Technogel Mixpasto 60 Operation instructions

Page 1 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

1

CODE: xxxxxxxx EN

USE AND MAINTENANCE INSTRUCTIONS

Model: MIXPASTO 60/120

Serial No.: 00

Year of manufacture: 2013

Conformity:

TECHNOGEL SpA

Via Boschetti n°51

24050 GRASSOBIO (BG) –Italy

Tel. (+39) 035-4522062

Fax (+39) 035-4522682

www.technogel.com

Page 2 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

2

INDEX

1 GENERAL WARNINGS AND STANDARDS

2 TECHNICAL FEATURES AND DATA

3 INSTALLATION

4 FUNCTIONING AND USE

5 USER INSTRUCTIONS

6 ROUTINE AND EXTRAORDINARY MAINTENANCE

7 DIAGNOSIS

8 ATTACHED DOCUMENTATION

1 - GENERAL WARNINGS

1.1 INTRODUCTION

The machine described in this manual is intended for professional use and must not be considered

as a household appliance: therefore, personnel in charge must be adequately trained.

Read the entire instructions manual before operating on the machine, in order to protect the operator and

avoid damaging the machine.

This manual must be fully integral and legible. All operators in charge of using the machine, the maintenance

or adjustment manager must know its location and be able to consult it at any moment.

TECHNLOGEL SpA reserves all reproduction rights for this manual.

This manual cannot be transferred to third party without TECHNOGEL SpA written authorisation.

The text cannot be used in other print-outs without TECHNOGEL SpA written authorisation.

The description and illustrations in this manual are not binding.

TECHNOGEL SpA reserves the right to make any changes it considers opportune.

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA

ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

This manual was edited in accordance with Machinery Directive 2006/42/EC requirements.

1.2 METHODS OF CONSULTATION OF THE MANUAL

1.2.1 Structure of the manual

The manual is divided into chapters gathering all the necessary information for using the machine without

risks.

Each chapter is divided into paragraphs containing essential points. Each paragraph may have clarifications

entitled with a subtitle and a description.

Page 3 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

3

Each chapter has a right page that recalls the number and title of the chapter.

A chapter, for example chapter 1, contains:

1 Heading of the chapter

1.1 Title of the paragraph

1.1.1 Heading of the subtitle

1.1.1.1 Any additional subtitle

The numbering of the figures and tables is reset at every chapter, therefore the progressive prefix indicating

the chapter and the number of the figure or table restarts from 1 at the beginning of each chapter.

1.2.2 Description of pictograms

The following symbols are used in the manual to highlight particularly significant indications and warnings:

ATTENTION:

This symbol shows accident-prevention standards for the operator and/or for any exposed people.

WARNING:

This symbol shows the existence of the possibility of damaging the machine and/or its components.

NOTE: This symbol provides useful information.

1.3 WARRANTY

The TECHNOGEL SpA manufactured machines are covered by WARRANTY, as provided by the general

selling conditions. In the event that defective or faulty machines parts are found during the validity period,

and when these parts are covered by the warranty, TECNOGEL SpA will repair or replace the part only after

having checked it with the distributor from whom the machine was purchased.

TECHNOGEL SpA considers itself responsible for the machine in its original configuration.

All interventions modifying the structure and functioning cycle of the machine must be expressly authorised

by TECHNOGEL SpA only.

All technical modifications affecting the functioning or safety of the machine must only be carried out by the

manufacturer's technical personnel or by its officially authorised technicians. If this is not the case,

TECHNOGEL SpA declines any liability for changes or damages that may derive there from.

TECHNOGEL SpA declines any liability for the machine improper use, for damages caused by operations

not addressed in this manual or unreasonable.

1.4 ARRANGEMENTS BY THE CUSTOMER

Detailed operating instructions are provided in chapter 3 of this manual (INSTALLATION).

A simple list of the arrangements by the customer is provided herein.

Except for specific contractual agreements, the following are the customer's responsibility:

- arrangement of premises (including masonry work, foundations or any requested channelling, etc.);

- arrangement of the place of installation and machine installation;

- arrangement of adequate auxiliary services for system requirements (e.g. water, electric mains, etc.);

Page 4 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

4

R

24050 Grassobbio (BG) - ITALY

Website: www.technogel.com

Tel.: +39 035 4522062 - Fax: +39 035 4522682

ICE CREAM EQUIPMENT AND MACHINES

Via Boschetti, 51

E-mail: [email protected]

TIPO MACCHINA / Machine Type: MATRICOLA N° / Serial Number:

ANNO / Year:

ALIMENTAZIONE / Source:

QUANTITA' GAS / Gas Quantity:GAS FRIGORIGENO / Refrigerant:

CORRENTE P. C. / Full Load Current:

POTENZA / Power:

- any upstream and downstream safety devices of the energy power supply lines (such as residual-current

devices, earthing systems, safety valves, etc.) provided by the legislation in force in the country of

installation;

- tools and consumption materials required for assembly and installation;

- materials, tools and equipment required for any machine acceptance tests.

1.5 DECLARATION OF CONFORMITY

Attached to this manual.

