Technoton DUT-E A5 User manual

FUELLEVELSENSORS

DUT-E 5

DUT-E 10

DUT-E F

DUT-E 232

DUT-E 485

INSTALLATIONMANUAL

Version 5.0

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 2 of 30

Content

Introduction.............................................................................................................. 3

1. Maindataandtechnicalcharacteristics..................................................................... 5

1.1Purposeof use.................................................................................................. 5

1.2Exterior viewanddeliveryset............................................................................. 5

1.3Technicalcharacteristics .................................................................................... 6

1.3.1Maincharacteristics..................................................................................... 6

1.3.2Characteristics of output signalforDUT-E 5andDUT-E 10 ........................... 6

1.3.3Characteristics of output signalforDUT-EF.................................................... 6

1.3.4Characteristics of output signalforDUT-E232 andDUT-E485.......................... 7

2.Installationandset-up ........................................................................................... 8

2.1Exterior examinationbeforestartingof works....................................................... 8

2.2Installationontheplaceof astandardfuelsensor................................................. 8

2.3Installationinto aspecialopening ..................................................................... 10

2.4 Cuttingof themeasuringpartforthenecessarytankdepth ................................. 13

2.5Lengthincreasing............................................................................................ 15

2.6Mounting ....................................................................................................... 15

2.7Electricalconnection........................................................................................ 17

2.8Set-upof theanalogorfrequencyDUT-Esensor ................................................ 19

2.9Set-upof thedigitalDUT-Esensor .................................................................... 19

2.10 Connectionof DUT-Etotheindicator of fuellevel.............................................. 20

2.11 Sealing ........................................................................................................ 21

2.12 Measurement precisioncheck ......................................................................... 22

2.12.1 Basic issues............................................................................................ 22

2.12.2 Controlteststeps.................................................................................... 22

3. Diagnosis and troubleshooting............................................................................... 23

3.1Diagnosis andtroubleshootingof analogDUT-E .................................................. 23

3.2Diagnosis andtroubleshootingof frequencyDUT-E.............................................. 24

3.3Diagnosis andtroubleshootingof digitalDUT-E................................................... 24

Appendix1. Actof thevehicleinspection.................................................................... 26

Appendix2. Tankcalibration..................................................................................... 27

Appendix3. Check-out testprotocol .......................................................................... 29

Appendix4. DUT-Efactorysettings............................................................................ 30

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 3 of 30

Introduction

Recommendationsandregulations given inthe installationmanual are referredto fuel level

sensorsDUT-E (hereinafter DUT-E),developedbyJV Technoton CJSC,Minsk,Belarus. This

document definestheprocedureforinstallationandconnectionof DUT-E,aswell as

providesguidance/recommendations ontheoperation.

DUT-E are used foraccurate measurement ofliquidfuellevelinthevehicle tanksand in

fixed/immovabletanks.

DUT-Ecanbeusedasa standardsensorofthefuel-levelindicator,aswellas apartof the

fuelconsumptioncontrolandvehiclemonitoring systems.

Distinctivefeaturesof DUT-E:

−deliveryset includesallnecessaryitemsforthe properinstallation and

connection, incl. mountingplate, connectingcable, rubbergaskets, screws andseals;

−supply voltage range is from 10 to 50 V;

−possibility toreduce the length upto 30% without calibration*;

−possibility toincrease thelength byusing the additionalsectionsofDUT-E;

−thermo-correction with adjustable coefficient allows tomake automatic updating of

measurements basedontheambient temperature **;

−easy bayonetfastening allows youto installandremovethesensorwithout any tools;

−bottomspringstop serves to give extra stiffness for sensormounting;

−openingsforsealing will help to prevent theunauthorized demounting or operating

troubles of DUT-E;

−self-diagnostic check of DUT-Eallows to controlthe sensor operation.**

*DUT-EA5, DUT-EA10, DUT-EF

** DUT-E 232, DUT-E 485

Themanualisfor the professional users whoarefamiliarwith therules for repairand

installation works onvehicles and whohave professionalknowledgeinthefieldof electrical

andelectronicequipment of various transport vehicles. Toensuretheproper functioningof

theDUT-E, itsinstallationand set-up shouldbecarriedout bycertifiedprofessionalstrained

by the manufacturer.

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 4 of 30

DUT-Ecanbeusedin moderate andcoldclimates.

As for the mechanical stability sensors arevibration-shockproofandvibration-crashworthy.

Marking of sensors is formedasfollows:

Fuellevelsensor DUT-E ХL=Y

To setup DUT-E232 andDUT-E485,Service kitSKDUT-Eis applied. (shouldbepurchased

separately).

Typeofsensor output signal:

5 – analogsignal, voltageupto 4.5V;

10 – analogsignal, voltageupto 9V;

F – frequencysignal, frequency upto

1500Hz;

232 – digitalsignal, interface RS-232;

485 – digitalsignal, interface RS-485.

Nominal length of themeasuring

part (inmm):

- analog: 180, 250, 350, 500,

700, 1000, 1400,2000;

- frequency: 180, 250, 350, 500,

700, 1000, 1400;

- digital: 700, 1000, 1400.

