-4

TRIM SHOCK PISTONS

Burrs interfere with smooth shock action within

the shock body. To remove from tree without

creating burrs, twist up, not down. Remove

two each of #1 and #2.

Remove remaining burrs carefully with hobby

knife.

burr

SHOCK SEAL PARTS

Install the #5407 and #6440

parts shown onto the #6429

tool tip.

Add 3-4 drops of #5428 oil to

the inside of the shock body,

and to the shock seal parts.

Insert the tool tip into the

shock body all the way. Push

easily

until the parts snap into

place.

Check the tool height in

photo. The right shock shows

just before snapping parts in

place, the left shows after.

If your shocks do not snap

together easily, check the

parts for burrs again.

Assemble the other shock

bodies the same.

DISMANTLING THE

SHOCKS WHEN IT'S

REBUILD TIME

Put the shock assembly tooltip

into the bottom of the shock

until it rests against the small

washer, as shown, then push.

cut-away view

of shock body

small washer

shock assembly tool

6459, 6417*, qty 2

rear shock shaft

6460, 6418*, qty 2

front shock shaft

5407, qty 8

red O-ring

6429, qty 1

shock assembly tool 6440, qty 4

split locking

washer

6440, qty 4

large spacer

6440, qty 8

small washer

6465, qty 2

shock piston #1 6428, qty 4

shock cap

6469, qty 4

large O-ring

6299, qty 8

E-clip

TEAM & F.T. ONLY

6435, qty 2

rear shock body

BASIC & SPORT ONLY

6424, qty 2

rear shock body

TEAM & F.T. ONLY

9310, qty 2

front shock body

BASIC & SPORT ONLY

9311, qty 2

front shock body

5428, qty 1

25 wt

silicone oil

1:1 1:1

6465, qty 2

shock piston #2

1:1 1:11:1

1:1 1:1 1:1

TRIM SHOCK WASHERS &

SPACERS

For best shock performance, trim

each part from the parts tree so no

part of the two molding runners

remain. It is safer to remove a tiny

amount of the part than to risk the

chance of a burr remaining.

Short

blade scissors or a hobby knife will

work fine, as shown at right. Run your

finger over the edges to feel for burrs

you cannot see. Remove the ones

you find. Burrs can keep the parts

from snapping in correctly, and can

cause the shock to leak or the shaft

to jam.

wrong

right

15

T O O L S U S E D

s t e p 1

s t e p 2

7217, qty 4

pivot ball

plastic

7217, qty 4

eyelet

nylon

1:1

6429

5407

6440

bottom of

shock body

6440

5428

O I L

5428

O I L

before snapafter snap

5

6

FILLING THE SHOCKS

Holding the shocks upright, fill

with oil to the top of the shock

body.

Slowly move the shaft up and

down several times to allow air

bubbles to escape to the top.

Refill with oil to the top of the

shock body.

Push the shaft in until the piston

is level with top of shock body.

The oil will slightly bulge up above

the shock body.

Install the #6428 shock cap and

tighten. There should be no gap

between the cap and the hex

portion of the shock body when

tight.

SETTING THE REBOUND

Move the shock shaft in and out

a few times an then push it all the

way in. It should be easy to push

the shaft in until the eyelet hits the

body.

1/4" to 3/8"

(6.3mm - 9.5mm")

6428

FINAL INTERNAL SHOCK ASSEMBLY

Add #6469 O-ring over threads of shock body.

For the #6460 (6418*) front shock shafts, install a #6299 E-

clip on either side of a #6465

(#2)

piston.

For the #6459 (6417*) rear shock shafts, install a #6299 E-

clip on either side of a #6465

(#1)

piston.

Place a couple drops of #5428 oil on threaded part of shaft

and insert into shock body.

Push the #7217 pivot ball and eyelet together, then screw

the eyelets onto the end of the shock shaft. Hold shaft with

rag and needlenose pliers next to threads.

6299 front: #6465 (#2)

rear: #6465 (#1)

6469

front: 6460, 6418* (short)

rear: 6459, 6417* (long)

7217

7217

6299

s t e p 4

s t e p 3 FOR BASIC & SPORT

front: 9311 gold (short)

rear: 6424 gold (long)

FOR TEAM & F.T. ONLY

front: 9310 (short)

rear: 6435 (long)

HOW TO

TIGHTEN

THE CAP

ON YOUR

SHOCK

Then the shaft should push itself out

approximately 1/4" to 3/8" (6.3mm -

9.5mm").

If the shocks do not push out this far,

there is not enough oil in them. Add just a

little oil and try steps 6-7 again.

If the shocks push out farther than the

distance in step seven, or you cannot push

the shaft in until the eyelet hits the body,

there is too much oil. Loosen the cap a half

turn (with the shaft extended) and pump out

a small amount of oil by pushing the shaft

in. Retighten the cap and try steps 6-7

again.

