Teckentrup dw 62-2ME Product guide

Operating / Assembly Instructions

& Installation Data

dw 62-2ME Steel Sliding Door

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 2 -

These assembly instructions are valid for the dw 62-2 ME steel sliding door.

Table of Contents

Chapter Title Page

1. General Information 3

1.1 Types of Walls 3

2. Assembly 3

2.1 Preparation 3

2.2 Maintenance/Inspections/Repairs 3

2.3 Operation/Utilisation 4

3. Warranty 4

4. Outside Doors 4

5. Arrangement of Wall Seals, Weight Boxes (optional) and Brackets 4

6. Assembly Process 5

7. Installation Details 5

7.1 Fixing the Brackets 5

7.2 Fixing the Lateral Wall Seals and the Weight Box 7

7.3 Runner Rail Assembly 8

7.4 Hanging the Door Leaves and Roller Mechanism 8

7.5 Assembly of the Door Leaves 9

7.6 Fixing the Lower Guide Bracket 9

7.7 Installation of the Lower Door Track 9

7.8 Fixing the Handles to the Door Leaves 10

7.9 Wicket Door 10

7.10 End Stoppers 11

7.11 Rain Guard 11

8. Glazing Elements 12

9. Drive 12

10. Doors with Counterbalance Weight 14

10.1 Rope Guidance and Counterweight Suspension 14

10.2 Rope Guidance and Weight Suspension 14

10.3 Assembly of the Hydraulic Brake Mechanism, Limit Stops and Magnetic Clamp 16

11. Special Versions 16

11.1 Artificial Lintel 16

11.2 Advanced Limit Stop 17

12. General Safety Instructions for Assembly 18

13. Maintenance 18

14. Declaration of Conformity and CE Mark 18

Inspection Book for Power Operated Doors 19-24

Last Update: 15.03.05

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 3 -

1. General Information

- These installation instructions provide an overview of the current state of development.

- The utmost care has been taken to ensure that these instructions are error free. However, we shall not be

liable for any possible printing errors or missing data.

- We reserve the right to make technical changes.

- In order to guarantee correct functioning and safe operation of the door only use original parts as

accessories, e.g. fittings, door latches, locks, locking mechanisms. Always observe the respective assembly

instructions. Spare parts and accessories can be purchased from an authorised distributor and Tekla-

Technik, Tor + Tür GmbH & Co. KG.

Important:

- In the interest of safety, only use the anchors, plugs and bolts supplied with the door for installation. The

following plugs and anchors are used: For masonry Fischer FUR and for concrete Fischer FAZ or FH-S.

Fixings not specified in the installation instructions require prior release by Tekla-Technik, Tor + Tür GmbH &

Co. KG.

- These instructions have been created for authorised technicians in accordance with EN 12635

requirements. Door assembly should only be carried out by technicians who fulfil these

requirements.

- Welding at the suspension should only be carried out by qualified welders (DIN EN 287-1 (Qualification test

of welders - Fusion welding)).

1.1 Types of Walls

The static stability of the frame and runner rail installation has to be designed for the actual weight of

the door! Static inspection/documentation has to be provided by the customer!

The sliding door can be mounted to the following walls:

- Masonry in accordance with DIN 1053-1, min. masonry strength class 12, min. masonry mortar group IIa,

wall thickness ≥ 240 mm or

- Concrete in accordance with DIN 1045, min. strength class B15, wall thickness ≥140 mm.

- Autoclaved aerated concrete blocks and high precision units – in accordance with DIN 4165, min.

masonry strength class 4

- Steel constructions with static documentation

2. Assembly

2.1 Preparation

- Ensure that the wall is plumb and level prior to assembly.

- Carry out plastering and painting work after assembling the door.

- Precisely even out any unevenness, etc. on the wall using pressure-resistant bases.

- Fix the sliding door to the adjacent constructional elements tightly enough to ensure that the static loads of

the closed and open door as well as the dynamic load of the opening and closing door are permanently

borne. These forces should not affect the stability of the adjacent wall.

- Ensure that the door is covered before plastering or painting work is carried out, since spots of mortar,

cement, plaster or paint can damage the surface.

- Make sure that the door does not come into contact with corrosive and caustic agents such as saltpetre

reactions from bricks or mortar, acids, alkalis, road salt, chlorine, corrosive paints or sealing compounds.

- Always observe and adhere to local regulations if the door is installed in

explosive areas. The owner has to inform the company commissioned to install

the door of these regulations.

Earthing measures should only be carried out by qualified electricians

2.2 Maintenance/Inspections/Repairs

The owner or a person authorised by the owner has to visually inspect the functionality of the door system

regularly and to check for any external damages in accordance with chapter 1 of the maintenance information

(see 1, Check List Power Operated Doors - Systems). Repair work should only be carried out by qualified

technicians or Tekla-Technik, Tor + Tür GmbH & Co. KG. Immediately ensure that an unsafe door cannot be

operated until it has been repaired correctly by a qualified technician or the door manufacturer. Always

observe the corresponding regulations for the maintenance and inspection of power operated doors and

create an inspection book. Record all carried out inspections. (see Appendix for Inspection Book)

Only replace defective parts with original ones. Please contact Tekla-Technik, Tor + Tür GmbH & Co. KG for

more information.