Commercialname

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 5 of 30

1. Maindata andtechnicalcharacteristics

1.1 Purposeof use

FuellevelsensorDUT-Eisdesignedtomeasure thelevelof liquidfuel andother non-

electroconductive liquidsintanks of mobile vehicles and fixed/immovable tanks.

1.2 Exterior viewanddeliveryset

DUT-E deliverysetincludes:

a) sensorDUT-Einset – 1 pce;

b) thebottomstop(forthesensorswith ameasuringpartlengthof 500 mm or more) –

1pce;

c) signalcable7m - 1 pce;

d) mountingplastic plate - 1pce;

e) rubbergasketforthemountingplate - 2pcs;

f) sealingO-ringplate - 2pcs;

g) self-drillingscrew - 5pcs;

h) screwM5x16 - 5 pcs;

i) seal - 2pcs;

j) sealingcord - 2 pcs;

k) specification - 1pce.

Fig.1. Delivery setof DUT-E

а

b

g

h

j

d

e

f i

с

k

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 6 of 30

1.3 Technical characteristics

Power supply of DUT-E is carried out via on-boardvehiclepower system, onwhichitis

installed.

1.3.1 Main characteristics

Table 1. DUT-E maincharacteristics

Therelativemeasurement inaccuracy (tothelength of

themeasuring part),% ±1

Supplyvoltagerange,V

10 - 50

Current

consumption

, mA

≤50 at 12 V

≤25 at 24 V

Protection from pulseinterferences, V

100

Readiness

timeafterpower

-

up,

s

≤10

Temperaturerange, °C

-40 …+85

Protection

levelof housing

IP54

1.3.2 Characteristics of outputsignal for DUT-E 5 and DUT-E 10

Thevoltage valueof the DUT-Eoutput signal hasalineardependence onthemeasuredfuel

level inthetank.

Theoutput signaldoesn’tdependon supplyvoltage.

Table2. Characteristicsof output signalfor DUT-E A5 and DUT-E A10

Voltage, V

Nominallength Aftercutting by 30%

DUT-EA5 Emptytank 1.5 0.65

Fulltank 4.5 2.65

DUT-EA10 Emptytank 2.5 0.65

Fulltank 9.0 5.30

1.3.3 Characteristics of outputsignal for DUT-E F

The frequency valueof the DUT-Eoutput signal hasalineardependence onthemeasured

fuel level inthetank.

Theoutput signaldoesn’tdependon supplyvoltage.

Output cascade – opencollector with loadresistor 10 kOhm.

Table3.Characteristicsofoutput signalfor DUT-EF

Frequency, Hz

Nominallength Aftercutting by 30%

Emptytank 500 270

Fulltank 1500 970

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 7 of 30

1.3.4 Characteristics of outputsignal for DUT-E 232 and DUT-E 485

Characteristicsof output signalof DUT-E232 andDUT-E485 correspond tothespecification

of interfacesof RS-232 andRS-485 accordingly.

Factory interface settings: 19200 bit/s, 8bit, 1stopbit.

Otherfactorysettings aregiveninAppendix4of this manual.

Speedof data exchange via digitalinterfacecanbechosenfrom thefollowing values:4800,

9600, 19200 bit/s.

Theresults of DUT-E measurements canbetransferred via digitalinterface as:

a) standardunits, from0to 1000 (0-emptytank,1000 - fulltank);

b) fuellevelinthetank, mm;

c) fuelvolume, l;

d) fuelvolumeinrelationto thefulltank, %.

Besidesthe remaining fuel amount in the tank,DUT-Epassesinformationabout current

temperature(measuredbythesensorlocatedon the electronic board).

Information transfer is carriedout accordingto DUT-ECOMprotocol.

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 8 of 30

2. Installationand set-up

This chapter provides basic recommendations for the DUT-E installation.

Beforeyou start,youshouldmake external check of thevehicle for any possible failures

andmakeInspectionActof thevehicle (seeAppendix 1)

2.1 Exterior examination before startingof works

Beforeyou start,youshouldmake external check of DUT-Efor any possibledefectsthat

occurredduringtransportation, storageorcarelesshandling:

a) visible damage ofthehousing,measuringpart,mountingplate,rubber gaskets,signal

cableorconnector;

b) tubeplay of themeasuringpart in relation to eachotherand/or to the housing.

By discoveringanydefects, please,contact theproduct supplier.

DUT-Ecanbeinstalled as intotheopeningof the standardfuelsensor* as intoa special

opening inthetank.

*Studycarefullytheschemeof the mountingopeningsforthestandardfuelsensorand

comparewiththeDUT-Einstallationscheme(SeeFigure 9).

ATTENTION! By installingthesensor youshouldfollow safetyrules of the repairworks on

automotive vehicles aswell as safetyrequirements prescribedbytheenterprise.

2.2 Installation on theplaceofa standard fuel sensor

ATTENTION! It is not recommended toinstallthe DUT-E on the place of a standard fuel

sensor because ofitsfarlocation from the geometric center of the tank, and as a result,

inaccuracy in the fuel levelmeasurement may occur. Thereasonforthatissignal

fluctuationof DUT-E thathappens becauseof fuelflowinginsidethetank.

