TECALEMIT DE9015/1 User manual

USER MANUAL

DE9015/1 Mk.2

TECALEMIT

MOTOR-CYCLE BRAKE TESTER

(2001/10/06)

Please read the user manual before starting the test procedure!

Document number: 303755

Date: 2001/10/06

Number of pages: 15

Tecalemit Garage Equipment Co.Ltd.

Eagle Road, Langage Park,

Plymouth, PL7 5JY

United Kingdom

Tel.: +44(0) 1752 219 100 (Service)

Tel: +44(0) 1752 219 111 (Sales)

Fax: +44(0) 1752 219 128 (Sales & Service)

E-mail: sales@tecalemit.co.uk Web http://www.tecalemit.co.uk

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

2

TABLE OF CONTENTS

1 Introduction 3

2 General product description MCBT 3

2.1 The infra red remote control and digital display 4

2.1.1 Infra red remote control 4

2.1.2 Digital display 5

3Safety 6

3.1 Introduction 6

3.2 Safety- and health risks 6

3.3 Safety devices 7

3.4 Misuse 7

4MOT regulations 8

5User instructions MOT testing procedure 9

5.1 Preparations before starting a brake test 9

5.2 Testing motor-cycles with single brake control systems 9

Testing the front wheel 9

Testing the rear wheel 10

5.3 Test results 11

5.4 Testing procedure without remote control 11

5.5 Printing test results (optional) 12

5.6 Testing motor-cycles with linked (dual) brake systems and/or sidecar 12

5.6.1 Testing linked (dual) brake systems 12

5.6.2 Testing sidecars 12

5.6.3 Test results 13

6 Trouble shooting & maintenance 14

7 Warranty 14

Appendix A: Product specifications 15

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

3

1 Introduction

This manual describes how to safely use the Tecalemit DE9015/1 Mk.2 motor-cycle brake tester (herein

refer to as MCBT) for statutory Vehicle Inspection test class I and II motor-cycles (herein refer to as MOT

class I&II). The manual is intended for users of this equipment. Another manual for installation, service and

calibration is available. The MCBT is designed for testing commercially available motor-cycles for road use.

The maximum wheel load during the test is 750 kg. The test speed is 2.9 km/h.

See Appendix A. for detailed product specifications.

This manual gives the instructions in carrying out a brake test according to the GB Department of Transport

compulsory schemes. The manual provides the MOT braking measurement requirements and describes a

complete test procedure as set out in the MOT inspection manual current at the time this user manual was

written. Please refer to the latest MOT inspection manual to check for any changes.

The motor and control gear of the MCBT are not flameproof and it is the responsibility of the operator to

make sure that the proposed site and the aspects of the installation comply with the Petroleum Regulations

and that they satisfy the local Petroleum Officer’s requirements.

2 General product description MCBT

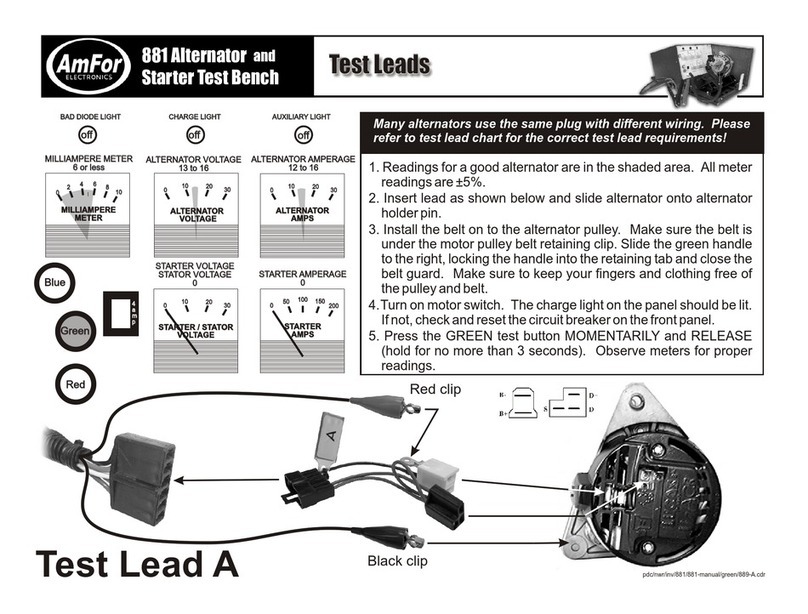

The roller brake tester consists of a digital display and a mechanical unit. The mechanical unit contains an

