TECE Lux Mini Instruction Manual

FLUSH PLATES

Sanitary systems

TECHNICAL GUIDELINES

Overview -

Cleaning TECE flush plates -

TECEantibac -

Flush-mounted installation -

Dry-wall – toilet flush plate -

Installing the toilet flush plate in a dry-wall -

Brick-wall – toilet flush plate -

Installing the toilet flush plate in a brick-wall -

Dry-wall – urinal flush plate -

Installing the urinal flush plate in a dry-wall -

TECElux Mini -

Wall-mounted installation of the toilet flush plate -

Flush-mounted installation of the toilet flush plate -

Installing the transformer with connection cable -

Programming the electronics -

Installing the anti-theft device -

TECEsquare -

Installing the TECEsquare II metal toilet flush plate -

Wall-mounted installation of the glass toilet flush plate -

Flush-mounted installation of the glass toilet flush plate -

Wall-mounted installation of the glass urinal flush plate -

Flush-mounted installation of the glass urinal flush plate -

Installing the metal urinal flush plate -

TECEloop -

Wall-mounted installation of the plastic toilet flush plate -

TECEloop modular system -

Wall-mounted installation of the glass toilet flush plate -

Flush-mounted installation of the glass toilet flush plate -

Wall-mounted installation of the plastic urinal flush plate -

Wall-mounted installation of the glass urinal flush plate -

Flush-mounted installation of the glass urinal flush plate -

TECEplanus -

Installing the toilet flush plate -

Installing the urinal flush plate -

TECEplanus infrared electronics -

Toilet infrared electronics -

Programming the toilet infrared electronics -

Installing the toilet infrared electronics, V battery -

Installing the toilet infrared electronics, V mains -

Contents

-

Flush plates

TECEplanus urinal infrared electronics -

Programming the urinal infrared electronics -

Technical data -

Installing urinal infrared electronics for the U urinal flusher, V battery -

Installing the urinal infrared electronics, V mains -

TECEplanus electronics, remote release -

TECEplanus radio switch -

Toilet electronics, remote release, V battery -

Installing the toilet electronics, remote release, V battery -

Toilet electronics, remote release, V mains -

Installing the toilet electronics, remote release, V mains -

TECEplanus electronics, cable-connected remote release -

Toilet electronics, cable-connected remote release, V battery -

Installing the toilet electronics, cable-connected remote release, V battery -

Toilet electronics, cable-connected remote release, V mains -

Installing the toilet electronics, cable-connected remote release, V mains -

TECEnow -

Wall-mounted installation of the toilet flush plate -

Flush-mounted installation of the toilet flush plate -

Installing the urinal flush plate -

Flush-mounted installation of the urinal flush plate -

TECEambia -

Installing the toilet flush plate -

Installing the urinal flush plate -

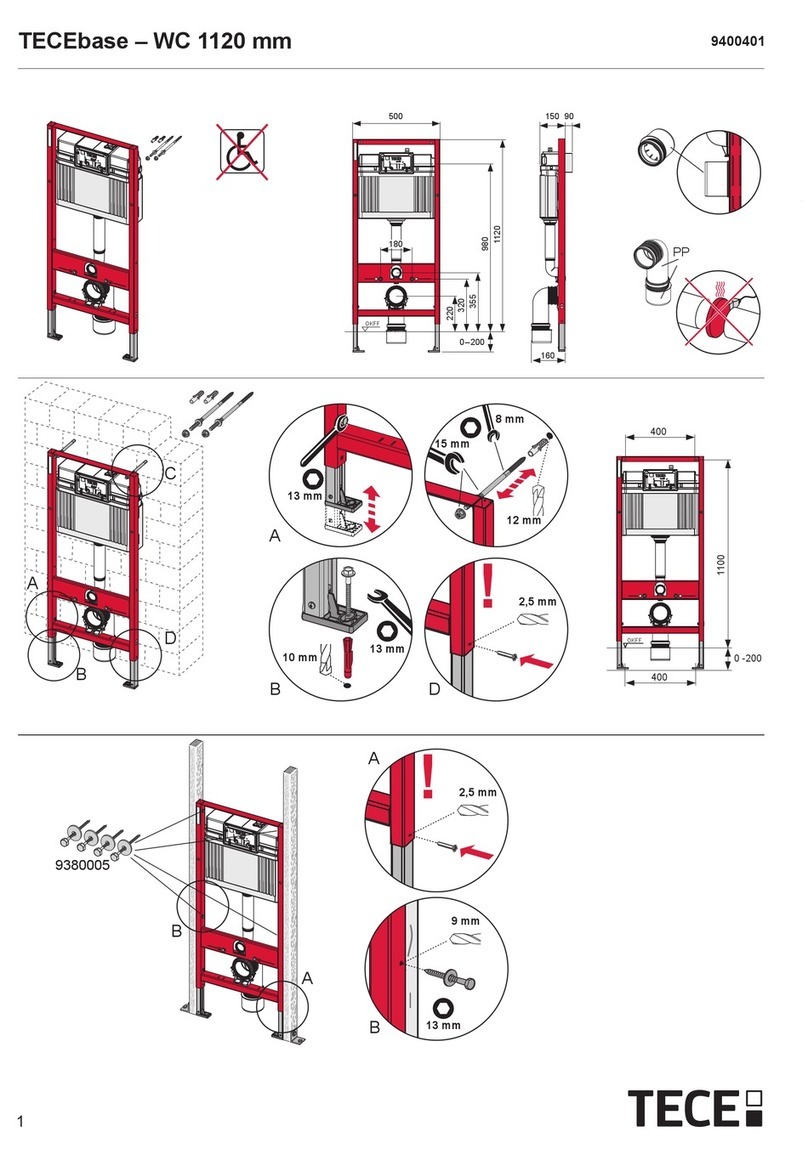

TECEbase -

Installing the toilet flush plate -

TECEfilo urinal -

Bare wall – mounting and installation -

Installing the wall-mounted TECEfilo urinal flush plate / V -

Installing the flush-mounted TECEfilo urinal flush plate / V -

Programming the urinal electronics -

Toilet flush handle -

Installing the rotary mechanism -

Insert chute -

Operating the insert chute -

Installation dimensions for TECE flush plates -

-

Flush plates

TECE flush plates – Overview

Overview

TECE flush plates come in a wide variety of shapes, mate-

rials and colours. The various materials meet the require-

ments of dierent application areas. These flush plates,

with their robust actuation mechanism, can be installed

from the front or from the top. TECE flush plates are some

of the most compact models available on the market.

Thanks to the cistern's special design, the mounting space

inside is easily accessible, despite the flush plate's small

size.

