TECHTOP MS1/MS2 Series User guide

Installation, operation,

maintenance and safety manual

LOW VOLTAGE MOTORS

rev. 01

ENGLISH

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

2

Installation, operation,

maintenance and safety manual

LOW VOLTAGE MOTORS

1. GENERAL SAFETY WARNING

1.1 Declaration of Conformity

1.2 Validity

2. HANDLING

2.1 Reception check

2.2 Transportation and storage

2.3 Lifting

2.4 Machine weight

3. INSTALLATION AND COMMISSIONING

3.1 General

3.2 Insulation resistance check

3.3 Foundation

3.4 Balancing and tting coupling halves and pulleys

3.5 Mounting and alignment of the motor

3.6 Slide rails and belt drives

3.7 Cabling and electrical connections

3.7.1 Connection for different starting methods

3.7.2 Connection of auxiliaries

3.8 Terminals and direction of rotation

p.04

p.04

p.04

p.05

p.05

p.05

p.05

p.06

p.07

p.07

p.07

p.08

p.08

p.08

p.09

p.09

p.09

p.10

p.10

LIST OF CONTENTS

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016 3

p.10

p.10

p.11

p.11

p.11

p.12

p.12

p.13

p.14

p.15

p.18

p.19

p.19

p.19

p.19

p.19

p.19

p.20

p.23

4. OPERATION

4.1 Use

4.2 Cooling

4.3 Satety considerations

5. MAINTENANCE

5.1 General inspection

5.2 Lubrication

5.2.1 Machines with permanently greased bearings

5.2.2 Motors with regreasable bearings

5.2.3 Lubrication intervals and amounts

5.2.4 Lubricants

6. AFTER SALES SUPPORT

6.1 Spare parts

6.2 Rewinding

6.3 Bearings

7. ENVIRONMENTAL REQUIREMENTS

7.1 Noise levels

8. TROUBLESHOOTING

9. RECYCLE POLICY

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

4

1. GENERAL SAFETY WARNING

NOTE

These instructions must be followed to ensure safe and proper installation, operation and maintenance of the machine. They should be brought to the

attention of anyone who installs, operates or maintains the machine or associated equipment. The machine is intended for installation and use by qualied

personnel, familiar with health and safety requirements and national legislation. Ignoring these instructions may invalidate all applicable warranties.

Safety equipment necessary for the prevention of accidents during installation and maintenance during operation must comply with national regulations in

force in the country of installation.

WARNING!

Controls for emergency stop must be equipped with restart lockout devices, after an emergency stop, star command can take effect only after intentionally

reset of the lockout devices.

WARNING!

Electric motors are components with dagerous parts under tension and moving parts during operation.

Improper use, protections removal without having proceeded to dissect the power supply line, disconnect the protective devices, not make periodic

inspections or maintinance, can be cause serious damage.