electrical motor, three measuring rollers, one brake force transducer, four weighing transducers and

additional safety sensors. The digital display contains a computerised processing system, a manual start button,

an emergency stop button, a main switch and an infra red remote control handset.

The motor-cycle wheel is driven by the rollers. Applying the motor-cycle brake exerts a reaction force on the

electric motor. An electronic transducer with strain gauges measures these reaction forces. The roller

diameter is sufficiently large to keep the tyre flexing to a minimum. The special coating of the rollers is very

wear resistant and also provides good friction values, both wet and dry. The third smaller roller, between the

wheel supporting rollers, has two safety functions: The first is to detect if a wheel is present in the roller bed

(a built in safety device prevents the motor to start without a wheel in place). The second function is to detect

if the tyre slippage on the roller does not exceed the maximum value.

If the tester is not being used, it must be closed with the roller bed cover plate.

The roller brake tester is equipped with an integrated weighing system.

During the test, the computer measures the weight and brake force values. When the motor-cycle has been

tested, the brake efficiency of the brake systems will be calculated by the computer if desired (the efficiency

can also be calculated manually).

Main switch

Emergency switch

Manual start/stop button

Read out unit

Infra red

remote control

V

S

P

S

Measuring roller

Measuring roller

Slip detection roller

Chassis c/w

-cover plates

-electric motor

-transducers

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

4

2.1 The infra red remote control and digital display

The equipment can be switched on by means of the main switch on the side of the display cabinet. Usually

the unit is operated through the infra red remote control. The system however can also be operated manually

(see chapter 5.4). The system can be switched off at any time by pressing the emergency stop button, located

on the side of display cabinet. The functions of the remote control and the display cabinet are explained in

the two following paragraphs 2.1.1 and 2.1.2. There is a separate user manual for an optional printer.

