Technics SL-Q303 User manual

Other Technics Turntable manuals

Technics

Technics SL-1600MK2 User manual

Technics

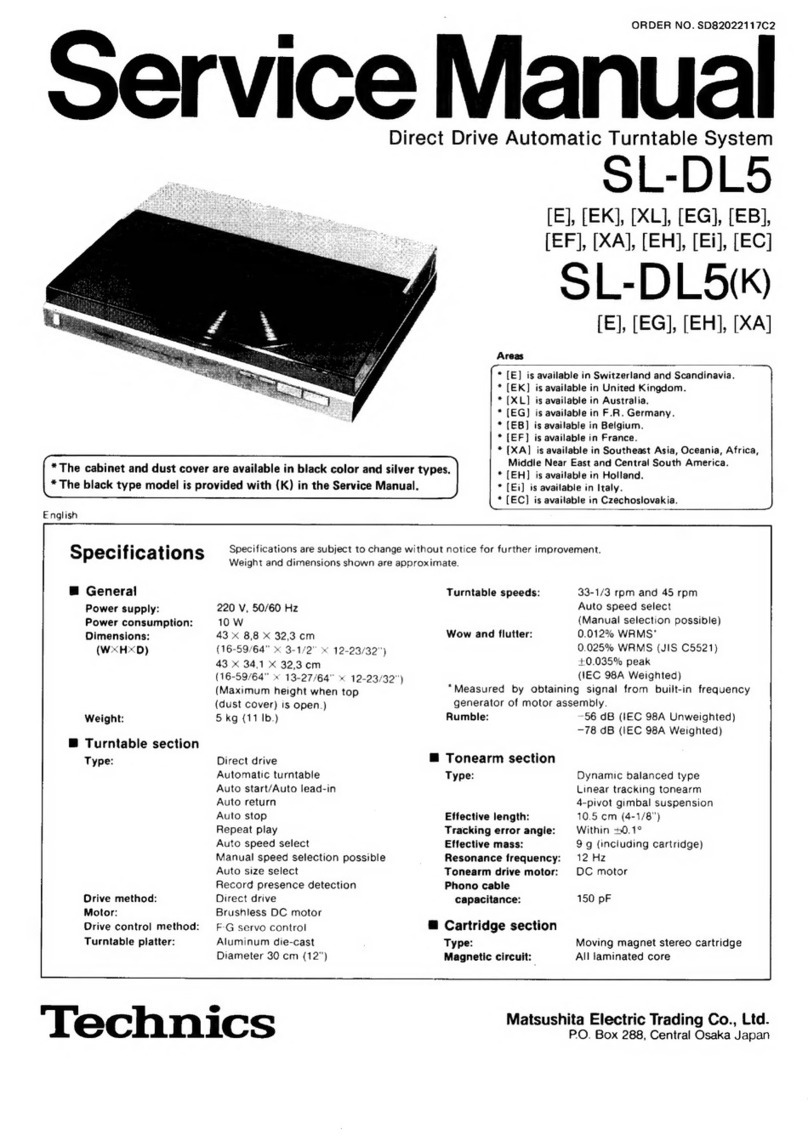

Technics SL-DL5 User manual

Technics

Technics SL-1200MK5GT User manual

Technics

Technics SL-1900 (MC) User manual

Technics

Technics SH-1000R User manual

Technics

Technics SL-1200MK2 User manual

Technics

Technics SL-D202 User manual

Technics

Technics SL-1300MK2 User manual

Technics

Technics SL-1200LTD User manual

Technics

Technics SL-1200MK2 User manual

Technics

Technics SL-B200 User manual

Technics

Technics SL-1650 User manual

Technics

Technics SL-1200MK2 Operating manual

Technics

Technics SL-D303 User manual

Technics

Technics SL-7 User manual

Technics

Technics SL-1200G-S User manual

Technics

Technics SL-Q33 User manual

Technics

Technics SL-1200GR2 User manual

Technics

Technics SL-QL15 User manual

Technics

Technics SL-1300MK2 User manual