2.3 Operation/Utilisation

- The ready to use door has to comply with EN 12604 and EN 12453 requirements.

- Never place objects within the movement range of the door.

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 4 -

- Ensure sure that nobody can be trapped or injured between objects or the wall and the opening and closing

door.

- Ensure that no unauthorised people are in the opening and closing zone.

3. Warranty

Warranty with regard to function and safety can only be guaranteed if:

- Assembly is carried out correctly in accordance with the instructions,

- Only original parts are used,

- No additional objects are attached to the door,

- Regular maintenance of the door and its accessories is carried out,

- There is no damage caused by improper use or external influences.

- Warranty does not cover glazing elements not installed by the manufacturer. (See 12)

4. Outside Doors

- Check whether the intended type of mounting is correct for the planned application. For outside doors, the

door should preferably be mounted on the inside and open inwards.

- Doors mounted on the outside have to be equipped with a rain guard above the roller track.

- Ensure sufficient drainage in the area in front of the door. If necessary, plan a sloping surface or a drain

gutter in front of the door. Avoid a build up of water underneath the door.

- Make sure that the building is dry and sufficiently ventilated.

- It is essential to immediately paint a top coat on outside doors after assembly. The door is coated with a 2

component acrylic primer and can be painted with all standard paints.

Caution: The use of alkyd resin-based paints on galvanized surfaces exposed to harsh weather conditions

can lead to a later loss of adhesion of the entire coating. In these cases, it is recommended to use a 2

component acrylic or a 2 component polyester primer.

These planning, installation, maintenance and operating instructions provide an overview of the current

state of development. Subject to technical changes.

5. Arrangement of Wall Seals, Weight Boxes (optional) and Brackets

Leaf division: A symmetrically divided door is standard, so that leaf division (FT) = door clearance/2

Refer to the assembly/installation instructions for the FT dimensions of asymmetrically divided doors

1

2

3

4

lateral wall seal

upper wall seal

bracket

weight box

door clearance

door clearance (l.D.)

FT + “M”

11

44

2

“G”“F”

“B” “B”

“H”

“H”

“J ”

“J ”

“D”

“C”

3

33

“K”

“K”

7575

“G”

leaf division (FT)

“F”

75

FT + “M”

leaf division (FT)

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 5 -

Fixing Distances

Type of

Door

Door Area

m2

“B“

“C“

“D“-“G“

“H“-“K“

“M“

dw 62-ME - 5 25 Please refer to the enclosed

assembly/installation

instructions for dimensions

See brackets

for

dimensions 150

Important:

- Compare the door number in the assembly/installation instructions with the door number on the end panel to

ensure correct assembly.

Assembly Preparation

Check the completeness and correctness of the delivery including the individual parts and accessories.

end panel

door number

6. Assembly Process

1. Check and compare the dimensions of the wall opening with the dimensions in the assembly drawing.

2. Determine the height and lateral distances of the wall seal and brackets

3. Assemble wall seal and brackets (see 1). Assemble the run-in bracket (see 2)

4. Assemble runner rails, align, clean and coat running surfaces with a resin-free oil (see 3)

5. Hang the door leaves and roller mechanism (see 4). Start with the run-in elements.

6. Connect the door leaves at the top (see 5)

7. Connect the door leaves at the bottom (see 6)

8. Position guide shoe/roller (see 7)

9. Assemble accessories (e.g. recessed handles, wicket door, etc.) (see 8)

10. Assemble metal casing at the top (see 9)

11. Insert door

7. Installation Details

7.1 Fixing the Brackets

Prior to assembly, please refer to the assembly and installation instructions enclosed with the sliding door for all

dimension and fixing information.

Brackets for concrete in the opening and sliding area

Using FAZ 12/30 stay bolts

Drill bit: Ø12mm

Drilling depth: Min. 115mm

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 6 -

Using FAZ 16/25 stay bolts

Drill bit: Ø16mm

Drilling depth: Min.130mm

Caution:

For brackets with two bore holes:

Drill the first bore hole and fix and

align. Subsequently drill the

second bore hole

Brackets for masonry in the sliding area

Insert bolt. Fix the angle bracket

using a plain washer and hexagon

nut. Tighten the counter plate to the

outside of the wall using a plain washer

and a hexagon nut.

Using M12 through bolt

Drilling depth: Through bore

Drill bit: Ø12mm

Drill bit for sleeve: Ø30mm

Drilling depth for sleeve: Min. Ø80mm

Using M16 through bolt

Drill bit: Ø16mm

Drilling depth: Through bore

Drill bit for sleeve: Ø30mm

Drilling depth for sleeve: Min. Ø80mm

Caution:

For brackets with

two bore holes: Drill

the first bore hole

and fix and align.

Subsequently drill

the second bore

hole.