5428

B A G F

6474, qty 4

spring collar 6478, qty 2

rear spring

silver

6494, qty 2

front spring

green

16

s t e p 5

REMOVE THESE

PARTS FOR:

Step 5

FINAL SHOCK ASSEMBLY

Install one #6474 spring collar onto the shock body.

Install the correct spring for front and back shocks.

Pull the shock shaft out as far as it will go, compress the

spring, then insert the #6474 spring cup over the #7217

eyelet.

Twist two 1/4" thick #8846 preload spacers from the tree.

For the front shocks, slide a preload spacer between the

spring collar and shock body hex.

Twist two 1/16" and 1/8" thick preload spacers off the tree.

Slide them onto the rear shocks between the spring collar

and shock body hex.

6474

spring cup

install 6474

after spring

8846

front: 1/4"

8846, qty 6

preload spacer

rear: 6478 (silver)

front: 6494 (green)

6474

spring collar

7217

8846

rear: 1/16" & 1/8"

REAR SHOCK MOUNTING

Add the #6473 bushings as shown.

Push cap over bushing and add #6222

locknut. Do not overtighten or the shock

will bind.

Fasten the lower shock with the #6918

screw into the arm outer hole.

FRONT SHOCK MOUNTING

Add the #6473 bushings as shown.

Push cap over bushing and add

#6222 locknut. Do not overtighten or

the shock will bind.

Fasten the lower shock with the #6918

screw into the arm inner hole

Do the other front shock.

6222, qty 4

4-40/5-40

locknut

B A G F

REMOVE THESE

PARTS FOR:

Steps 7-8 6918, qty 4

4-40 x 1/2

6473, qty 4

shock bushing

1:11:11:1

B A G G

9180, qty 1 ea

servo horns

1:1

ASSEMBLE THE SERVO

Find the approporiate #9180 servo horn for your servo,

marked "A" for Airtronics, "F" for Futaba, "J" for JRPropo, and

"H" for Hitec. Remove the servo horn from your servo and

replace with the #9180 horn, then fasten with the stock

mounting screw.

Install the #6270 ball end into the servo horn. Add the #6272

dust cover.

Attach the #7336 mounts with the #6917 (6860*) screws and

#7337 washers. Add the #7336 spacers if you have an

Airtronics servo.

6270, qty 1

ball end 6272, qty 1

dust cover 7336, qty 2

servo mount

7336, qty 2

servo mount

spacer

7337, qty 4

washer

1:1

1:1

T O O L S U S E D

T O O L S U S E D

s t e p 1

s t e p 7

R I G H T S I D E

s t e p 8

R I G H T S I D E

1/16", 3/32"

1/16"

17

REMOVE THESE

PARTS FOR:

Step 1

9180

7336

7337

6917,

6860*

7336

use spacers with

Airtronics servo

6272

6270

7336

7336

7337

use spacers with

Airtronics servo

1

4

BASIC, SPORT, TEAM ONLY

6917, qty 4

4-40 x 3/8

OR

FACTORY TEAM ONLY

6860*, qty 4

4-40 x 3/8

1:11:1

6917,

6860*

stock mounting

screw

7673,

6933*

6681

6951 6936

6515

B A G G

REMOVE THESE

PARTS FOR:

Step 2

9170, qty 2

servo link cup 9170, qty 1

servo link

MOUNT THE SERVO

Mount the servo with two #7673 (6933*) screws.

Assemble the #9170 servo link, matching the length to the

true scale drawing.

Use needle-nose pliers to attach link to ball ends.

7673, 6933*, qty 2

4-40 x 5/16

1:1

13/16"

.812"

20.4mm

9170 9170

B A G G

6515, qty 2

3mm x 6mm

gold

1:1

INSTALL THE MOTOR

Attach three capacitors to your motor according to the

instructions that came with your motor, if they are not on

already. For the

Sport kit,

solder the colored plug wire to a

positive tab on the motor and the black wire to a negative tab.

For the

Basic, Team & Factory Team kits,

you must buy

your own motor, then follow this step.

Install the #6681 gear with the #6951 set screw going to the

flat side of the shaft. For the

Basic, Team & Factory Team kits,

you must buy your own pinion gear. If you use an electonic

speed control, see its directions for installing motor

capacitors.

Use two #6515 screws and two #6936 washers to mount the

motor as shown so the gears mesh.

SET THE GEAR MESH

You should be able to rock the spur gear back and forth in the

teeth of the pinion gear without making the pinion gear move.

