6

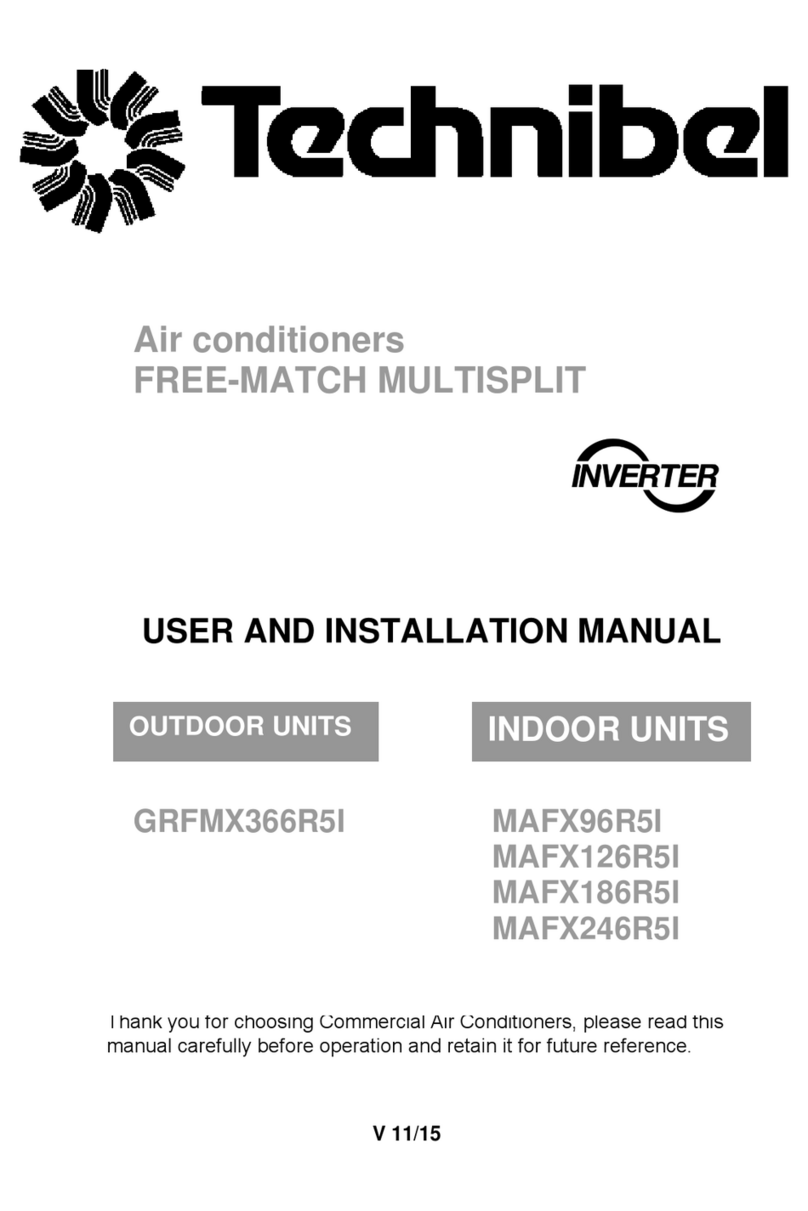

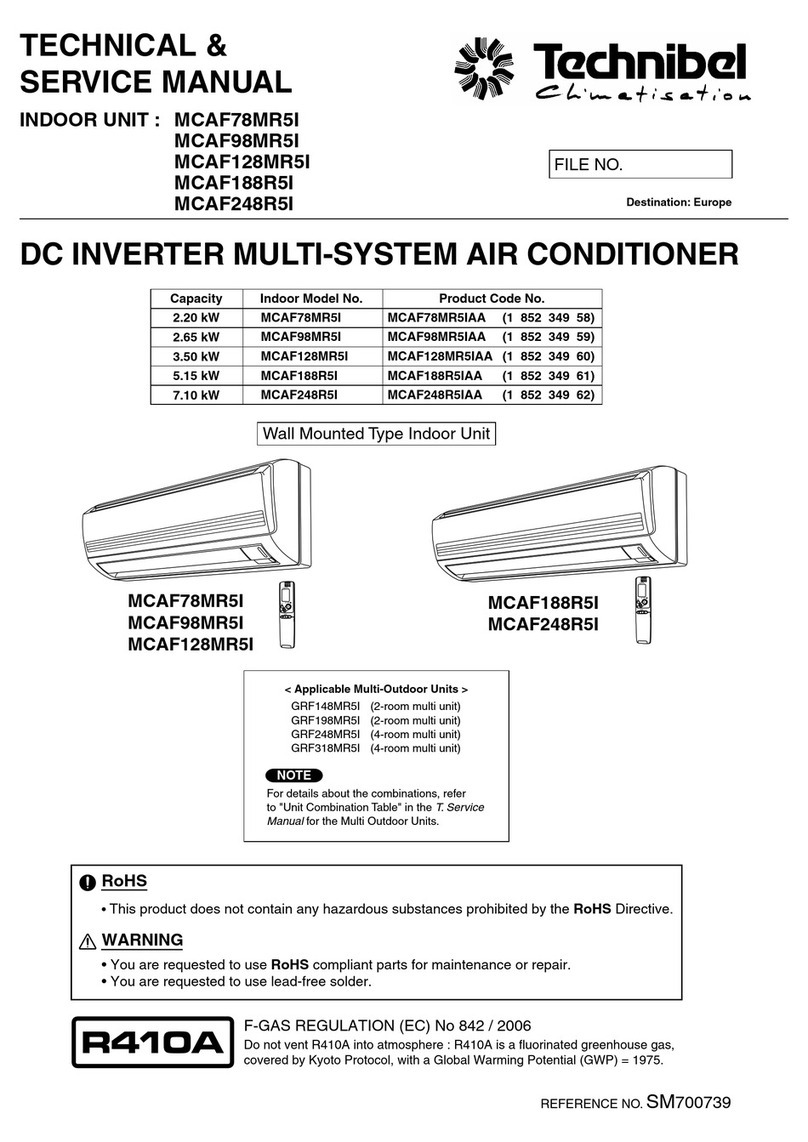