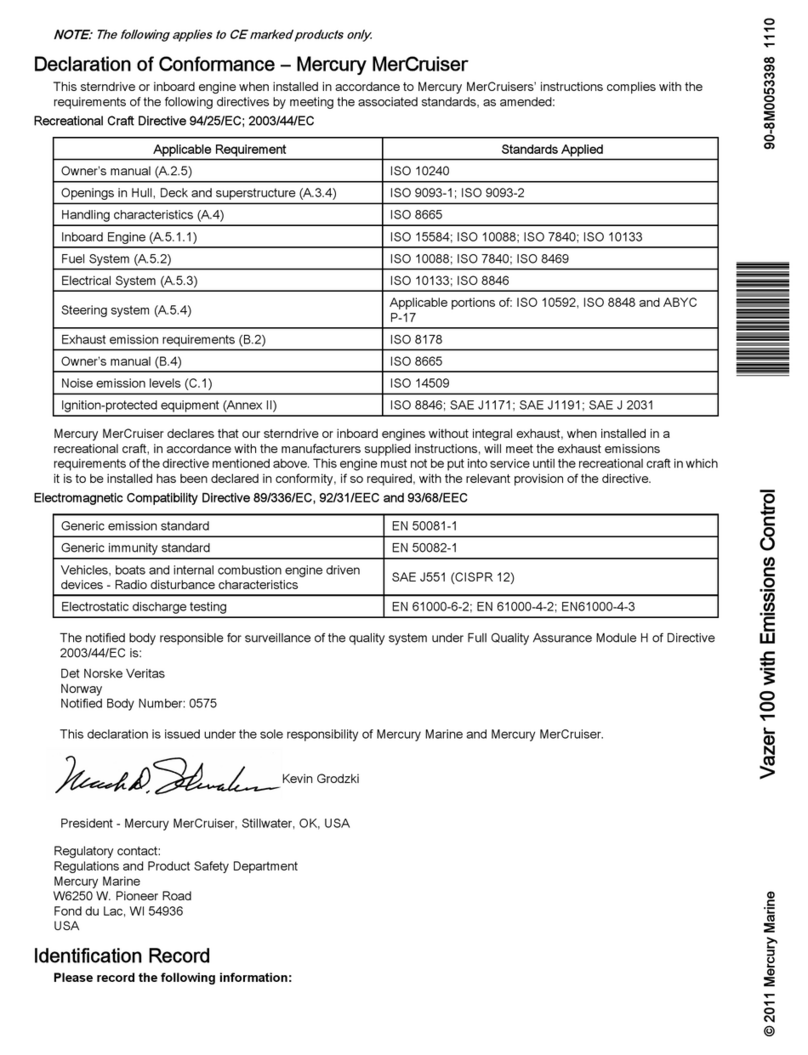

1.1 Declaration of Conformity

Motor is manufactured in compliance with the international standard IEC 34-1 (EN 60034-1) and to following European Directives:

Low Voltage Directive (LVD) 2014/35/UE

Electromagnetic Compatibility Directive (EMC) 2014/30/UE egarding the intrinsic characteristics to emission and immunity levels.

Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS)

2002/95/EC

The captioned motors are also in compliance with the “Machinery Directive” 98/37/EC( amended by 2006/42/EC), assuming for this, that the motor component

may not be put into service before the machine in which it will assembled, has been declared to be in compliance with the Directive provisions.

When operating the motor, it is necessary to assure that the Standard EN 60204-1 and the installation and safety instructions of the manufacturer’s operating

handbook are observed. Conformity declaration can be supplied when requested.

1.2 Validity

The instructions are valid for the following TECHTOP electrical machine types, in both motor and generator operation.

Series: MS1/MS2 (TM), MSB, MSD, MSC/MYC, MSV (TMV), MYV, T1A,T2A,T3A,TXA

Series: MY/MYT, ML, MC

Series: Y/Y2 ( TM ), YC, T1C ( TM ), T2C ( TM/TCF ), T3C ( TCF ), TCI/TCP, TG,TXC in frame sizes 56-500

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016 5

2. HANDLING

2.1 Reception check

Immediately upon receipt check the motor for external damage (e.g. shaft-ends and anges and painted surfaces) and if found, inform the forwarding agent

without delay.

Check all rating plate data, especially voltage and winding connection (star or delta). The type of bearing is specied on the catalogue of all motors.

2.2 Transportation and storage

The motor should always be stored indoors (above –20°C), in dry, vibration free and dust free conditions. During transportation, shocks, falls and humidity

should be avoided. In other conditions, please contact TECHTOP.

Unprotected machined surfaces (shaft-ends and anges) should be treated against corrosion.

It is recommended that shafts are rotated periodically by hand to prevent grease migration.

Anti-condensation heaters, if tted, are recommended to be used to avoid water condensing in the motor.

The motor must not be subject to any external vibrations at standstill so as to avoid causing damage to the bearings.

Motors tted with cylindrical-roller and/or angular contact bearings must be tted with locking devices during transport.

2.3 Lifting

All TECHTOP motors above 25 kg are equipped with lifting lugs or eyebolts.

Only the main lifting lugs or eyebolts of the motor should be used for lifting the motor. They must not be used to lift the motor when it is attached to other

equipment.

Lifting lugs for auxiliaries (e.g. brakes, separate cooling fans) or terminal boxes must not be used for lifting the motor.

Motors with the same frame may have a different center of gravity because of different output, mounting arrangements and auxiliary equipment. Damaged

lifting lugs must not be used. Check that eyebolts or integrated lifting lugs are undamaged before lifting.

