Tecfluid FLOMAT Series User manual

R-MI-FAXL1 Rev.: 0 english version

Series FLOMAT

Sensor FLOMAT-XL + Converter XL1

Instructions manual

The art of measuring

2

Thank you for choosing a product from Tecfluid S.A.

This instruction manual allows the installation, configuration,

programming and maintenance. It is recommended to read it before

using the equipment.

This document shall not be copied or disclosed in whole or in any

part by any means, without the written permission of Tecfluid S.A.

Tecfluid S.A. reserve the right to make changes as deemed

necessary at any time and without notice, in order to improve the

quality and safety, with no obligation to update this manual.

Make sure this manual goes to the end user.

Keep this manual in a place where you can find it when you need

it.

In case of loss, ask for a new manual or download it directly from

our website www.tecfluid.com Downloads section.

Any deviation from the procedures described in this instruction

manual, may cause user safety risks, damage of the unit or cause

errors in the equipment performance.

Do not modify the equipment without permission. Tecfluid S.A. are

not responsible for any problems caused by a change not

allowed. If you need to modify the equipment for any reason,

please contact us in advance.

PREFACE

WARNINGS

3

TABLE OF CONTENTS

SERIES FLOMAT

1 INTRODUCTION ........................................................................... 5

2 RECEPTION ................................................................................. 6

2.1 Unpacking .......................................................................... 6

2.2 Storage temperatures ......................................................... 6

3 HANDLING ................................................................................... 6

4 INSTALLATION ............................................................................. 6

4.1 Straight pipe sections ......................................................... 6

4.1.1 Mixtures ................................................................ 8

4.2 Sensor position .................................................................. 8

4.3 Valves ............................................................................... 8

4.4 Pumps ................................................................................ 9

4.5 Aeration ............................................................................. 9

4.6 Vibrations ........................................................................... 10

4.7 Magnetic fields .................................................................. 10

4.8 Temperature ...................................................................... 10

5 MOUNTING .................................................................................. 11

5.1 Pipe adaptor mounting ....................................................... 11

5.2 Sensor mounting ................................................................ 13

5.3 Tightening torque ................................................................ 13

5.4 Electronic converter connection .......................................... 13

5.5 Electronic converter programming ........................................ 13

6 ELECTRICAL CONNECTION ........................................................... 14

6.1 Power supply wiring ............................................................ 14

6.2 Analog output wiring ........................................................... 15

6.3 Digital output wiring ............................................................ 16

7 ASSOCIATED SOFTWARE WINSMETER XL1 ................................. 18

7.1 USB cable connection and software installation ................... 18

7.2 Port connection ................................................................... 19

4

7.3 Password ........................................................................... 20

7.4 Access to “Installation” ....................................................... 24

7.4.1 Sensor .................................................................. 24

7.4.2 Power supply ......................................................... 24

7.5 Access to “Programming” ................................................... 25

7.5.1 Current loop .......................................................... 25

7.5.2 Units ....................................................................... 26

7.5.3 Digital output ......................................................... 26

7.5.4 Current loop calibration .......................................... 26

7.6 Visualization ....................................................................... 27

7.7 Zero flow drift adjustment .................................................... 27

7.8 Datalogger ......................................................................... 28

7.9 Firmware updates ............................................................... 29

7.10 Configuration file ................................................................. 30

8 MAINTENANCE ............................................................................ 31

9 TECHNICAL CHARACTERISTICS ................................................... 32

10 SAFETY INSTRUCTIONS ............................................................... 33

10.1 Pressure equipment directive .............................................. 33

10.2 Certificate of conformity TR CU (EAC marking) ..................... 33

11 DIMENSIONS ............................................................................... 34

12 TROUBLESHOOTING .................................................................... 37

ANNEX Flow rate diagram ................................................................... 38