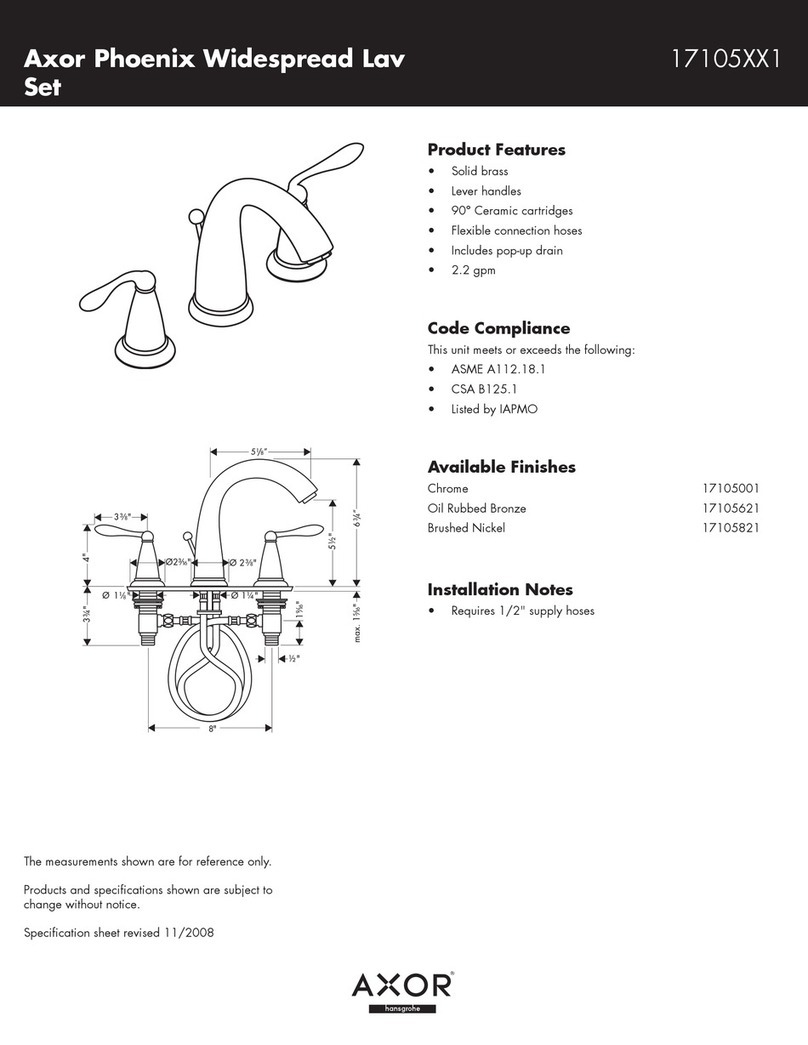

Overview of TECE flush plates

TECElux Mini

TECEsquare II metal

TECEsquare glass

TECEsquare metal

TECEloop plastic

TECEloop glass

TECEplanus

TECEnow

TECEambia

TECEbase

Toilet flush handle

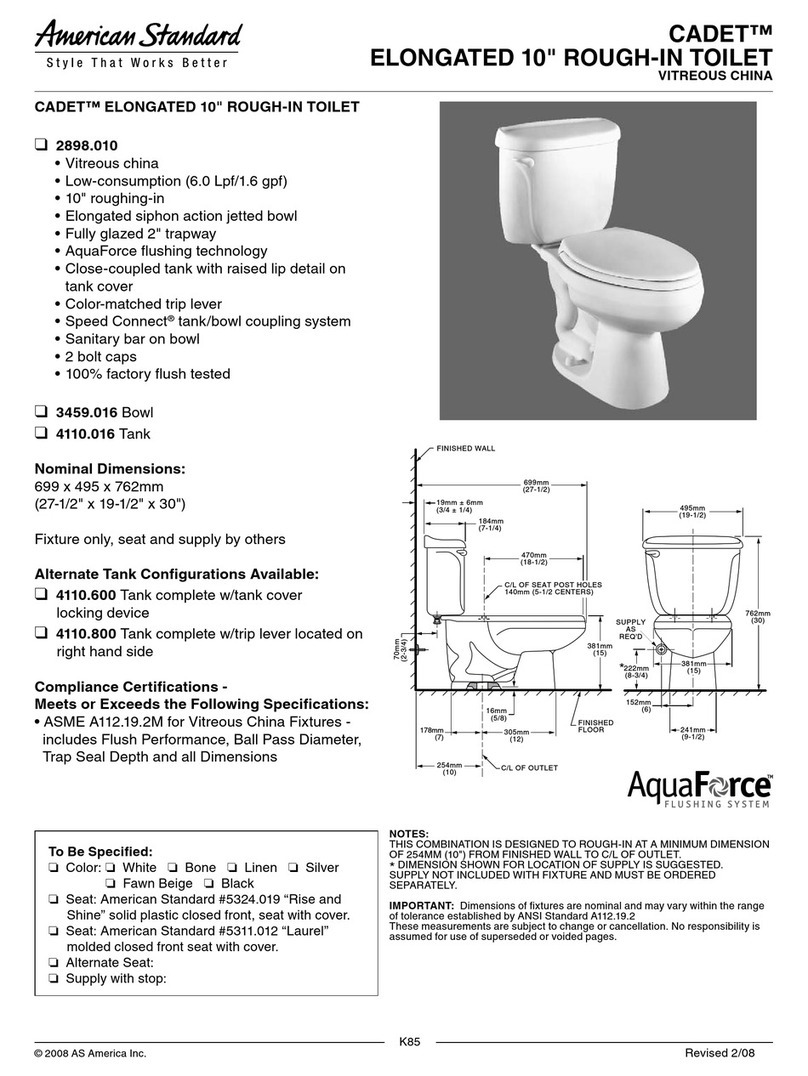

Single and dual-flush technology

Depending on the flush plate, the TECE flush-mounted

cistern oers the option of single or economic dual-flush

technology. When installing a single-flush system, just one

actuating rod is installed, whereas for a system with dual-

flush technology, two actuating rods are installed.

Single and dual-flush technology (here, the TECEplanus model)

-

Flush plates

Cleaning TECE flush plates

To ensure that the surface of the flush plate retains its orig-

inal appearance, we would ask you to pay attention to the

following information:

• Always clean the flush plate with a soft cloth.

• Use warm water to clean the visible surfaces.

• To clean glass surfaces, you can also use a mild, colour-

less glass cleaning product.

• Do not spray the cleaning product directly onto the

glass.

• Remove any dirt with a moist cloth, gently applying pres-

sure.

• Never use frothy, aggressive cleaning agents or cleaning

sponges.

TECEantibac

The “TECEantibac” versions of the TECEambia and TECE-

loop (toilet and urinal) flush plates have antibacterial

properties. They are only available in white. Both TECEan-

tibac flush plates are available with single and dual-flush

technology.

What is TECEantibac?

The TECEantibac flush plate is made of a new, high-tech

plastic containing microscopically small silver ions. The

silver ions eectively prevent the spread of bacteria on the

flush plate surface.

As the silver particles are distributed within the material,

the eect continues throughout the plate's entire useful

life. So it is more than just a coating. Therefore surface

wear through use or cleaning does not impair the long-

term eect.

The antibacterial eect of the TECEantibac flush plates

has been demonstrated in an expert report written by the

Hohenstein Research Institute: “Under practical conditions,

this test demonstrated that the TECEantibac product exhib-

its significant or strong antimicrobial activity”.

