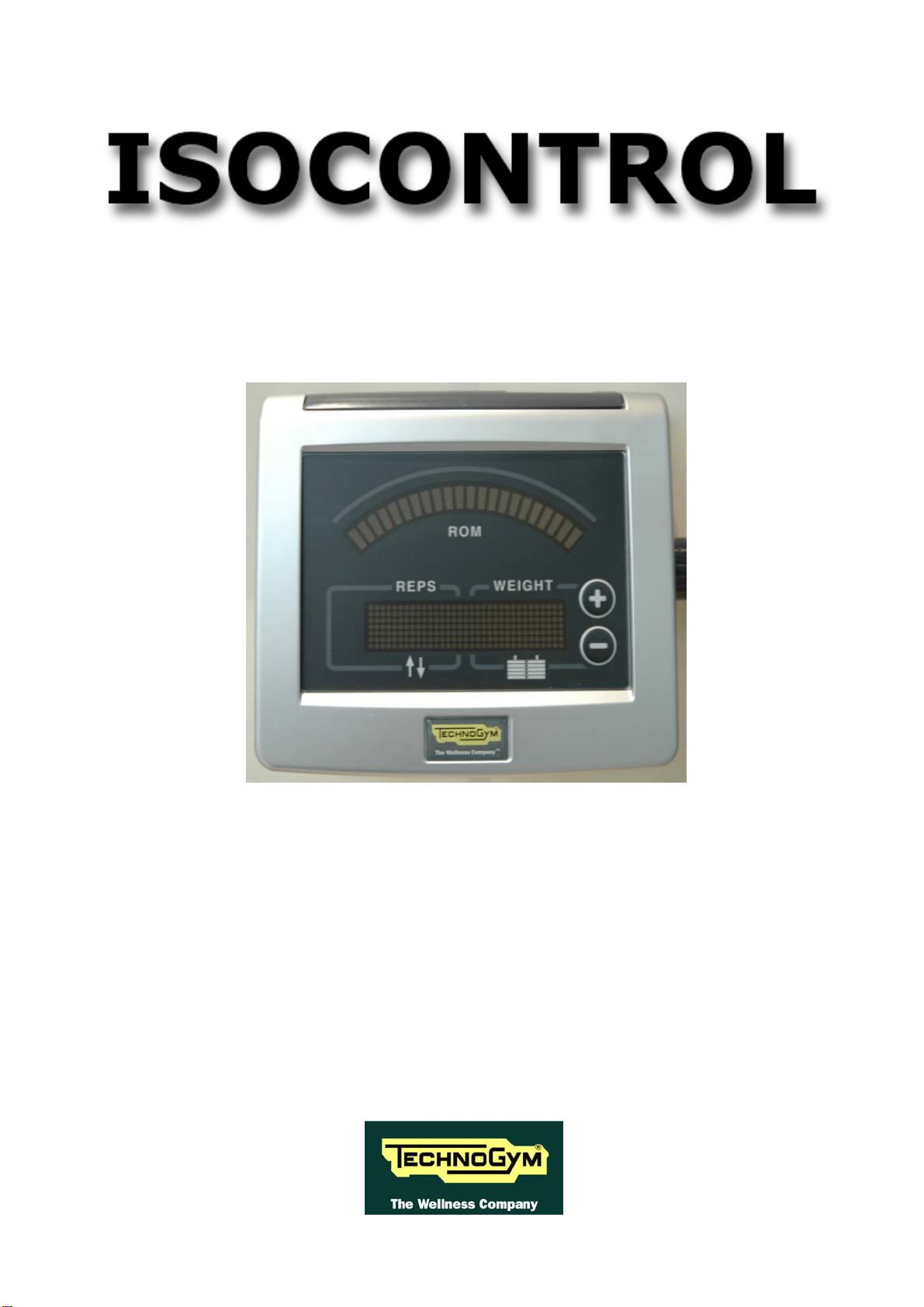

ISOCONTROL: Service & Maintenance Manual - rev. 1.2

Pagina i

Contents

AVVERTENZE GENERALI................................................................................................................................1.1