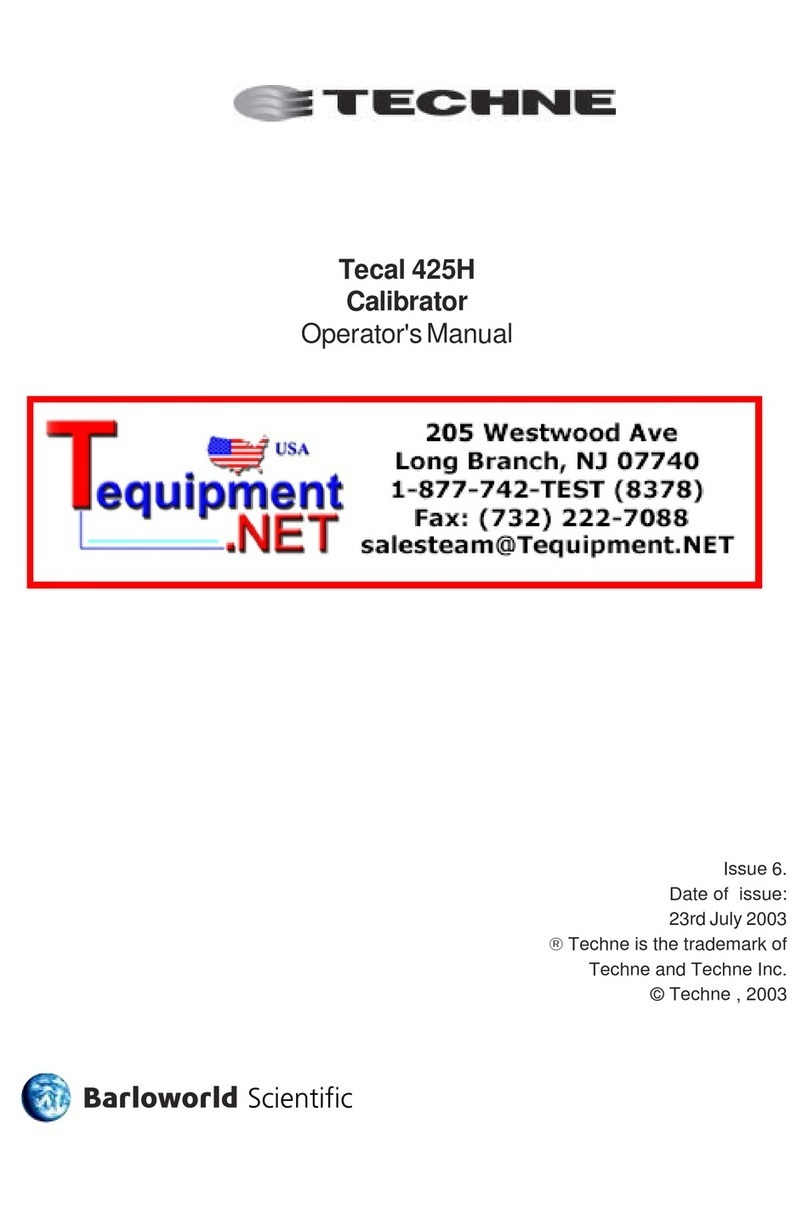

2.1.1 Infra red remote control

The system is controlled by means of an infra red remote control with the following functions.

Front

Rear

Sidecar

Reset

%

Front

Rear

Sidecar

Sidecar

Normal

Reverse

PRINT

Motor-cycle Brake Tester

RESET

1

2

3

4

5

6

7

8

9

0

BRAKE CONTROL 2(kgf/kg)

BRAKE CONTROL 1(kgf/kg)

START / STOP (kg)

RESULTS

Assign Brake Control 1 for:

Brake test Front wheel

Brake test Rear wheel

Brake test Sidecar

Assign Brake Control 2 for:

Brake test Front wheel

Brake test Rear wheel

Brake test Sidecar

Start /Stop normal direction

Start /Stop reverse direction

Assign weight independent

sidecar / sidecar w/o brakes

Show efficiency results

Brake Control system 1

Show efficiency results

Brake Control system 2

Print test results

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

5

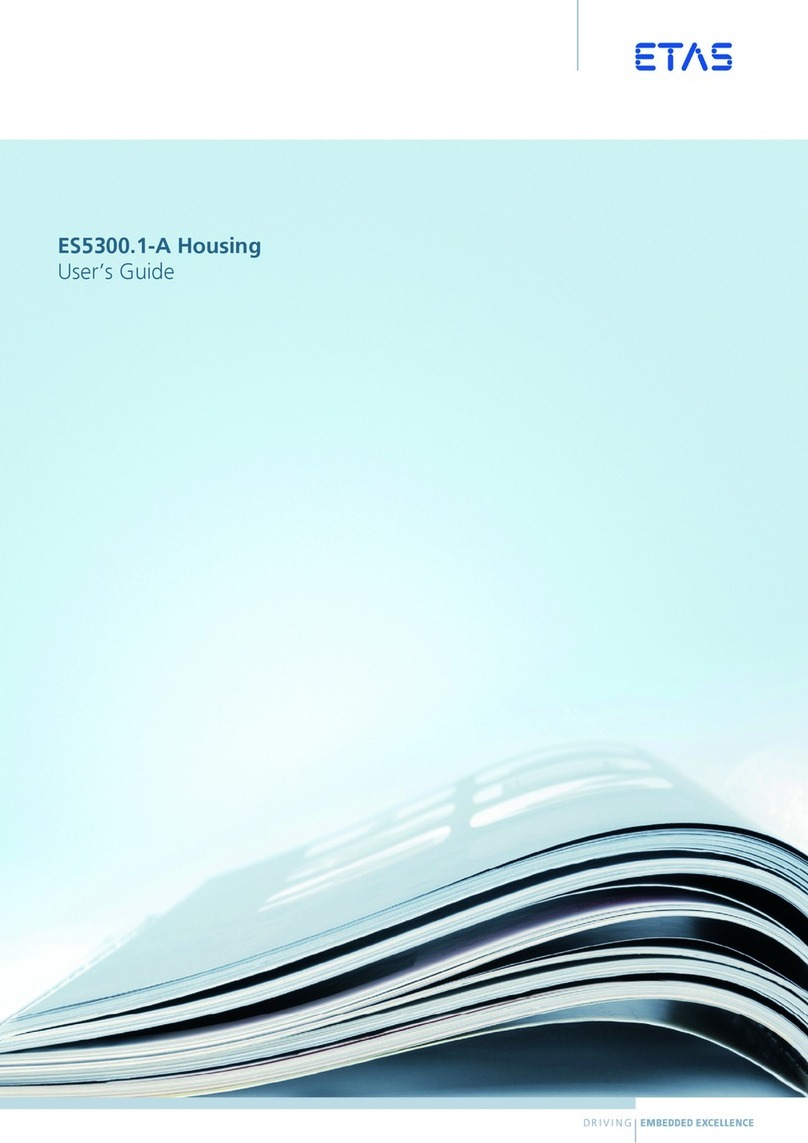

2.1.2 Digital display

The display cabinet contains an analogue display, a digital display for numerical values, eight indication

lamps, a main switch, a manual start/stop button and an emergency stop switch.

Analogue display Displays real time brake force in kgf for:

-The front wheel, the rear wheel and the sidecar.

Digital LED display Right Displays the weight in numerical values in kg for:

-The front wheel, the rear wheel, the sidecar and the total motor-cycle.

Digital LED display Left Displays the brake force in numerical values in kgf for:

-The front wheel, the rear wheel, the sidecar, total per brake control system.

Digital LED display Centre Displays in numerical values:

-The brake efficiency in %for brake control systems 1 (BC1) & 2 (BC2)

Eight lamps -2 lamps to indicate the drive direction.

-2 lamps to indicate brake control system BC1 and BC2.

-3 lamps to indicate the assigned wheel: front, rear, sidecar.

-1 lamp to indicate wheel lock (slip).

Emergency switch -To be used to stop the rollers in case of an emergency.

Manual start button -For testing without the infra red remote control.

Functions as: (start/stop normal direction).

Analogue display

•

•

•

•

•

kgf

%

kg

118 30 35

50

150

100

200

250

300

0

kgf

•

lock

•

•

Digital LED display

Lamps:

Sidecar brake

Rear brake

BC2

Front brake

BC1

Wheel lock lamp

Normal drive

direction lamp

Reverse drive

direction lamp

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

6

3 Safety

3.1 Introduction

In this chapter all safety aspects for the MCBT are described.

In order to comply with your responsibilities under the Health and Safety at Work Act 1974, it is essential

that this brake tester and any optional accessories are sited, installed, operated, and maintained by:

•A competent person with a minimum of 18 years of age and have a minimum qualification of

NVQ 3 (or an equivalent qualification) and / or experience within their own field of responsibility,

E.g. installation engineering, automobile engineering etc.

3.2 Safety- and health risks

Please note the following safety and health risks.

•All persons installing, operating or maintaining this brake tester and any optional accessories must be

familiar with the layout of the equipment, the safety precautions, the emergency shutdown

procedures and motor-cycle braking systems.

•Appropriate training is required, prior to installing, using or maintaining this MCBT.

•In case of an emergency, all electric power can be disconnected by pushing the emergency button on

the side of the display, or turn the main power switch off.

•The instructions in this manual have to be strictly adhered to, to avoid injuries to personnel and

damage to machine and motor-cycle.

•The equipment may be operated only within its rated capacity. The equipment is designed for motor-

cycles and scooters stated as MOT class I and II.

•During the test nobody is to stand close to the mechanical units.

•The danger zone should be clear of personnel, tools and equipment before starting each stage of the

test.

•Do not stand on or walk over the rollers at any time.

•The unit should be placed inside a rigid, flat and clean surface, protected against water, humidity and

weather influences.

•Only a qualified technician should carry out any work on the electrical system, if necessary.