Brackets for ceiling mounting

Using FAZ 12/10 stay bolts

Drill bit: Ø12mm

Drilling depth: Min. 95mm

Distance: 94mm

Dimension “X“: 51mm

Using FAN 16/25 stay bolts

Drill bit: Ø16mm

Drilling depth: Min. 130mm

Distance: 124mm

Dimension “X“: 36mm

d

istance

X

Alternative bracket fixing by welding onto a bracket preset in concrete

Lintel mounting Ceiling mounting

Set the bracket plate in concrete

while constructing the lintel or

ceiling. Weld the angle brackets or

ceiling brackets to the bracket

plates. (See 1 “General Instructions

– bullet 7!)

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 7 -

Assembly of the angle and ceiling brackets

- Check height over the entire width (observe unevenness of the floor!)

- For wall mounting

Measure the height for the angle brackets from the highest point of the floor (for rough concrete from the

metre level). It is essential to observe the minimum dimension “D” (see table above) from the lower edge of

the lintel to the bracket bore holes. Mark further divisions using a tube level or surveyor’s level.

- For ceiling mounting

Measure the distance from the lower edge of the ceiling to the highest point of the floor. Subsequently fix the

ceiling mounting bracket to the lowest point. Mark further divisions using a tube level or surveyor’s level.

Position the ceiling mounting brackets with flat steel for metal casing attachment (see 9) at equal distances.

Fixing the upper wall seals

For wall mounting

Fix all the wall brackets together

with the upper wall seal,

since one side of this wall seal

is jammed between the lintel

and the angle bracket

For ceiling mounting

Using FAZ 12/10 stay bolts

Drill bit: Ø12mm

Drilling depth: Min. Ø95mm

For brackets set in concrete

Weld the wall seal to the

bracket plates.

Welding (s): a ≥4, l ≥30mm

7.2 Fixing the Lateral Wall Seals and the Weight Box:

Tlg. 600£

Tlg. 300£

Tlg. 450£

4

4

4

3

1

22

Tlg. 450£

4

Tlg. = division (div.)

- Bolt on the weight box (1)

- Fix the run-in bracket (2) to the weight box

using steel blind rivets ∅4x8mm or plug welding.

- Bolt on the lateral wall seal (3)

- Fix the upper wall seal (4)

(see above)

See tables for fixing equipment (5)

Push the lateral wall seal up underneath the

upper wall seal. The lateral wall seal (3) has to be

fixed in place before hanging the last door leaf

otherwise it is covered and no longer accessible

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 8 -

Fixing equipment for wall seals and counterweight

For concrete: - Use Ø12mm expansion anchor; (Ø12mm drill bit, min. drilling depth 50mm)

- Use M10 heavy duty anchor; (Ø10mm drill bit, min. drilling depth 80mm)

For masonry: - Use Ø12mm synthetic plug; 135mm long; (Ø12mm drill bit, min. drilling depth

150mm)

For autoclaved aerated concrete: - Use M12 through bolts

7.3 Runner Rail Assembly

- Use a cloth soaked in resin-free oil to clean

the inside of the runner rail

- For wall mounting:

Fix the sleeves to the brackets and align.

Insert the runner rail into the sleeves.

Attach the runner rail and the sleeves

at the same time if there is a shortage of space.

- For ceiling mounting

Insert the runner rail into the ceiling mounting sleeves.

Attach the runner rail and the sleeves

at the same time if there is a shortage of space

Use a connection sleeve (1)

to interconnect several runner rails.

Runner rail arrangement for weight arrangement

7.4 Hanging the Door Leaves and Roller Mechanism

- Screw the carrier bar into the bore hole in the door leaf

- Insert the roller mechanism into the runner rail

- Place the door leaf underneath the roller mechanism

- Screw together the roller mechanism and the carrier bar.

Adjust to the correct height to ensure precise running of the roller

mechanism by screwing the carrier bar in the door leaf clockwise

or anti-clockwise (minimum screw-in depth of the carrier bar = 25mm)

The roller mechanism can be completely screwed into the door leaf

for larger spaces. Subsequently insert the door leaf together with the

roller mechanism into the runner rail from the rear. For doors

with counterweight balance at the first roller mechanism, as viewed from the

closing side, attach the metal clip for the traction rope complete

with rope when screwing in the carrier bar.

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 9 -

7.5 Assembly of the Door Leaves

- Using leaf connector

After pushing together the single leaves (1 + 2)

(tongue and groove system) in package

order, use the leaf connector (flat steel)

to connect them, screw it tight using

hexagon nuts (M 8) and plain washers

(for elongated holes) or without washers

(for bore holes).

A tensioning strap can be used to hold the

the door leaves in place in order to screw the

door together at the nominal width.

6

OFF

1/2 1/2

height of door leaf

OFF (upper edge

finished floor

)

- Tilting lock for clear opening width of >5,000mm

or height of >4,000mm and for wicket door

with a sill. Use the tilting lock

to interconnect the leaves.

Subsequently align and connect

using the leaf connector (see above).

CAUTION! Leaves connected with

a tilting lock cannot be dismantled

– observe the correct leaf order!

48 46

9

12

11

10

10

11

22

33

9

11

10

+

10

-2

OFF

7.6 Fixing the Lower Guide Bracket

Push the lower guide bracket (9) over the

leaves (10). Align it to the floor

(see diagram 6.1) and fix it

to the leaves using 4.8x16mm self

drilling screws (11) in the pre-drilled holes.