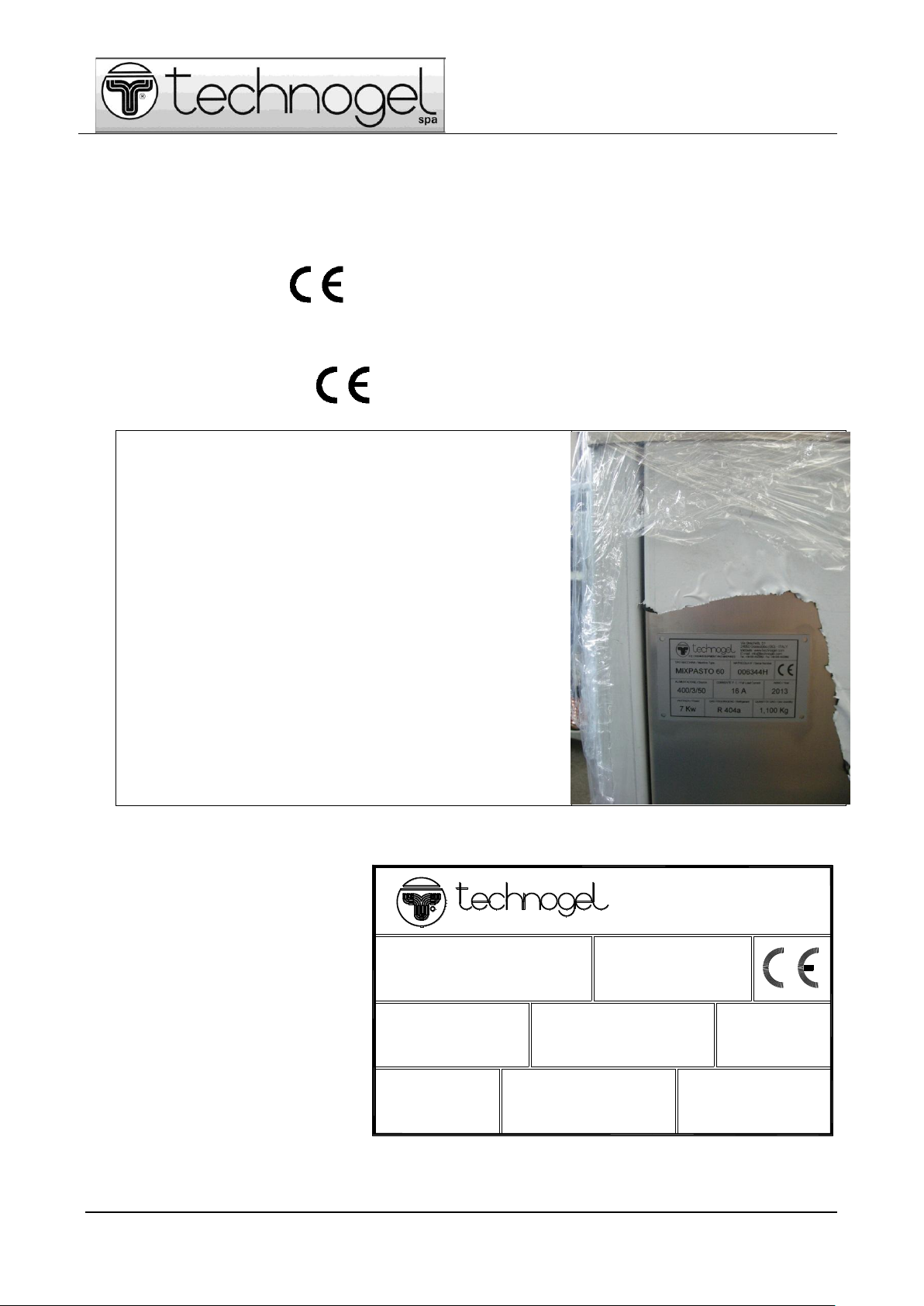

1.5.1 Identification plate

This machine is manufactured in an EU country and must,

therefore, meet the safety requirements of Machinery

Directive 2006/42/EC in force since 29 December 2009.

The EC Declaration of Conformity is attached to this

document.

This conformity is certified and the machine has the "EC"

marking on the support structure, as shown in figure 1-1.

The EC marking and data plate must not be removed or

damaged. It shows the data indicated in fig. 1-2:

Fig. 1-1 –Plate position

Fig. 1-2 –Data on the plate

Page 5 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

5

1.6 INSTRUCTION FOR REQUESTING ASSISTANCE

Always state the following data whenever contacting the assistance centre:

- type of machine;

- serial number;

- year of manufacture;

- when possible, specify the nature of the detected machine problem or defect, e.g.: electric, mechanical

nature or in terms of processing quality.

Contact the technical assistance service through your area dealer or use the details in par. 2.2.

1.7 MACHINE DESCRIPTION

The MIXPASTO 60/120 PASTEURISER machine pasteurises mixes for ice cream by heating the products at

85° for high pasteurisation and break-down everything in the least possible time at 4°C.

The mix must then be preserved at 4°C to 6°C for the entire period of use that can be at a maximum of 72h.

The products are mixed during the process by means of a stirrer in tank that, based on the stirrer speeds

and shapes, favours the thermal exchange, gives consistency and different softness to the finished products.

The pasteurisation temperature can be lowered to 65°C depending on the ingredients, proportionally

extending the maintenance times to the temperature (low pasteurisation).

The machine consists of a 60 or 120 l tank protected by a transparent lid. The tank contains a motor-driven

stirrer and a pick-up cock on the bottom.

The machine heats the product through the circulation of a water and glycol mix heated at an adequate

temperature in a copper coil wrapped on the tank's outer surface. Cooling is through the circulation of freon

gas in another copper coil also wrapped on the tank's outer surface.

The water and glycol mix is heated by an armoured heater in a boiler and is pushed by a pump in the closed

circuit.

The water and glycol mix is pressurised in the circuit having an expansion vessel and safety valve (max 0.7

bar). The glycol temperature is electronically controlled by a safety thermostat that interrupts the heaters'

power supply if a safety temperature is exceeded (max 120°C).

Opening the lid interrupts stirring, isolating the motor's power supply, the heating/cooling and the glycol

circulation. The machine is ready to restart when the lid is closed. Opening the lid causes one or more

magnets to move away from the relative magnetic sensor that, in turn, switches off the relay and relative

contactors.

1.8 OPERATORS' QUALIFICATION

The operators and maintenance technicians in charge of machine functioning or maintenance must have the

specific professional requirements for every provided operation.

They must be trained and aware of the tasks entrusted to them.