BeforetheDUT- Einstallationit isnecessaryto remove the standard fuelsensorandclean

the installationplace (seeFigure 2)

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 9 of 30

Fig.2. Standardfuelsensorremoval

Aligntheholesof themountingplateandrubber gasketwith theholesinthetank,thenfix

withthe screws thatcometogether with theDUT-E set (seeFigure 3).Screwheadsmustbe

deeplyput into themountingplate.

Fig.3. Mounting plateontheplaceof astandardfuelsensor

Installationof the DUT-E sensor inthemountingplateis given in chapter 2.6of this

manual.

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 10 of 30

2.3 Installation into a specialopening

ATTENTION! Beforedrilling the holesinthetank youshould dismantleit, evaporate oradd

water.

ATTENTION! Beforeyoustartdrillingthehole,please,makesurethatthere are no

partitions insidethetankundertheselectedlocation, whatcanpreventDUT-Einstallation.

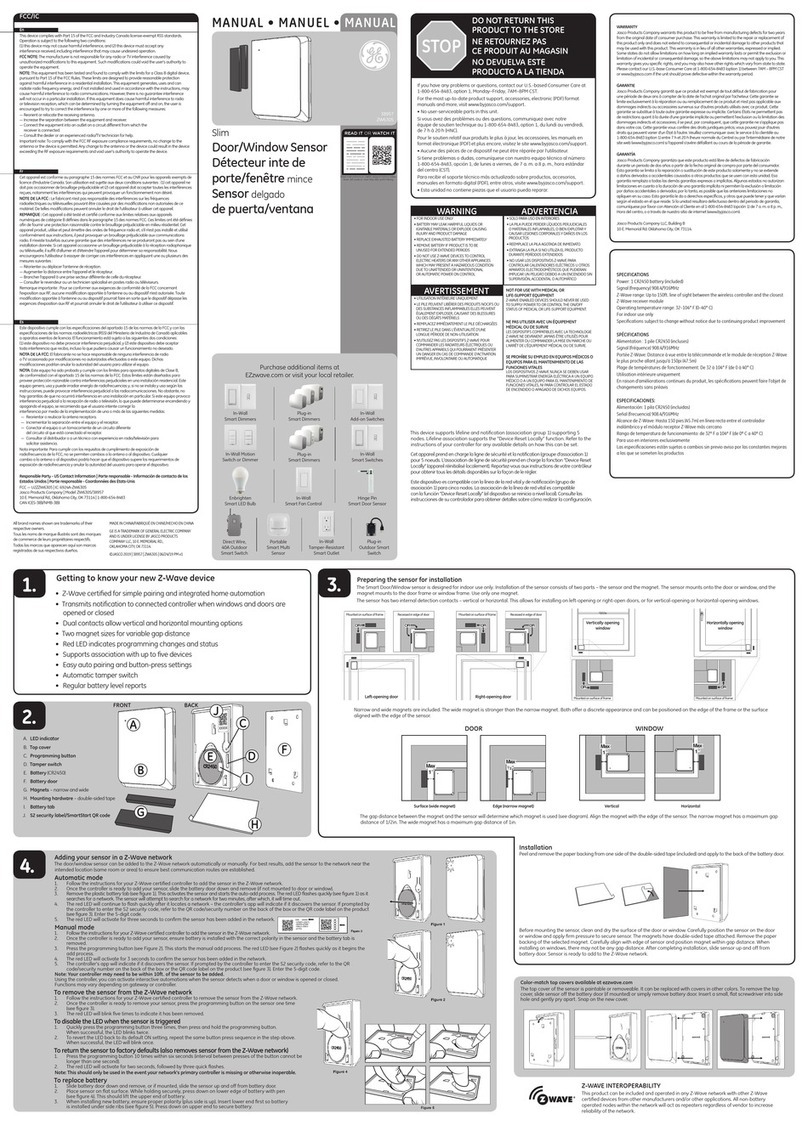

Installationsteps:

