Team SILK AX48-120 User manual

INSTRUCTION MANUAL

AX48-120 FLANGE FACING MACHINE

Revision D

TEAM®

Shap Road

Kendal

Cumbria

LA9 6RU

United Kingdom

Tel: +44 (0) 1539 729009

Fax: +44 (0) 1539 729359

TEAM® is an ISO9001 registered company

© Copyright 2022 TEAM®

AX48-120 Flange Facing Machine

1

THIS INSTRUCTION MANUAL

This Instruction Manual describes how to safely install, operate and maintain the AX48-120

Flange Facing Machine. It is an essential part of the equipment and it is important that you

take the time to read it thoroughly.

Additional copies are available for purchase from TEAM® or from an authorised agent.

HEALTH AND SAFETY AT WORK

This document should be read carefully and fully understood before proceeding to install,

use, maintain or service the equipment.

DO NOT USE THE EQUIPMENT UNTIL YOU ARE SURE YOU KNOW HOW IT WORKS

AND WHAT ITS INTENDED FUNCTION IS.

The equipment described in this document is intended to be used by professional personnel

in an industrial environment.

Installation, operation, maintenance and servicing should only be carried out by suitably

qualified and experienced personnel.

The following symbols are used to highlight important areas of this document which relate to

potential hazards and residual risks:

Important statements regarding the use, handling or operation

of the equipment.

Warnings to prevent injury to operator and or local personnel.

Cautions to prevent misuse and damage to the equipment.

IMPORTANT NOTICE

TEAM® has made every effort to ensure that the information given in this document is as

accurate and as up-to-date as possible at the time of publication.

TEAM® will not be held responsible for any accident or equipment failure that may occur due

to misuse, unauthorised modification, inadequate maintenance, use of non-genuine parts or

use by unsuitable personnel.

TEAM® reserves the right to update, correct or otherwise change any information relating to

this equipment, at any time and without obligation.

AX48-120 Flange Facing Machine

2

TEAM® also reserves the right not to provide updated, corrected or amended versions of this

publication.

The specification and design of the AX48-120 Flange Facing Machine (including the

copyright, design right or other intellectual property in them) shall, at all times, remain the

property of TEAM®. Where any designs or specifications have been supplied by the client for

manufacture by TEAM® or to the order of the client then the client warrants that the use of

those designs or specifications for the manufacture, processing, assembly or supply of the

AX48-120 Flange Facing Machine shall not infringe the rights of any third party.

WARRANTY, SPARES AND AFTER SALES SERVICE

Subject to the provisions of any bespoke terms and conditions of sale, this AX48-120 Flange

Facing Machine is guaranteed for twelve (12) months from the date of purchase against

faulty materials and/or workmanship. During this period it will be repaired or have parts

replaced free of charge provided that:

1 it is returned immediately to TEAM® with evidence of the purchase date;

2 it has been purchased by the user and has not been used for hire purposes;

3 it has not been misused or handled carelessly and has been stored and maintained in

accordance with any instructions provided by TEAM®;

4 repairs have not been attempted other than by a member of TEAM® service team or by a

service provider duly authorised by TEAM® to carry out such repairs; and

5 the cost of such repair or replacement does not exceed the original purchase value.

A full spare parts service is available from TEAM® or from an authorised agent. Additionally,

TEAM® can supply a recommended spare parts kit suitable for a specified period of normal

service life.

Also offered is a Factory Service, in which the equipment can be returned to TEAM® for

inspection. A quotation may then be given for the overhaul, repair or replacement of the

equipment.

TEAM® warrants that the AX48-120 Flange Facing Machine supplied will at the time of

delivery correspond to the description given by TEAM®. All other warranties, conditions or

terms relating to fitness for purpose, quality or condition of the AX48-120 Flange Facing

Machine, whether express or implied by statute or common law or otherwise are excluded to

the fullest extent permitted by law.