If the plastic gear is tight, then loosen the #6515 screws and

move the motor away, then try again. A gear mesh that is too

tight or too loose will reduce power and damage the gear

1:1

6936, qty 2

#4 washer

1:1

6951, qty 1

4-40 x 1/8

set screw

SPORT ONLY

6681, qty 1

23 tooth

pinion gear

SPORT ONLY

6742, qty 1

motor connection plug

SPORT ONLY

580, qty 1

motor

SPORT ONLY

6520, qty 3

.1uf capacitor

1:11:1

PARTS REMOVED

TO IMPROVE CLARITY

9170

T O O L S U S E D

18

.050", 1/16"

s t e p 2

R I G H T S I D E

s t e p 3

R I G H T S I D E

T O O L S U S E D

.050", 3/32"

1:1

REMOVE THESE

PARTS FOR:

Step 3

7673,

6933*

MODIFY THE SERVO HORN

There are many servo horns available. The round one is the best

one.

You must modify the horn if you are not using the round one.

Trim them so they don't go beyond the #6712 throttle wiper arm

outer edge. Also trim so it will clear the resistor.

B A G G

7527, qty 2

throttle servo mount

1:1

MOUNTS TO SERVO

Attach the #7527 mounts to the servo with four #6932 screws and

four #6936 washers. Orient your servo output shaft as shown here.

FINAL RESISTOR/

SERVO ASSEMBLY

Attach the #6712 arm to

the horn with the #3721

screw and #2 washer.

Mount the arm and horn

to the servo with the

screw from your servo.

Trim the #3721 screw tip

if it contacts the servo

body.

Add the #6714 mount

using #6925 screw and

#6242 locknut.

Add the #6714 bypass

tab to the #6714 mount

with a #6924 screw and

#6936 washer.

6932, qty 6

4-40 x 5/16

1:1

6936, qty 7

#4 washer

8850, qty 1 ea.

throttle resistor

mounting brackets

6711, qty 1

throttle resistor 6712, qty 1

throttle wiper arm 6714, qty 1

throttle bypass

mount

6925, qty 1

4-40 x 1/2

6714, qty 1

throttle bypass tab 6924, qty 1

4-40 x 3/8

1:1

1:1 1:1

RESISTOR TO SERVO

Push the #8850 brackets

into the #6711 resistor.

Attach the brackets to the

mounts with two #6932

screws and two #6936

washers.

6242, qty 1

4-40 locknut

T O O L S U S E D

s t e p 4 s t e p 5

s t e p 6

19

ASSEMBLED THROTTLE ARM AND RESISTOR

3/32"

1:11:1

3721, qty 1

2-56

self-tapping

qty 1

#2 washer

REMOVE THESE

PARTS FOR:

Sport: steps 4-6

S P O R T K I T O N L Y

best one trim horns so they

don't go beyond wiper arm

or hit the resistor

6712 arm

horn

3721

#2 screw

6714

6925

6242

6714

6936

6924

7527

7527

6932

6932

6936

8850

6711

6932

6932

6932

6936

6936

6936

6932

6936 8850

6936

screw from

your servo

#2 washer

B A G G

WIRE THE RESISTOR

Solder the short red wire between the positive resistor tab and the brass bypass tab.

Solder the #6745 harness wires to the wiper arm and negative tab on the resistor.

Solder the #6747 harness to the positive and negative tabs on the resistor.

Run the wire of the servo attached to the resistor through the battery slot area.

6747

SPEED CONTROL TO CHASSIS

Attach speed control to chassis with two

#6917 screws from the bottom.

6745

6745, qty 1

motor output harness

6747, qty 1

battery input harness

6917, qty 2

4-40 x 3/8

1:1

PARTS REMOVED

TO IMPROVE CLARITY

RADIO RECEIVER TO CHASSIS

Cut a piece of servo tape, remove the paper from one side, and attach it to the bottom of your receiver.

Slip the receiver wire through the built-in chassis antenna mount.

Remove the paper from the other side and attach to the chassis as shown.

Plug the small #6747 BEC plug (of step 7) into the receiver's on/off switch.

Follow the instructions that accompany your radio receiver system.

BEC plug

qty 1

servo tape

(roll, #6726)

T O O L S U S E D

s t e p 7 s t e p 8

L E F T S I D E

s t e p 9

L E F T S I D E

1/16"

20

red

black

REMOVE THESE

PARTS FOR:

Sport: steps 7-9

S P O R T K I T O N L Y

6917

PARTS REMOVED

TO IMPROVE CLARITY

6917

A L L K I T S

5

B A G H

REMOVE THESE

PARTS FOR:

Steps 1-2 6285, qty 2

4-40 x 1/4

1:1

GEAR COVER

Trim the #9247 gear cover, cutting out three

holes shown. Insert the #9247 insert button

into the large hole cut into the gear cover.

Mount the cover with two #6285 screws.

