ORDER

NO.

SD81041862C8

-

Service

Manual

Direct

Drive

Automatic

Turntable

System

Areas

oL-DL1

[E],

[EK],

[XL],

[EB],

[EF],

[EG],

[El],

[EH],

[XA],

[XM]

SL-DL1(k)

[E],

[XL],

[EG],

[EH],

[XA],

[XM]

*

[E]

is

available

in

Switzerland

and

Scandinavia.

7]

Bo)

@

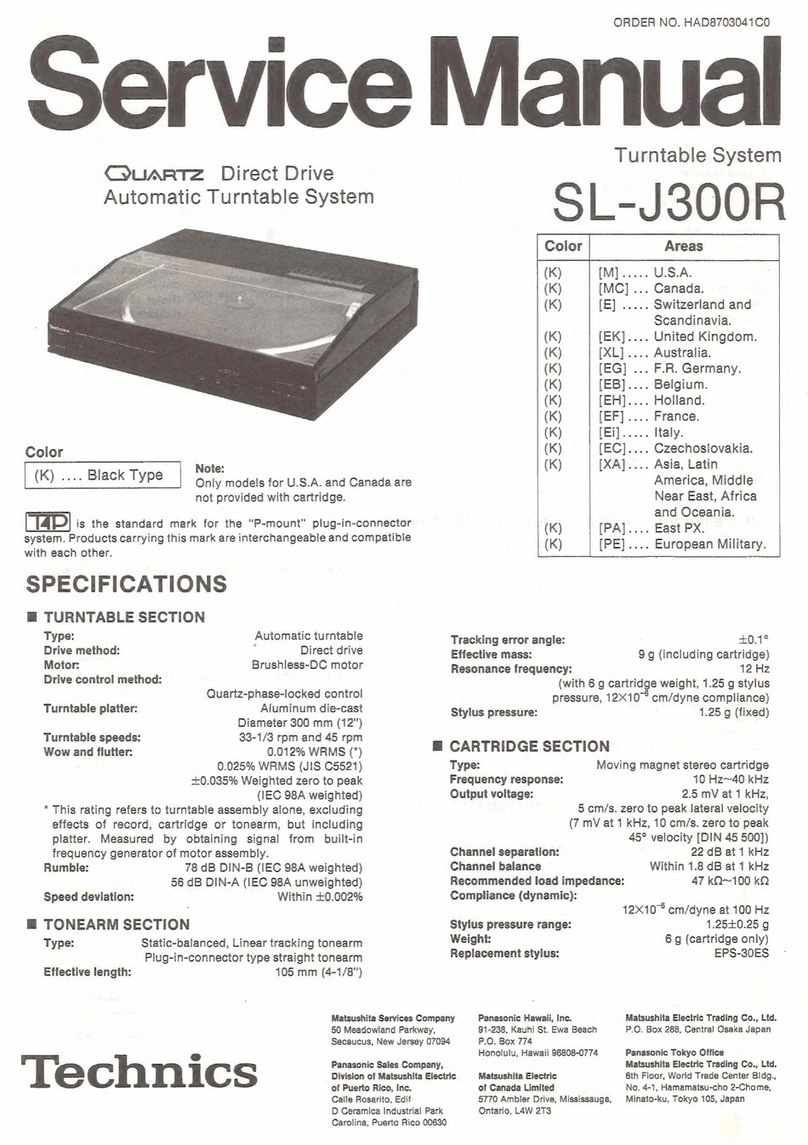

Cartridge

section

Type:

Magnet:

Magnetic

circuit:

F

requency

response:

Output

voltage:

Deutsch

TECHNISCHE

DATEN

@

Allgemeine

Daten

Moving

magnet

stereo

cartridge

One

point

suspension

system

Samarium

cobalt

(Sm-Co)

All

laminated

core

10

Hz

to

35

kHz

20

Hz

to

10

kHz

+

1dB

2.5

mV

at

1

kHz,

5cm/s.

zero

to

peak

lateral

velocity

(7

mV

at

1

kHz,

10cm/s.

zero

to

peak

45°

velocity

[DIN

45

500]

)

Channel

separation:

Channel

balance:

Recommended

load

impedance:

Compliance

(dynamic):

Stylus

pressure

range:

Weight:

Replacement

stylus:

Anderungen

der

technischen

Daten

vorbehalten.