The guide bracket has to be 48mm from the edge of the

leaf impact and project from the other

leaf impact element by 46mm.

7.7 Installation of the Lower Door Track

For sliding doors without wicket door and for wicket door with sill

Fix the guide shoe (1) in front of the

run-in bracket (2) and the guide roller (3)

in front of and behind the lateral wall seal.

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 10 -

For sliding doors with wicket door without sill

3

5

Fix the guide shoe (1) in front of the run-in bracket (2), see above,

and the guide shoe (6) behind the lateral wall seal (4).

Two guide shoes (6 & 1) are additionally positioned in the sliding area

in accordance with the dimensioned diagram.

Fixing the Door Track

For finished floor – using expansion anchor ∅10mm. All the necessary plugs and anchors are included in the

accessory pack. For rough concrete, use an appropriate underfill material to which the tracks can be welded.

7.8 Fixing the Handles to the Door Leaves

- Recessed Handles

Both sides One side

Fix the recessed Fix the recessed

handles (10) using the handle (13) using

sleeve screws (11) and M5x50mm ST4.8x13mm sheet metal

countersunk screws (12). screws (14).

Handle bars

Type 1 Type 2

Use M6x16mm counter Use M8x25mm

sunk bolts (16) and the counter sunk bolts (19),

blind rivet nuts (17) in the washers and the blind

door leaf to fix the handle rivet nuts (20) in the door

bar (15) into position. leaf to fix the handle

bar (18) into position.

7.9 Wicket Door

- Wicket Door with Sill:

Hang the leaves (1; 2 and 3) and interlock them

using the tilting lock (4). Align and connect the leaves

at the top using the leaf connectors (5) (see 5).

Insert the bottom sill (6) between the leaves (1 and 3)

and clamp tight.

Hang the wicket door, insert the ball bearings (7)

and knock in the hinge bolts (8) (see diagram right

and general hinge information).

Use a set screw (9) to fasten the hinge.

Caution: It is strictly forbidden to use wicket doors

with sills for escape routes and emergency exits!

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 11 -

- Wicket door without sill:

Install and align the leaf together

with the wicket door.

Use the leaf connector to connect the

upper leaves (see 5).

Additionally screw the 3 M10x210mm

countersunk screws (10) through

the door frame into the adjacent leaf

on the hinge side.

Use 2 M5x50mm countersunk screws (13)

with sleeve screws to fix the guide bracket

(see 6) in the wicket door area

on the hinge sides.

Sliding door track:

Additionally fix two guide shoes in the sliding area

(see 7 with the respective diagram)

General hinge information:

- Lubricate hinge bolts

- When knocking in the hinge bolts, ensure that the

notch (14) is positioned in the hinge bracket gap.

Installation of the door latches and door closer

- Assemble the door latches. Install the flat latch facing the wall

- Assemble and adjust the door closer. The setting has to ensure that the door closes automatically from

any opening angle. (Please refer to the instructions of the respective upper door closer for assembly and

adjustment instructions)

- Check closing function (the wicket door has to close from every possible position)

- Check latch bolt contact (min. 6mm)

Note: The wicket door position of sliding doors with an automatic electric drive has to be checked via

magnetic contacts (2 contacts integrated into the frame and door leaf). The door should only move if the

wicket door is completely closed. Refer to the enclosed wiring diagram for the connection diagram.

7.10 End Stoppers

Use hexagon bolts (3) and clamp (4)

to fix the end stoppers (2). Attach the end stoppers

when the door is either open or closed so that they come

up against the roller mechanism.

7.11 Rain Guard

(Optional extra, e.g. for outside doors)

Position the rain guard (6) and fix it to the

mounting brackets (8 and 9) using 4.8x16mm

self drilling screws (7).

Outside doors: The customer should seal the

upper gap between the rain guard and the lintel/wall.

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 12 -

8. Glazing Elements

Various glass and glazing elements can be supplied.

Glazing elements are fixed in rubber frames by the manufacturer. However, glazing elements can also be fixed in

aluminium profiles by the customer.

- The manufacturer shall assume no liability for injuries or damage to persons or property caused by non

shatter-proof glass or incorrect installation by third parties.

- The manufacturer only installs shatter-proof glass which complies with the requirements of DIN EN 12600.

- Please note that any replacement glass has to have the same performance properties in accordance with

DIN EN 12600 as regards impact resistance, etc. as the glazing elements installed by the manufacturer.

- Please contact Tekla-Technik, Tor + Tür GmbH & Co. KG for more information about permissible and

manufacturer installed glazing elements.

- Glazing work should only be carried out by qualified personnel. The retrofitting of door leaves with

transparent panels (glass) is strictly forbidden.

leaf glazing element with aluminium profile

leaf glazing element in rubber frame

ZZ

9. Drive (special version)

Dw 62 ME sliding doors can optionally be equipped with an electric drive with either “deadman” or “pulse

function”. The control button OPEN or CLOSED has to be pressed continuously for door movement with an

electric drive with “deadman operation”.

For automatic or pulse function, door movement OPEN, CLOSED or STOP is triggered via a pulse at the button.