WARNING

All technical modifications affecting the functioning or safety of the machine must only be

carried out by the manufacturer's technical personnel or by its officially authorised

technicians. On the contrary, TECHNOGEL SpA declines any liability for changes or damages

that may derive there from.

Page 6 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

6

2 - TECHNICAL FEATURES AND DATA

2.1 TECHNICAL FEATURES

MIXPASTO 60

MIXPASTO 120

Dimensions and weight

Machine height

1060 mm

1060 mm

Machine length

1000 mm

1000 mm

Machine width

400 mm

640 mm

Overall weight

200 kg

275 kg

Product load with full load

60 litres

120 litres

Product load with reduced load

20 litres

40 litres

Performance/consumption

Average water consumption

300 l/h

500 l/h

Min pressure

0.15 MPa

0.15 MPa

Well water min temperature

5˚C

5˚C

Tower water max temperature

29˚C

29˚C

Cycle time with full load (*)

(*)

(*)

Tab. 2-1

(*) The value is subject to changes based on the type of processed mix, the volume, the surrounding

conditions, etc.

Electrical system

MIXPASTO 60

Power circuit

220 V

220 V

400 V

400 V

480V

Frequency

50 Hz

60 Hz

50 Hz

60 Hz

60Hz

Type of power supply

Three-

phase

Three-

phase

Three-

phase

Three-

phase

Three-

phase

Max absorbed power

7 kW

7 kW

7 kW

7 kW

7 kW

Max absorption

20 A

20 A

16 A

16 A

16 A

Section - line cable

4 x 4 mm²

4 x 4 mm²

5 x 2.5

mm²

5 x 2.5

mm²

5 x 2.5

mm²

MIXPASTO 120

Power circuit

220 V

220 V

400 V

400 V

Frequency

50 Hz

60 Hz

50 Hz

60 Hz

Type of power supply

Three-

phase

Three-

phase

Three-

phase

Three-

phase

Max absorbed power

13 kW

13 kW

13 kW

13 kW

Max absorption

35 A

35 A

24 A

24 A

Section - line cable

4 x 6 mm²

4 x 6 mm²

5 x 4 mm²

5 x 4 mm²

Page 7 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

7

Tab. 2-2

2.2 MANUFACTURER DATA

Name: TECHNOGEL SpA

Registered office: Via Boschetti n°51

24050 GRASSOBIO (BG) –Italy

Tel. 035-4522062

Fax 035-4522682

www.technogel.com

Comp. Reg. Court of Bergamo No. 12583

E.A.I. of Bergamo No. 166982

VAT No. - Tax Code IT 00709420160

2.3 CHARACTERISTICS OF THE TREATED PRODUCT

The MIXPASTO 60/120 PASTEURISER is designed for preparing bases and mixes for the production of ice

cream, which recipe is the responsibility of the machine user.

The manufacturer only prescribes that the percentage of dry product in the mix be less than 42%.

2.4 NOISE

The noise level during normal functioning must never exceed 70 db(A).

2.5 ADMITTED ENVIRONMENTAL CONDITIONS

Install the machine in closed premises with adequate micro-climate for the presence of operators and

product processing.

Avoid atmospheres polluted by vapours or gas, float dust, bacterial loads, insects or anything else that might

endanger the product's hygienic conditions or the health of operators.

The rear part of the machine must be detached from wall or other impediments for sufficient air to circulate:

leave a space of at least 50 cm.

We recommend the work environment temperature to be below + 35°C, without direct exposure to sun and

to other heat sources.

ATTENTION

The machine is not designed to function in potentially explosive atmosphere.

Its installation and use in such environments is, therefore, forbidden.

3 - INSTALLATION

3.1 GENERAL SAFETY WARNINGS

•Wear suitable protective equipment for the operations to be carried out.

Clothing must adhere to the body and resist to cleaning products.

Page 8 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

8

Avoid wearing ties, necklaces or belts that might get tangled between moving parts; wear a protective

helmet in case of lifting and transporting.

•When required, properly tie-up hair to avoid it getting tangled up between moving parts.

•Do not remove the safety devices or accident-prevention protections.

•Lift the machine and its components by carefully following the use and maintenance instructions, using an

adequate lifting mean with the utmost attention (for the weight, see paragraph 2.1 "Technical features").

•Do not dismantle machine units or parts without express authorisation and training.

•Make sure the used lifting means have an adequate capacity for the loads to be lifted and that they are in

good conditions (for the weight, see paragraph 2.1 "Technical features").

•Do not dismantle machine units or parts without express authorisation and training.

•Follow the environmental protection laws in force to dispose of the different packaging materials.

3.2 MACHINE TRANSPORT

ATTENTION

Purposely trained and authorised personnel must anchor the elements transported to the

transport mean.

WARNING:

The machine container must be protected during machine transport against atmospheric

agents using protective nylon to prevent water infiltrations and deposits on the elements in

question.

ATTENTION

The machine must be fastened to the platform or forklift truck forks using fastening

systems (belts or ropes) to avoid unbalances and falls.

The machine in question must be transported respecting the original packaging methods. It is necessary to

fasten the machine to the packaging sub-base (pallet with wooden crate) and protect the machine body

using the original packaging protections.

Where required, secure the machine container to the transport mean anchoring systems using belts with

adequate capacity to the weight to be secured.

The packaging is designed to perfectly protect the machine against impacts. Transport the packaged

machine as close as possible to the place of installation.

Insert the forks underneath the frame base of the machine where indicated to lift using forklift truck or

transpallet.

Pay the utmost attention in arranging the belts for lifting with crane or bridge-crane, in order to guarantee

machine stability during lifting; use belts with adequate capacity for insertion underneath the machine frame.

Pay proper attention in executing this operation to guarantee the required stability during machine handling.