The measured reduction in germs achieved by TECEan-

tibac was, on average, .%. The test method used

was the only standardised method that currently exists

in accordance with the Japanese Industrial Standard JIS

:. This method is internationally acknowledged

and used in Japan, the USA and Europe. The expert report

can be requested from TECE.

-

Flush plates

Flush-mounted installation

Flush-mounted installation is a distinctive characteristic

of the TECElux Mini, TECEloop glass (toilet and urinal),

TECEsquare glass (toilet). and TECEnow flush plates (instal-

lation including spacing frame). When using the installation

frame, these flush plates can be flush-mounted as required

both in dry-walls (toilet and urinal) and in brick-wall struc-

tures (toilet).

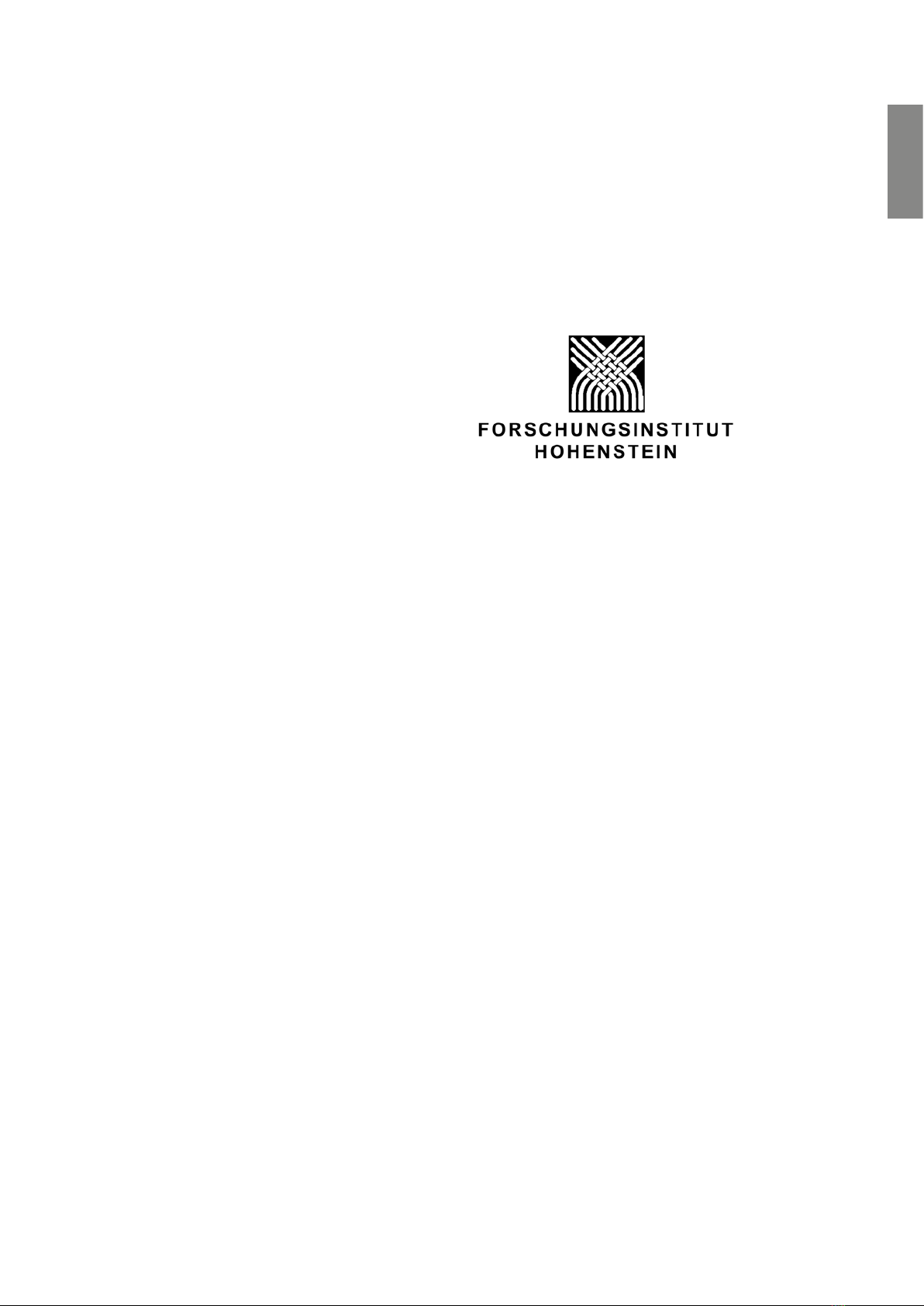

Flush-mounted installation frame for toilet flush plate

Flush-mounted installation frame for urinal flush plate

Dry-wall – toilet flush plate

The TECEprofil dry-wall module and the toilet installation

frame are required for installation in dry-wall structures.

Dry-wall modules of all installation heights can be com-

bined with the flush-mounted installation frame.

Components required:

TECEprofil module Installation frame for

toilet

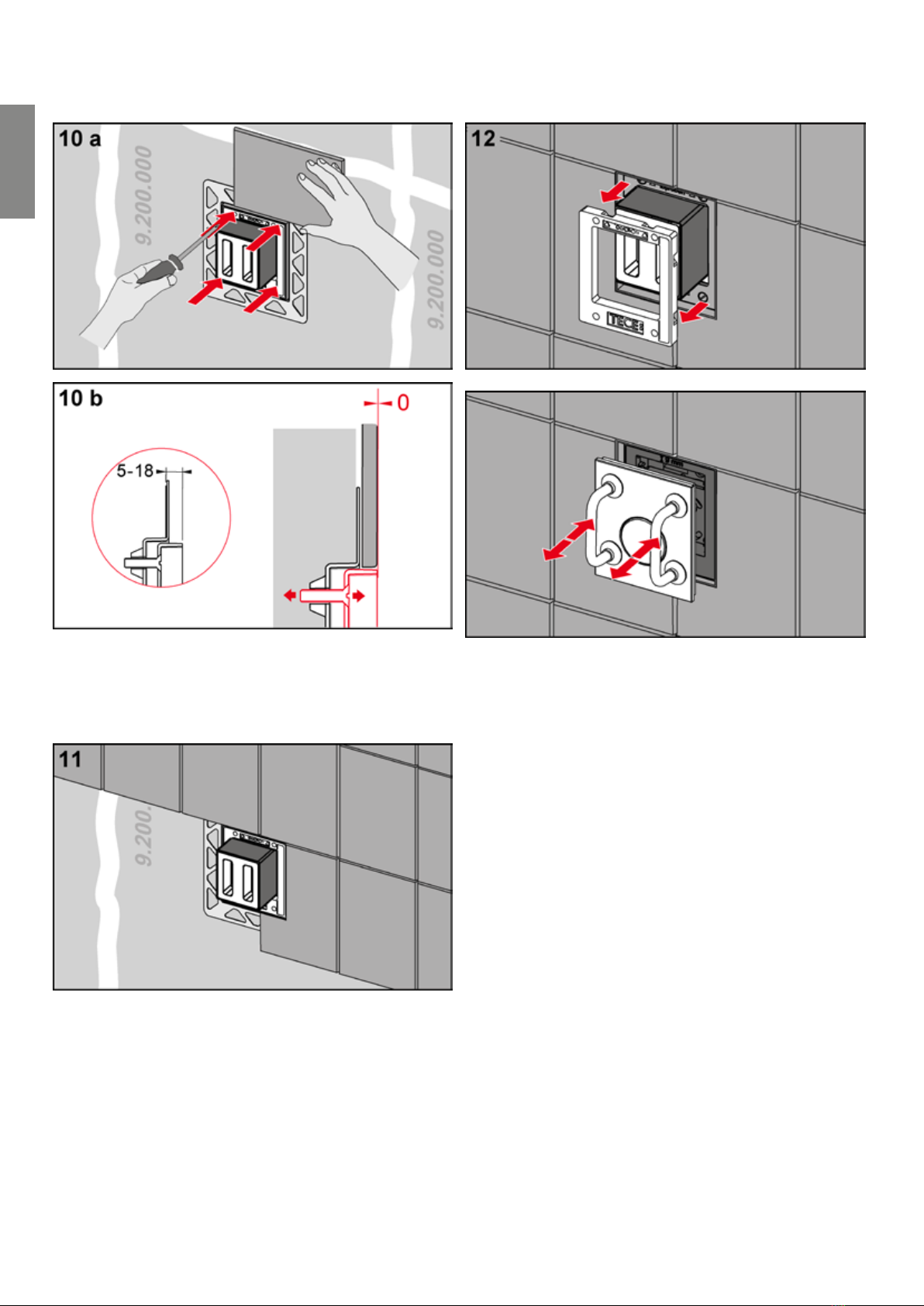

Installing the toilet flush plate in a dry-wall

To insert the flush-mounted installation frame into the

plasterboard, a recess for the cistern's inspection opening

must be made in the plaster board.

To do this, place the installation frame over the polystyrene

bare-wall protection.

TECE flush plates – Flush-mounted installation

-

Flush plates

Mark the dimensions of the inside of the installation frame

– width mm, height mm – in the centre of the

plasterboard.

Saw the required opening for the installation frame in the

board.

Screw the plasterboard centrally over the module.

Remove the protective foils from the bonding surfaces on

the installation frame, and stick them, together with those

of the support frame, onto the plasterboard. Observe the

correct position of the “TOP” marking, and ensure horizon-

tal alignment.

-

Flush plates

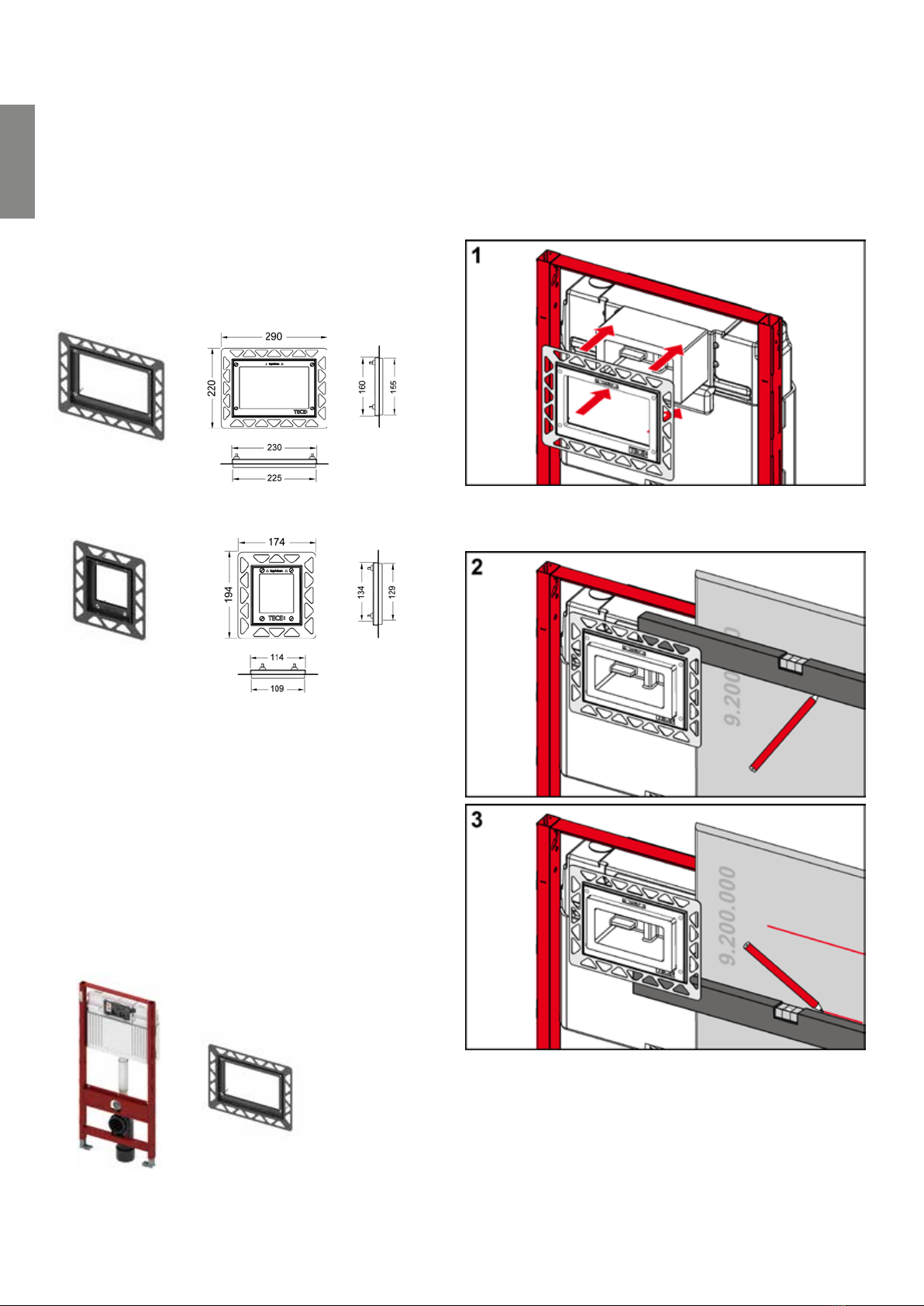

Adjust the depth of the installation frame to the tile thick-

ness (– mm). If the wall structure is thicker (up to

mm), as is the case for example with natural stone, you can

use a suitable upgrade kit (order no. ).

After adjusting the depth, you can tile right up to the instal-

lation frame.

Tip:

To obtain a perfect tile edge around the installation frame,

TECE recommends cutting the tiles with a water jet cutter.

Remove the support frame and polystyrene bare-wall

protection. Then mount the matching support frame as

described in the respective installation instructions (TECE-

loop or TECEsquare). Finally, insert the flush plate with the

aid of the bow-type handles (supplied with the installation

frame) into the flush-mounted installation frame.

TECE flush plates – Flush-mounted installation

-

Flush plates

Installation from above

The flush-mounted installation frame can also be used for

top actuation. Installation is the same as installing the flush

plate from the front. The frame must be mounted in the

“reading direction” (= “TOP” lettering to the wall).