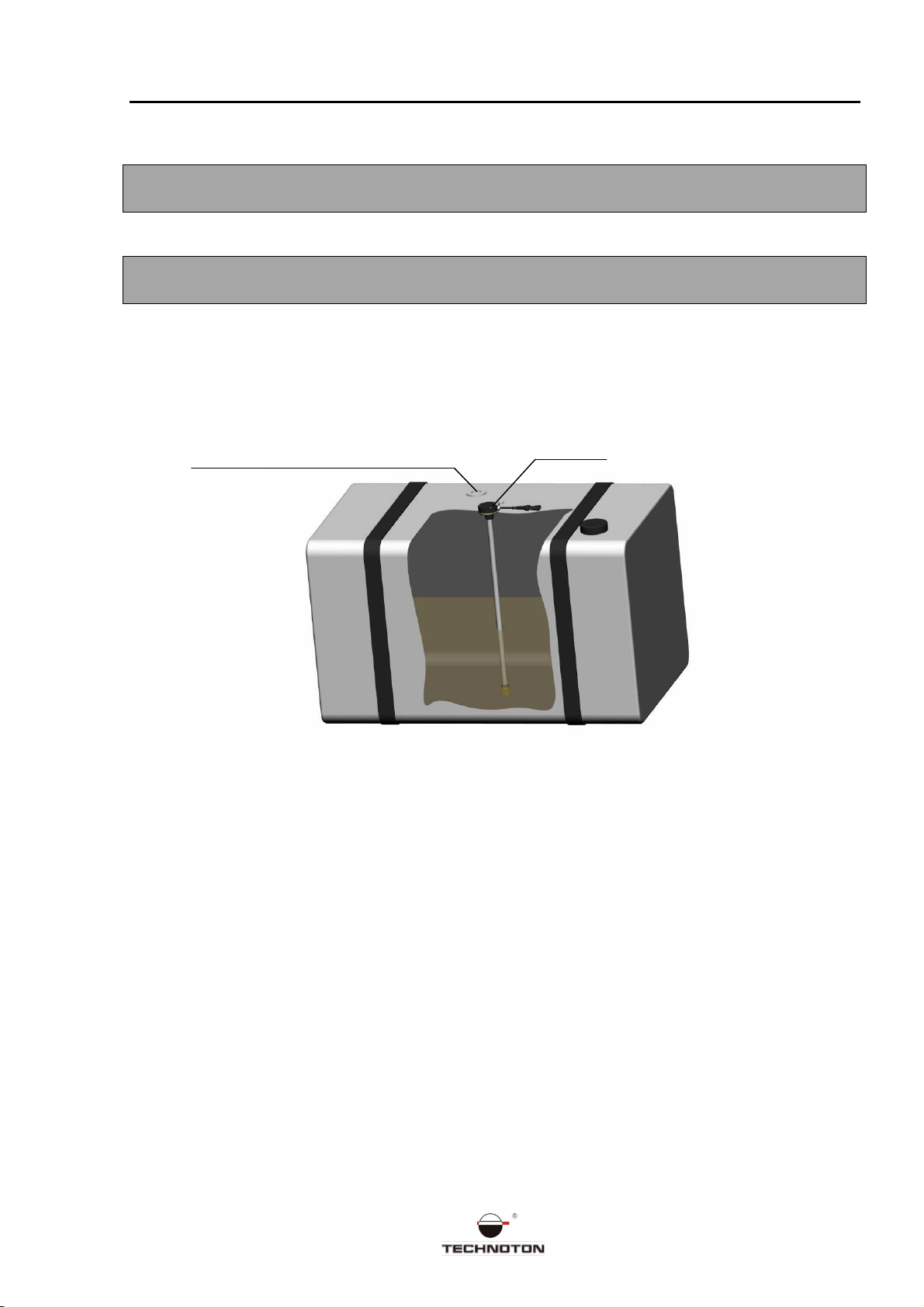

a) Identify the place where it is supposed to install the sensor. Itisrecommendedtochoose

aplaceinthegeometriccenter ofthetankasit will reducetheerror of fuelvolume

measurement byits vibration duringthemovement;