•He should follow procedures pre-described by national standards and the regulations of the local

power company.

•It is not allowed to make the safety features inoperative or to remove them.

•Do not park a vehicle on any part of the tester.

•It should only be used where the operator has a good view of the whole machine.

•Don’t leave the MCBT switched on and unattended.

•Keep the operating environment clean and free of oil; don’t leave loose objects around the MCBT.

•When the MCBT is not working correctly, switch off the MCBT immediately and refer to the user

manual or contact Tecalemit.

•Isolate the MCBT from the power supply before starting a reparation or maintenance, by switching

off the main power and to secure it with a lock.

•Make sure the remote control is stored safely, when not in use.

•Always use the original tools to adjust the MCBT.

•Follow the maintenance specifications accurately.

•Avoid the entangling from clothes (e.g. ties) and/or limbs between the rollers or chains.

•Avoid any direct- or indirect electrical contact.

•Avoid any electrostatic influences.

•Do not test a motor-cycle when there is insufficient light.

•Take precautions to extract exhaust in the workplace properly while testing.

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

7

3.3 Safety devices

With the design of the MCBT the following safety devices have been installed, to reduce risks as much as

possible.

•The MCBT is provided with an emergency stop button, by which the machine can be stopped

immediately in case of an emergency.

•The MCBT can only be switched on if the centre rotating measuring roller is pressed down, i.e.

when there is a motor-cycle wheel in the roller brake tester.

•By applying the brake force and locking the wheel under test, the rollers will stop immediately.

•Closed covers for the chain and electrical components.

•The electrical circuits are built in the display cabinet, to reduce any direct danger.

•The MCBT is ground wired to earth.

•A roller cover plate is provided to close the mechanical unit when the brake tester is not in use.

•The controlling software has been tested extensively.

•A list of safety rules is included in this user manual (see chapter 3.2).

3.4 Misuse

It must NOT be used for any other purpose e.g.

•‘Running in’ of brake linings.

•Brake adjustments.

•Diagnosis of motor-cycle faults e.g., tyre examination etc.

•Any purpose requiring the operator to be in the danger zone, other than to conduct a brake test

and/ or maintenance and calibration purposes (authorised personnel only).

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

8

4 MOT regulations

•The efficiency of each system operated by a single brake control is the ratio of the retarding force

generated by that system divided by the weight of the machine and the rider.

•Most machines have two controls, one operating the front wheel brake and the other operating the

rear wheel brake.

•Where a linked or dual system is operated by one control, the retarding force used in the efficiency

calculation is the total from both wheels when operated by that control only. In this case the other

control will probably operate on one wheel.

•Efficiency calculation:

Total retarding force for one system

Efficiency % =

x 100

Weight of machine plus rider

The MOT brake efficiency requirements are specified as:

•Minimum brake efficiency of not less than 30% when one of the brake controls is operated.

•Minimum brake efficiency of not less than 25% when the other brake control is operated.

•Minimum brake efficiency of not less than 30% when only one means of operating the brakes is

required for motor-cycles registered before 1 January 1927.

Source: The “MOT Inspection Manual Motor Cycle Testing, 1992 edition”

•The Department of Transport allows the use of an electronic calculator to perform the calculation of

brake efficiency.

•The brake force is indicated in kgf.

•The weight is indicated in kg.

•The brake efficiency is indicated in %.

•The first brake control system is called BC1 (usually the hand brake control system).

•The second brake control system is called BC2 (usually the foot brake control system).

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

9

5 User instructions MOT testing procedure

See latest MOT Inspection Manual to check for any recent changes.

5.1 Preparations before starting a brake test

A Check if the tyres are in good condition, correctly inflated and free from mud and stones.

B. Remove the roller cover and switch the power on.

C. Determine if the brake control system is single brake controlled or linked/dual brake controlled.

•The motor can always be stopped by pressing any KEY on the remote control and the test will

be aborted.

•In the event of an emergency, these procedures must be followed:

(1). Press any KEY on the remote control. This will stop the rollers or

(2). Press the manual start/stop button on the side of the cabinet or

(3). Push the red emergency stop switch, to isolate the electrical supply to the roller bed

•When using the roller brake tester the wheel not on the rollers must be braked and chocked against

the reaction force.