AX48-120 Flange Facing Machine

3

CONTENTS

SECTION 1 TECHNICAL DESCRIPTION ........................................................................... 8

1.1 Introduction ...................................................................................................... 8

1.2 Equipment description ..................................................................................... 8

1.2.1 Turntable assembly ............................................................................... 8

1.2.2 Feed gearbox ......................................................................................10

1.2.3 Surfacing arm assembly and toolpost .................................................10

1.2.4 Mounting base assembly ....................................................................11

1.2.5 Optional accessories ...........................................................................12

SECTION 2 SPECIFICATIONS .........................................................................................13

SECTION 3 SAFETY INFORMATION ..............................................................................16

3.1 Warnings and cautions ..................................................................................16

SECTION 4 CONTROLS AND BASIC OPERATION .......................................................19

4.1 Location and function of the controls.............................................................19

4.1.1 Machine controls .................................................................................19

4.1.2 Filter/lubricator pack controls ..............................................................21

4.2 Basic operation of the equipment ..................................................................22

4.3 Lifting and slinging arrangements .................................................................22

SECTION 5 SITE OPERATION .........................................................................................23

5.1 Warnings and cautions ..................................................................................23

5.2 Setting up the equipment ..............................................................................24

5.2.1 Unpacking the machine .......................................................................24

5.2.2 Mounting base installation ...................................................................26

5.2.3 Centralising the base within the bore ..................................................29

5.2.4 Machine installation .............................................................................30

5.2.5 Setting up the tool ...............................................................................32

5.2.6 Toolpost overrun and gearbox protection device ................................32

5.2.7 Installing and machine balancing - (vertical flange) ............................33

5.2.8 Setting up the tool - facing and grooving ............................................36

5.3 Using the equipment......................................................................................37

5.3.1Connection to Air Supply .....................................................................37

5.3.2 Starting the machine - Facing and Grooving ......................................38

5.4 Removing the equipment ..............................................................................39

5.5 Storing the equipment ...................................................................................39

SECTION 6 FAULT DIAGNOSIS ......................................................................................40

6.1 Introduction ....................................................................................................40

6.2 Fault diagnosis chart .....................................................................................40

SECTION 7 MAINTENANCE INSTRUCTIONS ................................................................42

7.1 Introduction ....................................................................................................42

7.2 Periodic maintenance ....................................................................................42

7.3 Recommended lubricants ..............................................................................43

7.4Removal and refit procedures .......................................................................44

7.4.1 Drive motor ..........................................................................................44

7.4.2 Removal of gearbox ............................................................................44

7.4.3 Replacement of shear pins .................................................................45

7.4.4 Surfacing arm ......................................................................................46

AX48-120 Flange Facing Machine

4

7.4.5 Toolpost ...............................................................................................47

7.4.6 Toolpost overrun/gearbox protection device .......................................48

SECTION 8 PARTS LISTS ................................................................................................49

8.1 Mast and turntable assembly ........................................................................52

8.2 Surfacing arm assembly ................................................................................56

8.3 Gearbox assembly.........................................................................................59

8.4 Base assembly ..............................................................................................62

8.5 Toolpost assembly.........................................................................................64

8.6 Base centraliser .............................................................................................66

8.7 Counter balance ............................................................................................68

APPENDIX A Cutting tools as applied to portable machines .........................................69

APPENDIX B Surface metrology .......................................................................................72

APPENDIX C V-Groove measurement ..............................................................................75

APPENDIX D Air motor manufacturers information ........................................................77

APPENDIX E Fall-Stop Kit ..................................................................................................84

1. Technical description .....................................................................................84

2. Specifications .................................................................................................85

3. Safety information ..........................................................................................85

4. Installation of the equipment ..........................................................................86

5. Operation of the equipment ...........................................................................88

6. Maintenance instructions ...............................................................................88

7. Periodic maintenance ....................................................................................89

APPENDIX F Declaration of Conformity ...........................................................................90