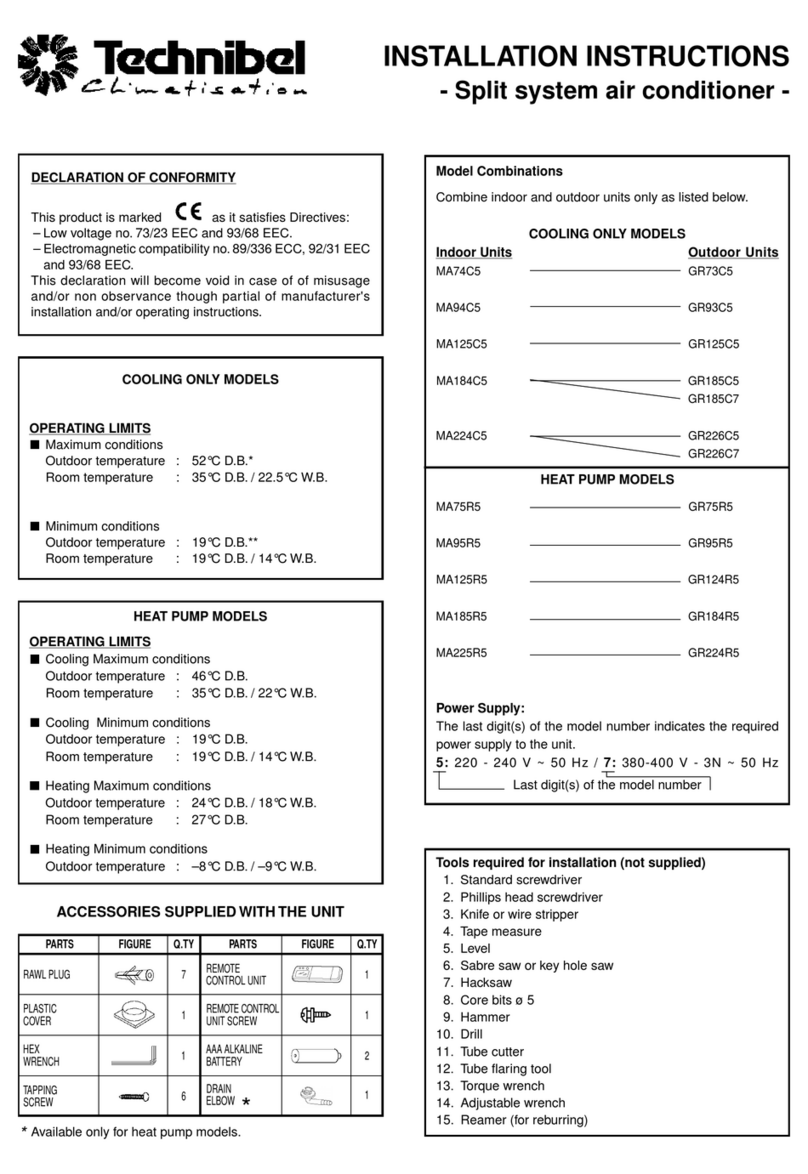

4 - CONNECTIONS

1-Gas refrigerant connection.

