Tech-Aero ultra IBEC User manual

“Ultra IBEC” Ignition Battery Eliminator Circuit

Users Manual

* Always follow receiver manufacturer range testing guidelines prior to flight!

Copyright 2010 Tech-Aero Designs

www.tech-aero.net

Figure 1 - Tech-Aero Ultra IBEC

”Ultra IBEC” Features

Eliminates the need for a separate ignition battery and mechanical on/off switch.

Compatible with the power requirements of single and twin cylinder model CDI ignition

modules via jumper selectable 5V, 5.3V, 6V and 6.6V voltage outputs.

Enhanced flexibility and safety via transmitter controlled on/off control of CDI ignition

power from a spare receiver auxiliary channel.

Tech-Aero exclusive 4 stage filtering blocks interference from CDI ignition noise in the

wiring path to the receiver, permitting use with 2.4 GHz Spread Spectrum and 72 MHz

FM radio receivers. *

oFilter stages 1 & 2: An advanced 2

nd

order common mode LC power lead filter.

oFilter stage 3: Three power filter capacitors combine to provide over twice the

capacity of others, enhancing peak impulse current delivery to the CDI module.

oFilter stage 4: An optical isolator circuit prevents any stray noise from feeding back

into sensitive receiver electronics via the signal lead.

A high precision, very low dropout power regulator design further assures power receiver

bus isolation with superior performance during peak current demand.

One IBEC model fits all: compatible with any battery technology commonly used for

radio control use, with a usable input voltage range from 4.8V to 13V.

Bright 3mm LED CDI power on/off indicator.

High reliability Surface Mount components reduce weight to only 0.6 oz and size to 1” x

1 ¾”.

Heavy duty 22 gauge twisted wire power extensions.

“Ultra IBEC” Ignition Battery Eliminator Users Manual

Copyright 2010 Tech-Aero Designs

www.tech-aero.net

2

Overview

Thank you for purchasing the Tech-Aero Designs “Ultra IBEC”. The Ultra IBEC eliminates the need to

carry the extra weight of a separate ignition battery and mechanical On/Off ignition switch in your

model. The Ultra IBEC offers better flight performance by not only reducing flying weight, but also by

assuring that a consistent supply voltage and robust current on demand is provided to the CDI ignition

module throughout the flight. The Ultra IBEC On/Off “kill switch” capability also enhances safety,

allowing control of ignition power to the engine the entire time the model aircraft is being operated.

When combined with the “failsafe” features that many radio control systems now provide, the Ultra

IBEC can be configured to kill ignition module power in the event that radio communications are

unexpectedly lost between the transmitter and receiver.

The Ultra IBEC plugs into a spare receiver auxiliary channel and provides switchable power to the CDI

ignition module from the receiver bus, while safely isolating the receiver and servos from high

frequency ignition noise that may be present on the wiring path between the CDI module and the Ultra

IBEC. The Ultra IBEC can also be connected to power bus expander products, provided that an

auxiliary channel capability is available at that connection point.

Please note that although the Ultra IBEC is highly effective at isolating the receiver and servos from

ignition noise that may be present in the wiring path between it and the CDI ignition module, it does not

eliminate the ignition noise that is always radiated by the CDI module itself and from the high voltage

wiring connection(s) to the engine sparkplug(s). This is the case with any and all ignition battery

eliminator and optical kill switch type products. Consequently, it is necessary to follow the installation

guidelines of the CDI ignition module and engine manufacturers to assure that adequate separation

exists between all parts of the receiver, servos, batteries and wiring. It is also necessary to assure, as

with any model ignition engine installation, that the shielding for the high voltage connections to the

engine sparkplug(s) are undamaged, and that proper grounding of the shielding to the engine case is

properly accomplished. Most modern CDI modules have the grounding built into the design of the

spark plug connector cap, but it is wise to assure that these connections are made correctly per the

manufacturer’s instructions.

To do its job most effectively, the twisted wire power connection from the Ultra IBEC to the CDI

module is purposely short, to assure that it is mounted near the CDI module. It has a long, twisted wire

lead to the receiver to allow installation with adequate separation from the receiver. Particularly in the

case of use with 72 MHz FM receivers, it is advisable to take full advantage of the length of wire

available on the receiver side connection, to assure adequate separation of any source of radiated

ignition noise from the CDI Module power connection side of the Ultra IBEC. Think of that as the

“dirty side”, whereas the wiring connection from the Ultra IBEC to the receiver is the “clean side”.

Note that the use of twisted wire helps reduce the antenna effect that exists with all electronics wiring.

This minimizes the pickup of ignition noise that is radiated by the CDI module high voltage output and

spark plug, and also limits the amount of re-radiated ignition noise that is present in the wiring directly

between the CDI module and the output power side of the Ultra IBEC.