The buttons only have to be pressed briefly during pulse operation. A remote control or similar device can be

optionally integrated.

Right-hand version: “drive - lintel mounting”

Electric drive with the drive rail attached to the runner

rail.

FAZ 12-10

e <650

cheese head screw

bracket

"rail-mounted"

drive

door link

drive rail

drive rail

main contact edge

with rubber trim

"rail-mounted"

drive

bracket

"rail-mounted"

drive

door link bracket

drive rail

drive rail

main contact edge

with rubber trim

"rail-mounted"

drive

cheese head screw

Left-hand version: “drive - ceiling mounting”

Electric drive with the drive rail attached to the runner

rail.

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 13 -

Assembly instructions for sliding doors with CarTeck 252 electric drive

Important: The electric drive stated below (Marantec, type 252) should only be used for doors with a leaf area of

≤25m2. This drive is not permitted for larger leaf areas.

- Open the door in order to install the guide rail.

- Use the fixing brackets to install the guide rail in front of the runner rail (see diagram)

- Lengthwise, the guide rail should be set so that the end position of the door link bracket in the guide rail is at

least 100mm behind the fully open door, i.e. that the door link bracket can never move to the end of the rail.

The same applies for the closed position.

door end position OPEN

runner rail

door link bracket

A

warning sign should be

placed in the area of the

wall soffit for doors with

Marantec automatic operation.

This sign has to warn of the

potential dangers resulting

from automatic door closing

ab

dosolute end position

or link bracket drive rail

drive head opening direction

~100

Warning!

Never place hands or other objects

between the wall and door

Programming the electric drive in accordance with the CarTeck Installation and Operating Instructions Parts 1+ 2.

Before programming the electric drive it is important to check whether the door runs freely in the parallel running

guide rail. The door link bracket of the guide rail has to be unlocked for this task (see Fig. D10 - D12, Installation

Instructions Part 2). Subsequently check whether the door and guide rail run smoothly without jamming along the

entire travel of the door (end position open and closed).

Ensure that the door link bracket has locked into place in the guide rail prior to programming! (see D23,

Installation Instructions Part 2)

- Programming procedure for basic drive functions page 26 of the Installation and Operating Instructions Part 1

- Programming end position OPEN and CLOSED page 28 – 29. Caution: When programming the end position

CLOSED, ensure that the rubber trims of the main contact leaf edges are not resting on each other! The

distance between the rubber trims has to be approx. 2 – 5mm (see diagram)

- Programming radio control page 30

- Programming automatic switch-off OPEN and CLOSED. With this function, the upper force limit of the drive

for OPEN and CLOSED movement has to be set to the smallest value sufficient enough to move the door

(pages 36 – 39)

- Programming SOFT STOP CLOSED (page 54). The factory setting for the Soft Stop Closed is 200 mm.

Select the fourth programming level. Change the Soft Stop Closed from 200 to 300mm per drive (level 3),

subsequently exit the programming level. Both drives have to be set to level 4 if the leaves are moved

separately, not synchronously (500 + 500mm)

- Any other program level and steps should only be selected and changed in special cases.

Note: Only use electric drives tested and released by the door manufacturer. Contact Tekla-Technik, Tor + Tür

GmbH & Co. KG for information about which drives have been tested and released for your requirements when

retrofitting a drive to a manually operated door.

(Also see 14. Declaration of Conformity)

Always observe the respective Schnetz installation instructions for doors with deadman drive type. ATS...WST

from Schnetz

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 14 -

Note: BMH hook bolt lock

The door can be equipped with a hook bolt lock by the manufacturer. An information sticker should be affixed to

both sides of the door leaf in the lock area to explain lock functioning and prevent damages. The information

stickers are included in the accessories if the door has been equipped with this type of lock by the manufacturer.

Hook bolt position 1:

Lock is unlocked - Hook bolt locked in open position.

Door can be opened and closed unhindered.

Hook bolt position 2:

Lock pre-locked. The spring-loaded hook bolt locks the door

after closing. Open the hook bolt via the profile lock.

Hook bolt position 3:

Lock pre-locked. Hook bolt locked in the closed position.

Caution! The hook bolt should not be locked when the door is

open, otherwise the door can be damaged during closing!

Information for sliding doors fitted with a triple action BMH hook bolt: This information sticker

should be affixed to both sides of the door leaf directly next to the profile lock. Also refer to the

Planning, Installation and Maintenance Instructions for 1 & 2 leaf sliding doors and elements.

10. Doors with Counterbalance Weight (special version)

10.1 Rope Guidance and Counterweight Suspension

• Rope fixing

Assemble the weight box according to 1.5. Fix the rope to the

roller mechanism and the weight suspension; use 3 rope clamps (7).

Hang and counterbalance the weights (see 2.6).

Fix the weight box cover according to 2.6.

Ensure that the rope and the weights do not catch on protruding rivets, screws or bolts.

Rope guidance in the weight boxes

Caution: Ensure that the weights are 50mm

(safe distance) above the finished floor.

5

3

1

4

2

43

2

3

3

4

4

2

2

1

5

10.2 Rope Guidance and Weight Suspension:

- Wall mounting

- Ceiling mounting

Rope guidance:

Caution: In order to attach the rope, fix

the clip with the rope (1) to the first roller

mechanism - as viewed from the leaf impact (see 2.1).