2-Liquid refrigerant connection.

3-Electrical connection.

4-Condensate drainage.

5-Mains supply with isolating and protective device.

6-Remote control (accessory).

4.1 - CONNECTION OF THE CONDENSATE LINES

4.1.1 - VERTICAL MOUNTING

•Use the 12 mm dia. x 16 mm hose supplied.

•Pass it with refrigerant pipes through one of the covers and connect it to

a pipe of minimum internal diameter 12 mm, respecting a slope in the

liquid's flow direction.

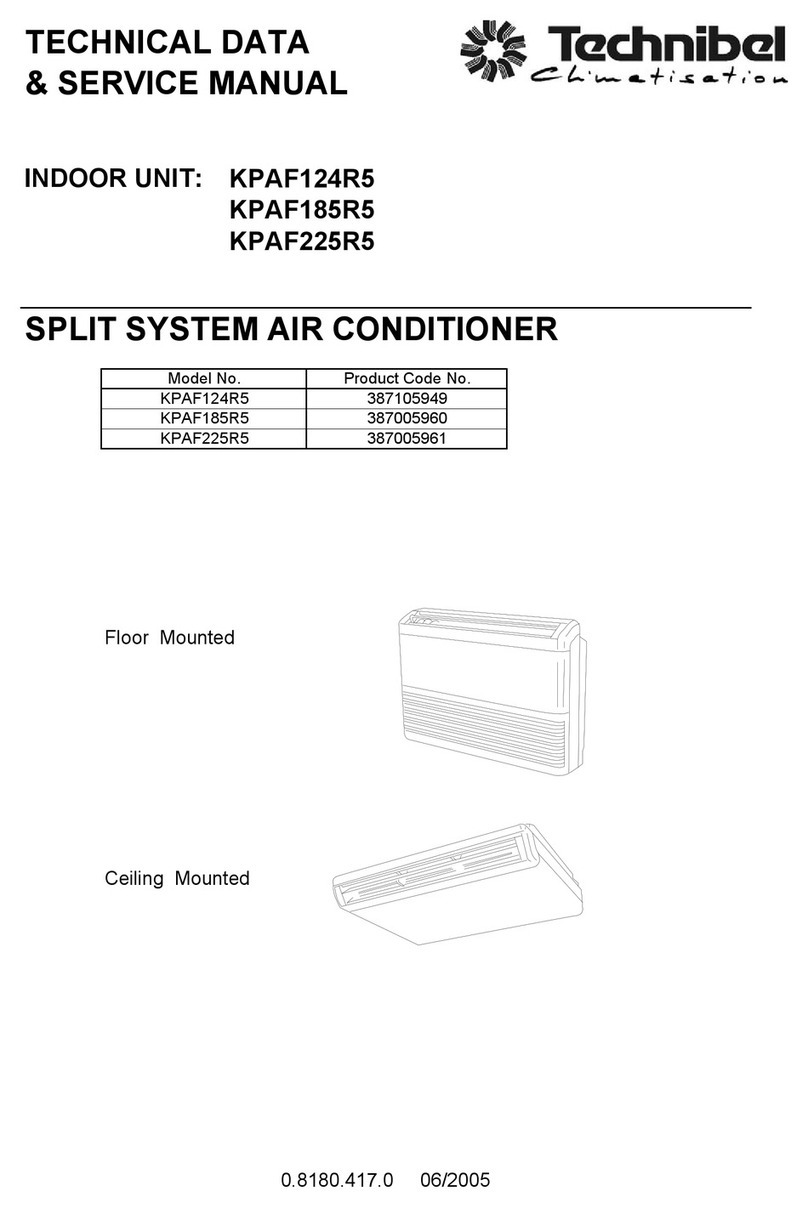

4.1.2 - CEILING MOUNTING

• Use the copper pipe and the end piece supplied.

