Technics SLD210 User manual

Other Technics Turntable manuals

Technics

Technics SL-1210GAE User manual

Technics

Technics SL-1500C User manual

Technics

Technics SL-DD33 - SERVICE User manual

Technics

Technics SL-1200MK7 User manual

Technics

Technics SL-1200 User manual

Technics

Technics SL-100C User manual

Technics

Technics SL-BD22 User manual

Technics

Technics SL-12000MK2 User manual

Technics

Technics SL-J300R User manual

Technics

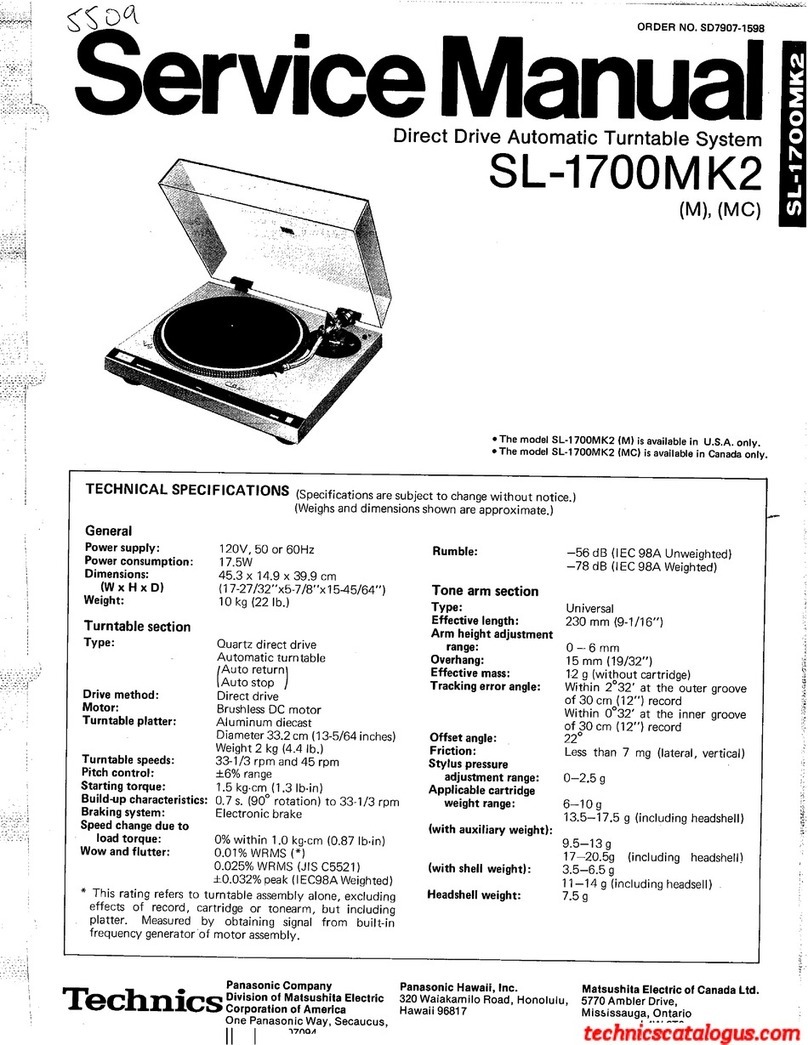

Technics SL-1700MK2 (M) User manual

Technics

Technics SL-1500 User manual

Technics

