Pioneer QuartzPLL PL-540 User manual

Other Pioneer Turntable manuals

Pioneer

Pioneer PL-L1000 User manual

Pioneer

Pioneer PL-530 User manual

Pioneer

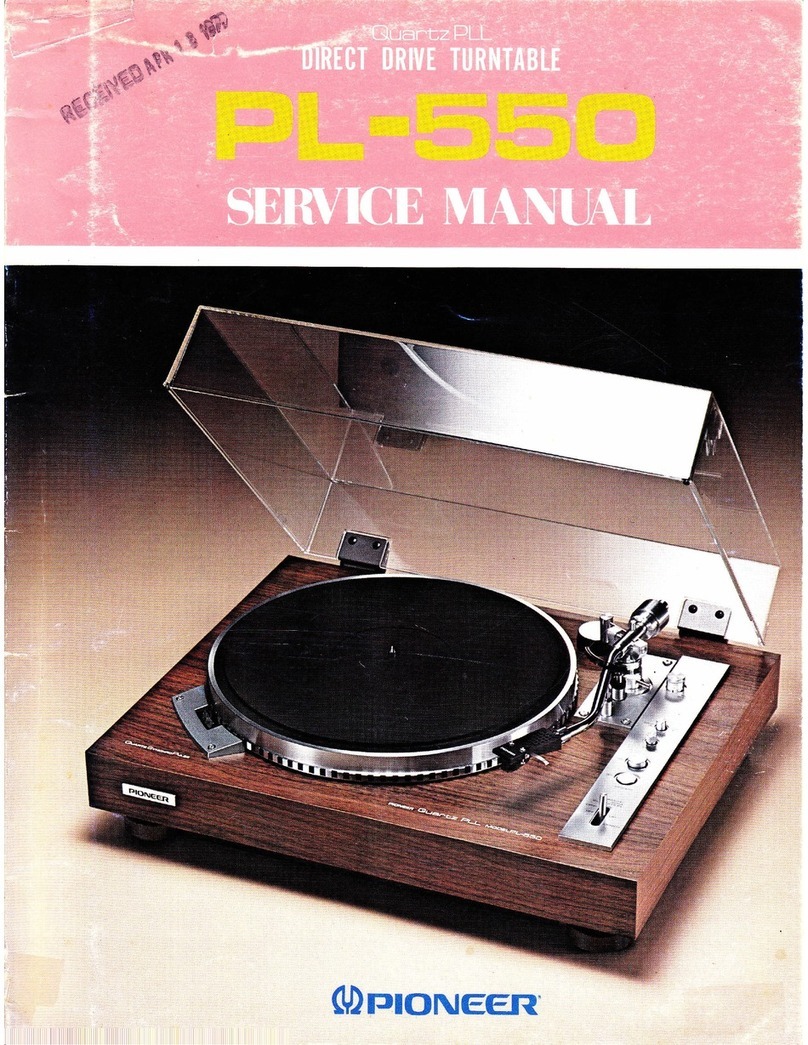

Pioneer PL-550 User manual

Pioneer

Pioneer PL-600 User manual

Pioneer

Pioneer LD-1100 User manual

Pioneer

Pioneer PL-516 KCT User manual

Pioneer

Pioneer PL-5 User manual

Pioneer

Pioneer LD-V4300D User manual

Pioneer

Pioneer PL-117D User manual

Pioneer

Pioneer PL-512 User manual

Pioneer

Pioneer PL-6 User manual

Pioneer

Pioneer PL-707 User manual

Pioneer

Pioneer PL-514 User manual

Pioneer

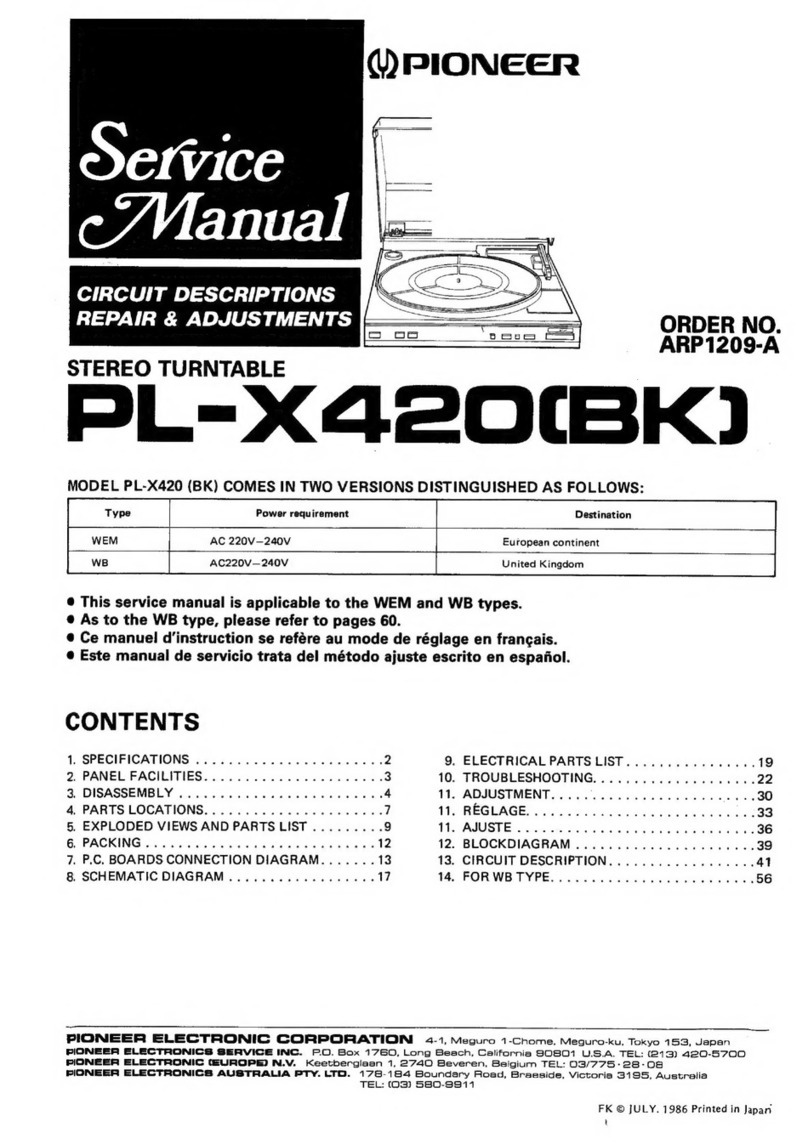

Pioneer PL-X420 User manual

Pioneer

Pioneer RX-510 User manual

Pioneer

Pioneer PL-560 User manual

Pioneer

Pioneer PL-Z94 User manual

Pioneer

Pioneer PL-71 User manual

Pioneer

Pioneer PL-570 User manual

Pioneer

Pioneer PLX-1000 User manual