TECALEMIT DE 7288/2005 Owner's manual

HT1-Issue 1 (August 2009)

DE 7288/2005

HEADLIGHT

BEAM TESTER

Installation

Operation

Maintenance

Tecalemit Garage Equipment Co. Ltd. Eagle Road Langage Park Plymouth PL7 5JY UNITED

KINGDOM

Tel +44 (0) 1752 219100 Service Tel +44 (0) 1752 219111 Sales Fax +44 (0) 1752 219128 Sales and

Service

1

Changes to this manual are as shown below. Revised or additional issues of this manual are available from

Tecalemit Garage Equipment Co. Ltd. PLYMOUTH.

Minor changes are indicated by the use of a broad line adjacent to the affected text.

ISSUE STATUS DATE

Issue 1 18/08/2006

Copyright © Tecalemit Garage Equipment Co. Ltd. No part of this publication may be

reproduced, stored or introduced into a retrieval system, or transmitted in any form or by

any means (electronic, mechanical, photocopying, recording or otherwise) without the prior

written permission of Tecalemit Garage Equipment Co. Ltd.

Contents

HEALTHANDSAFETY 3

WARNINGS, CAUTIONS AND NOTES 3

DESCRIPTION 4

INSTALLATION 5

Site 5

Installing Rails 5

General Installation 7

AlignmentMirror 7

Column Locking Pedal 7

Column Guide Adjusters 8

CALIBRATION - SAFETY PRECAUTIONS See Separate manual

METHODOFINSPECTION 9

EUROPEAN TYPE HEADLAMP - CHARACTERISTICS 14

ReasonforRejection 14

BRITISH AMERICAN TYPE (CHECKED ON MAIN BEAM) – CHARACTERISTICS 22

Reason for Rejection 22

BRITISH AMERICAN TYPE (CHECKED ON DIPPED BEAM) – CHARACTERISTICS 24

Reason for Rejection 24

MAINTENANCE 26

Weekly 26

Six Monthly 26

MAINTENANCE - LUXMETER 26

DISPOSAL 26

SPECIFICATION 27

2

HEALTH AND SAFETY

In order to comply with your responsibilities under the Health and Safety at Work Act 1974, it is essential

that this vehicle headlamp tester and any optional accessories are sited, installed, operated, and maintained

by *competent persons in accordance with the instructions in this manual.

*A competent person should be a minimum of 18 years of age and have a minimum

qualification of NVQ 3 (or an equivalent qualification) and / or experience within their

own field of responsibility, e.g. Installation engineering, automobile engineering etc.

It is important that all persons installing, operating, maintaining or calibrating this headlamp

tester and optional accessories must be familiar with the layout of the equipment, safety

precautions, using appropriate training methods and supervision as may be required, prior to

installing, using, maintaining or calibrating this headlamp tester.

WARNINGS, CAUTIONS AND NOTES

‘WARNING’ is used in the text of this manual to identify specific hazards which can cause injury or death.

‘CAUTION’ is used in the text of this manual to identify incorrect procedures which can cause damage to

the lift.

‘NOTE’ is used in the text of this manual to draw attention to specific points of importance.

3

DESCRIPTION

The DE 7288/2005 HBT is designed to VOSA 2005 specification to facilitate the rapid accurate testing

and adjustment of car and commercial vehicle headlamps in accordance with VOSA MOT test

requirements.

The optical box is mounted on a single vertical column and it is easily adjusted for height and it will

remain in the position selected. The column is rigidly connected to a four wheeled trolley which moves on

two rails fastened to the floor. The wheels of the trolley are machined in a wide 'V' section, to run on a

similar section rail. The 'V' section reduces the likelihood of the trolley assembly rocking and therefore

increases the stability and the accuracy of measurement.

The optical box consists of a condensing lens and aiming screen which can be viewed through the

observation panel in the top of the unit. A light cell fitted to ensure that the 'hot spot' can be accurately

determined. Provision is made for the instrument to traverse each side of centre, to permit alignment with

the longitudinal axis of the vehicle.

To calibrate the DE7288/2005 in accordance with the requirements of VOSA requirements, it is necessary

to use Calibration kit OA50709. This consists of a Class 2 laser device mounted on a stand. The calibration

of the DE7288/2500 should only be completed by an authorised competent person.

Fig. 1

4

INSTALLATION

Site

The floor area designated for headlamp testing requires careful selection and preparation. For MOT requirements the

vehicle standing area and the equipment area where the rails are to be fitted must be level as follows:

Rails +/-2mm

Standing Area +/-6mm over 3 metres.