Page 9 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

9

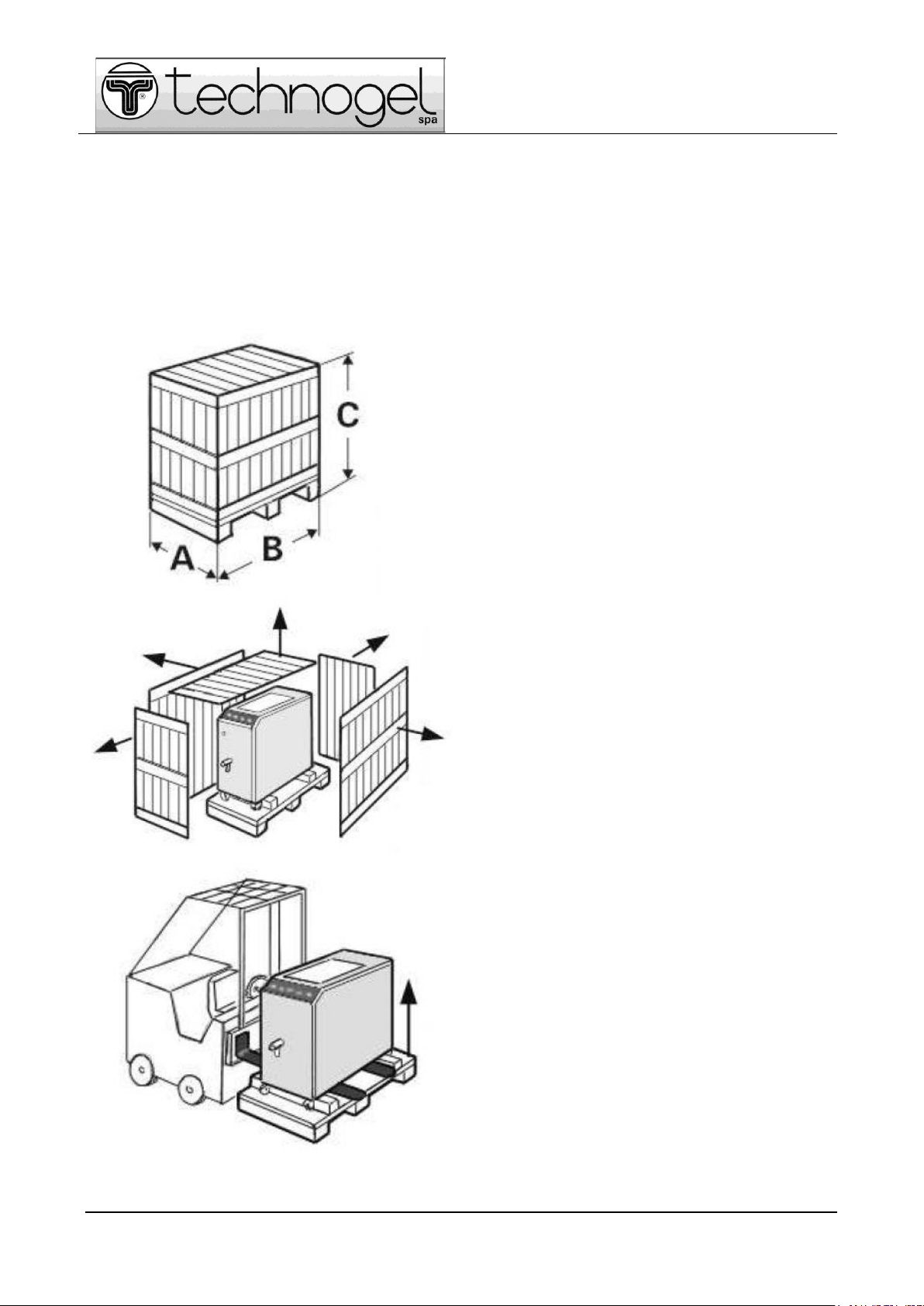

3.3 UNPACKING AND MACHINE HANDLING

Remove the packaging as follows:

MIXPASTO 60

GROSS WEIGHT = KG. 300

A = 650 mm

B = 1250 mm

C = 1600 mm

MIXPASTO 120

GROSS WEIGHT = KG. 375

A = 900 mm.

B = 1250 mm.

C = 1600 mm.

Remove all wooden side and top panels from the

packing.

Lift the machine using a fork-lift truck introducing the

lifting blades between the bottom of the machine

and the base of the crate.

Page 10 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

10

Loosen the four bolts blocking the machine from

underneath the base of the crate.

ATTENTION:

After having remove the bolts the bottom of the

crate comes away from the machine bottom.

After having removed the crate bottom, lower the lift

and deposit the machine on the ground.

The machine can be moved by holding it from the

specific handles.

THE TYPE OF WOOD USED FOR THE PACKAGING CRATE IS NATURAL FIR

WITHOUT ANY CHEMICAL SUBSTANCE, THEREFORE PERFECTLY RECYCLABLE.

MIXTPASTO 60

NET WEIGHT = KG. 200

A = 400 mm.

B = 1000 mm.

C = 1060 mm.

MIXPASTO 120

NET WEIGHT = KG. 275

A = 640 mm.

B = 1000 mm.

C = 1060 mm

Lift the machine using a fork-lift truck introducing

the lifting blades at the side of the machine,

between the front and rear wheels.

Page 11 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

11

Lift the machine using belts, holding them as in

figure near the front and rear wheels. The tie-rod

lifting the machine must position exactly at the

centre of the machine

Move the machine by holding it from the specific

handles

Once the machine is in position, block the front

wheels brakes using the feet

DO NOT USE HANDS!!

N.B.: Visually check the status of integrity. Contact the dealer or manufacturer in case of evident

damages.

Properly lift the machine from the base platform and use suitable means to extract the latter.

Careful not to damage the power supply cable. Avoid using ropes or chains that might damage the machine.

Now set the packaging materials aside and keep them for future transport.