AX48-120 Flange Facing Machine

5

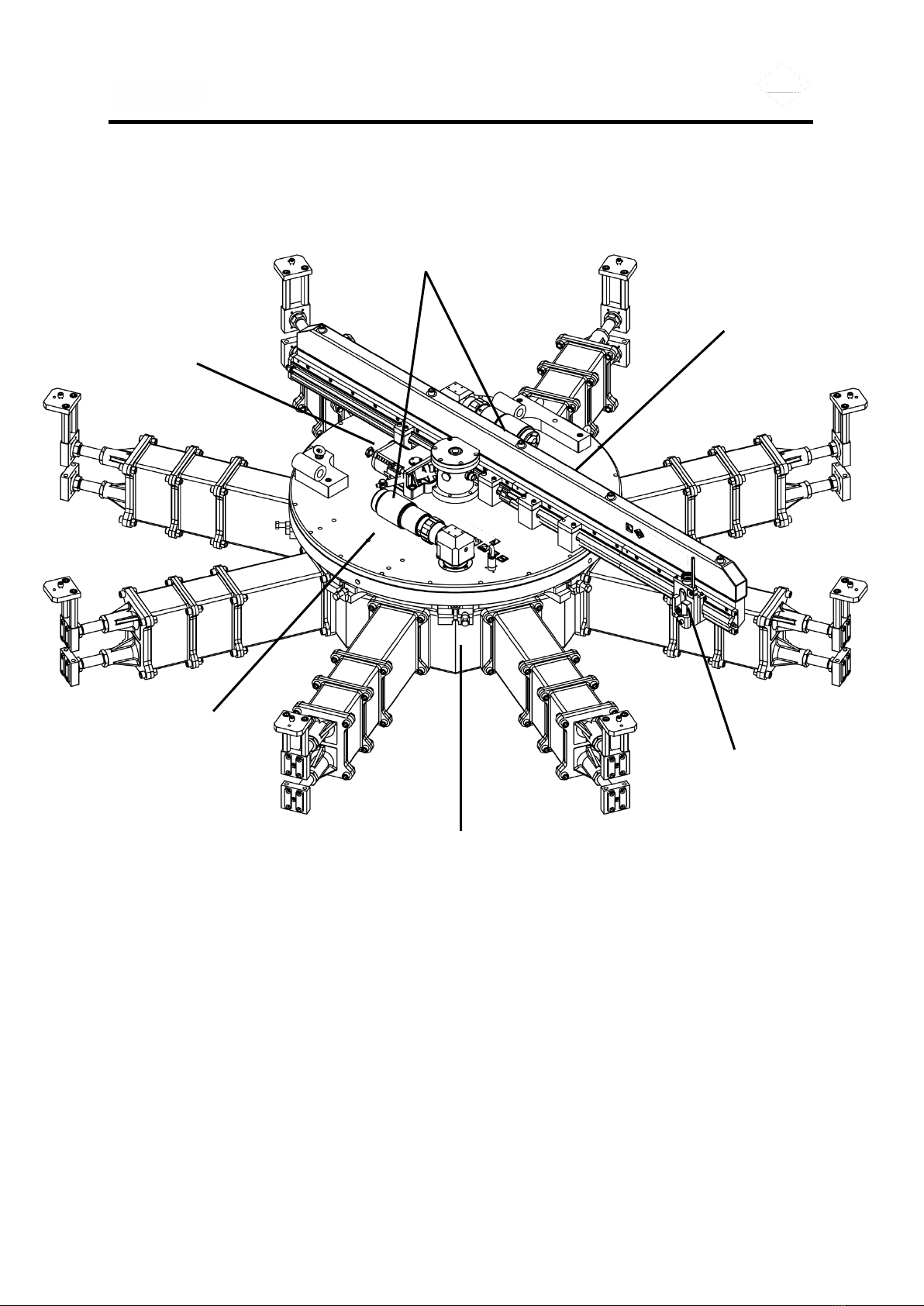

Fig. 1 AX48-120 Flange Facing Machine – full assembly

Drive motors

Surfacing arm

assembly

Mounting base

assembly

Feed

Gearbox

Toolpost

Turntable

Assembly

AX48-120 Flange Facing Machine

6

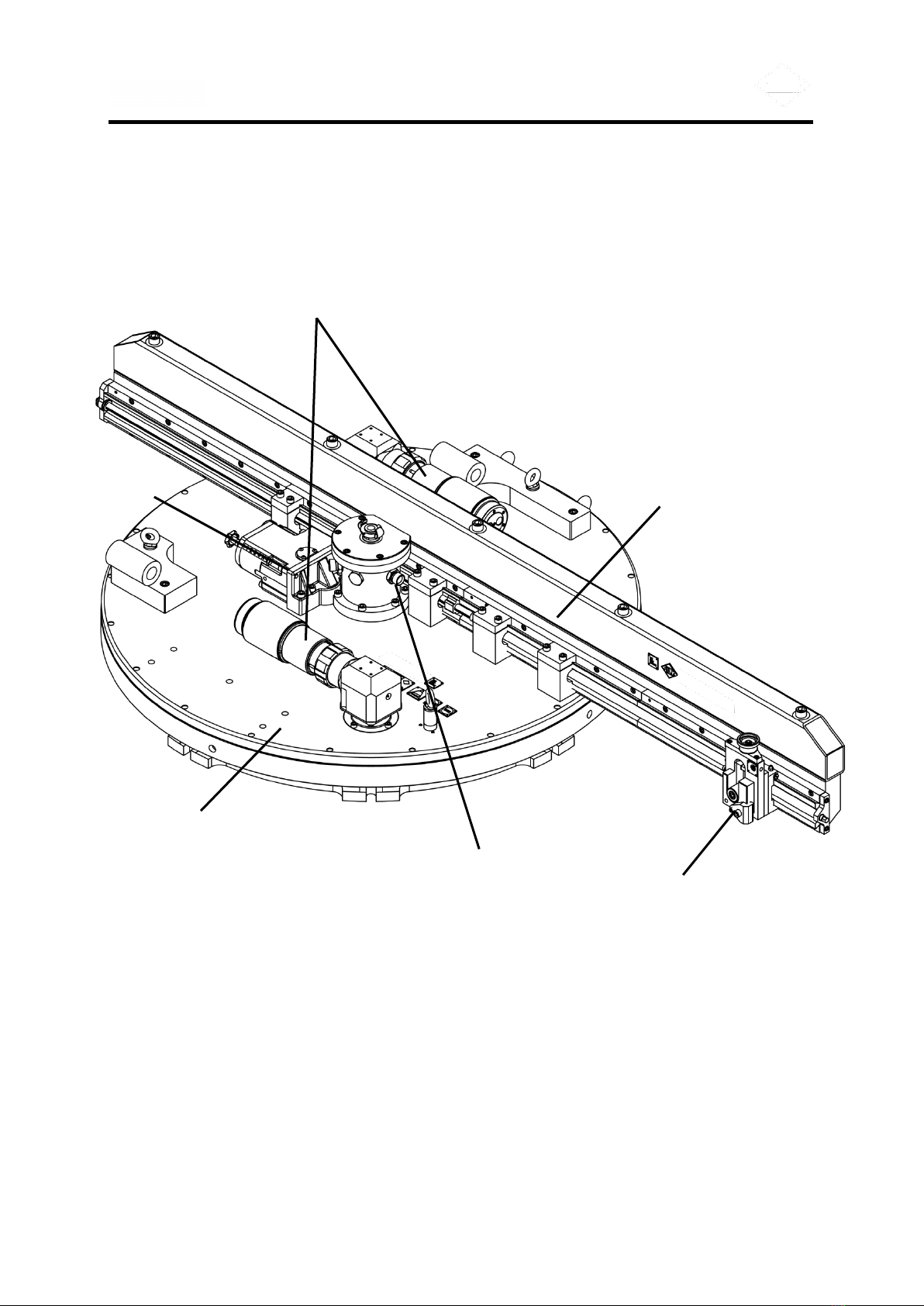

Fig. 2 AX48-120 Flange Facing Machine – turntable and machining arm assemblies

Drive motors

Surfacing arm

assembly

Mast

Toolpost

Turntable

Assembly

Feed

Gearbox

AX48-120 Flange Facing Machine

7

Fig. 3 AX48-120 Flange Facing Machine – exploded view

Drive motors

Surfacing arm

assembly

Mounting base

assembly

Feed

Gearbox

Toolpost

Turntable

Assembly

AX48-120 Flange Facing Machine

8

SECTION 1 TECHNICAL DESCRIPTION

1.1 INTRODUCTION

The TEAM® AX48-120 Flange Facing Machine is constructed from the highest quality

materials and great care has been taken in its design and manufacture. Its design will give

every satisfaction provided that it is properly installed, operated and maintained in

accordance with the information contained within this manual.

Take care of this manual; it is an essential source of information.

1.2 EQUIPMENT DESCRIPTION

The AX48-120 Flange Facing Machine is designed to machine full face, raised face and

grooved flanges from 1220mm to 3048mm (48" to 120") in diameter at any location having a

minimum pneumatic air supply of 5.8 m3/m at 6 bar (205 cfm, 90 psi).