For non MOT requirements the vehicle standing area does not need to be precisely level as a slight continuous

gradient, maximum 0.4% will not affect accuracy.

NOTE: Preparation of the site to these standards is the customer's responsibility.

Installing Rails

Two sets of rails, each secured to the floor by screws and plastic rawlplugs. The rails are positioned at right angles

to the vehicle's longitudinal axis. The two rails must be levelled with each other, shimmed as necessary, and re-

checked after tightening down. In the final position the rails must be level within +/-2 mm.

Where the vehicle tested, or any other traffic, will pass over the rails, each rail must be recessed into the floor and

fully supported along its entire length by grouting as necessary, see Fig. 2. It is helpful if lines are painted on the

floor at 90 degrees to the Tester's rails to enable the accurate positioning of vehicles for testing.

Levelling the trolley

The two rear wheels are equipped with an integral cams which are factory set and normally do not require

adjustment. The level can be checked placing a spirit level on the trolley base together with the use of a plumb line

attached to the column. Should any adjustment be required the cams can be adjusted as follows (See Fig. 3):

Loosen screw 1 and just slacken screw 2.

Raise or lower the wheel as necessary.

• Fully tighten both screws.

Re-check level of trolley base using a spirit level.

Re-check that the column is vertical, using a plumb line.

5

6

GENERAL INSTALLATION

The DE7288/2005 comes ready assembled, with exception of the alignment mirror and column locking

pedal, which are fitted as follows:

Column Locking Pedal

• Insert brass locking pin through the threaded boss into the column support bearing.

• Fit the pedal assembly in the trolley base as shown in Fig. 5.

• Ensure that the column assembly locks correctly when the pedal is operated. Re-position the pedal if

necessary.

Column

• Holding the column vertically, locate spigot at the base into the column support bearing.

• Check column locks correctly when the pedal is operated.

• Retain column in position with the circular retaining plate and two cap head screws.

Alignment Mirror

• Fit the mirror assembly in position and tighten the two M4 x 20 screws (1) as shown in Fig. 4.

• Ensure that it rotates smoothly and that the leading edge of the optical box aligns correctly with the line

on the mirror.

Column Guide

• Tighten the four cap head screws and nuts just sufficiently to remove excessive play.

• Tighten the two column guide adjusters just sufficiently to remove side play. (See Fig. 1) Ensure that they

are not over-tightened, so restricting free vertical movement of the optical box.

7

8

METHOD OF INSPECTION

Positioning the vehicle (See Fig. 7)

To check headlamp aim:

1 Refer to the Tester's Manual for guidance on test procedures, types of headlights and

pass/fail criteria.

2 Position the vehicle as accurately as possible at 900 to the tester rails. The headlamp

lens should be positioned 350mm (+/- 150mm) from the lens of the beam tester. Ensure

that the headlight lens is clean.

3 Measure the height to the centre of the headlight lens from the floor and adjust the

height of the optical box to the same height. If the rails are recessed then this must be

added to ensure the optical box is at the correct height. There is a tolerance of +/- 10mm.

(NOTE 1) The above information is based on the criteria published in the MOT Inspection Manual which is an HMSO

publication and is available from most bookshops. Always refer to the current edition for any amendments or changes

to current legislation.

9

10

Checking the optical box alignment.

It is very important to align the optical box with the longitudinal axis of the vehicle. This

is to ensure that the aim of the headlight to the left or to the right is correct. To verify and

adjust the position of the optical box is as follows:

•Position the mirror so that it is facing downwards towards the optical box.

• Standing behind the tester, slowly rotate the mirror so that the reflection of the front of

the vehicle can be seen. See Fig. 9

• Identify two symmetrical points as close to the sides of the vehicle as possible. See

Fig.8

• Check that the line engraved on the mirror accurately bisects both points. See Fig. 9

Fig. 8

11

12

Adjusting the alignment of the optical box.

If the line on the mirror does not accurately bisect the two points, then the optical box has to be realigned.

To realign the optical box, release column by pressing the foot pedal and rotate the optical box and column

until the correct alignment is obtained. Lock column by pressing the foot pedal. Re-check that the

alignment is correct. See Fig. 11.

CHECKING THE HEADLIGHT AIM.