“Flush-mounted installation from above”– dimensions

However, thicker minimum panel facing is required due to

the dimensions of the installation frame:

A minimum panel facing of mm corresponds to a panel

facing with

- x mm or

- x . mm thick plaster board.

“Flush-mounted top actuation” installation – minimum wall structure

On a minimum wall structure, there is no space left

between the installed flush plate and the wall (see picture

above). However, for aesthetic reasons, an equal distance

in front of and behind the flush plate is preferred (see

picture below). This also applies to the installation of the

TECEsquare metal flush plate which has slightly larger

dimensions.

“Flush-mounted installation from above” – wall structure (suggestion)

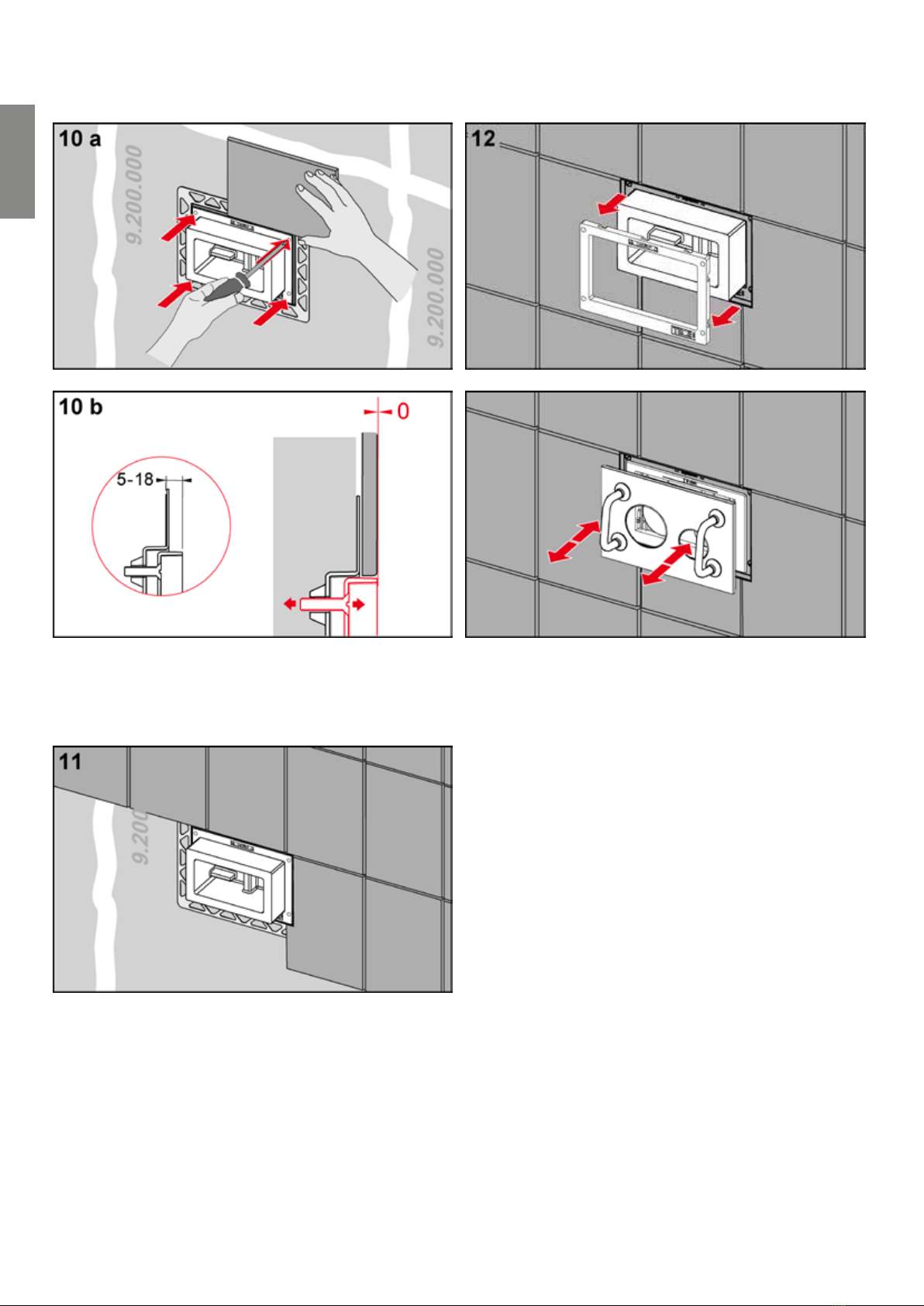

Brick-wall – toilet flush plate

In contrast to the dry-wall, for the brick-wall, an extended

bare-wall protection is required in addition to the TECEbox

brick-wall mounted cistern.

However, TECE cisterns of all installation heights can also

be used in brick-walls.

Components required:

TECEbox module Brick-wall bare-wall

protection

Installation frame for

toilet

Installing the toilet flush plate in a brick-wall

Remove the standard bare-wall protection and mount the

larger brick-wall bare-wall protection for flush-mounted

installations (order no. ).

-

Flush plates

Mount the expanded metal, reinforcement fabrics or similar

in the cistern area. Apply a layer of plaster of at least

mm thick (measured from the front edge of the splash

guard) to the wall.

Remove the brick-wall bare-wall protection.

Remove the protective foils from the bonding surfaces on

the installation frame, and stick them, together with those

of the support frame onto the plastered surface. Observe

the correct position of the “TOP” marking, and ensure

horizontal alignment.

TECE flush plates – Flush-mounted installation

-

Flush plates

Adjust the depth of the installation frame to the tile thick-

ness (– mm). If the wall structure is thicker (up to

mm), as is the case for example with natural stone, you can

use a suitable upgrade kit (order no. ).

After adjusting the depth, you can tile right up to the instal-

lation frame.

Tip:

To obtain a perfect tile edge around the installation frame,

TECE recommends cutting the tiles with a water jet cutter.

Remove the support frame and polystyrene bare-wall

protection. Then mount the matching support frame as

described in the respective installation instructions (TECE-

loop or TECEsquare). Finally, insert the flush plate into the

flush-mounted installation frame with the aid of the bow-

type handles. The handles are included in the installation

frame's scope of supply.

-

Flush plates

Installation from above

In a brick-wall structure too, the flush-mounted installation

frame can be used to install the flush plate from the top.

Installation is the same as installing the flush plate from the

front. The frame must be mounted in the “reading direc-

tion” (= “TOP” lettering to the wall).

“Flush-mounted installation from above”– dimensions

Due to the installation frame's dimensions a thicker wall

structure is necessary:

Minimum wall structure = mm

“Flush-mounted installation from above” – minimum wall structure

On a minimum wall structure, there is no space left

between the installed flush plate and the wall (see illus-

tration above). However, for aesthetic reasons, an equal

distance in front of and behind the flush plate is preferred

(see illustration below). This also applies to the installation

of the TECEsquare metal flush plate which has slightly

larger dimensions.