The disposal operation is safe as the packaging is made of fully recycle material.

3.4 GENERAL NOTES ON THE FOUNDATION TECHNIQUES

The machine does not require particular foundation work. Make sure the support base where the machine

will be installed is flat, stable and able to support its weight.

It is fitted with wheels that cannot be adjusted in height; the front wheels can be blocked with brake and the

rear are swivel and cannot be blocked.

Page 12 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

12

3.5 INSTALLATION

The following rules must be respected during installation:

Placement

Place the machine onto a flat and solid surface.

Avoid the direct exposure to sunbeams and nearby heat sources.

Leave at least 50 cm of free space in front of the grids to enable the perfect functioning of the refrigeration

system.

Set-up

The machine is supplied with all its parts permanently installed.

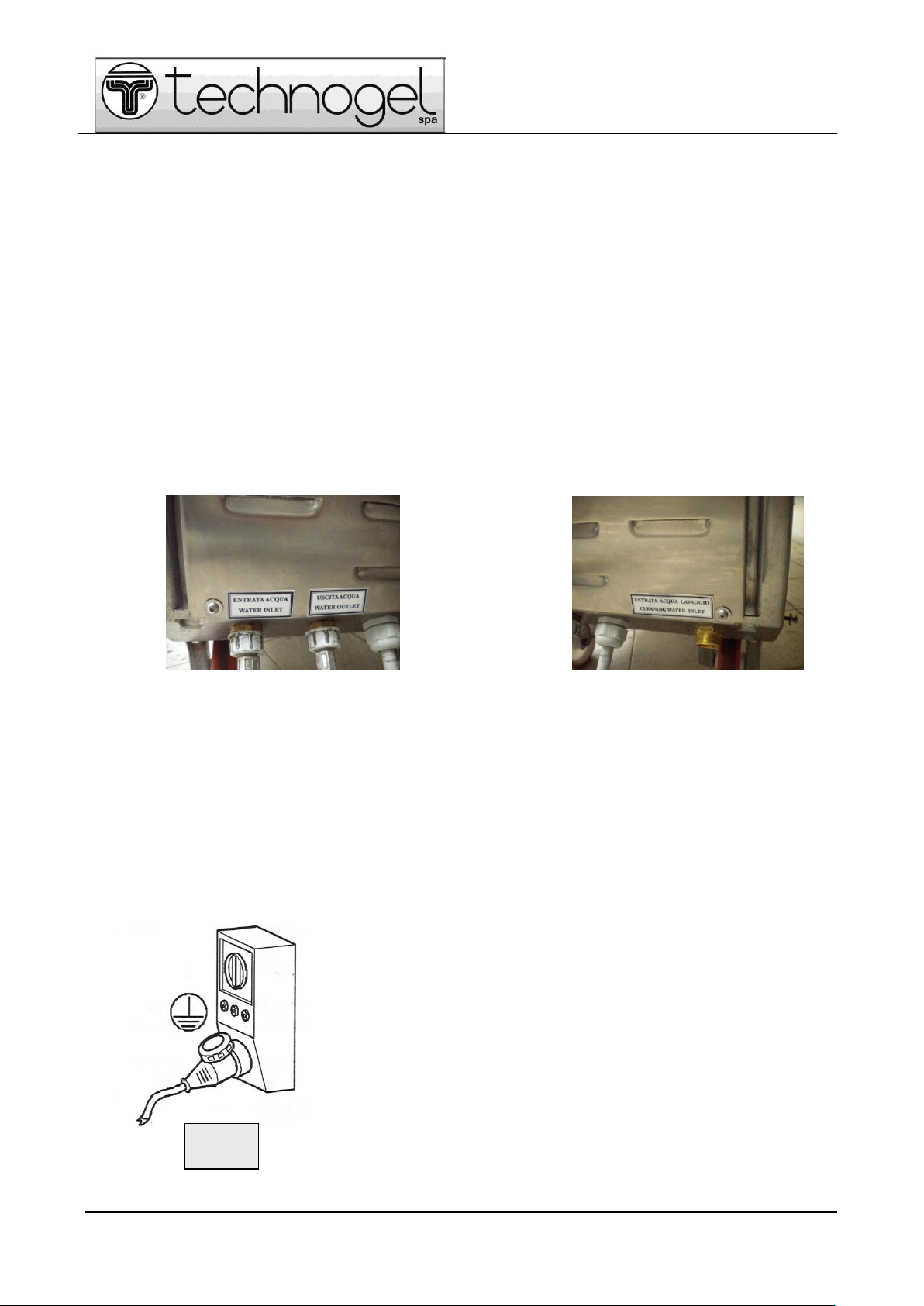

Connection to water mains

Connect the water piping of the cooling circuit to the fittings accessible from the rear of the machine and

identified by the specific wording (see Fig. 3.2a).

Use water from the well or the mains with temperature below 30°C. The guaranteed flow rate must be 500

l/h. The machine pressure valve regulates the flow of the condenser's cooling water.

Then connect the water pipe for washing hand shower (fig. 3.2b)

Fig. 3.2a Fig. 3.2b

Connection to electric mains

The power supply system must have a 5-pole socket for 3N three-phase power supply for 400 V and at 4-

poles 3F for 220 V voltages of approved type.

The current socket must be protected by a type B residual current device calibrated at 300 mA, by a circuit

breaker suitable for the currents indicated in tab. 2.1, and be equipped with earth connection.

Check the mains voltage and frequency correspond to those required by the machine, indicated on the EC

plate or technical manual.

Connect the machine using the power plug to the power supply. This must be close and easily accessible

and managed by the operator

A main switch must be provided in the socket or in an easily accessible place, that completely disconnects

voltage from the socket (isolation) and enables the interaction or execution of operations requiring access to

moving parts (see fig. 3.3.).

The electrical system for powering the machine must be perfect.

The manufacturer is not liable for inadequate power supply and

earthing system and/or non-conform to standards.