From the radio receiver perspective, the Ultra IBEC behaves much as if it were just another high torque

servo. It is preset to switch CDI power ON at approximately the midpoint and higher “travel” setting for

the auxiliary channel it is connected to. Power to the CDI module will be switched OFF below that same

“Ultra IBEC” Ignition Battery Eliminator Users Manual

Copyright 2010 Tech-Aero Designs

www.tech-aero.net

3

midpoint auxiliary channel setting. Adjust the travel direction on the transmitter auxiliary channel

configuration to assure that the ON and OFF settings make logical sense for how the CDI module “Kill

switch” function will work, based on the direction of the lever or switch movement that you prefer.

Adjust the auxiliary channel ATV (travel endpoints) to 100% or more in each direction of travel, and be

sure that its sub trim is zeroed out (neutral). It is highly advisable to also set up a failsafe condition for

the Ultra IBEC auxiliary channel, so that if radio communications are lost, the Ultra IBEC can perform

its “Kill Switch” function to stop the engine. It’s easy to test this on the bench while setting up the radio

for this configuration, since the Ultra IBEC’s LED is illuminated when CDI power is switched ON.

The amount of current draw taken from the receiver flight pack battery is dependent on the brand/model

of CDI ignition module, the number of engine cylinders and the RPM that the engine is running at. As a

general rule of thumb, for a 10 minute flight, conservatively plan that approximately 100 to 120 MAh

per spark plug (2 cylinders max per each Ultra IBEC) will be drawn from the batteries to power the CDI

module. This will vary due to the design of the various CDI modules available, and with your flying

style. Higher average RPM’s during flight will always result in greater battery capacity usage than

lower average RPM’s. It is recommended that the battery capacity be monitored to determine the true

average usage of the combined load of servos and ignition module during a typical flight. As always,

pre-flight checks of battery condition are strongly advised. Never begin a flight without knowing that

there is adequate battery capacity to complete the flight with some reserve left over!

Installing and Configuring the Ultra IBEC

Figure 2 – Ultra IBEC Connection to Receiver and CDI Module

“Ultra IBEC” Ignition Battery Eliminator Users Manual

Copyright 2010 Tech-Aero Designs

www.tech-aero.net

4

Please refer to Figure 2, which depicts the Ultra IBEC connected to an auxiliary channel of a

receiver. The Tech-Aero Ultra IBEC provides significant flexibility in your choice of supply voltage and

battery configurations. For example, dual redundant regulators and batteries are ideal to provide the

assurance that the entire flight pack and ignition module will continue to operate in the event of a single

battery, wiring, or even a regulator failure. Alternatively, the Ultra IBEC may be used in configurations

where the receiver and servos are powered by one or more unregulated NiCad or NiMh, A123, LiPo or

Li-Ion battery packs. NiCad or NiMh packs up to 8 cells may be used if desired, and up to 3 cell A123,

LiPo or Li-Ion battery packs may be used for power with the Ultra IBEC, provided that the rest of the

flight pack (receivers & servos) can tolerate such high voltages. The Ultra IBEC will take care of

providing the correct voltage to the CDI module via its jumper selectable voltage output feature. This is

a powerful feature that protects against obsolescence with the advent of high voltage (HV) technology

servos that are becoming more popular.

The voltage output from the Ultra IBEC is easily jumper configurable to safely meet the voltage

rating requirements of all popular model aircraft CDI modules. Please note however, that the voltage

output level of the IBEC will never exceed the voltage level being provided to it by the receiver’s power

bus. For example, if you want to power an ignition module that requires 6.5V or more, you would need

to not only configure the jumpers to the 6.6V setting, but would need to also assure that the receiver

power bus was configured with batteries (and perhaps regulators) that would provide a minimum of

6.7V. The reason for allowing a 0.2V margin of extra voltage at the receiver side vs. the CDI side is due

to the very small voltage dropout that will exist in the wiring and electronics during normal operation.

Figure 3 - Ultra IBEC 6.6V Jumper Configuration

“Ultra IBEC” Ignition Battery Eliminator Users Manual

Copyright 2010 Tech-Aero Designs

www.tech-aero.net

5

Figure 4 - Ultra IBEC 6V Jumper Configuration

Figure 5 - Ultra IBEC 5.3V Jumper Configuration

“Ultra IBEC” Ignition Battery Eliminator Users Manual

Copyright 2010 Tech-Aero Designs

www.tech-aero.net

6

Figure 6 - Ultra IBEC 5V Jumper Configuration

Additional Usage Guidelines

Mounting the Ultra IBEC should be done with the same care needed for other airborne electronics,

such as the receiver in the model. Fasten the Ultra IBEC with a Velcro

®

strap around the mid-section A

piece with ¼” or thicker foam padding placed underneath the unit. Make the strap just snug enough to

press the unit lightly into the foam padding beneath it. Alternatively, a piece of adhesive backed

Velcro

®

can be used on the bottom side of the circuit board. The 3mm LED can be mounted by gluing

in a location that makes it easy to observe during engine starting operations. To allow easy removal to

remount in a different model, a non-acidic adhesive such as Goop can be used. Use care to avoid getting

any glue on the LED lens!