Lifting eyebolts must be tightened before lifting. If needed, the position of the eyebolt can be adjusted using suitable washers as spacers.

Ensure that proper lifting equipment is used and that the sizes of the hooks are suitable for the lifting lugs.

Care must be taken not to damage auxiliary equipment and cables connected to the motor.

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

6

2.4 Machine weight

The total machine weight can vary within the same frame size (center height) depending on different output, mounting arrangement and auxiliaries.

The following table shows estimated maximum weights for machines in their basic versions as a function of frame material.

The actual weight of all TECHTOP’s motors is shown on the catalogue.

Frame size

Aluminum

Weight

kg

Cast iron

Weight

kg

56 4

63 5

71 7

80 11 19

90 18 27

100 28 38

112 36 50

132 64 84

160 98 147

180 128 195

200 158 270

225 320

250 427

280 667

315 1270

355 1850

400 3000

450 3800

500 5300

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016 7

3. INSTALLATION AND COMMISSIONING

WARNING!

Disconnect and lock out before working on the motor or the driven equipment.

3.1 General

All rating plate values must be carefully checked to ensure that the motor protection and connection will be properly done.

WARNING!

In case of motors mounted with the shaft upwards and water or liquids are expected to go down along the shaft, the user must take in account to mount

some means capable of preventing it.

Remove transport locking if employed. Turn shaft by hand to check free rotation if possible.

Motors equipped with roller bearings:

Running the motor with no radial force applied to the shaft may damage the roller bearing.

Motors equipped with angular contact bearing:

Running the motor with no axial force applied in the right direction in relation to the shaft may damage the angular contact bearing.

WARNING!

For machines with angular contact bearings the axial force must not by any means change direction.

Motors equipped with regreasing nipples:

When starting the motor for the rst time, or after long storage, apply the specied quantity of grease.

For details, see section “5.2.2 Motors with regreasable bearings“.

3.2 Insulation resistance check

Measure insulation resistance before commissioning and when winding dampness is suspected.

WARNING!

Disconnect and lock out before working on the motor or the driven equipment.

Insulation resistance, corrected to 25°C, must exceed the reference value, i.e. 100 MΩ (measured with 500 or 1000 V DC). The insulation resistance value is

halved for each 20°C rise in ambient temperature.

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

8

WARNING!

The motor frame must be grounded and the windings should be discharged against the frame immediately after each measurement to avoid risk of electrical

shock.

If the reference resistance value is not attained, the winding is too damp and must be oven dried. The oven temperature should be 90°C for 12-16 hours

followed by 105°C for 6-8 hours.

Drain hole plugs, if tted, must be removed and closing valves, if tted, must be opened during heating. After heating, make sure the plugs are retted.

Even if the drain plugs are tted, it is recommended to disassemble the end shields and terminal box covers for the drying process.

Windings drenched in seawater normally need to be rewound.

3.3 Foundation

The end user has full responsibility for preparation of the foundation.

Metal foundations should be painted to avoid corrosion.

Foundations must be even, and sufciently rigid to withstand possible short circuit forces. They must be designed and dimensioned to avoid the transfer of

vibration to the motor and vibration caused by resonance.

3.4 Balancing and tting coupling halves and pulleys

As standard, balancing of the motor has been carried out using half key.

Coupling halves or pulleys must be balanced after machining the keyways. Balancing must be done in accordance with the standard balancing method

specied for the motor.

Coupling halves and pulleys must be tted on the shaft by using suitable equipment and tools which do not damage the bearings and seals.

Never t a coupling half or pulley by hammering or by removing it using a lever pressed against the body of the motor.

3.5 Mounting and alignment of the motor

Ensure that there is enough space for free airow around the motor. Minimum requirements for free space behind the motor fan cover should be achieved.

Correct alignment is essential to avoid bearing, vibration and possible shaft failures.

Mount the motor on the foundation using the appropriate bolts or studs and place shim plates between the foundation and the feet.

Align the motor using appropriate methods.

If applicable, drill locating holes and x the locating pins into position.

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016 9

Re-check the alignment after nal tightening of the bolts or studs.

3.6 Slide rails and belt drives

Fasten the motor to the slide rails as shown in Figure 2.