INSTALLING THE BATTERY PACK

Install the three #9235 foam battery pads.

Install the two #9238 foam battery spacers. (The tuning section will show you how to

adjust your steering or traction by moving these spacers.)

Install your battery pack. (See step 5 if you need to assemble it first.)

Thread on the #6929 screw. Aim the body clip hole across the chassis. Add the #9230

(9229*) battery hold down strap. Adjust the screw so the batteries are held tight, but you

are still able to push the #6332 body clip through the screw.

9247, qty 1

gear cover

9247, qty 1

button

9235, qty 1

foam battery pads

9238, qty 2

battery spacer

6929, qty 1

4-40 x 3/8

1:1

9230, 9229*, qty 1

battery hold down strap

6332, qty 1

body clip

SOLDERING INDIVIDUAL CELLS

Solder connections properly to assemble a

battery pack from individual cells.

TIP:

Team racers prefer battery bars or braid

for sturdier connections. Insulated wire will not

allow the pack to fit in the battery slot.

solder connections

with battery bars

or braid

BATTERY PRODUCTS ARE

NOT INCLUDED IN KIT

T O O L S U S E D

21

3/32"

s t e p 1

L E F T S I D E

s t e p 2

R I G H T S I D E

PARTS REMOVED

FOR CLARITY

9235

9238

6929

9230,

9229*

6332

hook into rear shock

tower as shown

9247

6285

This manual suits for next models

2

Table of contents

Other Team Assocciated Motorized Toy Car manuals

Team Assocciated

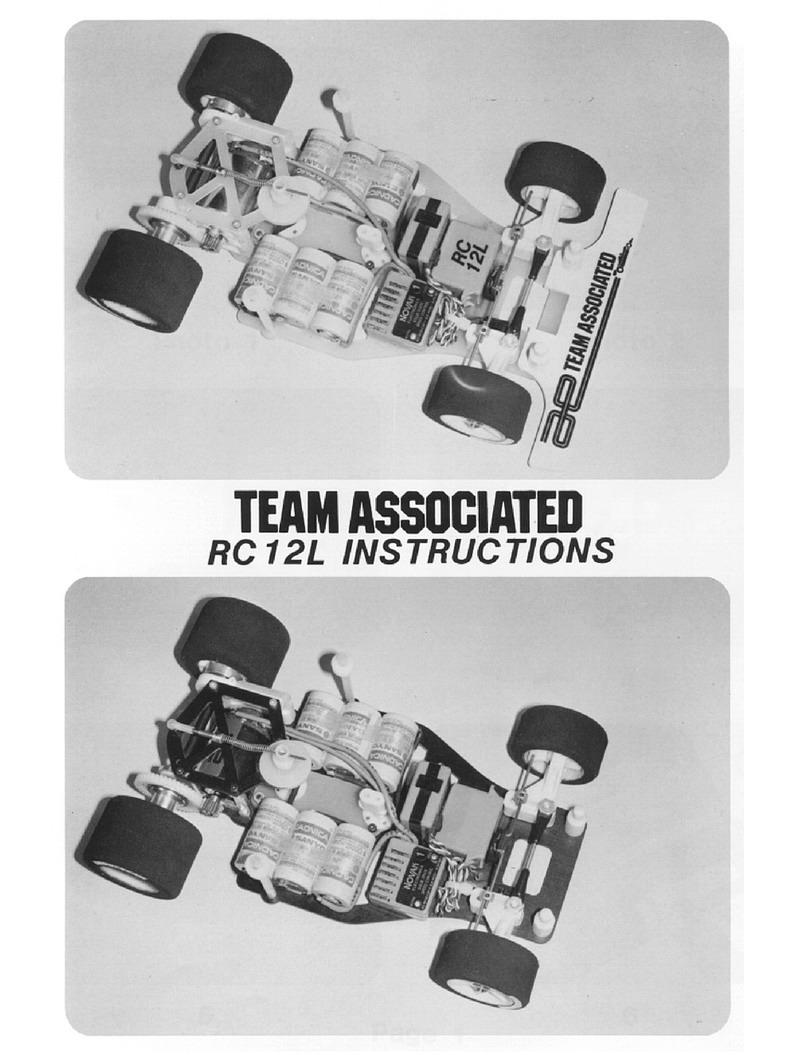

Team Assocciated RC 12L User manual

Team Assocciated

Team Assocciated Factory Team TC4 User manual

Team Assocciated

Team Assocciated SC10B RS RTR User manual

Team Assocciated

Team Assocciated RC10B6.1 Dirt Light Team Kit User manual

Team Assocciated

Team Assocciated Nitro TC3 User manual

Team Assocciated

Team Assocciated RC104T4.1 User manual

Team Assocciated

Team Assocciated TEAM ASSOCIATED RC10T4 User manual