Fig.4. Recommendedplacefor DUT-E installation

DUT

-

E

Regular/stand

ardfuellevelsensor

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 11 of 30

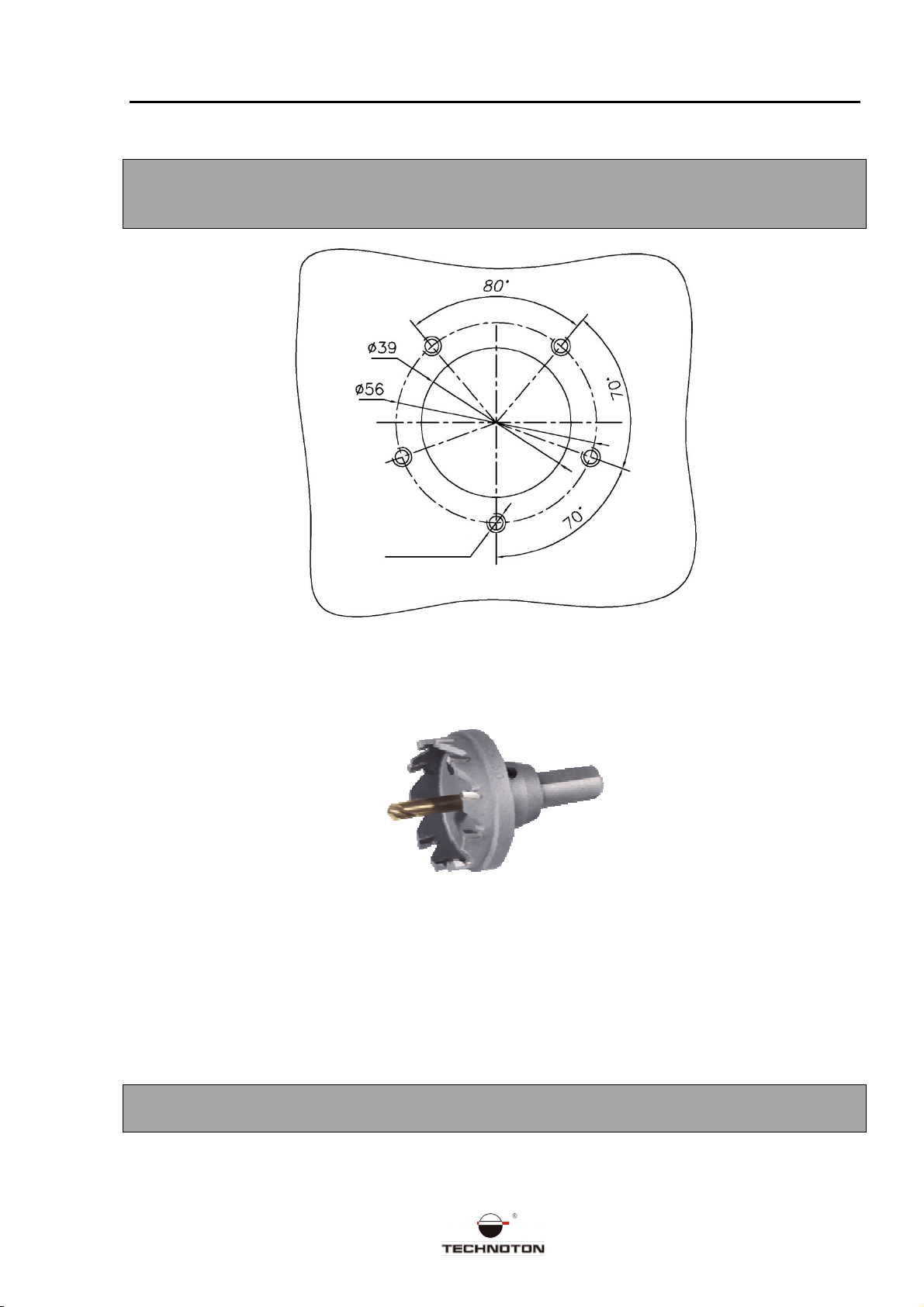

b) Marktheplaceanddrilltheholes accordingto thefollowingscheme(SeeFigure 5);

BEATTENTIVE! Mounting plate can be installed only in one position onthepre-drilled

holes! Prior to markingand drilling, please, study theplacewhereitis supposed toinstall

theplate so that holes for sealingwere locatedinanaccessibleposition.

Fig.5. Schemeof theholesforthemounting plate

Drillingis recommended to do with thecutter Ø38mm (seeFigure 6)

Fig.6. Cutter

Toprevent metalshavings in thetank it isrecommendedtoapplyalotofgrease, for

example, solid oil,on placeofthehole drilling.

c) Put thegasketandmountingplateonthepreparedhole,fixwith screwsorself-drilling

screws thatcomeinthedeliveryset.

ATTENTION! Forthe further sealingof thesensor it is recommended toput a sealing cord

throughtheholes forsealingof themountingplate prior toits installationonthefueltank!

5 HolesV5

-

6H

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 12 of 30

Fig.7. Installation scheme of the mounting plate

ATTENTION! While attachingtheplatetothetank,makesure, thatthescrewheads or

self-drilling screw headsare notwarped and deeplyput intothemountingplate so that to

provideelectricalinsulation of the vehicletankcasingfrom theDUT-E!

Asealing cord

Screw M5x16orself

-

drilling screw

Mounting plate

Rubbergasket

Fueltank

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 13 of 30

2.4 Cutting of the measuringpart forthenecessarytank

depth

Inordertoavoid the shortcircuitof themeasuringpart tubes causedby wateror

electroconductive residues that are gathered on thebottomof thetank,thereshouldbeat

least 2cmgapbetween thetube endof the DUT-E measuringpart andthebottomof the

fueltank.

ATTENTION!

For DUT-E A5, DUT-E A10, DUT-E F: allowed to make cutting upto 30% without further

calibration;

For DUT-E 232, DUT-E 485: allowed to make cutting up to 70% withfurthercalibration.

ATTENTION! DUT-E cutting shouldbe done bymeansof hacksaw or with a pipecutter of a

suitablediameter.Cuttingedges shouldbethoroughlycleaned upandwashedupwith the

fuel.

Steps by DUT-E cutting:

a) measurethedepth fromthemountingplatetillthetankbottom (seeFig. 8);

Fig.8. Measuring thedepth of thefueltank

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 14 of 30

b) cut theDUT-Emeasuringpartbasedonthelocationof thetubeendatadistanceof

2-3cmfromthetankbottom (seeFig. 9)

Fig.9. Cutting themeasuring partof DUT-E

c) cleantheedges fromburrsandshavings toremoveall elementsthatcan cause

electricalinterlocking of the tubes ofthe measuringpartbetween eachother (see

Fig. 10)

Fig.10. View of the cutting placeafter cleaning

d) in caseof DUT-E232 orDUT-E485 cuttingyou shouldcalibratethesensorusingthe

ServicekitSKDUT-E(Seeitem2.9).