Place the slide rails horizontally on the same level.

Check that the motor shaft is parallel with the drive shaft. Belts must be tensioned according to the instructions of the supplier of the driven equipment.

WARNING!

Excessive belt tension will damage bearings and can cause shaft damage.

3.7 Cabling and electrical connections

The terminal box on standard single speed motors normally contains six winding terminals and at least one earth terminal.

In addition to the main winding and earthing terminals, the terminal box can also contain connections for thermistors, heating elements or other auxiliary

devices.

Suitable cable lugs must be used for the connection of all main cables. Cables for auxiliaries can be connected into their terminal blocks as such.

Machines are intended for xed installation only. If not otherwise specied, cable entry threads are metric. The IP-class of the cable gland must be at

least the same as those of the terminal boxes.

Unused cable entries must be closed with blanking elements according to the IP class of the terminal box.

The degree of protection and diameter are specied in the documents relating to the cable gland.

WARNING!

Use appropriate cable glands and seals in the cable entries according to the type and diameter of the cable.

Earthing must be carried out according to local regulations before the machine is connected to the supply voltage.

Ensure that the motor protection corresponds to the environment and weather conditions; for example, make sure that water cannot enter the motor or the

terminal boxes.

The seals of terminal boxes must be placed correctly in the slots provided, to ensure the correct IP class.

3.7.1 Connections for different starting methods

The terminal box on standard single speed motors normally contains six winding terminals and at least one earth terminal.

This enables the use of DOL- or Y/D–starting. See Figure 1.

For two-speed and special motors, the supply connection must follow the instructions inside the terminal box or in the motor manual.

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

10

The voltage and connection are stamped on the terminal box cover.

Direct-on-line starting (DOL):

Y or D winding connections may be used.

For example, 690 VY, 400 VD indicates Y-connection for 690 V and D-connection for 400 V.

WARNING!

from 10KW Start/Delta (Y/D) starting is recommended Star/Delta starting (Y/D):

The supply voltage must be equal to the rated voltage of the motor when using a D-connection.

Remove all connection links from the terminal block.

3.7.2 Connections of auxiliaries

If a motor is equipped with thermistors or other RTDs (Pt100, thermal relays, etc.) and auxiliary devices, it is recommended they be used and connected by

appropriate means.

Maximum measuring voltage for the thermistors is 2.5 V. Maximum measuring current for Pt100 is 5 mA. Using a higher measuring voltage or current may cause

errors in readings or damage the system.

3.8 Terminals and direction of rotation

The shaft rotates clockwise when viewing the shaft face at the motor drive end, and the line phase sequence L1, L2, L3 is connected to the terminals as shown

in Figure 1.

To alter the direction of rotation, interchange any two connections on the supply cables.

If the motor has a unidirectional fan, ensure that it rotates in the same direction as the arrow marked on the motor.

4. OPERATION

4.1 Use

The motors are designed for the following conditions unless otherwise stated on the rating plate.

- Normal ambient temperature limits are -20°C to +40°C.

- Maximum altitude 1000 m above sea level.

- Tolerance for supply voltage is ±5% and for frequency ±2% according to EN / IEC 60034-1 (2004).

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016 11

WARNING!

Ignoring any of given instructions or maintenance of the apparatus may jeopardize the safety and thus prevents the use of the machine.

4.2 Cooling

Check that the motor has sufcient airow. Ensure that no nearby objects or direct sunshine radiate additional heat to the motor.

For ange mounted motors (e.g. B5, B35, V1), make sure that the construction allows sufcient air ow on the outer surface of the ange.

4.3 Safety considerations

The machine is intended for installation and use by qualied personnel, familiar with health and safety requirements and national legislation.

Safety equipment necessary for the prevention of accidents at the installation and operating site must be provided in accordance with local regulations.

WARNING!

Do not carry out work on motor, connection cables or accessories such as frequency converters, starters, brakes, thermistor cables or heating elements when

voltage is applied.

Points to observe

1. Do not step on the motor.

2. The temperature of the outer casing of the motor may be too hot to touch during normal operation and especially after shut-down.

3. Some special motor applications require special instructions (e.g. using frequency converter supplies).

4. Be aware of rotating parts of the motor.

5. Do not open terminal boxes while energized., for singhle phase motors pay attention at the capacitor descharge even when the line supply is disconnected.