• Screw or weld a double rope deflection pulley

(4) to the runner rail (3).

• Feed the other end of the rope (2) above or in front of the

runner rails/brackets downwards over the weight box

roller and fix it to the rope eye of the weight suspension

with 2 rope clamps [see 2.5].

Weight suspension:

Hang and counterbalance the weight.

Fix the weight box cover to the weight box bracket on both

sides using M6x8mm cheese head screws (5) (3x at the same height).

Weight counterbalance:

Only use the amount of weight required for safe closing of the door.

The door has to open with a max. force of 200 N.

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 15 -

• Standard Version

Fix the rope anchorage (1) to the last panel - viewed from the middle - using 2 M6x20mm bolts. The rope tension

pulley (2) is fixed to the last runner rail sleeve using its hexagon bolts (sleeve distance from edge of door is min.

400mm). The rope tension pulley (2) is located in front of the rope anchorage (1). The bracket (A) with the

hydraulic brake mechanism (3) is bolted tightly to the end of the runner rail using the M10x40mm hexagon bolts

and the clamp (C). Adjust the hydraulic brake mechanism so that the closing velocity does not exceed 0.2m/s or

fall below 0.08m/s. Tension the wire rope (4) via the spring-suspended tension pulley (2) until it can no longer slip.

The limit stops are adjustable hydraulic brake cylinders (end brakes (5+5a). For the position “door CLOSED“,

screw an end brake (5) into the bracket (B) 100/50/5, which has been previously fixed to the door leaf, using 4

M5x20mm bolts. The end brake comes up against the brackets (6) to be fixed to the runner rails – the brackets

are attached with clamps just like bracket (A). In the opening direction, the door comes up against the end brake

(5a) located in bracket (A). For larger doors, bolt a magnetic clamp (6) to bracket (A) using M4x10mm bolts. Fix

the magnetic clamp counterplate (6a) to the base plate on the rear door leaf using M4x8mm bolts. Weld or bolt

the base plate to the door leaf seal in advance. Use M8x30mm bolts for the latter option.

• Shortened Stop

Fix the rope anchorage (1) to the last panel - viewed from the middle of each door leaf - using 2 M6x20mm bolts.

The rope tension pulley (2) is fixed to the last runner rail sleeve using its hexagon bolts (sleeve distance from

edge of door is min. 400mm). The rope tension pulley (2) is located in front of the rope anchorage (1). The

bracket (A) with the hydraulic brake mechanism (3) is bolted tightly to the end of the runner rail using the

M10x40mm hexagon bolts and the clamp (C). Adjust the hydraulic brake mechanism so that the closing velocity

does not exceed 0.2m/s or fall below 0.08m/s. Tension the wire rope (4) via the spring-suspended tension pulley

(2) until it can no longer slip.

The limit stops are adjustable hydraulic brake cylinders (end brakes (5+5a. For the position “door OPEN“, “door

CLOSED“, screw the end brakes (5+5a) into the bracket (B) 100/50/5 which has been previously fixed to the door

leaf using 4 M5x20mm bolts. The end brake comes up against the brackets (6) to be fixed to the runner rails – the

brackets are attached with clamps just like bracket (A). In the opening direction the end brake (5a) comes up

against the bracket (A).

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 16 -

For larger doors, bolt a magnetic clamp (7) to bracket (A) using M4x10mm bolts. Fix the magnetic clamp

counterplate (7a) to the base plate on the rear door leaf using M4x8mm bolts. Weld or bolt the base plate to the

door leaf seal in advance. Use M8x30mm bolts for the latter option.

10.3 Assembly of the Hydraulic Brake Mechanism, Limit Stops and Magnetic Clamp

In the opening direction, the end brake (5a) comes up against the bracket (A). For larger doors, bolt a magnetic

clamp (6) to bracket (A) using M4x10mm bolts. Fix the magnetic clamp counterplate (6a) to the base plate on the

rear door leaf using M4x8mm bolts. Weld or bolt the base plate to the door leaf seal in advance. Use M8x30mm

bolts for the latter option.

11. Special Versions

10

5

8

11

17

2

6

39

4

98

11.1 Artificial Lintel

• Screw the box section (1) with the 50mm wide

insulating strip (2) to the ceiling

[Ø7mm countersunk screws (3)

with 10/200 plug (4) – Ø 10 drill bit,

drilling depth min. 100mm].

• Fix the housing (5) with the insulating strip

to the ceiling [FAZ 12/10 plug (6);

e≤500, Ø12mm drill bit, drilling depth min. 95mm]

• Laterally screw the insulating strips (7) with the

upper wall seal (8) to the box section (1)

[M8x45mm hexagon bolt (9) with washer].

• Subsequently connect the housing (5) to the wall

seal (8) [M5x40mm cheese head screw (10)

; e≤500].

• Fix the ceiling sleeve (11) as described in 1.4.