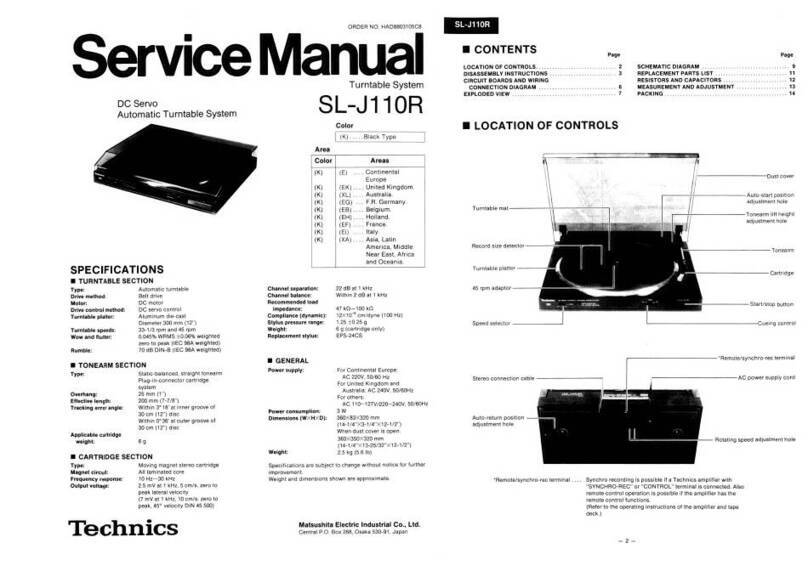

Technics SL-J110R User manual

Technics

Technics SL-1500 User manual

Technics

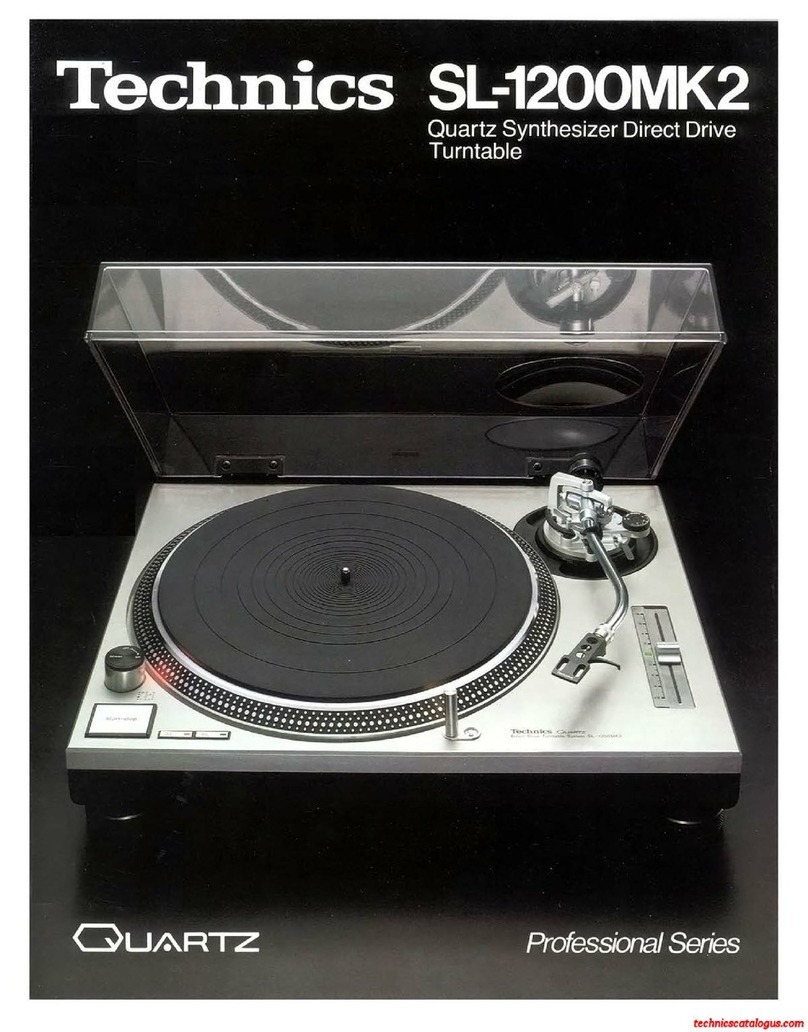

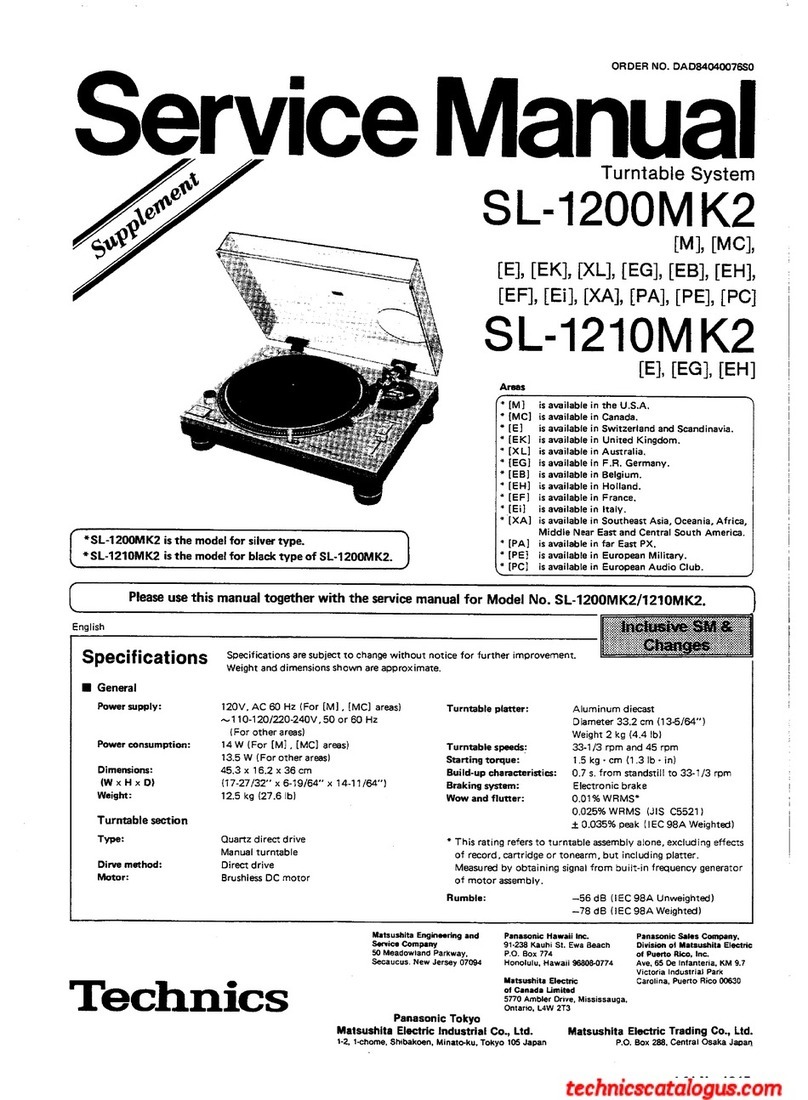

Technics SL-1200MK2 Operating manual

Technics

Technics SL-1200MK2 User manual

Technics