The described testing procedure assumes a normal (forward) driving direction.

The described KEYS correspond with the keys on the infra red remote control.

5.2 Testing motor-cycles with single brake control systems

TESTING THE FRONT WHEEL

Press RESET to clear the system’s memory from any previous results.

•Drive the front wheel in the rollers. Make sure that the motor-cycle is positioned on the rollers in a

straight line and that it is not in gear. The driver should sit on the motor-cycle as in a normal situation.

STEP 1: Measure brake force and weight front wheel

A. Press (start/stop normal direction)to start the measurement. The drive direction lamp lights.

This is also the indicator and warning that the rollers are running.

The weight of the front wheel is measured and displayed.

The weight value will remain displayed until the brake force measurement is finished.

A moment after the weight measurement is taken, the rollers of the MCBT will start.

B. Slowly increase the brake force on the first brake control system (BC1= hand brake) until maximum

effort is achieved, or until the wheel locks and slips on the rollers. The real time brake force is

displayed on the analogue LED dial.

At the slip limit the motor will be cut out immediately (to avoid unnecessary wear of the tyre) and

the lock lamp will light to indicate this wheel lock. If slip does not occur while the maximum brake

force is achieved, the rollers can be stopped by pressing (start/stop normal direction).

For an accurate measurement, the brake force has to be built up slowly over 10 seconds!

After the rollers have stopped, the maximum brake force, the weight and the efficiency (for that

particular measurement) will be displayed in numerical values. The values will remain displayed

until either the tester is manually reset or the rollers are re-started for the next measurement.

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

10

C. The operator has to observe and note the weight and brake force measurement for manual brake

efficiency calculation.

For automatic brake efficiency calculation press FRONT (Brake Control 1)to assign the front wheel

test results into the memory. Lamp “BC 1” and “FRONT” light to confirm this action.

The brake test can be repeated if necessary. By pressing FRONT (Brake Control 1)again, the result

is stored and overwrites the previous test result.

STEP 2: Observe brake force fluctuations front wheel

•After the brake force measurement, the front wheel is tested for brake force fluctuations.

D. Press (start/stop normal direction) to start the measurement.

A moment after the weight measurement is taken (irrelevant for measuring ovality), the rollers of the

MCBT will start.

Slowly increase the brake force and hold it steady at a constant value of approximately half the

maximum value measured in STEP 1. Visually check the brake force fluctuations on that wheel.

The operator should note and interpret the irregularities in the brake force behaviour.

Release the brake quickly and observe the way in which the braking effort reduces.

Press (start/stop normal direction) to stop the rollers.

Do not press any keys for assigning results, as this will erase previous brake tests.

TESTING THE REAR WHEEL

•Drive the rear wheel in the rollers. Make sure that the motor-cycle is positioned on the rollers in a

straight line and that it is not in gear. The driver should sit on the motor-cycle as in a normal situation.

STEP 3: Measure brake force and weight rear wheel

E. Press (start/stop normal direction)to start the measurement. The drive direction lamp lights.

The weight of the rear wheel is measured as described in STEP 1.

A moment after the weight measurement is taken, the rollers of the MCBT will start.

F. Slowly increase the brake force on the second brake control system (BC2= foot brake) until

maximum effort is achieved, or until the wheel locks and slips on the rollers. The real time brake

force is displayed on the analogue LED dial.

At the slip limit the motor will be cut out immediately (to avoid unnecessary wear of the tyre) and

the lock lamp will light to indicate this wheel lock. If slip does not occur while the maximum brake

force is achieved, the rollers can be stopped by pressing (start/stop normal direction).

After the rollers have stopped, the maximum brake force, the weight and the efficiency (for that

particular measurement) will be displayed in numerical values. The values will remain displayed

until either the tester is manually reset or the rollers are re-started for the next measurement.

G. The operator has to observe and note the weight and brake force measurement for manual brake

efficiency calculation.