5. MAINTENANCE

WARNING!

Voltage may be connected at standstill inside the terminal box for heating elements or direct winding heating.

WARNING!

The capacitor in single-phase motors can retain a charge that appears across the motor terminals, even when the motor has reached standstill.

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

12

WARNING!

A motor with frequency converter supply may energize even if the motor is at standstill.

5.1 General inspection

1. Inspect the motor at regular intervals, every 3 months is recommended,at least once a year. The frequency of checks depends on, for example, the humidity

level of the ambient air and on the local weather conditions. This can initially be determined experimentally and must then be strictly adhered to.

2. Keep the motor clean and ensure free ventilation airow. If the motor is used in a dusty environment, the ventilation system must be regularly checked

and cleaned.

3. Check the condition of shaft seals (e.g. V-ring or radial seal) and replace if necessary.

4. Check the condition of connections and mounting and assembly bolts.

5. Check the bearing condition by listening for any unusual noise, vibration measurement, bearing temperature, inspection of spent grease or SPM bearing

monitoring. Pay special attention to bearings when their calculated rated life time is coming to an end.

When signs of wear are noticed, dismantle the motor, check the parts and replace if necessary. When bearings are changed, replacement bearings must be of

the same type as those originally tted. The shaft seals have to be replaced with seals of the same quality and characteristics as the originals when changing

bearings.

In the case of the IP 55 motor and when the motor has been delivered with a plug closed, it is advisable to periodically open the drain plugs in order to ensure

that the way out for condensation is not blocked and allows condensation to escape from the motor. This operation must be done when the motor is at a

standstill and has been made safe to work on.

5.2 Lubrication

WARNING!

Beware of all rotating parts!

WARNING!

Grease can cause skin irritation and eye inammation. Follow all safety precautions specied by the gease manufacturer.

Bearing types are specied in the respective product catalogs.

Reliability is a vital issue for bearing lubrication intervals. TECHTOP uses mainly the L1-principle (i.e. that 99% of the motors are certain to make the life time)

for lubrication.

WARNING!

Due to the occurrence as described below, may manifest moderate grease, or grease components in liquid form,leakage from the bearings;as a result of the

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016 13

regreasing operations, in the rst hours of motor operation, when the motor work out of the nominal conditios, in case of use, in maintinace operation, non

compliant graeses respect those indicated by the manufacturer.

These grease leakage should be monitored during the periodic motor inspection, any leakage should be cleaned with care and caution to avoid damage to

the environment. Persistenceof these leaks should be avoided because it indicates that the motor operates out to the nominal conditions, or that have been

used, during maintinance operations, not complying grease.

5.2.1 Machines with permanently greased bearings

Bearings are usually permanently greased bearings of 1Z, 2Z, 2RS or equivalent types.

As a guide, adequate lubrication for sizes up to 200 can be achieved for the following duration, according to L10, until 200 size.

Duty hours for permanently greased bearings at ambient temperatures of 25 and 40° C are:

LUBRICATION INTERVALS ACCORDING TO L10 PRINCIPLE

Frame

Size Poles

Duty

hours at

25°C

Duty

hours at

40°C

Frame

Size Poles

Duty

hours at

25°C

Duty

hours at

40°C

56-63 2-8 40000 40000 132 4-8 40000 40000

71 2 40000 40000 160 2 40000 36000

71 4-8 40000 40000 160 4-8 40000 40000

80-90 2 40000 40000 180 2 38000 38000

80-90 4-8 40000 40000 180 4-8 40000 40000

100-112 2 40000 32000 200 2 27000 27000

100-112 4-8 40000 40000 200 4-8 40000 40000

132 2 40000 27000

*Data valid at 50 Hz, for 60 Hz reduce values for 20 %.

WARNING!

These values are valid for permitted load values given in the product catalog. Depending on application and load conditions, see the applicable product

catalog or contact TECHTOP. Data above reported will be in compliance with item 5.2, and are refered at the following motor working conditions, ambient

temperature 25°C, max bearing working temperature 80°C. Medium bearing lifetime value showed should be halved for each increment of 15°C of the

ambient temperature.