“Flush-mounted installation from above” – wall structure (suggestion)

Dry-wall – urinal flush plate

A flush-mounted installation frame also exists for uri-

nals. The TECEloop urinal flush plate can be installed by

flush-mounting this frame in dry-wall structures.

Installing the urinal flush plate in a dry-wall

To insert the flush-mounted installation frame into the

plasterboard, a recess for the cistern's inspection opening

must be made in the plaster board.

To do this, place the installation frame over the urinal bare-

wall protection.

TECE flush plates – Flush-mounted installation

-

Flush plates

Mark the dimensions of the inside of the installation frame

– width mm, height mm – in the centre of the

plasterboard.

Saw the required opening for the installation frame in the

board.

Screw the plasterboard centrally over the module.

Remove the protective foils from the bonding surfaces on

the installation frame, and stick them, together with those

of the support frame, onto the plasterboard. Observe the

correct position of the “TOP” marking, and ensure horizon-

tal alignment.

-

Flush plates

Adjust the depth of the installation frame to the tile thick-

ness (– mm). If the wall structure is thicker (up to

mm), as is the case for example with natural stone, you can

use a suitable upgrade kit (order no. ).

After adjusting the depth, you can tile right up to the instal-

lation frame.

Tip:

To obtain a perfect tile edge around the installation frame,

TECE recommends cutting the tiles with a water jet cutter.

Remove the support frame and proceed as described in

the installation instructions (installing the urinal cartridge,

installing the support frame, etc.). Finally, insert the flush

plate into the flush-mounted installation frame with the aid

of the bow-type handles. The handles are included in the

installation frame's scope of supply.

TECE flush plates – Flush-mounted installation

-

Flush plates

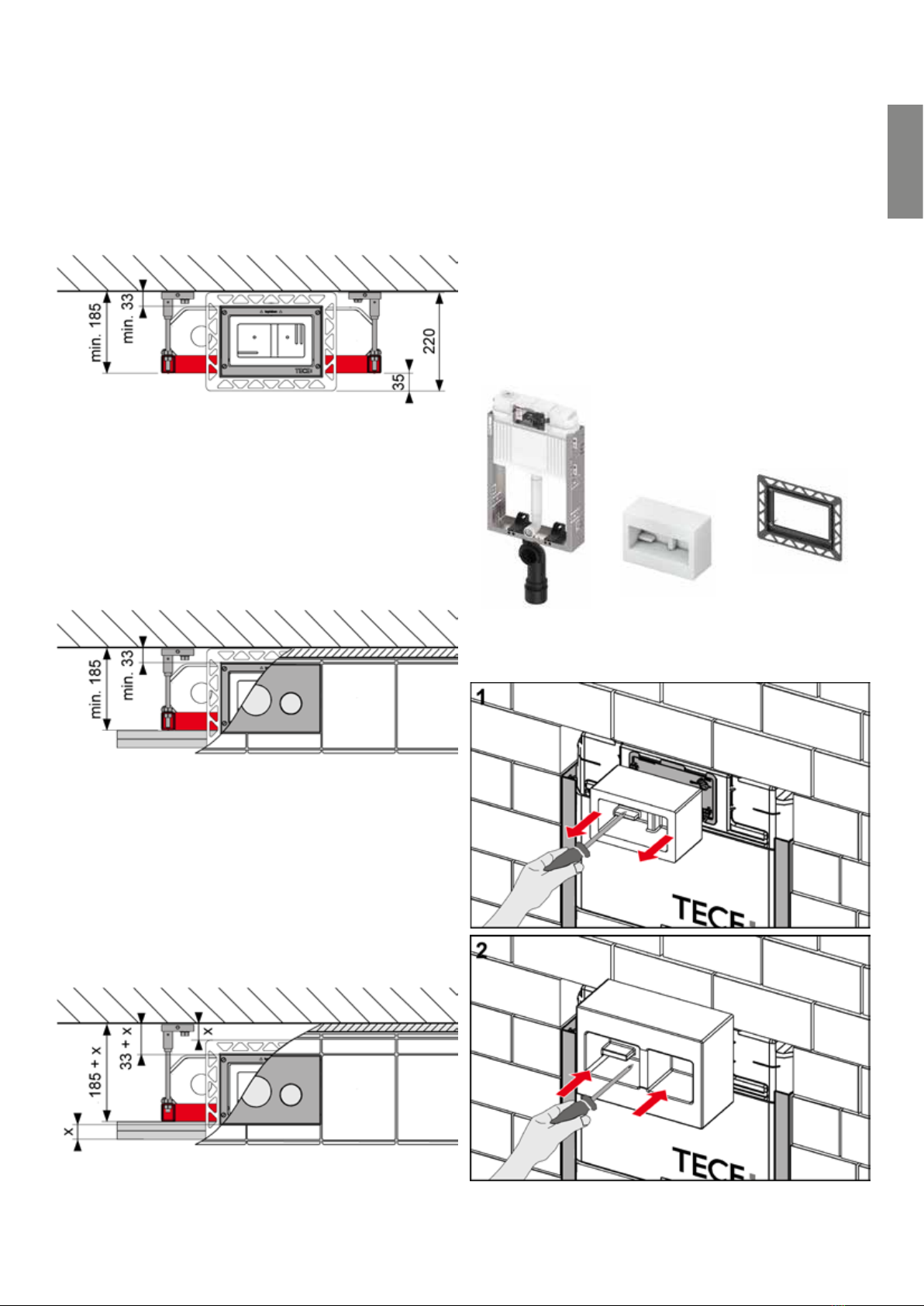

TECElux Mini

The TECElux Mini is a real glass flush plate with electronic

flush actuation. A sensor recognizes when somebody

approaches the toilet – at which point, the contours of the

sensor surfaces light up through the seamlessly smooth

glass facing.

Flushing is activated without contact or by a light tap.

The safety glass plate only stands out slightly from the

wall. Thanks to the installation frame, it can also be flush-

mounted in the wall.

150

220

8

TECElux Mini toilet flush plate, dual-flush technology

Wall-mounted installation of the toilet flush

plate

1

Open the splash guard.

2

Open the corner valve and suciently flush out the pipe.

3

Turn the corner valve to close it again and connect the

reinforced hose to the filling valve. If you wish to fill the

cistern with water (e.g. for the initial operation), you must

open the corner valve again.

4

40

18

Ø 14

If there is no hole in the splash guard, drill a hole on the

splash guard in the area shown.

5a

Mount the actuation motor onto the splash guard.

TECE flush plates – TECElux Mini

-

Flush plates

5b

Guide the cable and plug through the splash guard.

6

Place the splash guard and actuation motor back in the

cistern.

10 mm

7

Screw in both attachment rods – distance of attachment

rods to wall surface = mm.

