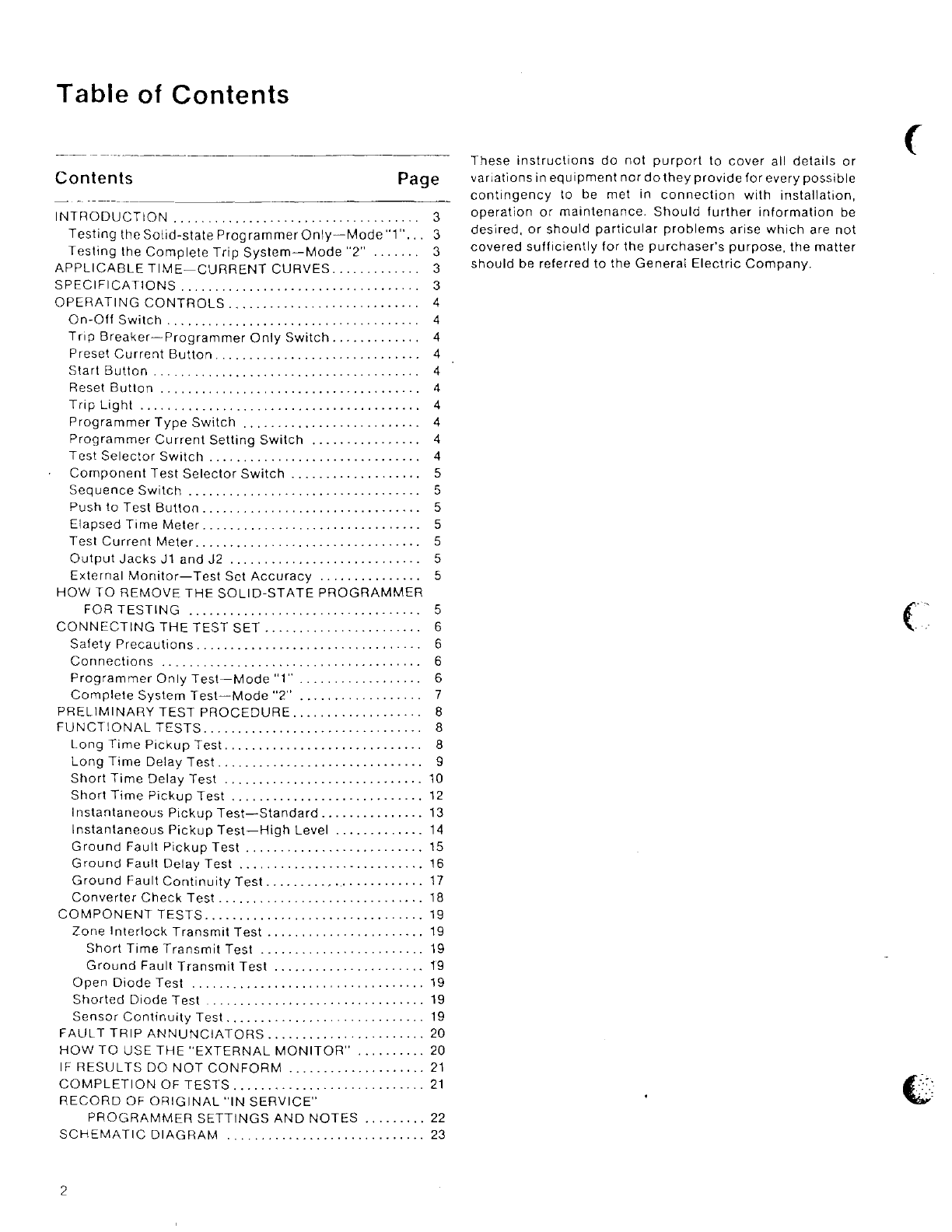

Table

of Contents

Contents

Page

INTRODUCTION.....

..

.............................

3

Testing

ttw

Solid-state

Prog

rammer

Only-Mode

"1"

..

. 3

Testing

the

Complete

Trip

System-Mode

"2"

.......

3

APPLICABLE

TIME-CURRENT

CURVES

.............

3

SPECiFiCATIONS

...................................