With an assistant sitting on the driving seat switch on the headlamps to the beam on which the headlamp is

to be checked. Note: When checking headlamp aim on vehicles with hydro-pneumatic suspension systems,

it may be necessary to have the engine idling. If this is required, ensure that the handbrake has been applied

and the transmission is in neutral or park before starting the engine. To check headlight aim, proceed as

follows:

• Determine the appropriate headlamp beam image and its aim (See Figs 12. 13 and 14).

NOTE: Pre C.1950 headlamp beam images may not conform to either diagrams 12, 13 or 14. In such cases

check that dip beam headlamps are aimed so they do not dazzle, i.e. the beam image brightest part is aimed

at least 0.5% below the horizontal or for headlamps which cannot be checked on dip beam, check that the

main beam headlights are aimed so that the beam image centre is on or slightly below the horizontal 0%

Line If the outline of the hot spot is difficult to determine then move the optical head and observe the

readings on the Luxmeter see Fig. 11, until the highest reading is obtained.

13

EUROPEAN TYPE HEADLAMP - CHARACTERISTICS (NOTE: 1 and 2)

1. An asymmetric dipped beam pattern with a distinctive horizontal cut-off on the right, and a 15 degree

wedge of light above the horizontal (the 'Kick up') towards the left

2 A lens with one or more asymmetric stepped patterns moulded in the glass

3 A lens may carry:

•European approval mark - a circle containing an 'E' and a number, or

• Rectangle containing an 'e', and a number

The European approval mark should incorporate a single or double-headed arrow.

The dipped beam is denoted by either:

• Capital letter 'C' above a capital 'E'

• Capital letter 'C' above an 'e'

NOTE: Setting 'E' Beam Headlamp Aim

These dip-beam headlamps should be set to aim downwards the amount shown on a marking which is

either close to the vehicle manufacturers’ plate or the headlamp.

For vehicles without a marking, the downward aim should be set as follows:

• 1.3%, if the headlamp centre is not more than 850 mm from the ground

• 2.0%, if the headlamp centre is more than 850 mm from the ground

Reason for Rejection

1. The beam image 'kick-up' is to the offside.

2. For headlamps with centres not more than 850 mm from the ground, the beam image horizontal cut-off is

not between the horizontal 0.5% and 2% lines, i.e. the red tolerance band.

3. For headlamps with centres more than 850 mm from the ground, the beam image horizontal cut-off is not

between the horizontal 1.25% and 2.75% lines, i.e. the blue tolerance band.

4. The beam image 'break point' is:

• To the right of the 0% vertical line, or

• To the left of the vertical 2% line

(NOTE 1) The above information is based on the criteria published in the MOT Inspection Manual which is

an HMSO publication and is available from most bookshops. Always refer to the current edition for any

amendments or changes to current legislation.

(NOTE 2) The specification of the aiming screen is being reised. The 3.25% and 4% will only be required

in designated HGV Test Stations

14

BRITISH AMERICAN TYPE (CHECKED ON MAIN BEAM) - CHARACTERISTICS: (NOTE: 1)

1. Headlamps tested on main beam have a symmetrical main beam pattern with a central area of maximum

intensity (hot spot)

2. This type of lamp generally has a circular lens which may be marked with a figure 1 followed by an

arrow indicating the direction of dip

Reason for Rejection

1. The 'hot spot' centre is above the horizontal 0% line.

2. The 'hot spot' centre is to the right of the vertical 0% line, or to the left of the vertical 2% line.

3. For headlamps whose centre is not more than 850 mm from the ground, the 'hot spot' centre is

below the horizontal 2% line.

4. For headlamps whose centre is more than 850 mm from the ground, the 'hot spot' centre is below

the horizontal 2.75% line.

(NOTE 1) The above information is based on the criteria published in the MOT Inspection Manual which is

an HMSO publication and is available from most bookshops. Always refer to the current edition for any

amendments or changes to current legislation.

(NOTE 2) The specification of the aiming screen is being reised. The 3.25% and 4% will only be required

in designated HGV Test Stations

15

BRITISH AMERICAN TYPE (CHECKED ON DIPPED BEAM) - CHARACTERISTICS: (NOTE: 1)

1. Asymmetric dipped beam pattern with an area of high intensity intended to be directed along the

nearside of the road

2. Circular lens marked with the figure 2 which may also have an arrow showing the direction of dip

Reason for Rejection

1. The upper edge of the 'hot spot' is above the horizontal 0% line.

2. The upper edge of the 'hot spot' is below the horizontal 2.75% line.

3. The right hand edge of the 'hot spot' is: to the right of the vertical 0% line or to the left of the vertical 2%

line.