WARNING!

With the aim to keep the stated average lifetime it is important to perform periodical inspections on the motor, in order to prevent temperature increases on

the bearings due to eventual dirt accumulating on the motor housing or on the ventilation system.

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

14

In the event fo motors driven by frequency converter, the stated average lifetime have to be reduced by 25%. Operation hours for vertical motors are half of

the above values.

5.2.2 Motors with regreasable bearings

WARNING!

During the rst start or after a bearing lubrication a temporary temperature rise may appear, approximately 10 to 20 hours.

Lubrication intervals are driven in accordance to the following motor parameters:

1) horizzontal mounting position B3

2) ambient temperature 25°C

3) max bearing working temperature 80°C

4) motor operating condition in line with the nominal parameter reported in the motor name plate, like rspeed,power,etc.

WARNING!

Bearings lifetime values below reported, are valid for permitted load values given in the product catalog. Depending on application and load conditions, see

the applicable product catalog or contact TECHTOP. Data above reported will be in compliance with item 5.2, and are refered at the following motor working

conditions, ambient temperature 25°C, max bearing working temperature 80°C. Medium bearing lifetime value showed should be halved for each increment

of 15°C of the ambient temperature.

WARNING!

With the aim to keep the stated average lifetime it is important to perform periodical inspections on the motor, in order to prevent temperature increases on

the bearings due to eventual dirt accumulating on the motor housing or on the ventilation system.

In the event fo motors driven by frequency converter, the stated average lifetime have to be reduced by 25%.

Operation hours for vertical motors are half of the above values.

A. Manual lubrication

Regreasing while the motor is running

– Remove grease outlet plug, located down in the front shield/ange and in the rear shield.

– Be sure that the lubrication channel located on the front shield/ange (DE side) and on the rear shield (NDE side) is open

– Inject the specied amount of grease into the bearing.

– Let the motor run for 1-2 hours to ensure that all excess grease is forced out of the grease outlet plug. Close the grease outlet plug.“

Regreasing while the motor is at a standstill

If it is not possible to regrease the bearings while the motors are running, lubrication can be carried out while the machine is at a standstill, repeat the

instruction for regreasing while the motor running, with the described below variants:

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016 15

– In this case use only half the quantity of grease and then run the motor for a few minutes at full speed.

– When the motor has stopped, apply the rest of the specied amount of grease to the bearing.

– After 1-2 running hours close the grease outlet plug.

Greasing nipple dimension (mm)

B. Automatic lubrication

The grease outlet plug must be removed permanently with automatic lubrication.

TECHTOP recommends only the use of electromechanical systems.

The amount of grease per lubrication interval stated in the table should be multiplied by four if an automatic regreasing system is used.

When 2-pole motors are automatically regreased, the note concerning lubricant recommendations for 2-pole motors in the Lubricants chapter should be

followed.

5.2.3 Lubrication intervals and amounts

As a guide, adequate lubrication for motors with regreasable bearings can be achieved for the following duration, according to L1. For duties with higher

ambient temperatures please contact TECHTOP. The formula to change the L1 values roughly to L10 values: L10 = 2.7 x L1.

WARNING!

Lubrication intervals for vertical machines are half of the values shown in the table below.

The lubrication intervals are based on an ambient temperature +25°C. An increase in the ambient temperature raises the temperature of the bearings

correspondingly. The values should be halved for a 15°C increase and may be doubled for a 15°C decrease.

WARNING!

The maximum operating temperature of the grease and bearings, +110°C, must not be exceeded. The designed maximum speed of the motor must not be

exceeded.