The machine can achieve a variety of surface finishes from 6.3μm RA to 1.6μm RA when

turning and 1.6μm RA to 0.8μm RA when polishing. The machine can also produce a

'gramophone' finish, 'O' ring grooves, and 'V' grooves.

The machine consists of 4 main assemblies:

1. Turntable assembly

2. Feed gearbox

3. Surfacing arm assembly

4. Mounting base assembly

1.2.1 Turntable assembly

The turntable assembly consists of:

1. Turntable

2. Base plate sub assembly

AX48-120 Flange Facing Machine

9

Fig. 4 Turntable assembly

1. Turntable

The turntable is the rotating part of the machine providing a rigid support for the

surfacing arm assembly.

The drive for the turntable is supplied by two air motors through 90° bevel

gearboxes directly onto the turntable ring gear. Air for the motors is supplied via a

central connection on the mast through a rotary seal. The mast remains stationary

during operation.

2. Base plate sub assembly

The base plate sub assembly is the fixed part of the turntable assembly and

comprises of a base plate which is clamped to the mounting base assembly, a

mast gear used for the gearbox drive, and a central mast which supplies air to the

rotary air sealing cartridge. At the top of the central mast a quick release air

coupling is attached.

Drive motor

Feed gearbox

Turntable

Base plate

sub assembly

Mast

Drive motor

AX48-120 Flange Facing Machine

10

1.2.2 Feed gearbox