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 15 of 30

2.5 Length increasing

Length increasing is carriedout by attaching of DUT-E additional sectiontothe measuring

part.

Model range of DUT-Eadditionalsectionsinclude:KDC 250,KDC500 and KDC 1000 with

lengths of 250, 500 and1000 mm correspondingly.

Fig.11. Additionalsection of DUT-E

Lengthincreasingof analogandfrequencyDUT-E sensors ispossible only for restoring the

length after cuttingand only within limits of theDUT-Enominallength.

Lengthincreasingfor digitalDUT-E sensor is allowed to alengthof 6000mm.

Thedetailedinformationforthemountingprocessiscontainedinthe operationmanual for

DUT-Eadditionalsection.

Extra sectionsof DUT-Ecanbecut to thedesired length.When cuttingyoushould follow

therecommendations given in item 2.4of this guide.

2.6 Mounting

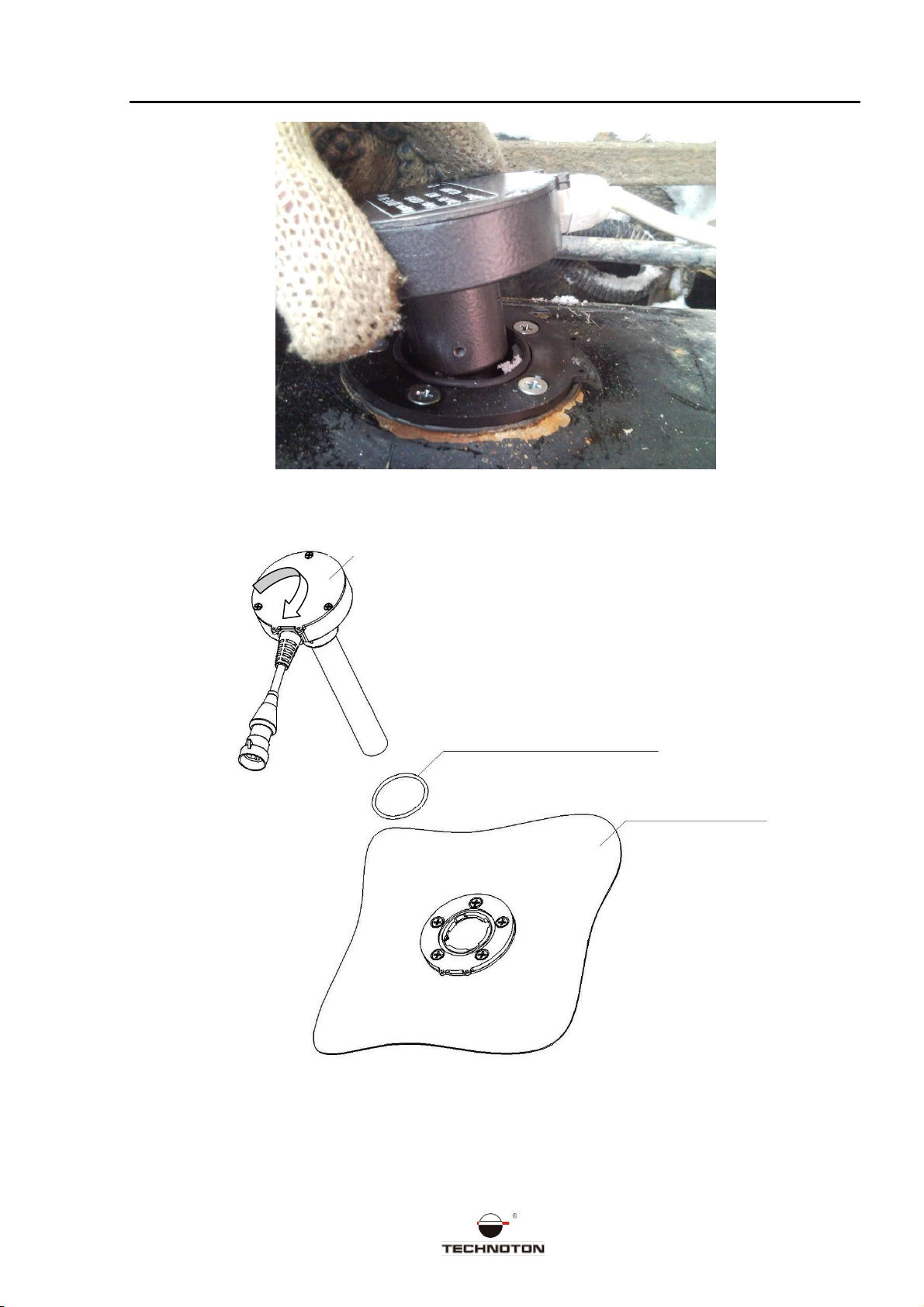

Toprovide extrastiffness tothesensor youneedtoinstall bottom spring stop (which isa

partofdeliveryset) ontheendof themeasuringpart of the DUT-E. Just put the bottom

springstop onthetube andfix toit bytighteningthescrewsattheendofthe bottom

spring stop.