1INTRODUCTION.................................................................................................................................................1.1

2RECOMMENDATIONS ........................................................................................................................................1.1

3GENERAL RULES FOR REPAIR PROCEDURES ......................................................................................................1.2

TECHNICAL CHARACTERISTICS..................................................................................................................2.1

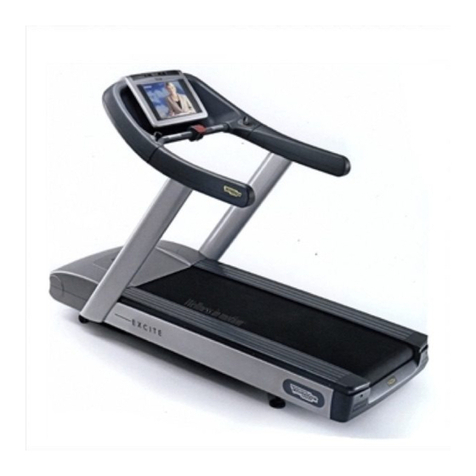

1MECHANICAL CHARACTERISTICS .....................................................................................................................2.1

2ELECTRICAL CHARACTERISTICS .......................................................................................................................2.1

3AMBIENT SPECIFICATIONS................................................................................................................................2.1

4CONFORMITY TO REGULATIONS........................................................................................................................2.1

5PRODUCT CODE ................................................................................................................................................2.2

6WIRING DIAGRAM ............................................................................................................................................2.3

6 1

Wiring...................................................................................................................................................2.4

PRINCIPLES OF OPERATION..........................................................................................................................3.1

1BLOCK DIAGRAM .......................................................................................................................................3.1

1 1

Display panel .......................................................................................................................................3.1

1 2

Encoder board......................................................................................................................................3.2

1 3

Power supply........................................................................................................................................3.2

ACCESSORI..........................................................................................................................................................4.1

1SERIAL CABLE FOR PC CONNECTION................................................................................................................4.1

2ELECTRICAL CONNECTION................................................................................................................................4.2

2 1

Direct connection.................................................................................................................................4.2

2 2

Daisy chain...........................................................................................................................................4.2

INSTALLATION INSTRUCTIONS....................................................................................................................5.1

1SPECIFICATIONS AND REQUIREMENTS ..............................................................................................................5.1

2INSTALLATION..................................................................................................................................................5.1

2 1

Preparing Selection machines frames that require drilling.................................................................5.2

2 2

Procedure for Selection machines........................................................................................................5.3

221 Templates for Selection machine frames which require drilling....................................................................................5.6

222 Pulleys to replace on Selection machines.......................................................................................................................5.9

2 3

Preparing Element machines frames that require drilling.................................................................5.14

2 4

Procedure for Element machines.......................................................................................................5.20

241 Template for Element machine frames which require drilling.....................................................................................5.24

3FIRST POWER-ON......................................................................................................................................5.25

TROUBLESHOOTING......................................................................................................................................6.27

1TEST PROCEDURE ...........................................................................................................................................6.28

1 1

LED Test.............................................................................................................................................6.28

1 2

Encoder test........................................................................................................................................6.28

2THE DISPLAY FAILS TO ILLUMINATE .................................................................................................6.29

3THE ROM IS NOT READ OR IS READ INCORRECTLY.........................................................................................6.31

4THE MACHINE DOES NOT READ THE TGS..........................................................................................6.35

DISASSEMBLY OF COMPONENTS.................................................................................................................7.1

1DISASSEMBLING THE DISPLAY..........................................................................................................................7.1

2DISASSEMBLING THE DISPLAY COMPONENTS...................................................................................7.2

3DISASSEMBLING THE ENCODER BOARD ON SELECTION MACHINES ....................................................7.3

4DISASSEMBLING THE ENCODER BOARD ON ELEMENT MACHINES.......................................................7.4

ADJUSTMENTS....................................................................................................................................................8.1