Technoton DUT-E 2Bio CAN User manual

Contents

DUT-E 2Bio fuel level sensors. Operation manual. Version 3.1

© Technoton, 2019 2

Contents

Contents ...................................................................................................................... 2

Revision history............................................................................................................. 4

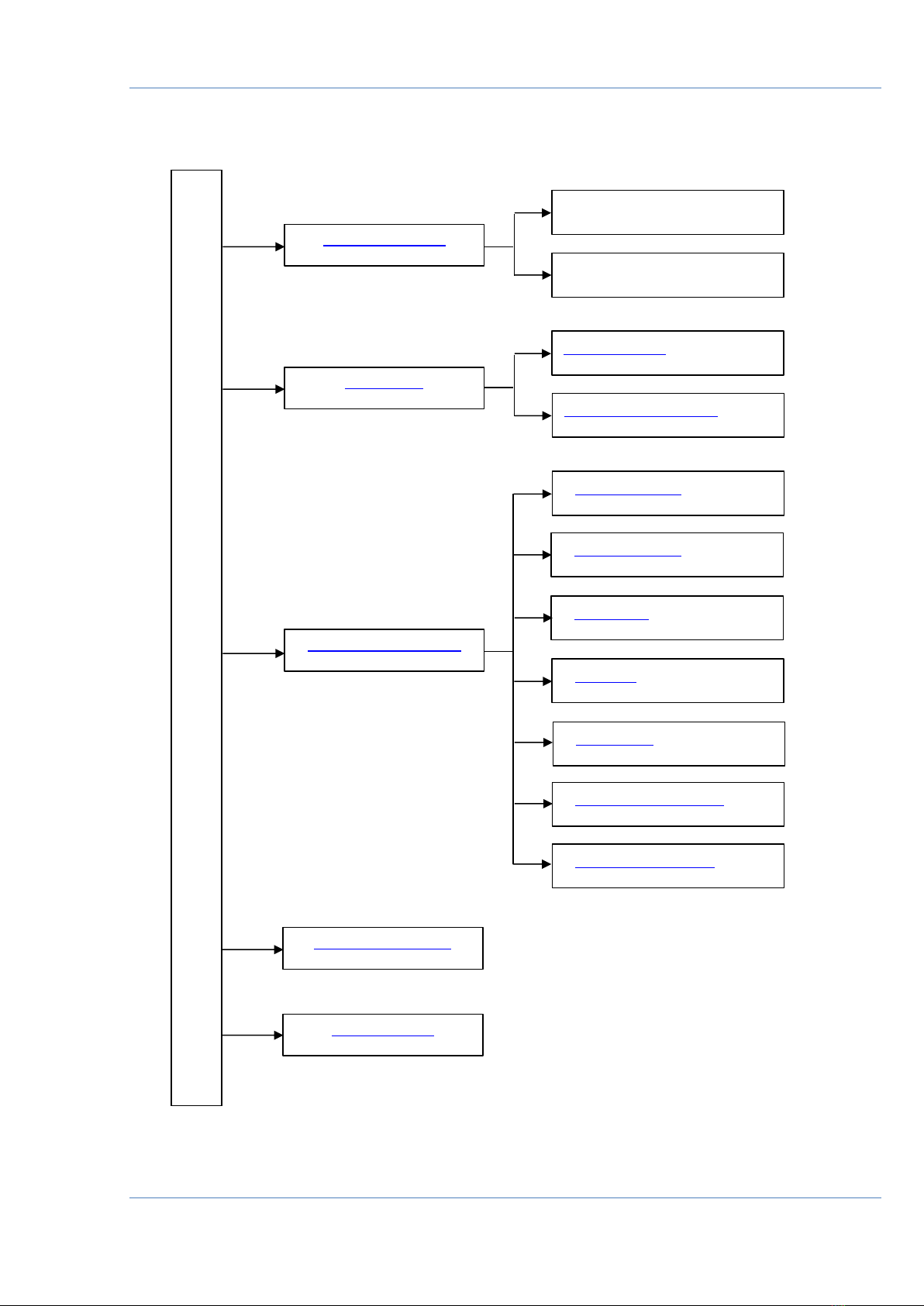

Structure of external links .............................................................................................. 5

Terms and Definitions .................................................................................................... 6

Introduction.................................................................................................................. 8

1 General information and technical specifications of DUT-E 2Bio....................................... 11

1.1 Purpose of use and application area, operation principle .......................................... 11

1.2 Exterior view and delivery set............................................................................... 15

1.3 DUT-E 2Bio design .............................................................................................. 16

1.4 Technical specifications........................................................................................ 17

1.4.1 Main specifications ........................................................................................ 17

1.4.2 Specifications of DUT-E 2Bio CAN output signal................................................. 18

1.4.3 Specifications of DUT-E 2Bio 232/485 output signal........................................... 19

1.4.4 Specifications of DUT-E 2Bio AF output signal ................................................... 21

1.4.5 Specifications of DUT-E 2Bio I output signal ..................................................... 22

1.4.6 Overall dimensions ........................................................................................ 23

2 DUT-E 2Bio installation .............................................................................................. 24