5

1INTRODUCTION

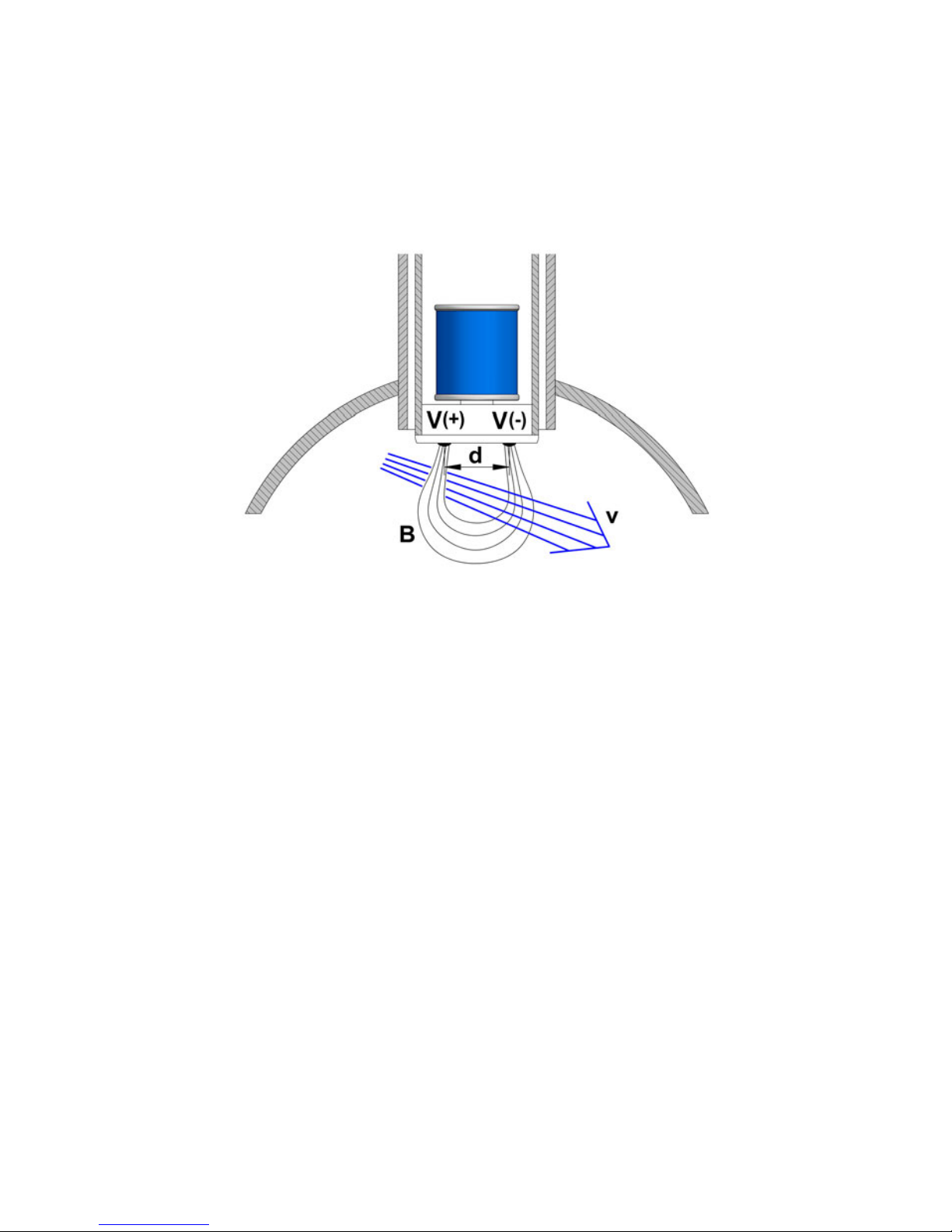

The FLOMAT electromagnetic flowmeters are based on Faraday’s induction law.

When an electrically conductive liquid flows through a magnetic field, perpendicular to the

flow direction, it induces a voltage V proportional to the liquid velocity.

Two electrodes in contact with the liquid and positioned perpendicularly to the magnetic

field, sense this voltage V.

The electronic converter is based on the most advanced technology in digital signal

processing, in order to obtain accurate and reliable measurements.

The device provides the following features:

Coil excitation by means of pulsed signal to obtain a negligible zero offset.

Pulse and current output proportional to the flow rate and user programmable.

V = B·v·d

Where:

V = Measured voltage in the electrodes

B = Magnetic field

v = Liquid velocity

d = Distance between electrodes

Other manuals for FLOMAT Series

1

This manual suits for next models

2

Table of contents

Other Tecfluid Accessories manuals