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 17 -

Runner rail casing (optional)

Type “A”

• Fix the runner rail casing to the rail sleeve

ype “B“ runner rail casing to the ceiling

min. 95mm]

1.2 Advanced Limit Stop of the hydraulic brake mechanism,

s

r by

aution! Correct functioning and installation according to the instructions has to be determined by an acceptance

he acceptance test should only be carried out by specialists of or authorised by the release or hold open

according to 2.8 (runner rail casing-

ceiling mounting.

T

• Fix the

[FAZ 12/10 plug (12); e≤500,

Ø 12mm drill bit, drilling depth

1

Assembly and commissioning

limit stops and magnetic clamp occur as described in

2.7. (The sleeve distance for fixing the tension pulley ha

to be at least 600mm from the edge of the door)

The limit stop (7) is fixed (as displayed) to the doo

the customer at the last panel – as viewed from the

closing side - (4.8x16mm bolts or welded).

12

“B”

“A”

Dimension

FT = Leaf Division

"Y“

≤34m² 300

>34m² 500

*1) Symmetrical division is standard, i.e. FT (L) and FT (R) = door clearance / 2

C

test and documented in an “Inspection Book for Hold Open Devices” after the installation of sliding doors with hold

open devices. The manufacturers of release devices and hold open devices should draw attention to this test. The

operator has to make sure that the necessary steps are taken.

T

device manufacturer or specialists of a specified inspection authority.

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 18 -

12. General Safety Instructions for Assembly

ds when using lifting gear he weight of the door

- ments ensure that the load is secured correctly and that it can neither become loose nor

Always use scaffolding or lifting platforms to carry work at >2 m.

Ensure that unauthorised persons cannot enter the installation area during assembly.

tructions.

Cau , fully functional doors. How door

has to be disassembled due to damage, the type of damage is decisive for the disassembly procedures. The

Doors should be serviced by a qualified technician at least every 12 months to avoid malfunctioning and to

ble-free operation.

the door leaf and runner rail for corrosion

runner rail attachment, if necessary, retighten fixings ension

Runner rail:

Lubricate runner rail and roller track

c brake mechanism and shock absorbers

If m diately

- Always observe the maximum permissible loa

is approx. 28kg/m². and devices. T

- Only use intact and certified lifting devices (assembly cranes, fork lifts) and lifting gear (cables, chains, belts).

Before lifting the ele

slip. The elements can suddenly jerk and swing – beware risk of injuries!

- During assembly avoid wind loads on the not fully assembled door, e.g. in thoroughfares or subways. Close

or secure all openings in advance.

- During the entire assembly period ensure that individual door elements and components cannot fall down or

be knocked down.

- Always wear suitable protective clothing (protective gloves, hats, boots, etc.) during assembly.

- out assembly

-

- Plan disassembly in accordance with local conditions.

- Disassembly is carried out in reverse order

to assembly. Observe the specified assembly safety ins

tion: The disassembly steps have been designed for undamaged ever, if a

steps listed below are, therefore, only intended as a rough guide in such cases. The sequence of actions may

change or not be necessary depending on the situation and damage. Disassembly should always be carried out

with the utmost care and attention and under the supervision of a specialist.

13. Maintenance

guarantee trou

General condition:

o Visual inspection of

o Check

o Check toothed belts and steel ropes for damages and correct t

o Clean runner rail

o

Braking system:

o Check and, if necessary, set hydrauli

alfunction cs o cur (e.g. stiff door operation, unusual noises during operation, etc.), imme contact a

spe alist co

ark

fter operative assembly of the door system (door and, if necessary, drive and/or hold open device), the door system

f Conformity (in accordance with Article 8 of the European Directive

in fully functional

ed under normal operating conditions -

ci mpany to carry out checks.

14. Declaration of Conformity and CE M

A

manufacturer has to issue an EC Declaration o

89/392/EEC) and present it to the owner for future reference. The door system is additionally provided with a “CE” mark.

Note: Manufacturer of the door system or the hold open device is the installation engineer or the installation company

hich is in charge of mounting the door system/hold open device, i.e. connecting and assembling the individualw

components (door and, if necessary, the hold open device and/or electric drive, etc.). It is expressly stated that it is not

automatically the door manufacturer or a subcontractor commissioned by the installation company.

The Marantec electric drive (type 252) has been designed for approx. 35,000 operating cycles provided that the

oors have a leaf area of ≤25m2and are operated under normal operating conditions -

d

condition - without impairments.

The Schnetz electric drive (type ATS 300 WST) has been designed for approx. 25,000 operating cycles

rovided that the doors are operatp

in fully functional condition - without impairments.

tenance ofPlease observe these specifications for future main

power operated doors.