Only enabled personnel can connect the electrical parts.

Fig. 3.3

Page 13 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

13

3.6 DEMOLITION AND DISPOSAL

With regard to demolishing and disposal, remember that the materials constituting the machine are not

dangerous and mainly consist of:

- stainless steel

- copper

- plastic materials (polycarbonate, various isolators, etc.)

- refrigerant gas R404A

- glycol

- electric motors;

- electric cables with relative sheaths.

ATTENTION

Evacuate and dispose of the materials from the machine demolition by following the

relative standards in force for the protection of the environment.

Take the necessary precautions to prevent the dispersion of refrigerant gas from the

cooling system into the air. This operation must be carried out by authorised personnel,

following the procedures approved by the public authority.

3.6.1 Procedure for dismantling the machine

Proceed as follows should it be necessary to dismantle the machine for its demolition:

•Consult the environmental protection laws in force in the user's country.

•As legally prescribed, activate the inspection procedure by the Body in charge and the consequent

reporting of the demolition.

•Group and separate the components according to their chemical nature.

•Proceed with the scrapping in respect of the laws in force in the user's country.

•During dismantling, carefully comply with the health and safety prescriptions of the operators.

ATTENTION

Dismantling must be carried out by qualified personnel.

ATTENTION

Different legislations are in force in different countries. Observe the prescriptions set by

the laws and the bodies in charge in the countries where the demolition occurs.

Page 14 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

14

4 - FUNCTIONING AND USE

4.1 DESCRIPTION OF THE FUNCTIONING

4.1.1 Description of controls

The machine controls are placed on its front panel in an ergonomically comfortable position for the operator

to access it.

The operator has direct access to the machine.

"START" KEY

Pressing this button switches on the machine placing it in "STAND-BY"

while awaiting further commands. The pressed button remains on (green

light). This button is used to switch-off the equipment in any functioning

cycle mode, with machine on.

The controls are located on the control panel (DISPLAY) enabling the interaction with the micro-processor

controlling machine functioning.

Fig. 4.1 –Control panel

1 - ARROW KEY

Page 15 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

15

Enables moving the display cursor upwards.

2 - HOSE SPRAY KEY

Pressing this key opens the timed passage (3 minutes) of the washing water in the manual hose spray.

The water flow is controlled by an hold-down lever of the tap.

3 - ARROW KEY

Enables moving the display cursor downwards.

4 - STIRRER KEY

When pressed it starts the stirrer functioning without heating or cooling phases. It is always active except

when the automatic cycle is started or during the refrigerator phase.

5 - CYCLE START KEY

Pressing this key starts the automatic functioning cycle.

6 - ARROW KEY

Enables moving the display cursor upwards.

7 - ENTER KEY

Enables confirming the command selected in the chosen menu.

8 - ARROW KEY

Enables moving the display cursor downwards.

9 - REFRIGERATOR CYCLE KEY

Enables immediately starting the refrigerator cycle without waiting for the times provides by the automatic

cycle. It is also active when not in cycle and enables reaching the permanent temperature of 4÷6 °C, at least

for as long as the START button is on (machine electrically powered).

10 - STOP KEY

Stops the cycle and brings the machine back in stand-by, without guaranteed temperature specifications.

4.1.2 Operating phases

The MIXPASTO 60/120 is intended for the pasteurisation of mixes for ice cream with heating and cooling

cycles controlled by a micro-processor programmable by the user.

The machine provides the following operative treatment phases for the ice cream mix:

1. pasteurisation

2. emulsifying

3. cooling

4. preservation (maturation)

Emulsifying happens by increasing the stirrer speed in view of the product temperature and by making the

product bang against the metal elements of a specifically designed grid.

The stirrer speeds are pre-set. There are normally 2 speeds set during heating and 2 during cooling; the

speed automatically changes when the mix reaches 55°C, both during heating and during cooling.

The user can request the setting of 3 speeds both during heating and during cooling, from the manufacturer's

Technical Service.

The stirrer speed is further reduced during preservation and it automatically intervenes for 1 minute at

intervals of 20 minutes.

The user can ask the manufacturer's Technical Service to set the functioning times of the stirrer during

preservation differently.

The operator can vary the stirrer speed at any moment by means of the LEFT ARROWS.

The cycle times in the chart of fig. 4.2 refer to laboratory tests with specific products that can differ based on

the type of mix and functioning conditions (environment temperature, water temperature, etc.).

Page 16 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

16

Fig. 4.2

The "bain-marie" method is used with the product tray wrapped by a coil in which a heat-transmitting fluid

(glycol+water) flows.

The product is loaded from above by lifting the polycarbonate lid; discharge is through the tap located in the

front part of the machine.

The user decides the composition of the mix to be pasteurised: the percentage of the dry part (the density of

the mix) can influence the outcome of the cycle: it must not, however, exceed the limit of 42%.

ATTENTION

The machine must never operate empty!

4.1.3 Use of commands

The machine is powered by connecting its plug to the mains; it does not have a main switch.

Pressing the START button activates the electric power supply. The control panel's screen switches on (see

fig. 4.1) and show the installed SW + HW upgrade index.

The user interacts with the machine micro-processor by means of the commands shown in fig. 4.1, that is:

- the screen

- the buttons.

Page 17 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

17

The user can select the entries of the different MENUS through the left arrows:

when the wanted entry is highlighted (lights-up), it is automatically selected.

The user can vary the value of a parameter using the right arrows (increase = top

arrow; decrease = bottom arrow)

It enables selecting the entry or value chosen by the user

Pressing the STIRRER key

opens the specific menu with

the spiral symbol. The bottom

of the screen shows the time in

progress (left) and the set time

(right).

The stirrer speed can be

increased or decreased with the

LEFT ARROWS.