Inorderto fix theDUT-E it isnecessaryto put an O-ringright on thedapof the mounting

plate,andthen put the sensor intothehole (see Fig.12), press it withforceandlockby

turningclockwise till sealingholesof theDUT-Ehousing andmountingplatecometogether

(seeFig. 13).

ATTENTION! During installationit isrecommendedtoapplyasmallamount of oilor fuel

ontheO-ring of the mountingplate so that toprevent itsdeformation whenyou fix the

DUT-Einside themountingplate.

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 16 of 30

Fig.12. Installationof DUT-E

Fig.13. Installation scheme of DUT-E

Installationshouldbedonein such awaythataftertheDUT-E mountingthe sealing openings

onthe mounting plateandDUT-E housing were locatedunder eachother.

SealingO-ring

Fueltank

DUT

-

E

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 17 of 30

2.7 Electrical connection

Theelectricalconnectionof analogand frequency DUT-E iscarriedout in accordancewith

thefollowing pinassignment (Figure 14, Table4):

Fig.14. Pins of analogandfrequency DUT-E sensors

Table4. Pin assignment of analogandfrequency DUT-E

PinNo Circuitname Cablecolour Remark

1. Т701/Т034 white Analogorfrequency

output

2. GND/Т734 brown "Ground" of the

vehicle

3. VBATT orange Powervoltage

Theelectricalconnectionof digital DUT-E is carriedout inaccordancewith thefollowing pin

assignment (Figure 15,Table 5).

Fig.15. Pins of digital DUT-E

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 18 of 30

Table5. Pin assignment of digital DUT-E

PinNo Circuitname Cablecolour Remark

1.

VBAT orange Powervoltage

2.

GND brown "Ground" of thevehicle

3.

232R/485A white

Receiveddata (RS 232)

Dataexchange (RS 485)

4. 232T/485B red

Transferreddata (RS 232)

Dataexchange (RS 485)

ATTENTION! Study thoroughly the textual wire tagging! Themanufacturerkeeps theright

to changethecolors ofthewires.

The DUT-E housingiselectricallyconnectedwiththe "minus" of DUT-E(brownwire

harness).

The mountingplatemadeof dielectric plastic material provides electricalinsulationof the

DUT-Ecasingfromthe vehiclecasing (of thetank).

ATTENTION! Signalcableis stronglyrecommended tostack togetherwith thestandard

wiring ofthevehicleand mandatory to fixitsposition bymeans of tie-laps every0.5 m.

(see Fig. 16).

Fig.16. DUT-E cablelaying

During the set-upof therecordinganddisplay devicesitisnecessarytomakeasetting

"DUT-E readings do notdependonthevoltage of on-board power system" (if suchsetting

available).

ATTENTION! Connectionof theDUT-Etotheon-boardpowersystemand"ground"is

carriedout inthesameplaces wheretherecordinganddisplay devicesareconnected.

Afterinstallationandconnectionof DUT-E you should calibratethe tank(See Appendix 2).

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 19 of 30

2.8 Set-up of the analogor frequency DUT-E sensor

Setup andcalibrationof analogandfrequencyDUT-Eis notrequired.

2.9 Set-up of the digital DUT-E sensor

ATTENTION! Setupof thedigitalDUT-Ecan bepossible onlybemeansof theprogram

"ServiceDUT-E" and servicekitSKDUT-E(shouldbepurchased separately).

Detailed descriptionof configurationoptionsDUT-Edescribedintheoperating manualfor

servicekitSKDUT-E.

AllDUT-E are deliveredcalibrated.

Thecalibration willbe broken after the lengthcuttingorincreasingof digitalDUT-E sensors.

Calibration of the sensor is possibleonlywiththehelpof Servicekit SK DUT-E. Detailed

informationabout calibrationprocess is givenintheoperationmanualfor SK DUT-E.

By meansof the "ServiceDUT-E" software you canalso setthedesiredDUT-E modes:

- Filtrationtime(default setting 10s);

- Interval ofperiodic dataoutput (default setting 1s);

- Data output mode (default setting HEX)(SeeFigure 17).

Filtrationtime is thetimeinterval that precede thedatatransmission and whichis used to

calculate the averagefuellevelinthetank. Thus, thevalueof thefuellevelinthetank

whichis transmitted by the sensor to therecording anddisplay device isnottheinstant

value, but the averaged value over theset periodoftime whichhasprecededthemoment

of thedatatransfer.

Fig.17. WindowoftheprogramService DUT-E

For the DUT-E485 thesettingof theuniqueaddress foreach sensor inthenetworkRS 485

is also available(See Figure 17).