More

than

22

dB

at

1

kHz

Within

1.8

dB

at

1

kHz

47

kQ

~100kQ

12x

10°

cm/dyne

at

100

Hz

1.25+0.25g

(125+

2.5

mN)

6

g

(cartridge

only)

EPS-23CS

(Equivalent

replacement

stylus:

EPS-23ES)

Die

angegebenen

Gewichts-

und

Abmessungsdaten

sind

circa

Werte.

*

[EK]

is

available

in

United

Kingdom.

*

[XL]

is

available

in

Australia.

*

[EB]

is

available

in

Belgium.

*

[EF]

is

available

in

France.

*

[EG]

is

available

in

F.R.

Germany.

~

110-120/220-240V

,,

50/60

Hz

Wechselstrom

Leistungsaufnahme:

17W

Abmessungen:

43

x

8,8

x

35cm

(Bx

Hx

T)

43

x

39,7

x

35

cm

(Maximale

Hohe

bei

vollstandig

gedffnetem

Gehauseoberteil.)

Gewicht:

7,1

kg

Rumpel-Fremd-

spannungsabstand:

Rumpel-Gerausch-

spannungsabstand:

Stromversorgung:

—56

dB

(IEC

98A

unbewertet)

—78

dB

(IEC

98A

bewertet)

*

[E11]

is

available

in

Italy.

*

(EH]

is

available

in

Holland

*

[XA]

is

available

in

East

South

Asia,

Oceania,

Africa,

Middle

Near

East

and

Central

South

America.

*

[XM]

is

available

in

Central

South

America.

*

The

colors

of

this

model

include

silver

and

black.

*The

black

type

model

is

provided

with

(K)

in

the

Service

Manual.

@

Tonarm

Typ:

Dynamisch

ausbalancierter

Tangential-Tonarm

mit

Kardan-

English

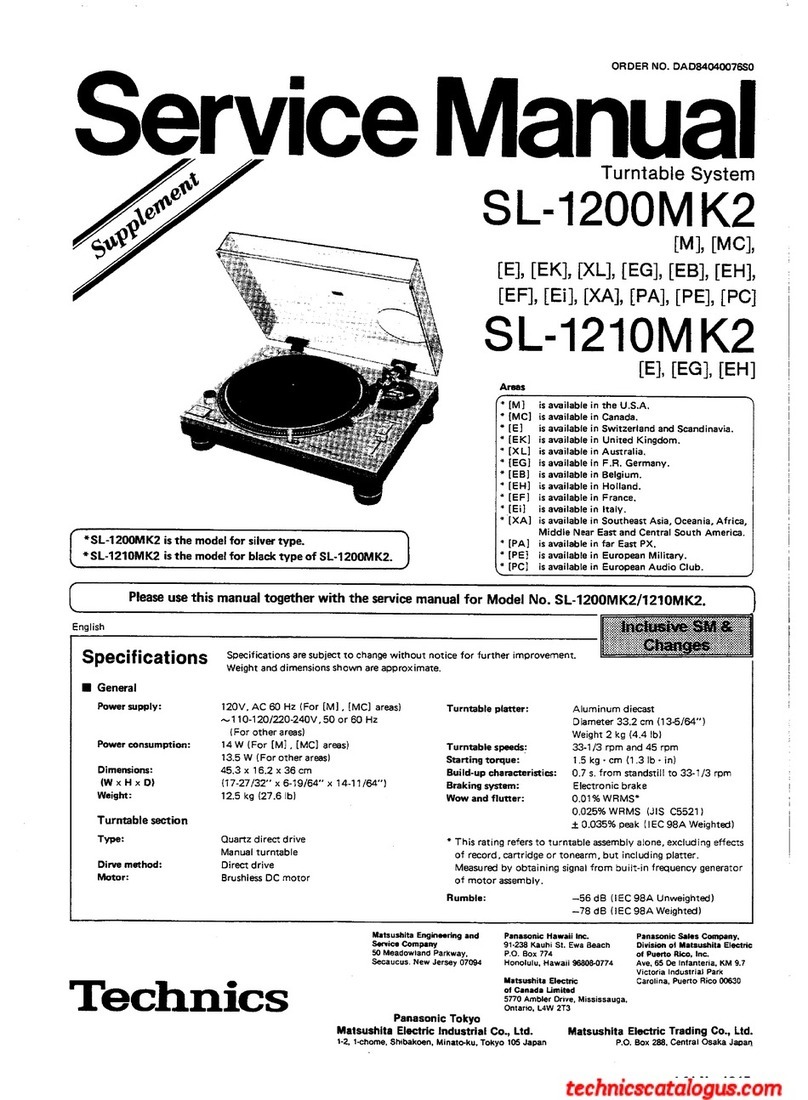

Specifications

@

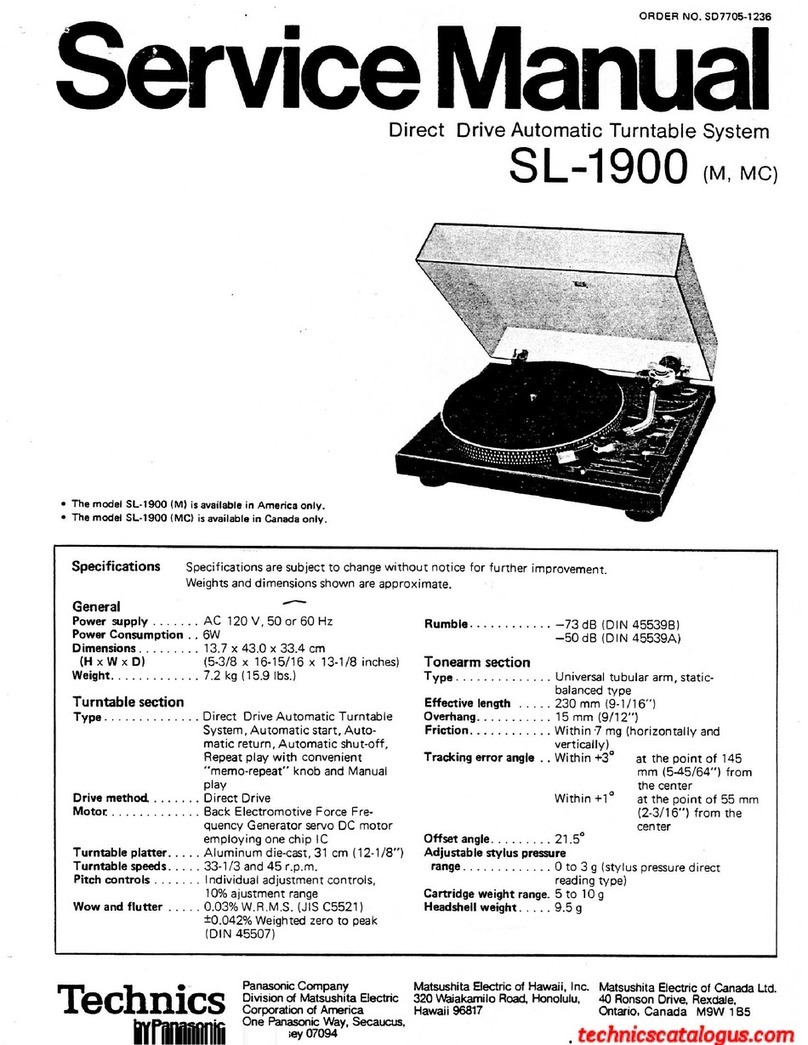

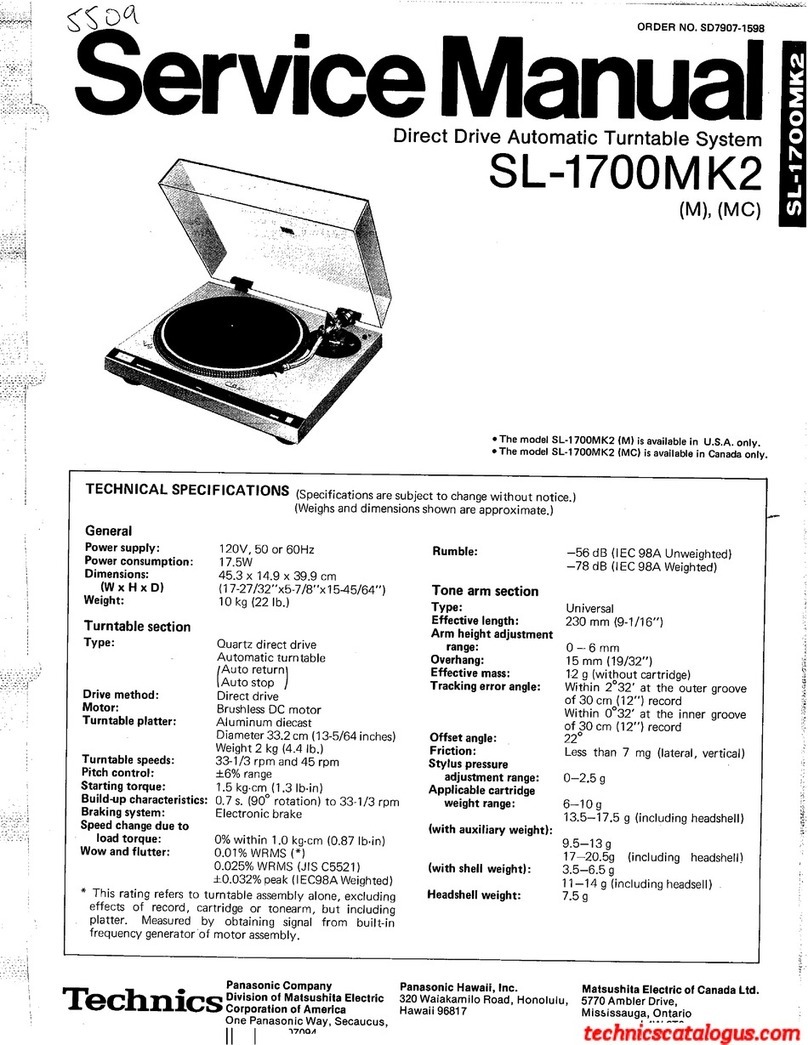

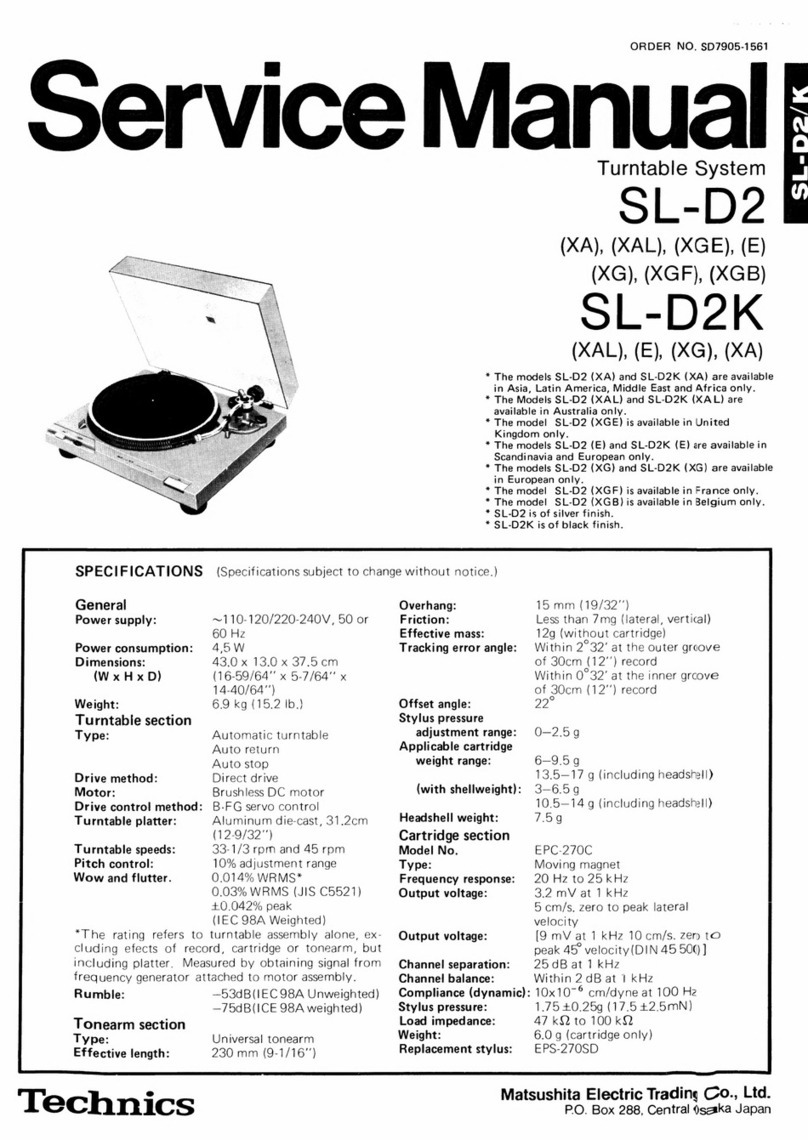

General

Power

supply:

Power

consumption:

Dimensions:

(Wx

Hx

D)

Weight:

@

Turntable

section

Type:

Drive

method:

Motor:

Drive

method:

Turntable

platter:

Specifications

are

subject

to

change

without

notice

for

further

improvement.