Disclaimer

Proper care and maintenance of your configuration is required for reliable and safe operation of

your model. It is your responsibility to follow these instructions, as well as those provided with all other

parts of your model aircraft that you have selected for your use. The Ultra IBEC is covered by a 1 year

limited warranty. If the Ultra IBEC is found to malfunction due to a product defect or failure, it will be

repaired or replaced during the warranty period. Tech-Aero Designs liability is strictly limited to the

replacement cost of the Ultra IBEC if it is found to be defective. Tech-Aero Designs assumes no

responsibility or liability for product misuse, neglect or crash damage, or for the careless or reckless

operation of the model aircraft in which it is installed.

Table of contents

Popular Controllers manuals by other brands

GJD

GJD Sapphire 1500 MK3 GJD005 manual

Keysight Technologies

Keysight Technologies N1002A quick start guide

Arcadia

Arcadia REPTILE CONTROLLER RACRE Installation and maintenance instructions

Centurion

Centurion D3 quick guide

X10

X10 MC460 owner's manual

O. Thompson

O. Thompson Microflite Ultra 2000 Installation & Adjustment Manual

Parker

Parker AC890PX Series product manual

Siemens

Siemens RWC32/82 Installation and commissioning guide

Jordan Valve

Jordan Valve Mark 60 Series Installation & maintenance instructions

Grundfos

Grundfos DID BF1 Installation and operating instructions

VICOR

VICOR PRM48AH480 200A00 Series manual

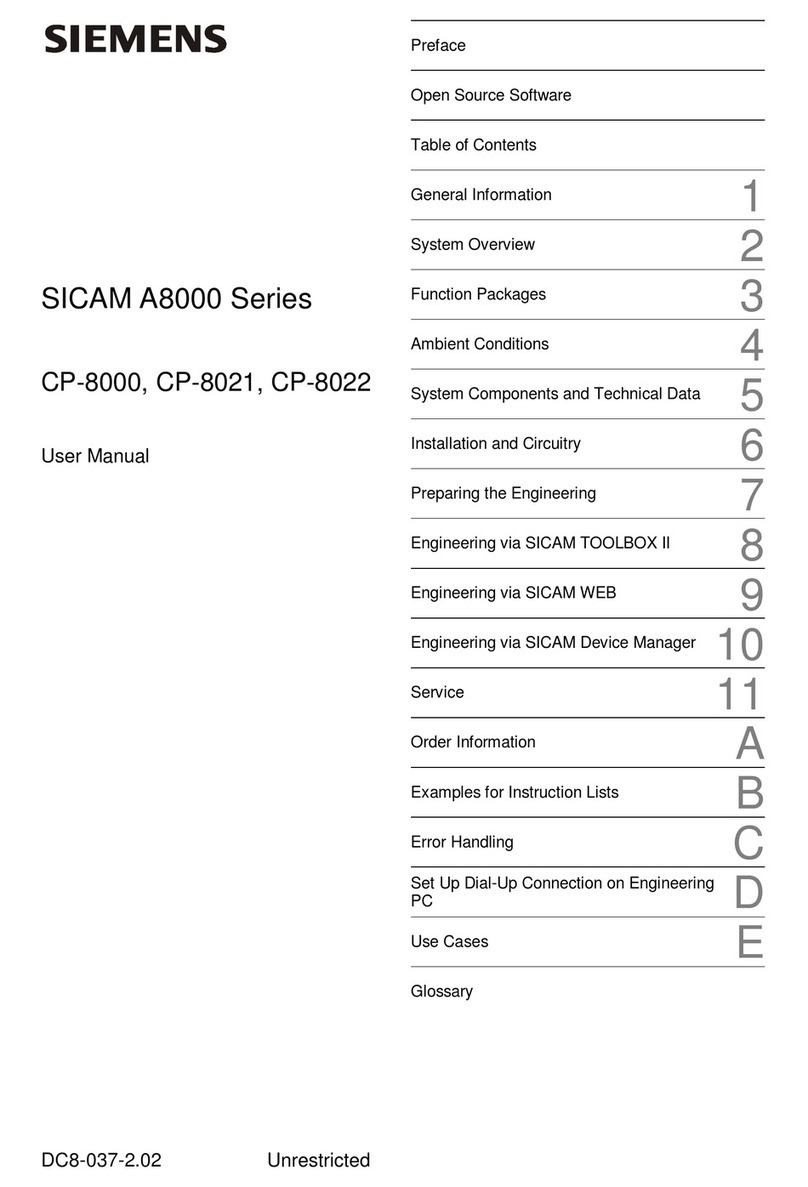

Siemens

Siemens CP-8000 user manual