Version 5.0DUT-EInstallationManual

©2007-2011, JV Technoton 20 of 30

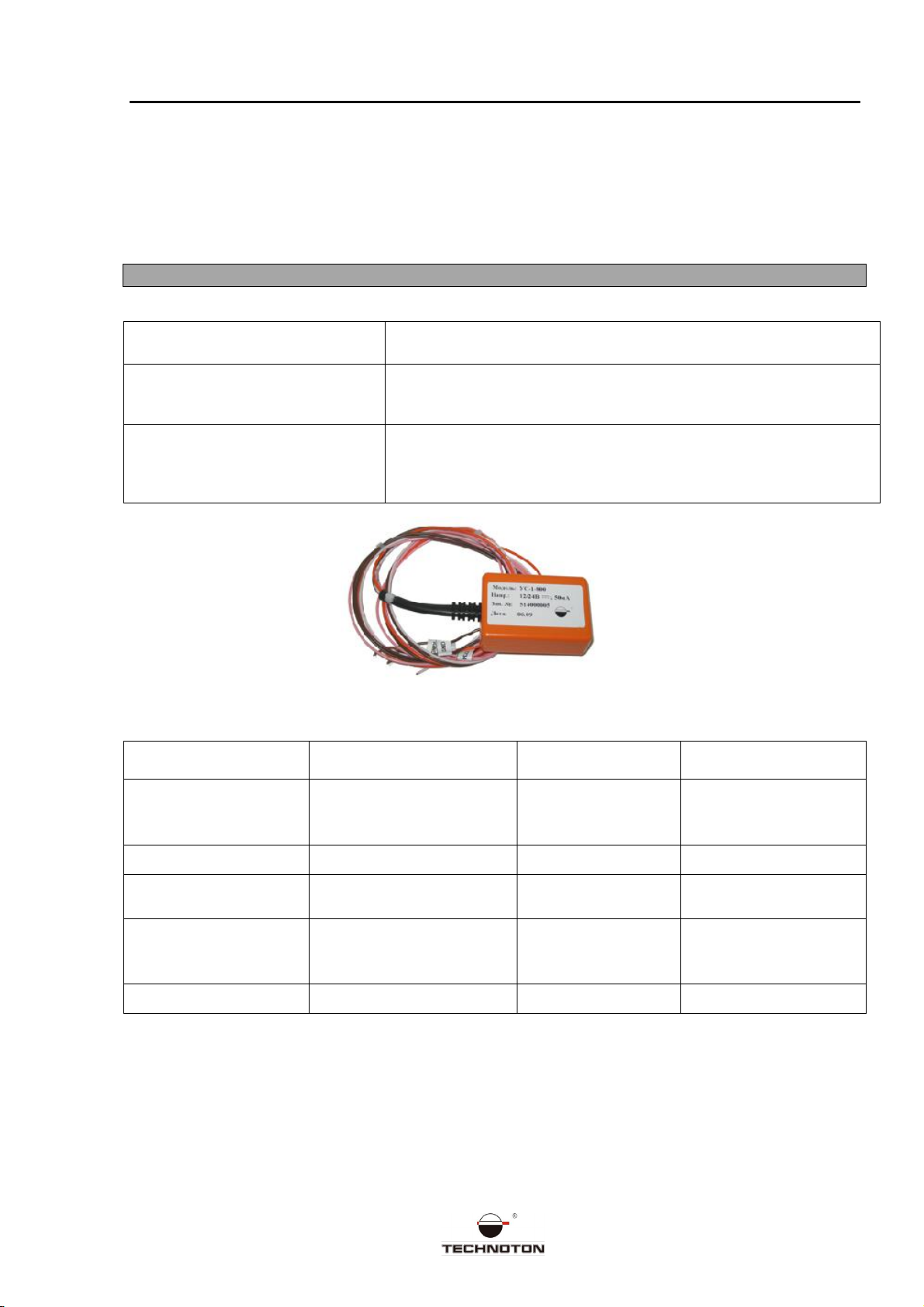

2.10 Connection of DUT-E to theindicator of fuel level

By installingtheDUT-E onthe placeof standard fuellevelsensor you may needto restore

the indicator of remainingfuelinthetank toworkingcondition. Inorder toimplement this

function you needto use an interfacedevice UC.

ATTENTION! Interfacedevicecomplies onlywith DUT-E A5!

Table 6. Interfacedevicemodels

ArticleorderNo Remark

UС-1-90 Emulation of the level sensor with low resistance:0-90 Ohm

UС-1-800 Emulation of the level sensor with high resistance: 800-185

Ohm

Fig.18. Exteriorviewof theinterfacedeviceU -1

Table7. Circuit nameandwirecolours:

PinNo Circuitname Wirecolour* Remark

1 T034 white Signal from the fuel

levelsensor (input)

2 GND brown Vehicleground

3 T734 pink Fuellevelindicator

(output)

4 T733 pink Controllamp of the

fuellevel (output)

5 VBAT orange Powervoltage

* Themanufacturerreserves theright to changethewire colours.

This manual suits for next models

4

Table of contents

Other Technoton Accessories manuals

Popular Accessories manuals by other brands

ROSE DISPLAYS

ROSE DISPLAYS SPIDER CEILING TRACK QUICK PAGE Installation

Dini Argeo

Dini Argeo LTP Installation and operating instructions

Panasonic

Panasonic CA-LSR10U - Sirius Satellite Radio Receiver operating instructions

Verilux

Verilux Rise & Shine VA05F manual

Denver Instrument

Denver Instrument P-114 Operation manual

schmersal

schmersal RSS260 operating instructions