Technics SL-1200G User manual

Technics

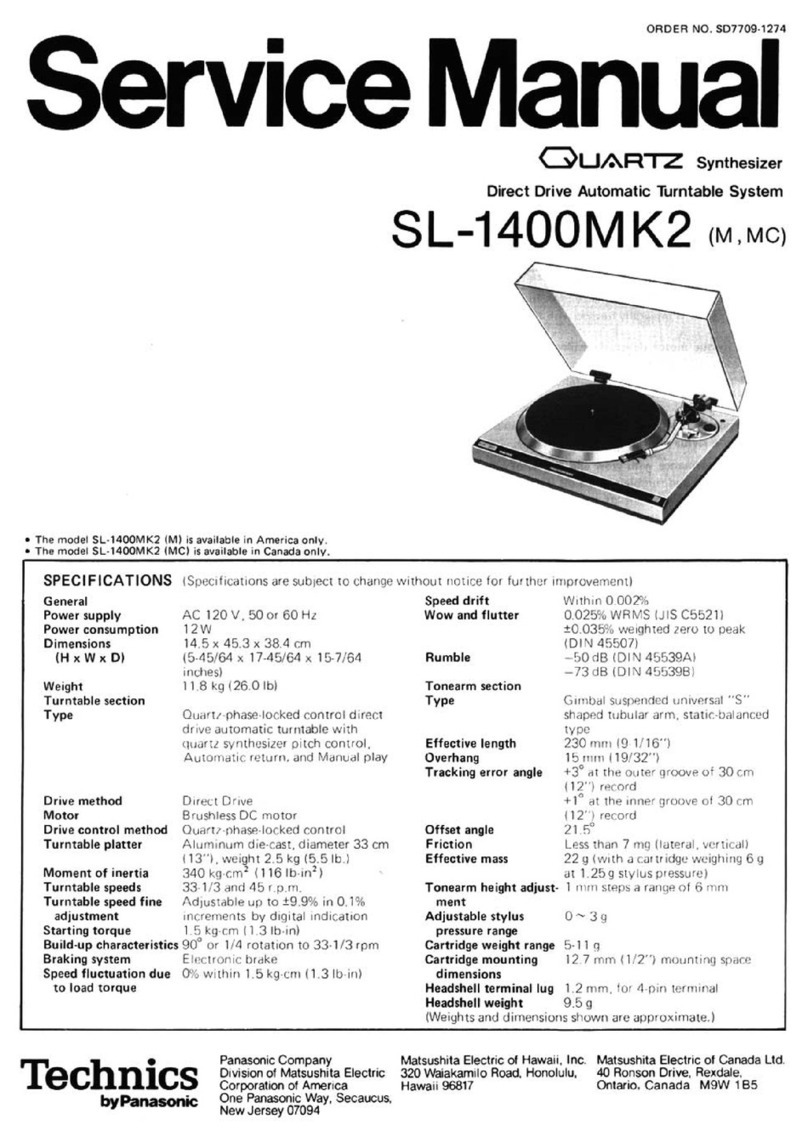

Technics SL-1400MK2 User manual

Technics

Technics SLDZ1200 - SD/CD D/D TURNTABLE User manual

Technics

Technics SL-1200GLD User manual

Technics

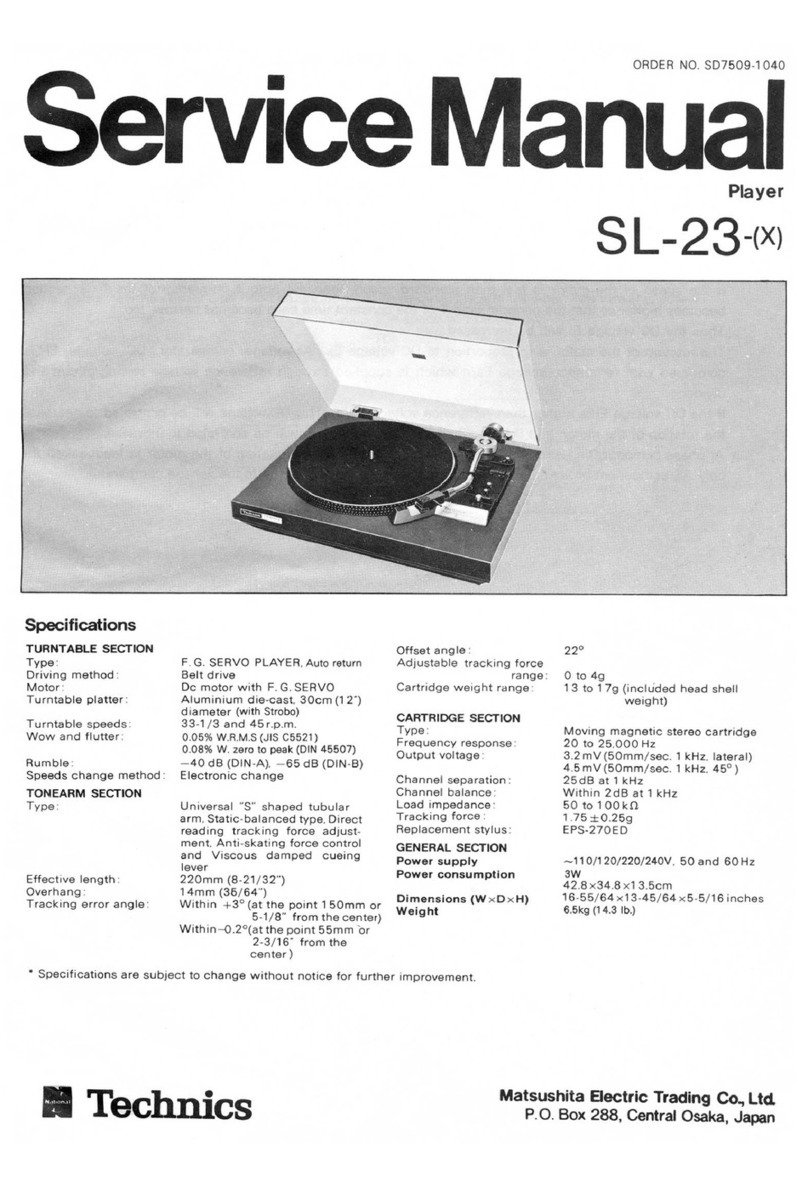

Technics SL-23X User manual