Team SILK AX08 User manual

INSTRUCTION MANUAL

AX08 FLANGE FACING

AND GROOVING MACHINE

Revision A

TEAM®

Shap Road

Kendal

Cumbria

LA9 6RU

United Kingdom

Tel: +44 (0) 1539 729009

Fax: +44 (0) 1539 729359

TEAM® is an ISO9001 registered company

© Copyright 2022 TEAM®

AX08 Flange Facing and Grooving Machine

1

THIS INSTRUCTION MANUAL

This Instruction Manual describes how to safely install, operate and maintain the AX08

Flange Facing and Grooving Machine. It is an essential part of the equipment and it is

important that you take the time to read it thoroughly.

Additional copies are available for purchase from TEAM® or from an authorised agent.

HEALTH AND SAFETY AT WORK

This document should be read carefully and fully understood before proceeding to install,

use, maintain or service the equipment.

DO NOT USE THE EQUIPMENT UNTIL YOU ARE SURE YOU KNOW HOW IT WORKS

AND WHAT ITS INTENDED FUNCTION IS.

The equipment described in this document is intended to be used by professional personnel

in an industrial environment.

Installation, operation, maintenance and servicing should only be carried out by suitably

qualified and experienced personnel.

The following symbols are used to highlight important areas of this document which relate to

potential hazards and residual risks:

Important statements regarding the use, handling or operation

of the equipment.

Warnings to prevent injury to operator and or local personnel.

Cautions to prevent misuse and damage to the equipment.

AX08 Flange Facing and Grooving Machine

2

IMPORTANT NOTICE

The contents of this manual, including the graphics contained herein, are solely intended for the use of

the original purchaser. Information and data contained in this manual is exclusively for the purpose of

assisting in the operation and maintenance of this equipment by the original purchaser of the

equipment. The equipment, its operation and use shall only be performed by experienced and trained

personnel. No express or implied warranty is created by this manual. Warranty obligations of the

equipment and associated items, including this manual are expressly limited to the warranty section of

the written contract(s) between the original purchaser and manufacturer.

The equipment provided and this manual is solely intended for the initial purchaser and shall not be

resold, conveyed or otherwise utilized used by any third parties.

Team Industrial Services, Inc. is in continuous product development and reserves the right to amend

this manual and specifications without notice. For the latest operation and manual please contact your

representative.

COPYRIGHT STATEMENT

Team Industrial Services, Inc. owns the copyright of this document, which is supplied in confidence.

This manual must not be used for any purpose other than that for which it is supplied and must not be

reproduced, in whole or in part stored in a retrieval system or transmitted in any form or by any means

without prior permission in writing from Team Industrial Services, Inc.

.

AX08 Flange Facing and Grooving Machine

3

CONTENTS

SECTION 1 TECHNICAL DESCRIPTION .......................................................................... 8

1.1 Introduction ...................................................................................................... 8

1.2 Equipment description ..................................................................................... 8

1.2.1 Drive ring and bearing assembly........................................................... 8

1.2.2 Saddle ................................................................................................... 9

1.2.3 Toolpost ...............................................................................................11

1.2.4 Mounting Plate ....................................................................................11

1.2.5 Motor unit ............................................................................................12

SECTION 2 SPECIFICATIONS ........................................................................................13

SECTION 3 SAFETY INFORMATION ..............................................................................15

3.1 Warnings and cautions ..................................................................................15

SECTION 4 CONTROLS AND BASIC OPERATION .......................................................18

4.1 Location and function of the controls.............................................................18

4.1.1 Machine controls .................................................................................18

4.1.2 Toolpost Adjustment ...........................................................................20

4.1.3 Filter/lubricator pack controls ..............................................................21

4.2 Basic operation of the equipment – inc. Mounting Plate Assembly ..............22

4.3 Basic operation of the equipment – exc. Mounting Plate Assembly .............22

4.4 Lifting and slinging arrangements .................................................................23

SECTION 5 SITE OPERATION ........................................................................................24

5.1 Warnings and cautions ..................................................................................24

5.2 Setting up the equipment ..............................................................................25

5.2.1 Unpacking the machine .......................................................................25

5.2.2 Drive Ring and Bearing Assembly Installation ....................................26

5.2.3 Setting up the tool - facing and grooving ............................................30

5.2.4 Selecting the traverse .........................................................................30

5.3 Using the equipment......................................................................................31

5.3.1 Connection to Air Supply .....................................................................31

5.3.2 Starting the machine - Facing and Grooving ......................................32

5.4 Removing the equipment ..............................................................................33

5.5 Storing the equipment ...................................................................................33

SECTION 6 FAULT DIAGNOSIS......................................................................................34

6.1Introduction ....................................................................................................34

6.2 Fault diagnosis chart .....................................................................................34

SECTION 7 MAINTENANCE INSTRUCTIONS ................................................................36

7.1 Introduction ....................................................................................................36

7.2 Periodic maintenance ....................................................................................36

7.3 Recommended lubricants ..............................................................................38

7.4 Removal and refit procedures .......................................................................39

7.4.1 Drive motor ..........................................................................................39

SECTION 8 PARTS LISTS ...............................................................................................40

8.1 AX08 Main Assembly ....................................................................................41

8.2 Saddle Assembly ...........................................................................................45

8.3 Base Clamping Assembly .............................................................................49

AX08 Flange Facing and Grooving Machine

4

8.4 Base Clamping Assembly .............................................................................50

8.5 Machine Tool Kit ............................................................................................51

8.6 Mounting Plate Assembly ..............................................................................52

8.7 Toolpost Assembly ........................................................................................54

APPENDIX A Cutting tools as applied to portable machines ........................................56

APPENDIX B Surface metrology .......................................................................................59

APPENDIX C V-Groove measurement ..............................................................................62

APPENDIX D Air motor manufacturers information .......................................................64

APPENDIX E DECLARATION OF CONFORMITY .............................................................65

Table of contents

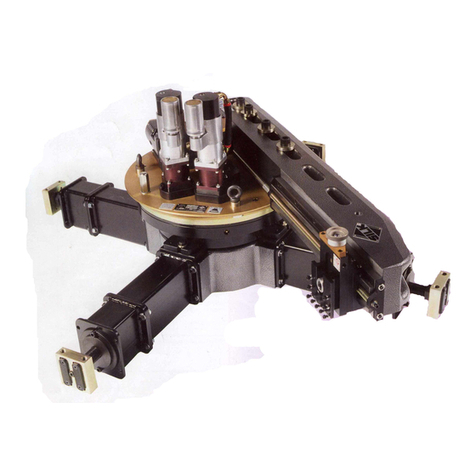

Other Team Industrial Equipment manuals