Pressing the REFRIGERATOR

key opens a specific menu with

the snow-flake symbol. The

stirrer speed can be increased

or decreased with the LEFT

ARROWS.

The current product

temperature, that drops to 4°C

(refrigerator preservation),

appears at the bottom of the

screen.

The user, in addition to the buttons, can use the commands selected on the control panel screen.

The interface between user and machine consists in a series of MENUS with which the operator can set the

wanted functioning.

Use the LEFT ARROWS to select "ESC" (top-left of each screen) followed by ENTER, to exit each menu: the

previous menu is in this way accessed.

Page 18 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

18

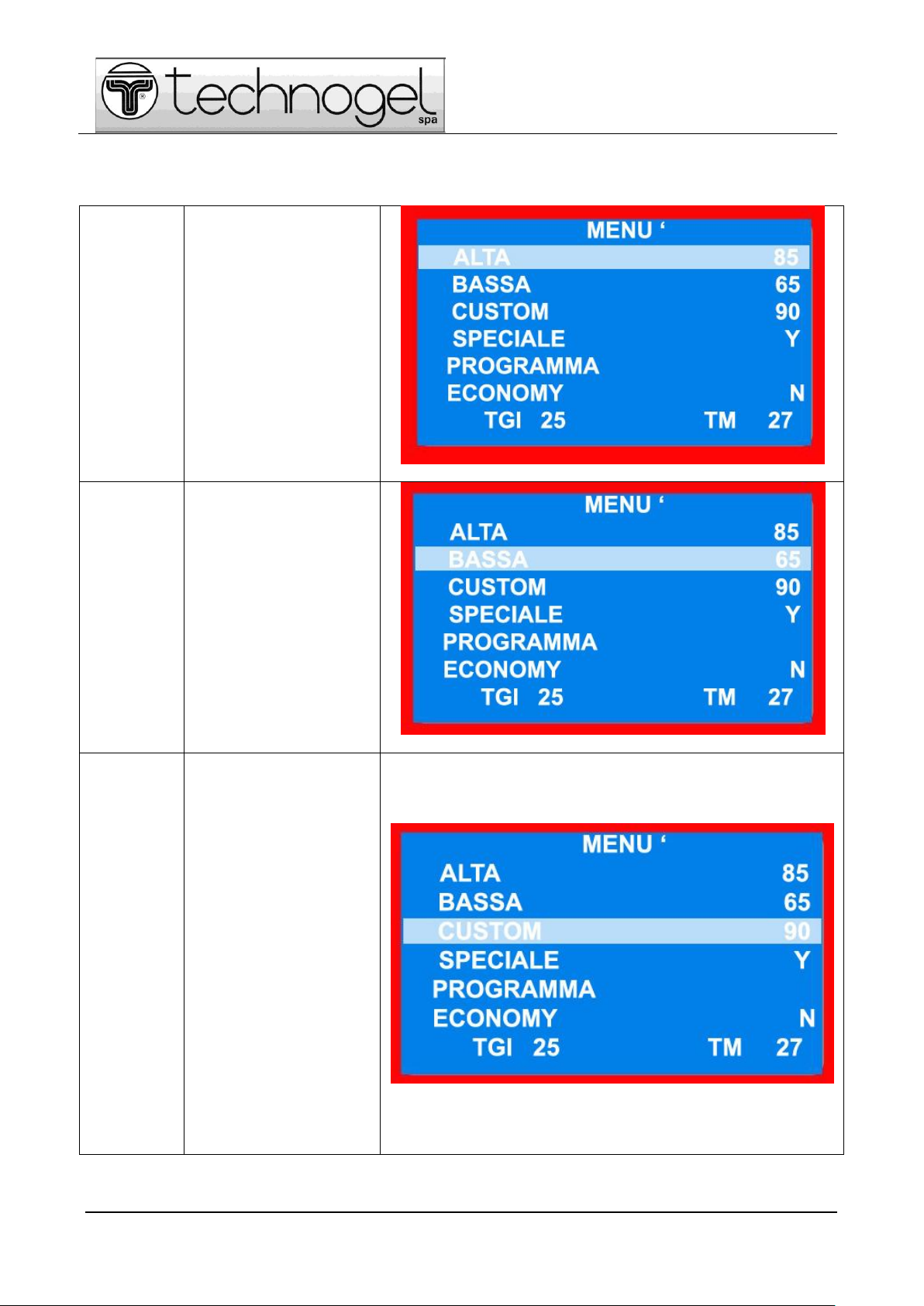

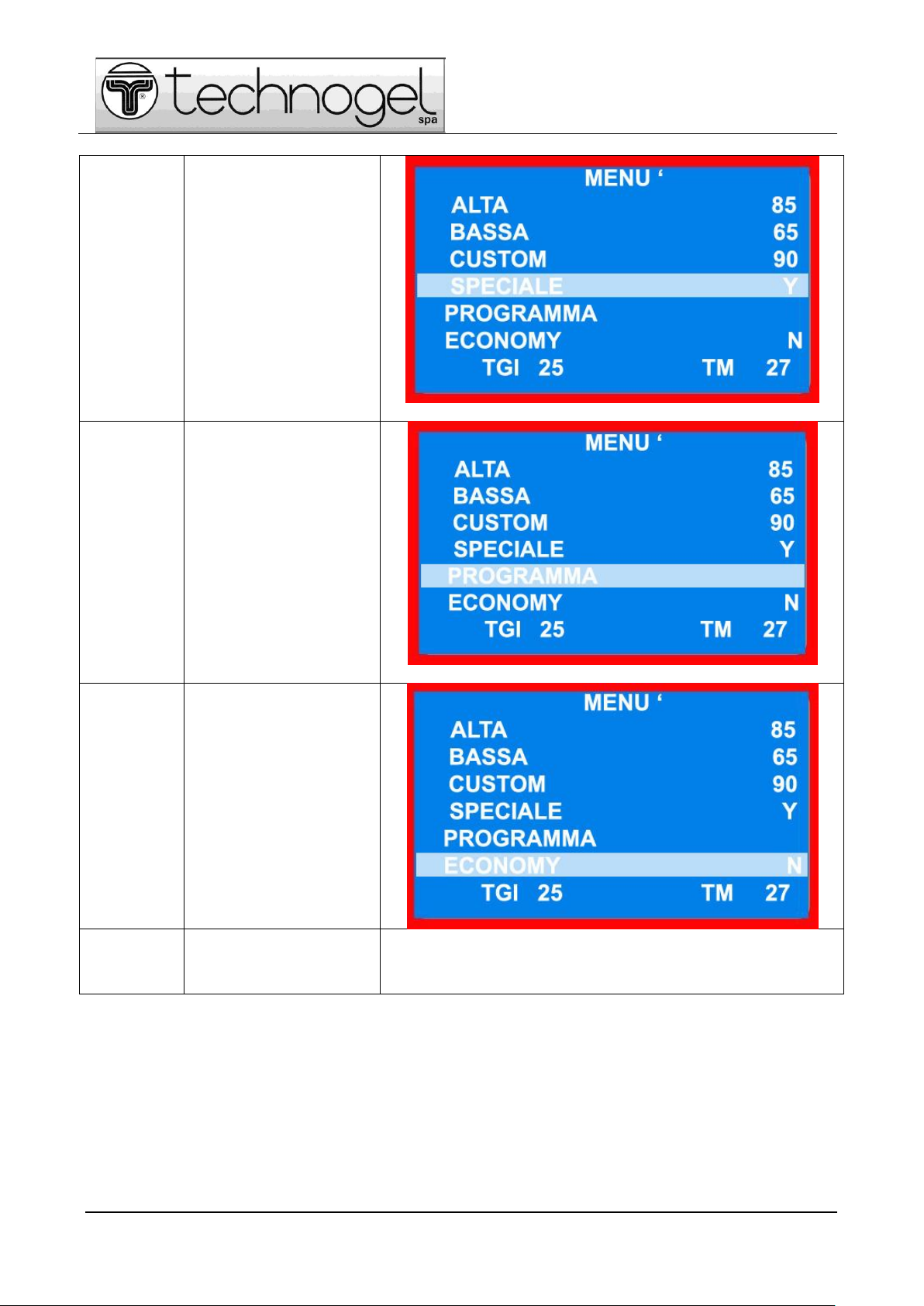

Press ENTER (7, fig. 4.1) after having switched on the panel: the screen shows the machine main menu composed as

follows:

HIGH

High pasteurisation cycle,

with heating at 85°C

followed by cooling at 4°C

LOW

Low pasteurisation cycle,

with heating at 65°C,

maintenance for 30 minutes,

followed by quick cooling at

4°C

CUSTOM

Cycle the user can

customise by selecting the

temperature from 60°C to

90°C. This cycle is required

as some ingredients are

sensitive to high

temperatures. The user can

select the different menus

entries using the left arrows

(pos. 6 and 8, fig. 4.1). The

wanted entry is

automatically selected when

highlighted (lit-up).

Using the left arrows (pos. 1

and 3, fig. 4.1) the

"Temperature" in the

CUSTOM cycle can be

varied (the Temperature in

the HIGH and LOW cycles is

fixed). The micro-processor

automatically defines the

Maintenance in temperature

time before quick cooling,

that is the same for all cycle

types.

Page 19 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

19

SPECIAL

Special programs pre-set by

the user can be selected

following the methods

explained in par. 4.1.4.

Once the entry is selected,

use the RIGHT ARROWS to

select one of the 5 special

programs the user can set

(see par. 4.1.4) namely:

YOGHURT Y

CHOCOLATE C

PROGRAM P1

PROGRAM P2