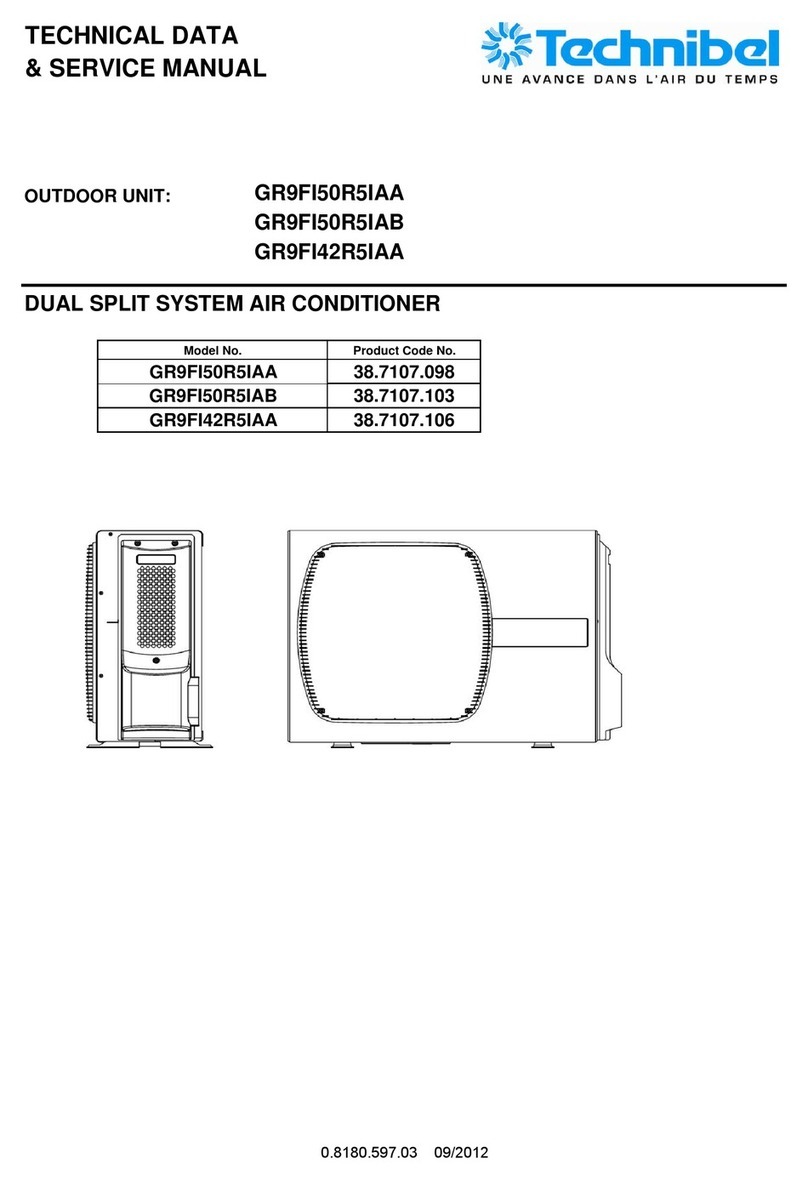

4.2 - REFRIGERANT CONNECTION

•If the difference in level is greater than 3 metres,

make an oil trap.

NOTE: Nominal cooling capacity is given for a total

pipe length of 8 m.

For pipe lengths over the maximum length, please

consult us.