For automatic brake efficiency calculation press REAR (Brake Control 2)to assign the front wheel

test results into the memory. Lamp “BC 2” and “REAR” light to confirm this action.

This brake test can also be repeated if necessary.

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

11

STEP 4: Observe brake force fluctuations rear wheel

H. After the brake force measurement, the rear wheel is tested for brake force fluctuations.

Follow the procedure as described in STEP 2.

Remember: Do not press any keys for assigning results, because this will erase previous brake tests.

5.3 Test results

After the complete test, or after testing one of the brake control systems, it is possible to display the calculated

brake efficiency by means of the infra red remote control.

For motor-cycles with two controls, one operating the front wheel brake and the other the rear wheel brake, the

calculation of the brake efficiency is as follows.

Test results first braking control system (BC1)

Kgf front

Efficiency % =

x 100

SUM kg front, rear, rider

Test results second braking control system (BC2)

Kgf rear

Efficiency % =

x 100

SUM kg front, rear, rider

When pressing key %on the remote control once, the efficiency result for BC1 is displayed.

When pressing key %on the remote control again, the efficiency result for BC2 is displayed.

When the efficiency for BC1 is displayed, the following appears:

•Numerical brake force value in the left part of the LED display.

•Numerical efficiency percentage for BC1 in the centre part of the LED display.

•Numerical total weight value of the motor-cycle in the right part of the LED display.

•BC1 lamp lights.

•Front lamp lights.

When the efficiency for BC2 is displayed, the following appears:

•Numerical brake force value in the left part of the LED display.

•Numerical efficiency percentage for BC2 in the centre part of the LED display.

•Numerical total weight value of the motor-cycle in the right part of the LED display.

•BC2 lamp lights.

•Rear lamp lights.

5.4 Testing procedure without remote control

It is possible to do a test without the remote control, however, you must consider that this test has its

limitations. This test procedure requires two persons to operate the MCBT. One person to do the test, while

the other person pushes the start/stop button on the display.

Weight and brake force will be displayed on the cabinet, however, these values can not be assigned and

stored into the computer memory and therefore automatic calculation of the brake efficiency is not possible.

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

12

A push button has been installed on the display cabinet. If you want to start the rollers, press the button for 1

second. The rollers will start in the normal (forward) direction. Press the button again to stop the rollers. The

test starts and the procedure is the same as described in paragraph 5.2. The manual button functions as key

on the remote control.

5.5 Printing test results (optional)

If a printer is connected, after a test, the operator can print a summary of the measurements by pressing

on the remote control.

5.6 Testing motor-cycles with linked (dual) brake systems and/or sidecars

5.6.1 Testing linked (dual) brake systems

If the first brake control system (BC1=hand brake) also operates the rear wheel, STEP 3 needs to be repeated

for BC1 when the rear wheel is still in the rollers.

•Press REAR (Brake Control 1)to assign and store the rear wheel test results for BC1.

Lamps “BC 1” and “REAR” light to confirm this action.

The brake test can be repeated if necessary.

By pressing REAR (Brake Control 1) again, the result is stored and overwrites the previous test.

If the second brake control system (BC2=foot brake) also operates the front wheel, STEP 1 needs to be

repeated for BC2 when the front wheel is still in the rollers.

•Press FRONT (Brake Control 2)to assign and store the front wheel test results for BC2.

Lamps “BC 2” and “FRONT” light to confirm this action.

•The brake test can be repeated if necessary.

By pressing FRONT (Brake Control 2)again, the result is stored and overwrites the previous test.

5.6.2 Testing sidecars

If the motor-cycle is equipped with a sidecar, both the weight, and any brake force produced by one of the

two brake control systems needs to be measured.

Drive the sidecar into the rollers. Make sure that the sidecar wheel is positioned on the rollers in a straight line

and that the motor-cycle it is not in gear.

Press (start/stop normal direction) to start the measurement.

The weight of the sidecar is measured as described in STEP 1 (chapter 5.2).

A moment after the weight measurement is taken, the rollers of the MCBT will start.

There are 4 possibilities to operate the brake of a sidecar.