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

16

Lubrication intervals according to L1 principle

Frame size

Amount of

grease

g/bearing

kW 3600 rpm 3000 rpm kW 1800 rpm 1500 rpm kW 1000 rpm kW 500-900

rpm

Ball bearings -- Lubrication intervals in duty hour

112 10 all 10.000 13.000 all 18.000 21.000 all 25.000 all 28.000

132 15 all 9.000 11.000 all 17.000 19.000 all 23.000 all 26.500

160 25 ≤18.5 9.000 12.000 ≤15 18.000 21.500 ≤11 24.000 all 24.000

160 25 >18.5 7.500 10.000 >15 15.000 18.000 >11 22.500 all 24.000

180 30 ≤22 7.000 9.000 ≤22 15.000 18.500 ≤15 24.000 all 24.000

180 30 >22 6.000 8.500 >22 14.000 17.000 >15 21.000 all 24.000

200 40 ≤37 5.500 8.000 ≤30 14.500 17.500 ≤22 23.000 all 24.000

200 40 >37 3.000 5.500 >30 10.000 12.000 >22 16.000 all 20.000

225 50 ≤45 4.000 6.500 ≤45 13.000 16.500 ≤30 22.000 all 24.000

225 50 >45 1.500 2.500 >45 5.000 6.000 >30 8.000 all 10.000

250 60 ≤55 2.500 4.000 ≤55 9.000 11.500 ≤37 15.000 all 18.000

250 60 >55 1.000 1.500 >55 3.500 4.500 >37 6.000 all 7.000

280 60 all 2.000 3.500 - - - - - - -

280 60 - - - all 8.000 10.500 all 14.000 all 17.000

280 35 all 1.900 3.200 - - - - - - -

280 40 - - - all 7.800 9.600 all 13.900 all 15.000

315 35 all 1.900 3.200 - - - - - - -

315 55 - - - all 5.900 7.600 all 11.800 all 12.900

355-500 35 all 1.900 3.200 - - - - - - -

355-500 70 - - - all 4000 5.600 all 9.600 all 10.700

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016 17

Lubrication intervals according to L1 principle

Frame size

Amount of

grease

g/bearing

kW 3600 rpm 3000 rpm kW 1800 rpm 1500 rpm kW 1000 rpm kW 500-900

rpm

Roller bearings -- Lubrication intervals in duty hour

160 25 ≤18.5 4.500 6.000 ≤15 9.000 10.500 ≤11 12.000 all 12.000

160 25 >18.5 3.500 5.000 >15 7.500 9.000 >11 11.000 all 12.000

180 30 ≤22 3.500 4.500 ≤22 7.500 9.000 ≤15 12.000 all 12.000

180 30 >22 3.000 4.000 >22 7.000 8.500 >15 10.500 all 12.000

200 40 ≤37 2.750 4.000 ≤30 7.000 8.500 ≤22 11.500 all 12.000

200 40 >37 1.500 2.500 >30 5.000 6.000 >22 8.000 all 10.000

225 50 ≤45 2.000 3.000 ≤45 6.500 8.000 ≤30 11.000 all 12.000

225 50 >45 750 1.250 >45 2.500 3.000 >30 4.000 all 5.000

250 60 ≤55 1.000 2.000 ≤55 4.500 5.500 ≤37 7.500 all 9.000

250 60 >55 500 750 >55 1.500 2.000 >37 3.000 all 3.500

280 60 all 1.000 1.750 - - - - - - -

280 70 - - - all 4.000 5.250 all 7.000 all 8.500

280 35 all 900 1.600 - - - - - - -

280 40 - - - all 4.000 5.300 all 7.000 all 8.500

315 35 all 900 1.600 - - - - - - -

315 55 - - - all 2.900 3.800 all 5.900 all 6.500

355-500 35 all 900 1.600 - - - - - - -

355-500 70 - - - all 2.000 2.800 all 4.800 all 5.400

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

18

5.2.4 Lubricants

WARNING

Do not mix different types of grease.

Incompatible lubricants may cause bearing damage.

When regreasing, use only special ball bearing grease with the following properties:

– good quality grease with lithium complex soap and with mineral- or PAO-oil

– base oil viscosity 100-160 cST at 40°C

– consistency NLGI grade 1.5 - 3*

– temperature range -30°C - +110°C, continuously.

*) For vertical mounted motors or in hot conditions a stiffer end of scale is recommended.

The above mentioned grease specication is valid if the ambient temperature is above -30°C or below +55°C, and the bearing temperature is below 110°C.

Grease with the correct properties is available from all the major lubricant manufacturers.

Admixtures are recommended, but a written guarantee must be obtained from the lubricant manufacturer, especially concerning EP admixtures, that

admixtures do not damage bearings or the properties of lubricants at the operating temperature range.

WARNING!