The feed gearbox is mounted on the turntable assembly and provides a variety of

cutting feeds for different machine applications. Drive from the feed gearbox to the

toolpost is via the surfacing arm leadscrew.

Drive input to the feed gearbox is derived from the mast transfer gear. The gearbox

provides four different feed rates, selected via the cutting feed rate push/pull

selector. Traverse direction is selected via the traverse direction push/pull selector,

which selects traverse IN, traverse OUT and neutral N position. The neutral (N)

position can be used for manually positioning of the toolpost and tool. An additional

neutral (N) position is also available by pushing the cutting feed rate selector fully

inwards past the No.4 feed position. This enables the operator to easily disengage

the feed gearbox from any feed.

Fig. 5 Feed gearbox

1.2.3 Surfacing arm assembly and toolpost

The surfacing arm assembly is mounted on the turntable assembly and provides a

rigid structure to which the tool post is secured. The arm can be positioned at any

diameter within the recommended facing range.

Toolpost feed in and out is provided by a leadscrew which is driven by the gearbox

pickup gear. The surfacing arm assembly can achieve cuts to a maximum depth of

1.0mm (0.040in) in flanges without bolt holes and 0.5mm (0.02in.) with bolt holes.

Alternative tools can be fitted to the tool post depending on the finish and cut

required.