A. It is controlled by BC1 (hand brake).

B. It is controlled by BC2 (foot brake).

C. It is controlled independently.

D. There is no brake control at all.

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

13

A. If the sidecar is controlled by BC1 (hand brake), slowly increase the brake force until maximum

effort is achieved, or until the wheel locks and slips on the rollers as described in STEP 1 (chapter 5.2).

•Press SIDECAR (Brake Control 1)to assign and store the sidecar test results into the memory.

Lamps “BC 1” and “SIDECAR” light to confirm this action.

B If the sidecar is controlled by BC2 (foot brake), slowly increase the brake force until maximum effort

is achieved, or until the wheel locks and slips on the rollers as described in STEP 1 (chapter 5.2).

•Press SIDECAR (Brake Control 2) to assign and store the sidecar test results in the memory.

Lamps “BC 2” and “SIDECAR” light to confirm this action.

C/D If the sidecar is not controlled by one of the two brake control systems or is operated with an

independent brake control system, only the weight of the sidecar is relevant. Its brake force is not relevant

for the brake efficiency calculation.

•Press SIDECAR (kg )to assign and store the sidecar weight into the memory.

The lamp “SIDECAR” lights to confirm this action.

After the brake force measurement, the sidecar wheel is tested for brake force fluctuations.

Follow the procedure as described in STEP 2 (chapter 5.2).

Remember: Do not press any keys for assigning results. This will overwrite previous brake tests.

5.6.3 Test results

The calculation of the test results of more complex motor-cycles is similar to the method described in

chapter 5.3:

Test results first braking control system (BC1)

SUM kgf front, rear, sidecar for BC 1

Efficiency % =

x 100

SUM kg front, rear, sidecar, rider

Test results second braking control system (BC2)

SUM kgf front, rear, sidecar for BC 2

Efficiency % =

x 100

SUM kg front, rear, sidecar, rider

When pressing key %on the remote control once, the efficiency result for BC1 is displayed.

When pressing key %on the remote control again, the efficiency result for BC2 is displayed.

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

14

6 Trouble shooting & maintenance

If the MCBT does not function, as it should, the operator should only take action when the failure appears to

be very simple to solve. For example changing the battery on the remote control or cleaning the front plate

for better signal receiving of the remote control.

If for example the motor is not starting when a motor-cycle is placed in the rollers or the MCBT makes

uncommon noises, please contact Tecalemit for service and do not open the MCBT for inspection yourself.

The MCBT is designed and constructed so maintenance can be reduced to a minimum.

Only the service technicians are allowed to perform adjustments. They are trained and have suitable

calibration instruments at their disposal.

Although the MCBT is designed with low maintenance involved, it is important that the following checks are

carried out properly:

•Check the roller coating twice a year (visually by the operator).

•Check the tension of the chains twice a year (recommended to be done by Tecalemit).

•Lubricate the chain every 3 months when used intensively (recommended to be done by Tecalemit).

For periodic maintenance, calibration and service contact Tecalemit.

Warning: Do not use high pressure or steam cleaners on the MCBT.

7 Warranty

Warranty conditions are available at request.

DE9015/1 Mk.2 MCBT

DE9015/1 Mk.2 Motor-cycle brake tester

TECALEMIT User manual

15

Appendix A: Product specifications MCBT

•Electrical connection (V/Hz/A) 1 phase 240 V / 50 Hz / 25 A

•Motor (kW) 2.2

•Test speed (km/h) 2.9

•Brake force range (kgf) 300

•Chassis dimensions (cm) 80 x 62 x 31

•Roller length (mm) 300

•Roller distance (mm) 400

•Roller diameter (mm) 206

•Slip roller diameter (mm) 80

•Max. wheel load (kg) 750

•Weight roller tester (kg) 80

•Friction roller surface (µ)0.9 dry, > 0.6 wet

•Dimensions display (cm) 68 x 68 x 12 cm (L x W x H)

•DMS electronic microprocessor controlled

•Epoxy roller surface

•Automatic slip stop

•Starting safety device

Tecalemit reserve the right to amend the specifications without notice.

Table of contents

Other TECALEMIT Test Equipment manuals