Oil

trap

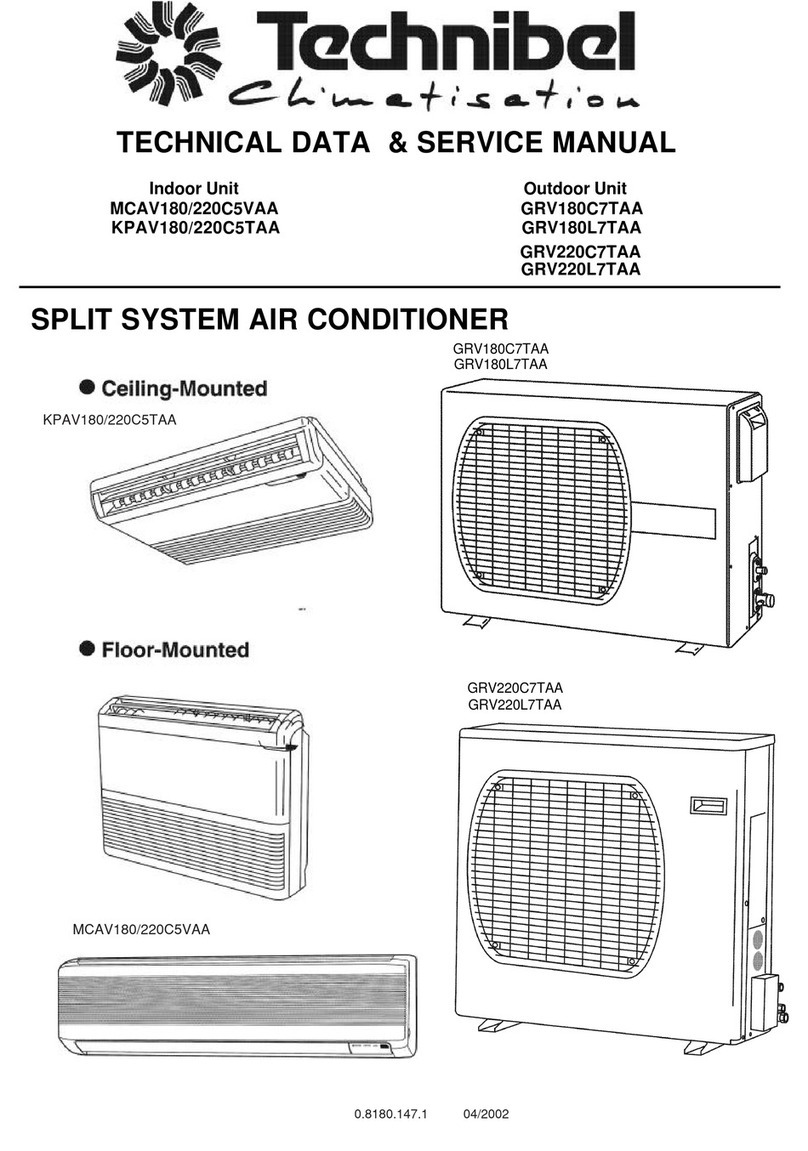

Ceiling mounting

3/8"

3/8"

1/2"

1/2"

CSCV 152 LL

CSCV 202 LL

CSCV 302 LL

CSCV 402 LL

1/4"

1/4"

1/4"

1/4"

15

15

25

25

15

15

20

20

7

7

7

7

730

800

750

1 660 1-phase

1 680 3-phase

8

8

4

8

123

5

6

GRV

TAV 4

End piece Copper pipe Hose

Addition of

refrigerant

above

(m)

Maximum

permissible

difference in

level B (m)

Maximum

permissible

length

A (m)

LiquidGas

Dia. of pipes Quantity of

refrigerant to

be added

(g/m)

Refrigerant

load

in the GRV

(g)

APPLIANCES FILLED WITH R 407 C

R 407 C

•FluidR 407 C,as opposedto R22,is nota purefluid but

a blend composed of:

-23% R 32 + 25% R 125 + 52% R 134 A.

•The compressors approved for operation with this fluid

are filled beforehand with polyalcohol oil.

Contraryto mineraloil, itis veryhygroscopic: itabsorbs

the humidity of the ambient air very quickly. This can

modify its lubricant properties and lead in time to the

destruction of the compressor.

MAINTENANCE INSTRUCTIONS

1-Never add oil to the appliance; the compressor is filled

with polyalcohol oil, a special oil which cannot tolerate

the presence of other oils.

2-The instruments used for:

-filling,

-pressure measurements,

-emptying under vacuum,

-recovering the fluid,

mustbecompatible and onlyusedfor theR407 Cfluid.

3-The weight of the refrigerant contained in the storage

bottle must be checked constantly. Do not use it from

the moment the remaining weight is less than 10% of

the total weight.

4-In the case of a new charge:

-do not use the charging cylinder,

-use a balance and a dip pipe type R 407 C cylinder,

-chargetheweight ofR407C asperthe valueindicated

on the unit’s identification plate (for "split systems",

refer to the installation instructions as the charge must

consider the length of the connecting lines),

-IMPORTANT: see paragraph 3.

5-The charge must be undertaken in liquid phase.

6-In case of leakage, do not complete the charge: recover

the remaining refrigerant for recycling and perform a total

charge.

Recovery, recycling or the destruction of the fluid must be

done in compliance with the laws in force in the country

concerned.

7-If the refrigerant circuit is opened, you must:

-avoid the entry of air into the circuit as much as

possible,

-replace the filter drier,

-perform the "vacuum operation" at a minimum level of

0.3 mbar (static).