Traverse

direction

selector

Cutting feed

rate selector

AX48-120 Flange Facing Machine

11

Fig. 6 Surfacing arm assembly and toolpost

1.2.4 Mounting base assembly

The mounting base assembly is provided to enable the machine to be installed in

the centre of a flange.

The mounting base assembly consists of a rigid central unit with eight radial

location bosses. The bosses allow extension legs and the clamping jaw assemblies

to be fitted to the base to suit the internal diameter of the flange to be machined.

The extension legs are precision manufactured to ensure perfect alignment when

fitted correctly.

The design and manufacture of the base and extension legs ensures a rigid

machine mounting structure. The rigid structure results in a precise distance from

each setting bracket mounting face to the corresponding machine support pad on

top of the mounting base. This allows any flange surface height deviation to be

averaged out over the eight legs thus reducing levelling adjustment to a minimum.

The mounting base is usually installed in the flange bore prior to the machine

installation.

Toolpost

Tool holder

Drive shaft

Pickup gear

(PTO)

Lead screw

AX48-120 Flange Facing Machine

12

–

Fig. 7 Mounting base assembly

1.2.5 Optional accessories

The following optional accessories are available upon request:

V-Groove machining kit

V-Groove measuring kit

Tube sheet machining kit

Tube sheet measuring kit

Lens ring machining kit

Fall stop kit

Setting strap

plate

Spigot

location hole

Threaded

collar

Short

extension leg

Long

extension leg

Clamping

jaws

Ram bolt

AX48-120 Flange Facing Machine

13

SECTION 2 SPECIFICATIONS

Fig. 8 Principal dimensions

PRINCIPAL DIMENSIONS:

Overall machine height

695 mm

27.4"

Mounting base thickness

290 mm

11.4”

Minimum mounting base diameter

1296 mm

51.0”

Minimum rotational diameter

2300 mm

90.6”

Flange depth required to set base using standard parts

Machine height above tube sheet on mounting plate

395 mm

432 mm

15.6”

17.0”

WEIGHTS:

Turntable and surfacing arm weight

Turntable and surfacing arm weight (With Fall Stop Kit)

681 kg

765 kg

1501 lbs

1686 lbs

Base weight (minimum diameter)

381 kg

840 lbs

Base weight (maximum diameter)

671 kg

1479 lbs

Counter balance total weight

67 kg

148 lbs

405 mm

(15.9”)

Mounting

base

thickness

290mm

(11.4”)

Overall

machine

height

695mm

(27.4”)

Minimum

depth of

flange

required

395mm

(15.6”)

AX48-120 Flange Facing Machine

14

TRANSPORTATION DIMENSIONS:

MACHINE

BASE

Net weight (without transport case)

681 kg

1501 lbs

671 kg

1479 lbs

Gross weight (including transport case)

935 kg

2061 lbs

835 kg

1840 lbs

Case dimensions

Length

2500mm

98”

1400mm

55”

Height

700mm

28”

900mm

35”

Width

1400mm

55”

1400mm

55”

OPERATIONAL DIMENSIONS:

Facing range:

Minimum diameter

1220 mm

48.0”

Recommended maximum diameter

3048 mm

120.0"

Gripping range:

Minimum recommended bore

1308 mm

51.5"

Maximum recommended bore

3052 mm

120.0"

Toolpost travel

40 mm

1.6"

Gearbox feed rate (per revolution):

Position 1

0.18 mm

0.007"

Position 2

0.25 mm

0.010"

Position 3

0.46 mm

0.018"

Position 4

0.84 mm

0.033"

Position ‘N’

neutral

Turntable free running speed

13 rpm ± 10%

NOISE EMISSION:

Emission sound pressure level

88 dB

Instantaneous sound pressure value. Indicate either

less than 63 Pa (130 dB) or actual value if above.

<130dB

Emission sound power level. Indicate either less than 80

dB (A) or actual value if above.

