4

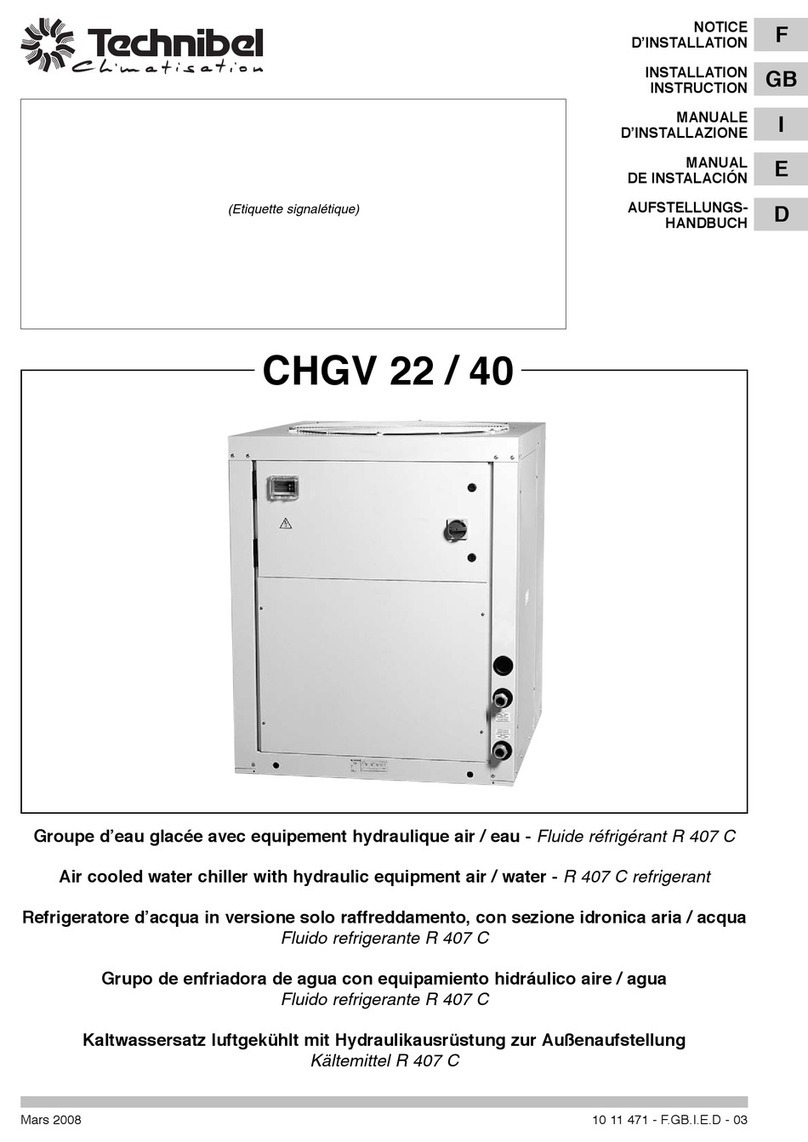

2.2 - COMPOSITION OF UNIT

i

f

e

b

d

c

4

6

1

g

a

j

h

2

8

5

37

9

9Supply

to installation Return from

installation

PMHRV

CONTROL 7

•Microprocessor µCHILLER control module, including:

-Chilled water temperature control.

-Control of operating parameters.

-Anti-short cycle system.

-Hour counter for each compressor.

-Automatic balancing of compressor operating time

(dual compressors).

-Air exchanger defrosting.

-Anti-freeze security (water exchangers).

-Digital display of:

.water temperature,

.set-point,

.alarm code (HP, LP, water output, thermal

protective devices, probes, anti-freeze…).

-Possibility of remote alarm signaling by a voltage-free

change-over contact and operating conditions via

remote µCHILLER display keypad (optional).

-Remote On/Off control via µCHILLER display keypad

(optional) or by voltage-free closing contact (remote

control box supplied with the unit).

-Circulation pump control.

•The thermostat controls fan rotation speed according to

the ambient temperature.

•For special applications, consult us.

CHASSIS - BODYWORK 8

•Galvanised sheet metal with light grey oven-baked

polyester powder paint.

BUILT-IN HYDRAULIC MODULE 9

a-1polyurethane insulated sheetmetal buffer tank.

b-1pumpwithinsulatedcontrolvalve-2shut-offvalves.

c-1filling valve Ø 1/2" female.

d-1pressure gauge, 0-4 bar.

e-1lack of water safety pressure switch.

f-1safety valve.

g-1air relief valve.

h-1drainage valve.

i-1expansion tank.

j-Placements for electric heating elements.

COMPRESSOR 1

•Hermetic SCROLL compressor with sound-proofing

cover.

•Installed on rubber anti-vibration pads.

•Internal thermal protection of the motor winding.

•Crankcase heater.

CONDENSER 2

•

Coil, consisting of copper pipes and crimped aluminium

fins.

•Protective grille.

•Condensation pressure probe with the proportional "All-

season" control.

•Probe for defrosting.

FAN 3

•Direct driven axial fan.

•2-speed motor, Y/∆switching, 400V/3Ph/50Hz.

•Rotation speed 700 - 550 rpm.

•Insulation classification F.

•Internal thermal protection.

•Protection class IP55.

•Proportional "All-season" control, available as option.

EVAPORATOR 4

•Plate-type stainless steel (AISI 316L) water treatment

section with freezing protection.

•Antifrost electric heating resistor.

•Watercirculationcontrolledbydifferentialpressureswitch.

•Water inlet temperature probes (for control).

•Temperature probe for antifrost protection.

REFRIGERANT CIRCUIT 5

•R407 C refrigerant.

•Thermostatic expansion valve.

•Drier filter.

•Automatic reset high pressure and low pressure

switches.

•Copper tubing.

•Liquid receiver.

SWITCH BOX 6

•Accessible via hinge-mounted door.

•Main switch.

•Phase-sequence tester.

•Power and control circuitry protected by magnetothermal

circuit breakers.

•Complies with standard EN 60 204-1.

•Short circuit current 10 kA, as per IEC 947-2.