2.1 Exterior inspection prior to works start .................................................................. 24

2.2 Probe cutting according to tank depth.................................................................... 25

2.3 Length extension ................................................................................................ 26

2.4 Screen-filter mounting......................................................................................... 27

2.5 Sensor setup using PC ......................................................................................... 28

2.5.1 Connecting sensor to PC ................................................................................ 28

2.5.2 Interface of Service S6 DUT-E software............................................................ 31

2.5.3 Authorization ................................................................................................ 32

2.5.4 Sensor profile ............................................................................................... 34

2.6 Wireless configuration of sensor using Android devices ............................................ 36

2.6.1 Wireless connection of the sensor to the Android device..................................... 36

2.6.2 Interface of S6 application.............................................................................. 39

2.6.3 Authorization ................................................................................................ 40

2.6.4 Operations with the sensor Profile ................................................................... 41

2.7 Mounting ........................................................................................................... 42

2.8 Electrical connection............................................................................................ 43

2.9 Sensor calibration ............................................................................................... 45

2.10 Fuel tank calibration table .................................................................................. 47

2.11 Adaptation of sensor to specific conditions of operation.......................................... 49

Contents

DUT-E 2Bio fuel level sensors. Operation manual. Version 3.1

© Technoton, 2019 3

2.12 Connection parameters for CAN j1939/S6 interface ............................................... 51

2.13 Connection parameters for

RS-232/RS-485 Modbus,

DUT-E COM (extended LLS)

interface..................................................................... 52

2.14 Voltage, frequency and current output parameters ................................................ 54

2.15 Summation of data............................................................................................ 55

2.16 Automatic recognition of fuel type ....................................................................... 59

3 Sealing .................................................................................................................... 61

4 Measurement accuracy check ..................................................................................... 62

4.1 Basic principles ................................................................................................... 62

4.2 Check tests procedure ......................................................................................... 63

5 Diagnostics and troubleshooting ................................................................................. 64

6 Maintenance............................................................................................................. 65

6.1 General instructions ............................................................................................ 65

6.2 Demounting ....................................................................................................... 66

6.3 Examination ....................................................................................................... 67

6.4 Cleaning ............................................................................................................ 68

7 Packaging ................................................................................................................ 69

8 Storage ................................................................................................................... 70

9 Transportation.......................................................................................................... 71

10 Utilization/re-cycling................................................................................................ 72

Contacts..................................................................................................................... 73

Annex A Template of check test report ........................................................................... 74

Annex B SPN of DUT-E 2Bio Functional modules .............................................................. 75

B.1 Self-diagnostics FM ............................................................................................. 75

B.2 Onboard clock FM ............................................................................................... 77

B.3 Fuel level sensor FM ............................................................................................ 78

B.4 Fuel level control FM ........................................................................................... 80

B.5 Vehicle power supply FM...................................................................................... 82

B.6 Events registrator FM .......................................................................................... 84

Annex C DUT-E 2Bio firmware upgrade .......................................................................... 85

Annex D Electromagnetic compatibility specifications of DUT-E 2Bio................................... 86

Annex E Videography ................................................................................................... 88

Revision history

DUT-E 2Bio fuel level sensors. Operation manual. Version 3.1

© Technoton, 2019 4

Revision history

Version

Date

Editor

Description of changes

1.0

08.2017

OD

Basic version

2.0

12.2017

OD

DUT-E 2Bio connection sequence to Android-device via Bluetooth

using S6 BT Adapter is added.

Sensor configuration procedure from Android-device using

Service S6 DUT-E (Android) is described.

Document’s terms and definitions are updated

(S6 Technology and IoT Burger Technology).

External link structure of the Manual is updated.

Examples of connection schemes of DUT-E 2Bio to telematics units

through S6 cabling system is updated.

3.0

07.2018

OD

New models are added:

- DUT-E 2 Bio 232;

- DUT-E 2 Bio 485;

- DUT-E 2 Bio AF;

- DUT-E 2 Bio I.

Delivery set description is updated.

Electromagnetic compatibility information is added.

Document’s terms and definitions are updated

(CAN j1939/S6 Telematics interface).

3.1

03.2019

OD

Feature of recognition of fuel type in use is added

for DUT-E 2Bio CAN;

Updated list of DUT-E 2Bio CAN data transfer protocol messages;

Register map of DUT-E 2Bio 232/485 output messages according

to Modbus protocol is updated;

SPN list of FM Fuel level sensor is updated.

Structure of external links

DUT-E 2Bio fuel level sensors. Operation manual. Version 3.1

© Technoton, 2019 5

Structure of external links

DUT-E 2Bio fuel level sensors. Operation manual

Document Center

S6 Website

Part S6 Data Base

Part S6 Functional modules

JV Technoton Website

Part Technical support

Part Software/Firmware

YouTube Technoton

ORF 4 Website

Page DUT-E

Page DUT-E GSM

Page DUT-E 2Bio

Page CANUp

Page DFM

DUT-E/DUT-E 2Bio/DUT-E GSM.

Installation manual

CAN j1939/S6 Telematics interface.

Operation manual

This manual suits for next models

4

Other Technoton Accessories manuals