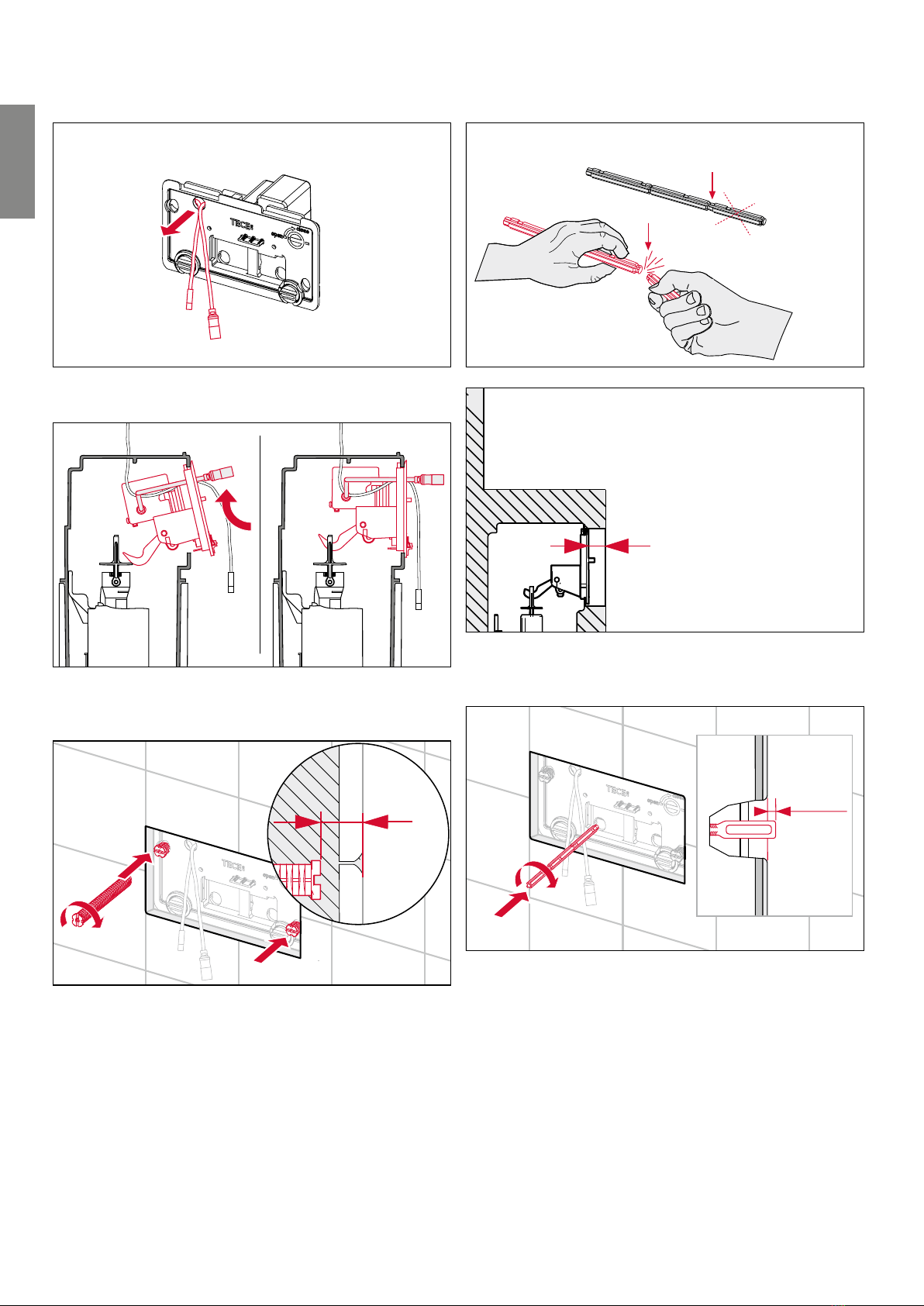

8a

A

8b

< 60 mm (A)

Break o the actuating rods according to the wall struc-

ture.

9

3 mm

Screw in both actuating rods – distance of actuating rods

to wall surface = mm.

TECE flush plates – TECElux Mini

-

Flush plates

10

The cover can be detached from the flush plate using

the disassembly tool. To do this, insert the tool into the

recesses on the underside of the flush plate and carefully

remove the cover.

11

Screw the support frame onto the attachment rods.

12a

2.

1.

12b

Connect the plug to the actuation motor and the trans-

former.

13

Mount the glass cover of the TECElux Mini electronics

14

Check whether the touch pad lights up.

-

Flush plates

The cover can be detached from the flush plate using

the disassembly tool. To do this, insert the tool into the

recesses on the underside of the flush plate and carefully

remove the cover.