Lubricants containing EP admixtures are not recommended in high bearing temperatures in frame sizes 280 to 355.

The following high performance greases can be used:

- Esso Unirex N2 or N3 (lithium complex base)

- Mobil Mobilith SHC 100 (lithium complex base)

- Shell Albida EMS 2 (lithium complex base)

- Klüber Klüberplex BEM 41-132 (special lithium base)

- FAG Arcanol TEMP110 (lithium complex base)

- Lubcon Turmogrease L 802 EP PLUS

- Total Multiplex S 2 A (lithium complex base)

NOTE!

Always use high speed grease for high speed 2-pole machines where the speed factor is higher than 480,000 (calculated as Dm x n where Dm=average bearing

diameter, mm; n=rotational speed, r/min).

The following greases can be used for high speed cast iron motors but not mixed with lithium complex greases:

- Klüber Klüber Quiet BQH 72-102 (polyurea base)

- Lubcon Turmogrease PU703 (polyurea base)

If other lubricants are used:

Check with the manufacturer that the qualities correspond to those of the above mentioned lubricants.

WARNING!

Lubrication intervals listed above, are based on the use of high-performance greases such as those listed above, the use of other thypes of grease can reduce

the lubrication intervals listed

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016 19

6. AFTER SALES SUPPORT

6.1. Spare parts

When ordering spare parts, the motor serial number, full type designation and product code, as stated on the rating plate, must be specied.

For more information, please visit our web site:

www.techtop.com

6.2 Rewinding

Rewinding should always be carried out by qualied repair shops.

Contact TECHTOP before rewinding the motors.

6.3 Bearings

Special care should be taken with the bearings. These must be removed using pullers and tted by heating or using special tools for the purpose.

For more details on how replace the bearings, please contact TECHTOP.

Bearings type mounted on the motor can’t be changed.

WARNING!

Unless expressly authorized by the manufacturer, any repair by the end user will void the warranty and any responsability of the manufacturer on the motor

conformity.

7. ENVIRONMENTAL REQUIREMENTS

7.1 Noise levels

Most of TECHTOP’s motors have a sound pressure level not exceeding 80 dB(A) at 50 Hz.

Values for specic machines can be found in the relevant product catalogues. At 60 Hz sinusoidal supply the values are approximately 4 dB(A) higher

compared to 50 Hz values in product catalogues.

LOW VOLTAGE MOTORS - Installation, operation, maintenance and safety manual - rev. 01 - 1.07.2016

20

8. TROUBLESHOOTING

These instructions do not cover all details or variations in equipment nor provide for every possible condition to be met in connection with installation,

operation or maintenance.

Motor troubleshooting chart

Your motor service and any troubleshooting must be handled by qualied persons who have proper tools and equipment.

TROUBLE CAUSE SOLUTION

Motor fails to

start

Blown fuses Replace fuses with proper type and rating

Overload trips Check and reset overload in starter

Improper power supply Check to see that power supplied agrees with motor rating plate and load factor

Improper line connections Check connections against diagram supplied with motor

Open circuit in winding or

control switch

Indicated by humming sound when switch is closed. Check for loose wiring connections.

Also ensure that all control contacts are closing

Mechanical failure Check to see if motor turn freely.

Check bearings and lubrication

Short circuited stator Indicated by blown fuses.

Motor must be rewound

Poor stator coil connection Remove end shields, locate fault

Rotor defective Look for broken bars or end rings

Motor may be overloaded Reduce load

Motor stalls

One phase may be open Check lines for open phase

Wrong application Change type or size,consult equipment supplier

Overload Reduce load

Low voltage Ensure the rating plate voltage is maintained,check connection

Ooen circuit Fuses blown, check overload relay, stator and push buttons

Motor runs and

then dies down Power failure Check for loose connections to line, to fuses and to control

This manual suits for next models

28

Table of contents

Popular Engine manuals by other brands

Briggs & Stratton

Briggs & Stratton 280000 Series Operating & maintenance instructions

Central Machinery

Central Machinery 96500 Assembly and operation instructions

Kohler

Kohler 7000 Series user manual

Perkins

Perkins 4.108 Workshop manual

O.S. engine

O.S. engine FS-52S Owner's instruction manual

Master

Master LINE user manual