94dB(A)

AX48-120 Flange Facing Machine

15

MOTOR INFORMATION:

Type: MODEC

MR30LT0133ECL1F

Power output

3.0 kW

4.0 hp

Maximum speed free running

256 rpm

Speed at maximum output

129 rpm ± 10%

Recommended air supply

5.8 m3/min

205 cfm

6.0 bar

90 psi

Air inlet thread

3/4" BSP

AX48-120 Flange Facing Machine

16

SECTION 3 SAFETY INFORMATION

3.1 WARNINGS AND CAUTIONS

GENERAL:

ALL SAFETY PROCEDURES MUST BE OBSERVED AND STRICTLY

ADHERED TO WHEN INSTALLING, USING, MAINTAINING AND

SERVICING THIS EQUIPMENT.

ONLY TRAINED AND COMPETENT PERSONNEL SHOULD INSTALL,

USE, MAINTAIN AND SERVICE THIS EQUIPMENT.

ENSURE AN EMERGENCY STOP IS ALWAYS WITHIN REACH OF THE

OPERATOR.

INTENDED USE OF THIS EQUIPMENT:

THIS EQUIPMENT IS FOR USE BY PROFESSIONAL, TRAINED

PERSONNEL WORKING IN AN INDUSTRIAL ENVIRONMENT.

THIS EQUIPMENT IS INTENDED FOR USE ON METALS AND

ANALOGOUS SUBSTANCES.

THIS EQUIPMENT IS NOT INTENDED FOR USE ON WOOD, PLASTIC OR

SIMILAR ANALOGOUS SUBSTANCES.

USE OUTDOORS:

THIS EQUIPMENT SHOULD NOT BE USED DURING SEVERE WEATHER

CONDITIONS.

PERSONNEL SHOULD NOT OPERATE THIS EQUIPMENT IN WEATHER

CONDITIONS WHICH MAY GIVE RISE TO THE FOLLOWING:

- INADEQUATE VISIBILITY

- THE BUILD-UP OF ICE, SNOW, WATER, SAND OR DUST ON

PLATFORMS, LADDERS, CONTROLS, VISUAL INDICATORS,

MOVING PARTS, ETC.

- RISK OF INJURY DUE TO STRONG OR GUSTING WINDS

THIS EQUIPMENT SHOULD BE SUITABLY PROTECTED FROM ALL

SEVERE WEATHER CONDITIONS.

AX48-120 Flange Facing Machine

17

PERSONAL PROTECTIVE EQUIPMENT:

THE USE OF PERSONAL PROTECTIVE EQUIPMENT IS

RECOMMENDED WHEN WORKING WITH THIS EQUIPMENT.

SUGGESTIONS INCLUDE SAFETY HAT, GAUNTLET GLOVES, SAFETY

GOGGLES, SAFETY SHOES, AND FLAME RETARDANT COVERALLS.

BREATHING APPARATUS MAY BE NECESSARY WHEN A TOXIC

ATMOSPHERE EXISTS.

OTHER PROTECTIVE EQUIPMENT MAY BE REQUIRED AS PER THE

PLANT OPERATOR’S REQUIREMENTS.

PERSONNEL WORKING ABOVE GROUND LEVEL MUST ALSO WEAR A

SAFETY HARNESS CONNECTED TO A SUITABLE ANCHOR POINT OR

FALL ARRESTOR.

LIFTING:

ENSURE LIFTING IS CARRIED OUT IN A SAFE AND PROPER MANNER,

IN ACCORDANCE WITH APPLICABLE HEALTH AND SAFETY

REGULATIONS.

ALWAYS KNOW THE WEIGHT OF THE EQUIPMENT AND THE

COMPONENT PARTS. REFER TO THE SPECIFICATION PAGE IN THIS

MANUAL OR THE MARKING PLATE ON THE EQUIPMENT.

THE USE OF MECHANICAL LIFTING DEVICES MAY BE A MANDATORY

REQUIREMENT FOR LIFTING THIS EQUIPMENT.