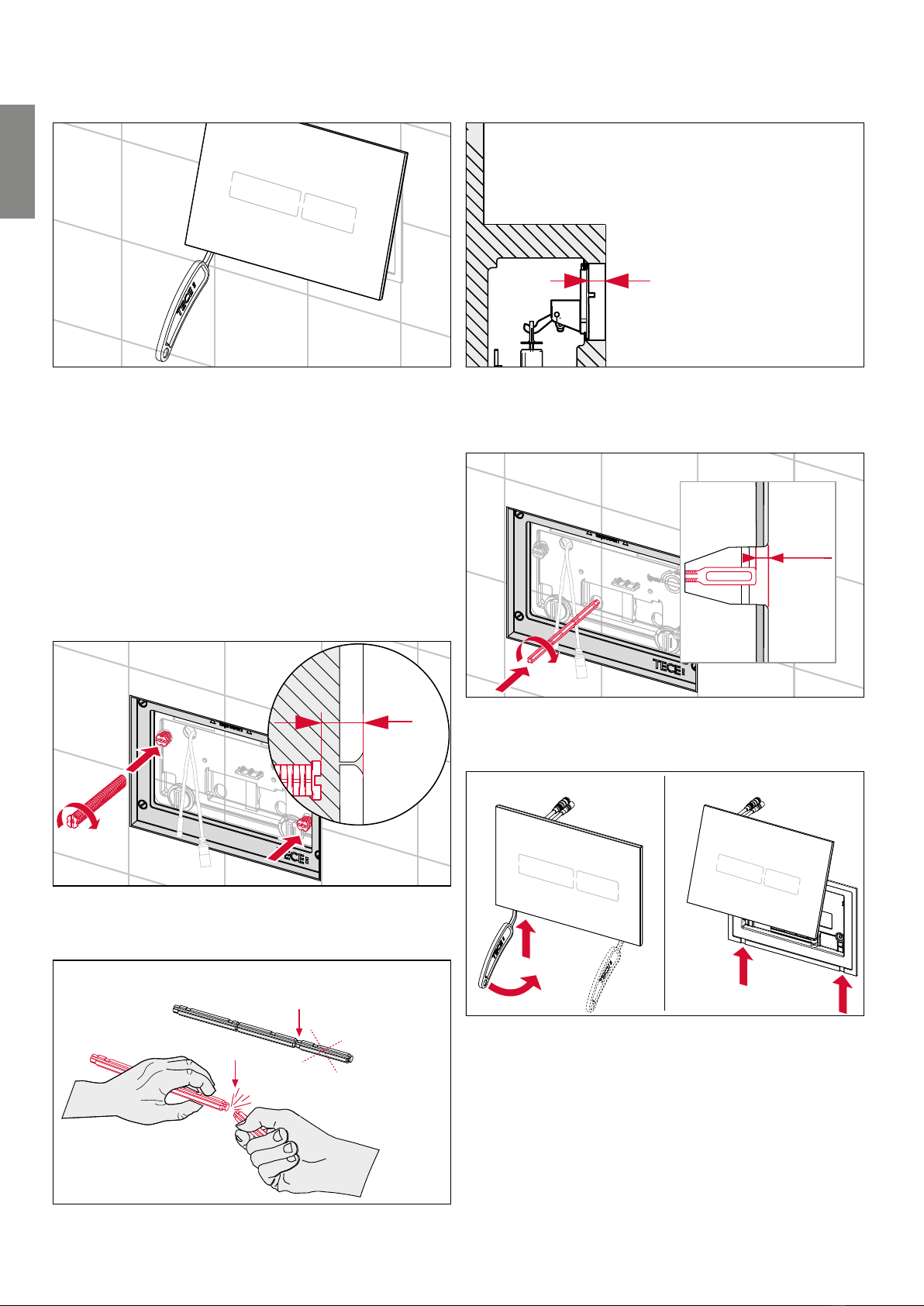

Flush-mounted installation of the toilet flush

plate

For the flush-mounted installation of the TECElux Mini

flush plate, follow the same first six steps for the wall-

mounted installation of the TECElux Mini.

7

18 mm

Screw in both attachment rods – distance of attachment

rods to wall surface = mm.

8a

A

8b

< 60 mm (A)

Break o the actuating rods according to the wall struc-

ture.

9

5 mm

Screw in both actuating rods – distance of actuating rods

to wall surface = mm.

10

The cover can be detached from the flush plate using

the disassembly tool. To do this, insert the tool into the

recesses on the underside of the flush plate and carefully

remove the cover.

TECE flush plates– TECElux Mini

-

Flush plates

11a

Stick the spacers onto the back of the TECElux Mini's sup-

port frame.

11b

Screw the support frame onto the attachment rods.

12a

2.

1.

12b

Connect the plug to the actuation motor and the trans-

former.

13

Mount the glass cover of the TECElux Mini electronics.

14

Check whether the touch pad lights up.

-

Flush plates

The installed cover can be removed from the flush plate

using the bow-type handles included in the installation

frame's scope of supply.

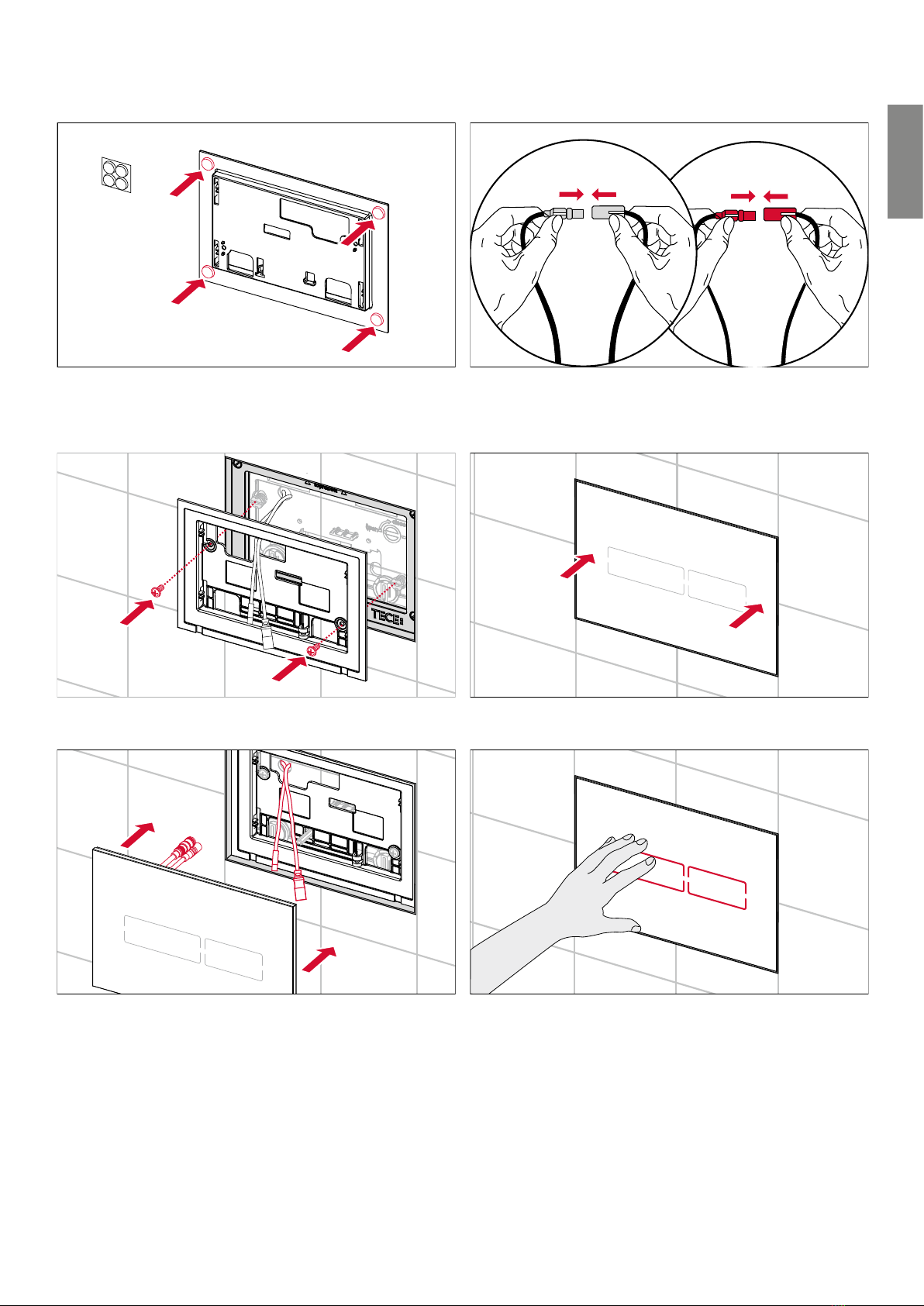

Installing the transformer with connection

cable

The transformer is required for the TECElux Mini's power

supply. A flush-mounted socket with a diameter of min.

60mm and a depth of 61 mm is suitable for installation in

dry-wall or brick-wall structures.

0–475 cm

0–475 cm

0–475 cm

230 V ~

OKFF

> 61

Ø 60

0–475 cm

TECE flush plates – TECElux Mini

Positioning the trans-

former: In the -cm

range around the cistern

(entire cable length: m).

-

Flush plates

This manual suits for next models

9

Table of contents

Other TECE Plumbing Product manuals

Popular Plumbing Product manuals by other brands

AWT

AWT 160 Series Installation and operation instruction

Blue Lagoon

Blue Lagoon UV-C Tech 15 WATT manual

Altair

Altair 51167-BAT-WH-FB manual

Sterling Plumbing

Sterling Plumbing Shower Receptor 72151100 Specification sheet

KEUCO

KEUCO Edition 90 59085 010901 Mounting instruction

Mora

Mora Rexx k5 Installation instruction