PROGRAM P3

PROGRAM

Press ENTER to access the

next menu for setting the

special programs as

required by the user (see

par. 4.1.4)

ECONOMY

This program enables using

the half tank load cycles:

use the 20 to 40 l program

for the "60" machine; the 40

to 100 l for the "120".

Once the entry is selected

set "Y" (YES) or "N" (NO)

using the RIGHT KEYS.

This is the first parameter to

be set when the machine

production cycle is started,

before setting the above

cycles.

TM

The current temperature of

the mix always appears

bottom-right of the main

menu.

Page 20 of 52

THIS MANUAL IS THE PROPERTY OF TECHNOGEL SpA–ALL REPRODUCTIONS, EVEN PARTIAL, ARE FORBIDDEN

20

Press the "CYCLE START" key (pos. 2, fig. 4.1) to

start the machine, after having selected the wanted

cycle.

The thermometer symbol appears on the screen if

the program provides a heating phase; the snow

crystal symbol appears if it provides a cooling

phase.

The stirrer speed can be increased or decreased

with the LEFT ARROWS.

4.1.4 Cycle programming

The operator can pre-set 5 customised programs for each of which the process parameters must be fixed.

Select PROGRAM from the main menu and press ENTER: the next menu

appears providing 5 rows (see figure at side), to each of which corresponds one of

the special programs.

It is possible to customise one of the 5 programs indicated on screen:

YOGHURT Y

CHOCOLATE C

PROGRAM P1

PROGRAM P2

PROGRAM P3

Every program is structured in 6 steps or operating phases.

Every step can be set as heating or cooling phase (RAMP) or as maintenance in

constant temperature phase (STOP).

Select the chosen program using the LEFT ARROWS and then ENTER

(e.g. program Y: the menu relating to STEP 1 appears.

Select the T RAMP entry using the RIGHT ARROWS: when highlighted,

the T RAMP and T STOP entries alternate using the LEFT ARROWS.

The user chooses the type of phase to be attributed to the STEP in

question, then press ENTER to acquire the setting.

This manual suits for next models

1

Table of contents

Other Technogel Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use