RS-M228X

CONTENTS

ITEM

PAGE

LOCATION

OF

CONTROLS

AND

COMPONENTS

------------

2

DISASSEMBLY

INSTRUCTION

--+----cseeers

sees

eeeee

te

teeee

ee

eees

3

MEASUREMENT

AND

ADJUSTMENT

METHODS

(without

dbx

SYSTEM)

‘ibietalerbisiaiolelala'e

einitie

slorw-sjateisiels

ewwle

eerie

viele

lois

5

MEASUREMENT

AND

ADJUSTMENT

METHODS

(for

dbx

SYSTEM)

(gE

ut

saiate

Syste

ySejeie

bie

ware

dig

915

olan

Cat

sigleieretelg

bate

ever

11

*

TROUBLESHOOTING

CHART

FOR

dbx

SYSTEM

----

11

*

ADJUSTMENT

PARTS

LOCATION

OF

dbx

SYSTEM

feesccceston

stoves

nnd

Sia

teowetnn

reduce

tet

ee

teenasiy

se

13

*

BLOCK

DIAGRAM

OF

dbx

SECTION

------+--eeeeeeeee

ee

13

*

dbx

SYSTEM

CHECKING

METHOD

..---------------e-5+

5

14

¢

ADJUSTMENT

OF

dbx

SYSTEM

--vecececececeeeeeeeeee

ees

15

*

CHECKING

PROCEDURE

FOR

PROBLEMS

-.----------

16

-

ELECTRICAL

PARTS

LOCATION

-:-:::ceccececeeeeeeteeeeeeneees

18

BLOCK:

DIAGRAM

2-:

seeds

eseeonseseocue

ttesseiag

sence

ecesce

vat

eecoess

20

ITEM

PAGE

SCHEMATIC

DIAGRAM

(MAIN/POWER

SUPPLY

SECTION)

----:++seereeeeeeeees

22

CIRCUIT

BOARDS

(MAIN/POWER

SUPPLY

CIRCUIT

BOARD)

----+-----

25

SCHEMATIC

DIAGRA

(dbx

SECTION)

---:-e:ceceseecee

eee

eeeeteeeeeeenteeneeeseereeeees

29

SCHEMATIC

DIAGRAM

(FL

METER

SECTION)

--c-eecceeeeece

eet

eceeseeeeeeeea

seen eres

30

CIRCUIT

BOARDS

(dbx/FL

METER

CIRCUIT

BOARD)

----:++-esreerrereees

31

WIRING

CONNECTION

DIAGRAM

.--eeeeeeeeeeeeeeeeneeer

tenes

33

CABINET

PARTS

LOCATION

<0:

-e:-sseececeeeeee

teste

eeeereeeaees

35

MECHANICAL

PARTS

LOCATION

-evcececcecececeteeeteeeeenee

37

MOTOR

UNIT

DISASSEMBLY

------:ereeceeteereeet

eee

eeteeea

ees

40

PRECAUTIONS

FOR

MECHANISM

UNIT

ASSEMBLY

----

40

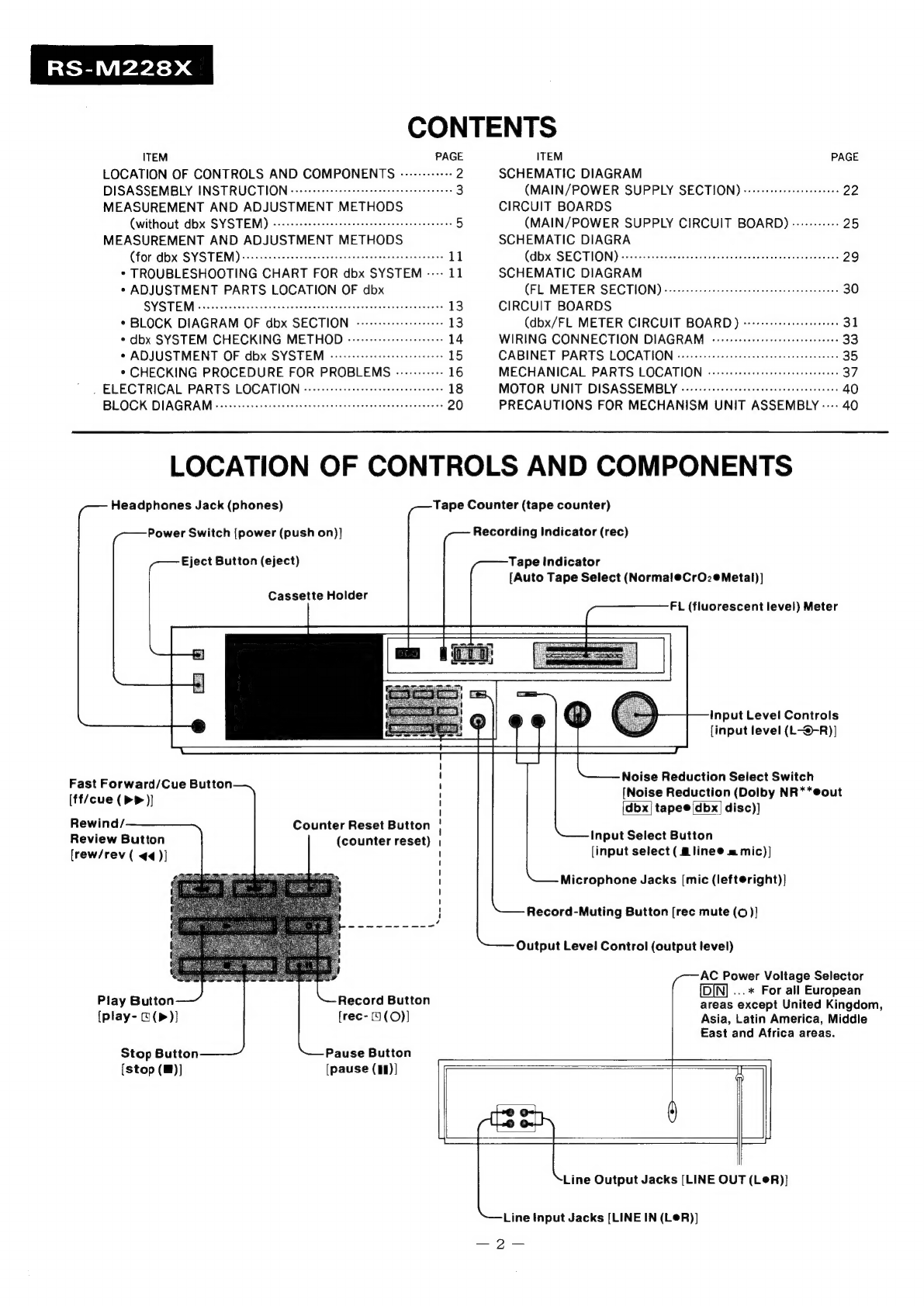

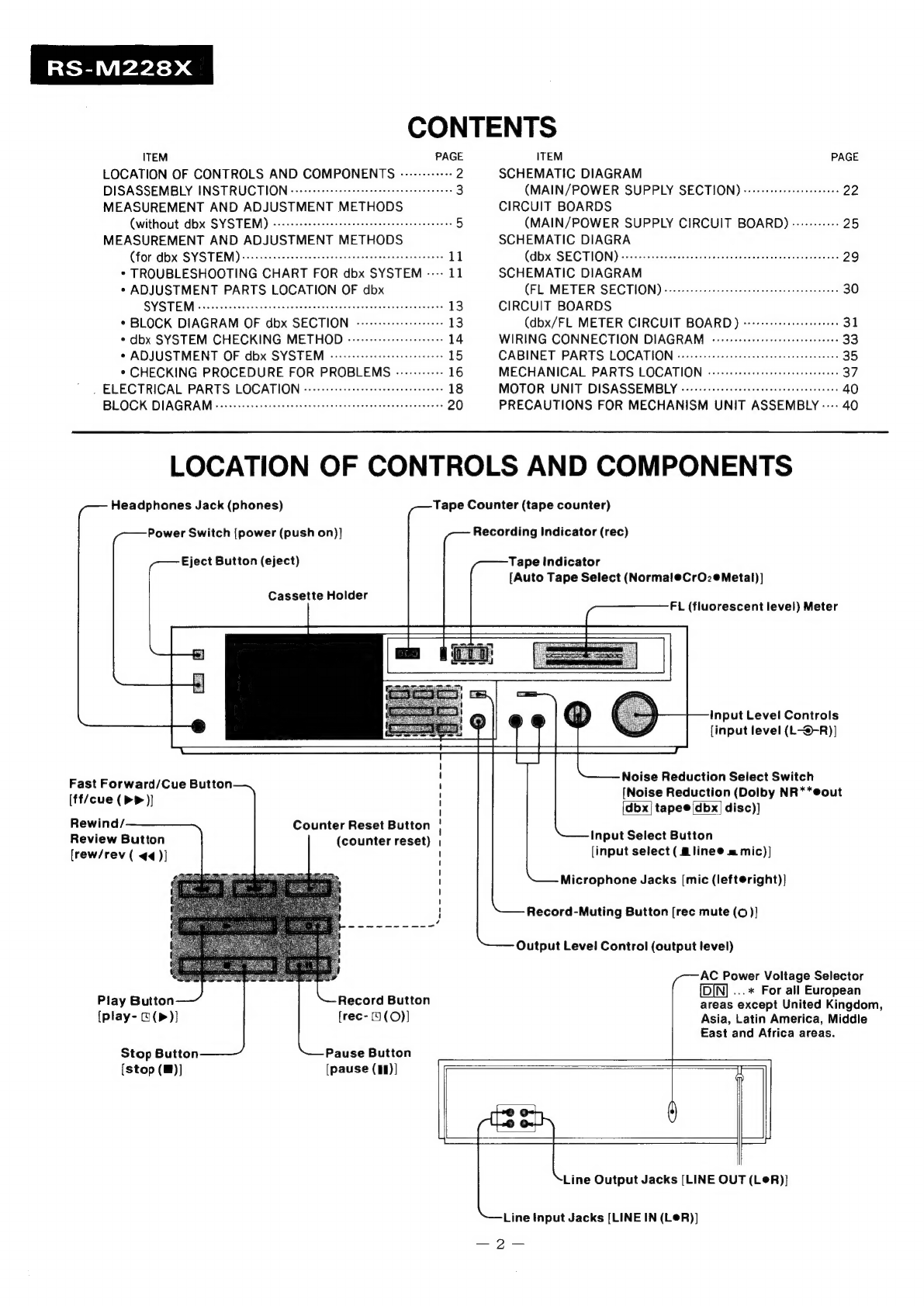

LOCATION

OF

CONTROLS

AND

COMPONENTS

Headphones

Jack

(phones)

Power

Switch

[power

(push

on)}]

Eject

Button

(eject)

Cassette

Holder

Tape

Counter

(tape

counter)

Recording

Indicator

(rec)

Tape

Indicator

[Auto

Tape

Select

(NormaleCrOzeMetal)]

FL

(fluorescent

level)

Meter

Input

Level

Controls

[input

level

(L-®-R)]

Noise

Reduction

Select

Switch

[Noise

Reduction

(Dolby

NR**eout

dbx]

tapee

(dbx|

disc)]

Fast

Forward/Cue

Button

[ff/cue

(>>

)]

Rewind/

Review

Button

{rew/rev

(

¢4)]

i}

i)

1

t

i}

1

Counter

Reset

Button

i

(counter

reset)

|

Input

Select

Button

i}

i]

i}

I

i}

!

!

i

¢

[input

select

(

@linee

=

mic)]

Microphone

Jacks

[mic

(left@right)]

Record-Muting

Button

[rec

mute

(0))

Output

Level

Control

(output

level)

(ea

he

Power

Voltage

Selector

[DIN]

...*

For

all

European

areas

except

United

Kingdom,

Asia,

Latin

America,

Middle

East

and

Africa

areas.

0

Record

Button

{rec-

9

(O)]

Play

Button

(play-

G(P))

Pause

Button

[pause

(1)]

Stop

Button

[stop

(@)]

;

Line

Output

Jacks

(LINE

OUT

(LeR)]

Line

Input

Jacks

[LINE

IN

(Le@R)]

—>

2

=—