3

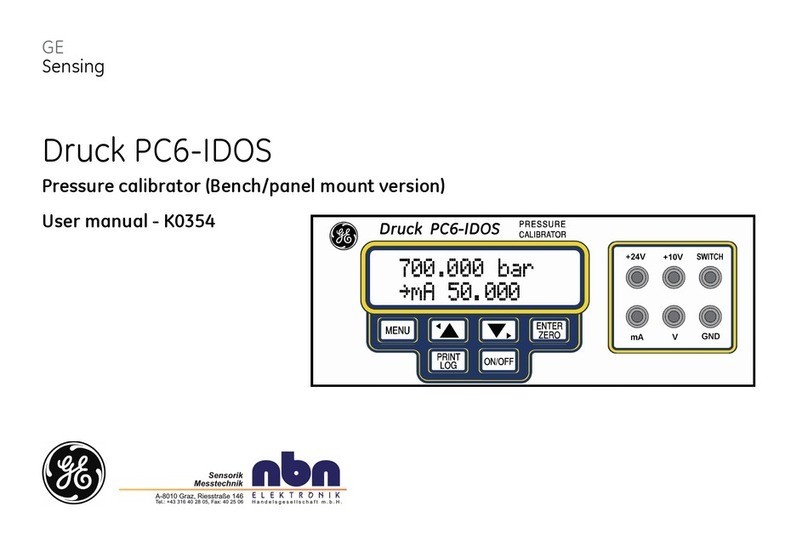

OPERATING

CONTROLS

............................

4

On-Off

Switch.

..

.

...

.

...

. .

...

...

. .

..

.

..

. .

..

..

.....

4

Trip

Breaker-Programmer

Only

Switch

..........

'"

4

Preset

Current

Button

...........................

'"

4

Start

Button

....................................

'"

4

Reset

Button

...................

'"

..............

" 4

Trip

Light.

...

. . .

....

.

..

........

.

...

. . .

....

........

4

Programmer

Type

Switch

..........

,

..

...

..

...

.....

4

Programmer

Current

Setting

Switch

................

4

Test

Selector

Switch

.............................

" 4

Component

Test

Selector

Switch

................

'"

5

Sequence

Switch

......

" .

...

.

........

......

.....

..

5

Push

to

Test

Button.....

. .

..

..

. . .

...

. . .

............

5

Elapsed

Time

Meter

.............

"

..

..

. . .

...

..

.....

5

Test

Current

Meter..

..

....

. . . .

....

......

.....

.

.....

5

Output

Jacks

J1

and

J2

............................

5

External

Monitor-Test

Set

Accuracy..

..

. .

..

.......

5

HOW

TO

REMOVE

THE

SOLID-STATE

PROGRAMMER

FOR

TESTING

..................................

5

CONNECTING

THE

TEST

SET.......................

6

Safety

Precautions

................................

. 6

Connections

......................................

6

Programmer

Only

Test-Mode

"1"

. .

..

.

...

.

.........

6

Complete

System

Test-Mode

"2"

..................

7

PRELIMINARY

TEST

PROCEDURE...................

8

FUNCTIONAL

TESTS

................................

8

Long

Time

Pickup

Test.............................

8

Long

Time

Delay

Test

...........................

'"

9

Short

Time

Delay

Test

.............................

10

Short

Time

Pickup

Test

............................

12

Instantaneous

Pickup

Test-Standard

...............

13

Instantaneous

Pickup

Test-High

Level

.............

14

Ground

Fault

Pickup

Test

..........................

15

Ground

Fault

Delay

Test

...........................

16

Ground

Fault

Continuity

Test

.....................

" 17

Converter

Check

Test

..............................

18

COMPONENT

TESTS

................................

19

Zone

Interlock

Transmit

Test.,

...

,

....

,

..

,

........

, 19

Short

Time

Transmit

Test

..

,.,

...

,',."

...

,

......

19

Ground

Fault

Transmit

Test

..............

,

.....

,.

19

Open

Diode

Test

.......

"

..

,

....

".,

..

,

..

"

..

,

...

, 19

Shorted

Diode

Test

...

,

....

"

..

,

..............

,

....

19

Sensor

Continuity

Test.,

....

,

..................

,

...

19

FAULT

TRIP

ANNUNCiATORS.,

....

,.,

............

,.

20

HOW

TO

USE

THE

"EXTERNAL

MONITOR"

..........

20

IF

RESULTS

DO

NOT

CONFORM

...........

,'

...

,'

,.21

COMPLETION

OF

TESTS

.................

,

...

"

.....

21

RECORD

OF

ORIGINAL

"IN

SERVICE"

PROGRAMMER

SETTINGS

AND

NOTES.,

....

,

,.

22

SCHEMATIC

DIAGRAM......

..

..................

23

2

These

instructions

do

not

purport

to

cover

all

details

or

variations

in equi

pment

nor

do

they

provide

for

every

possible

contingency

to be

met

in

connection

with

installation,

operation

or

maintenance.

Should

further

information

be

desired,

or

should

particular

problems

arise

which

are

not

covered

sufficiently

for

the

purchaser's

purpose,

the

matter

should

be

referred

to

the

General

Electric

Company.

(

("

..

4,::'··::",

~.