INSTALLATION AND REMOVAL:

THIS EQUIPMENT IS INTENDED TO BE PORTABLE AND MAY BE USED

IN A VARIETY OF LOCATIONS AND ORIENTATIONS. ALWAYS ENSURE

THAT THIS EQUIPMENT IS PROPERLY SUPPORTED AND RESTRAINED

DURING THE INSTALLATION AND REMOVAL PROCESS.

IF THE INSTALLATION, REMOVAL OR MACHING ACTIVITY IS TAKING

PLACE OVER AN OPEN HOLE, A FLANGE BORE FOR EXAMPLE, AND

THERE IS A RISK OF THE EQUIPMENT FALLING INTO THE OPENING.

THE MACHINE MUST BE FITTED WITH THE FALL-STOP ACCESSORY

KIT SUPPLIED TO PREVENT INJURY OR DAMAGE - SEE APPENDIX ‘E’

FOR DETAILS.

AX48-120 Flange Facing Machine

18

PNEUMATICS:

ENSURE THE CORRECT HOSES, VALVES AND FITTINGS ARE USED.

DO NOT PRESSURISE THIS EQUIPMENT IF ANY OF THE HOSES,

VALVES OR FITTINGS ARE LEAKING OR DAMAGED.

DO NOT PRESSURISE THIS EQUIPMENT UNTIL YOU ARE SURE THE

EQUIPMENT HAS BEEN CORRECTLY INSTALLED AND THE CONTROL

VALVES ARE CLOSED.

DO NOT USE AIR MOTORS WITH DEFECTIVE SILENCERS. THIS MAY

CAUSE UNNECESSARY NOISE AND IMPAIR THE PERFORMANCE OF

THE EQUIPMENT.

NEVER PLACE ANY BODY PARTS ADJACENT TO AN AIR EXHAUST.

COMPRESSED AIR FORCED INTO THE SKIN IS DANGEROUS AND MAY

RESULT IN A SERIOUS SKIN DISORDER.

ENSURE THE PNEUMATIC SYSTEM IS ISOLATED AND DE-

PRESSURISED BEFORE MAKING ANY ADJUSTMENTS TO THIS

EQUIPMENT.

ENSURE THE PNEUMATIC SYSTEM IS ISOLATED AND DE-

PRESSURISED BEFORE DISCONNECTING ANY HOSES.

DO NOT ALLOW THE LUBRICATOR TO SUPPLY EXCESSIVE AMOUNTS

OF OIL TO THE PNEUMATIC SYSTEM. 5 TO 6 DROPS PER MINUTE AT

FULL MOTOR SPEED IS RECOMMENDED.

NEVER LEAVE THE PNEUMATIC SYSTEM PRESSURISED WHILE

UNATTENDED.

AX48-120 Flange Facing Machine

19

SECTION 4 CONTROLS AND BASIC OPERATION

4.1 LOCATION AND FUNCTION OF THE CONTROLS

The following controls are incorporated into the machine:

4.1.1 Machine controls

Fig. 9 Machine controls

Traverse direction selector

Selects the direction of the toolpost as it traverses across the work piece. The fully

pulled out position ‘N’ disengages the traverse feed.

TRAVERSE DIRECTION

SELECTOR POSITION

TOOL DIRECTION

FEED IN

(selector fully pushed in)

Towards centre of work piece

FEED OUT

(selector in central position)

Away from centre of work piece

NEUTRAL (N)

(selector fully pulled out)

No movement

Traverse

direction

selector

Cutting feed

rate selector

FEED

OUT

FEED IN

NEUTRAL

N

1

2

3

4

NEUTRAL

N

Table of contents

Other Team Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Minebea Intec

Minebea Intec Inteco PR 6203 installation manual

Endress+Hauser

Endress+Hauser Soliwave FQR56 operating instructions

Virutex

Virutex PR25VJ operating instructions

Stahl

Stahl SolConeX 8573/14 Series operating instructions

CNC

CNC RAPTOR XPR user guide

SMC Networks

SMC Networks MHZ2-6C-M9PLS Operation manual