Weight

and

dimensions

shown

are

approximate.

~110-120/220-240V

,

50/60

Hz

17W

43

x

8.8

x

35cm

43

x

39.7

x

35cm

(Maximum

height

when

top

(dust

cover)

is

open.)

7.1

kg

(15.6

Ib.)

Automatic

turntable

Auto

start/Auto

lead-in

Auto

return

Auto

stop

Repeat

play

Auto

speed

select

Manual

speed

selection

possible.

Auto

size

select

2-speed

search

functions

Record

presence

detection

Direct

drive

Brushless

DC

motor

F.G.

servo

control

Aluminum

die-cast

Diameter

31.2

cm

Technics

Turntable

speeds:

Pitch

control:

Wow

and

flutter:

33-1/3

rom

and

45

rpm

Auto

speed

select

(Manual

selection

possible)

10%

adjustment

range

0.012%

WRMS*

0.025%

WRMS

(JIS

C5521)

+

0.035%

peak

(IEC

98A

Weighted)

*

Measured

by

obtaining

signal

from

built-in

frequency

generator

of

motor

assembly.

Rumble:

@

Tonearm

section

Type:

Effective

length:

Tracking

error

angle:

Effective

mass:

Resonance

frequency:

Tonearm

drive

motor:

Matsushita

Electric

Trading

Co.,

Ltd.

PO.

Box

288,

Central

Osaka

Japan

—56

dB

(IEC

98A

Unweighted)

—78

db

(IEC

98A

Weighted)

Dynamic

balanced

type

Linear

tracking

tonearm

4-pivot

gimbal!

suspension

10.5

cm

(4-1/8")

Within

+

0.1°

9

g

(including

cartridge)

12

Hz

DC

motor

@

Plattenspieler

Typ:

Antrieb:

Motor:

Antriebsregel-Methode:

Plattenteller:

Plattenteller-

Drehzahlen:

Drehzahl-

Feinregulierung:

Gleichlaufschwan-

kungen:

Automatischer

Plattenspieler

Auto-Start/Auto—Zufthrung

Ruck

filhrautomatik

Stopp-Automatik

Wiederhoi-Betrieb

Automatische

Drehzahlwahl

Manuelle

Orehzahlwah!

mdglich

2-Geschwindigkeiten-

Suchfunktionen

Plattenprasenz-Registrierung

Direktantrieb

Kollektorloser

Gleichstrommotor

FG-Servo-Steuerung

Aluminium-Druckgu

Durchmesser

31,2

cm

33-1/3

und

45

U/min

Automatische

Drehzahlwahl

(manuelle

Wahl

mdéglich)

10%

Einstellbereich

0,012%

WRMS*

0,025%

WRMS

(JIS

C5521)

+

0,035%

Spitze

(IEC

98A

bewertet)

*

Gemessen

anhand

von

Signalen

vom

eingebauten

Frequenzgenerator

des

Motorbauteils.

Effektive

Lange:

Spurfehlwinkel:

Effektive

Masse:

Resonanzfrequenz:

Tonarm-Antriebsmotor:

@

Tonabnehmer

Typ:

Magnet:

Magnetkreis:

Frequenzgang:

Ausgangsspannung:

Kanaltrennung:

Kanalabweichung:

Empfohlene

Endimpedanz:

Nachgiebigkeit

(dynamisch):

Auflagekraft-

Einstellbereich:

Gewicht:

Ersatznadel:

aufhangung

mit

4-Punkt-Drehlager

105

mm

Innerhalb

+

0,1°

9g

(einschlieRlich

Tonabnehmer)

12

Hz

Gleichstrommotor

Stereo-Magnet-Tonabnehmer

mit

Einpunkt-Aufhangungssystem

Samarium-Kobalt

(SM-Co)

Ganzlamellenkern

10

Hz

bis

35

kHz

20

Hz

bis

10

kHz+

1dB

2,5

mV

bei

1

kHz

5

cm/s.

Null-zu-Spitze,

lateral

(7

mV

bei

1

kHz

10

cm/s.

Null-

zu-Spitze,

45°

[DIN

45

5001)

Mehr

als

22

dB

bei

1

KHz

Innerhalb

1,8

dB

bei

1

kHz

47

kQ.

~

100k

12

x

10°

cm/dyn

bei

100

42

1,25+

0,259

(12,5

+

2,5rmN)

6

g

(nur

Tonabnehmer)

EPS-23CS

(Gleichwertige

Ersatznadel:

EPS-23ES)