(NOTE 1) The above information is based on the criteria published in the MOT Inspection Manual which is an HMSO

publication and is available from most bookshops. Always refer to the current edition for any amendments or changes

to current legislation.

(NOTE 2) The specification of the aiming screen is being reised. The 3.25% and 4% will only be required in designated

HGV Test Stations

16

17

MAINTENANCE

The DE7288/RS232 requires a minimal amount of maintenance.

Weekly

• Clean external paintwork and lens with a damp cloth.

• Check the operation of the Luxmeter.

• Check security of rails.

Six Monthly

• Check calibration.

MAINTENANCE - LUXMETER

If the Luxmeter is damaged or defective the Optical Box should be returned for a Service repair or

replacement.

DISPOSAL

The DE7288/RS232 must be disposed of in accordance with Local Authority regulations.

STEEL: Optical box, Column, trolley and rails.

LENS: Glass.

COPPER: Wiring and Luxmeter coils.

PLASTIC: Observation panel and miscellaneous small components.

PAPER: Packaging and instruction manual.

BATTERIES Not recyclable

18

SPECIFICATION

Lens to headlight lens focal length 350mm (+/-150mm)

Distance of lens in the front of the first rail 110mm

Maximum headlight height 1500mm

Tolerance on aiming height +/-10mm

Lens diameter 200mm

Focal length

Optical box size 250mm x 250mm x 610

Same or less than mW Accuracy Same or less than 1mm per metre

Distance between rails 395mm

Rail recess dimension 100mm x 27mm (min) / 29mm (max)

Min clearance behind optical box 500mm (VOSA Requirements)

19

Table of contents

Other TECALEMIT Test Equipment manuals

Popular Test Equipment manuals by other brands

IET Labs

IET Labs 1986 Omnical User and service manual

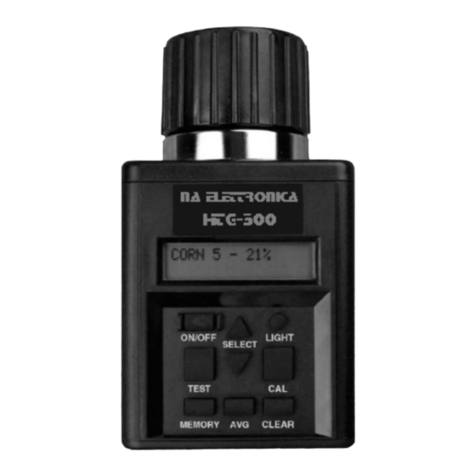

N.A. Elettronica

N.A. Elettronica HTG-300 Operator's manual

Powerfix Profi

Powerfix Profi 115001 Operation and safety notes

Keysight Technologies

Keysight Technologies N4917CPCA user guide

Baker

Baker D30R user manual

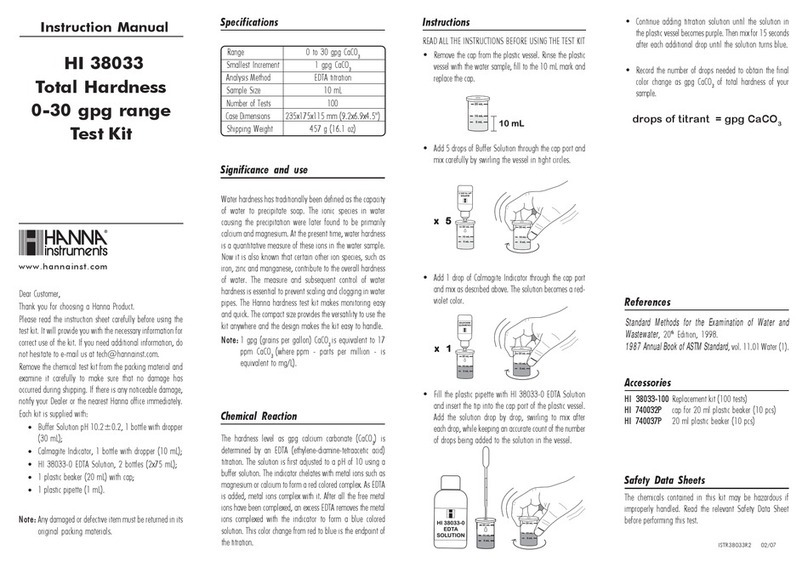

Hanna Instruments

Hanna Instruments HI 38033 instruction manual