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 19 -

Inspection Book

for Power Operated Doors

ulti-Purpose Sliding Doors dw 40 –1/-2 and dw 62-1/-2,

oor No.: ______________________________________________________________

______________________________________________________________

Teckentrup M

D

ompany: ______________________________________________________________C

______________________________________________________________

ite: ______________________________________________________________S

Planning, Installation, Maintenance and Operating Instructions dw 62-2 ME Sliding Doors

- 20 -

Basic Principles for the Inspection of Power Operated Doors

The safety technical requirements and test methods for the construction and equipment of

N 418 Safety of machinery – Emergency stop equipment

IN EN 12604 Doors and Gates – Mechanical aspects – Requirements

IN EN 12605 Doors and Gates – Mechanical aspects – Test methods

and Gates – Safety in use of power operated doors –

IN EN 12445 Doors and Gates – Safety in use of power operated doors –

nd Gates – Installation and use,

IN EN 12978 Doors and Gates – Safety devices for power operated doors and gates

uideline for Power Operated Windows, Doors and Gates”

ower operated doors have to be inspected by a qualified person prior to initial

qualified person is someone who, due to his/her technical training and experience,

hese specialists have to carry out their assessment impartially based on occupational

he inspection result has to be recorded in writing in an inspection book issued for the

power operated doors are specified in the European standard DIN EN 13241-1 : 2004, which

puts the general requirements of the European Construction Products Directive in concrete

terms. Normative references in DIN EN 13241-1: 2004 are especially:

E

D

D

DIN EN 12453 Doors

Requirements

D

Test methods

DIN EN 12635 Doors a

D– Requirements and test methods

The specifications of the “G

ZH1/494 are still valid for power operated doors which entered the market before 1

November 2000 or 1 June 2001. The standards do not demand the retrofitting of existing

systems which were installed before the aforementioned dates. However, the European

standards stated above are valid for all doors without powered operation which have been

retrofitted with an electric drive since 1 June 2001.

P

commissioning and as and when required – an inspection should be carried at least once a

year. This inspection cannot be equated with maintenance work.

A

possesses sufficient knowledge of power operated doors and of the respective official

occupational health and safety regulations, directives and generally recognised technical

rules (e.g. DIN standards, VDE specifications) to determine the safe condition of doors. This

person can be a qualified technician, an authorised employee of the manufacturer, supplier

or installation company, or an appropriately experienced employee of the owner.

T

health and safety regulations. They should not be influenced by any other circumstances,

e.g. financial reasons.

T

respective door. This written documentation should always be kept to hand for future

reference at the installation site of the power operated doors.

Table of contents

Popular Door Opening System manuals by other brands

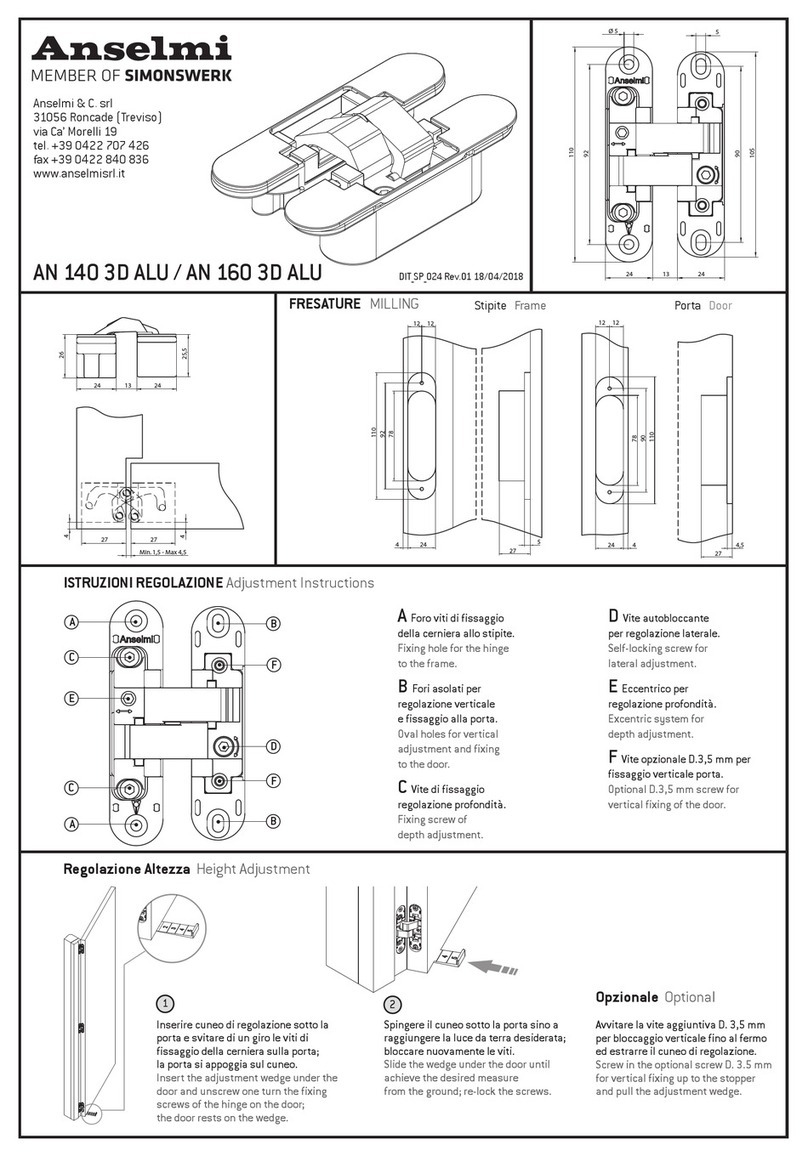

SIMONSWERK

SIMONSWERK Anselmi AN 140 3D ALU installation instructions

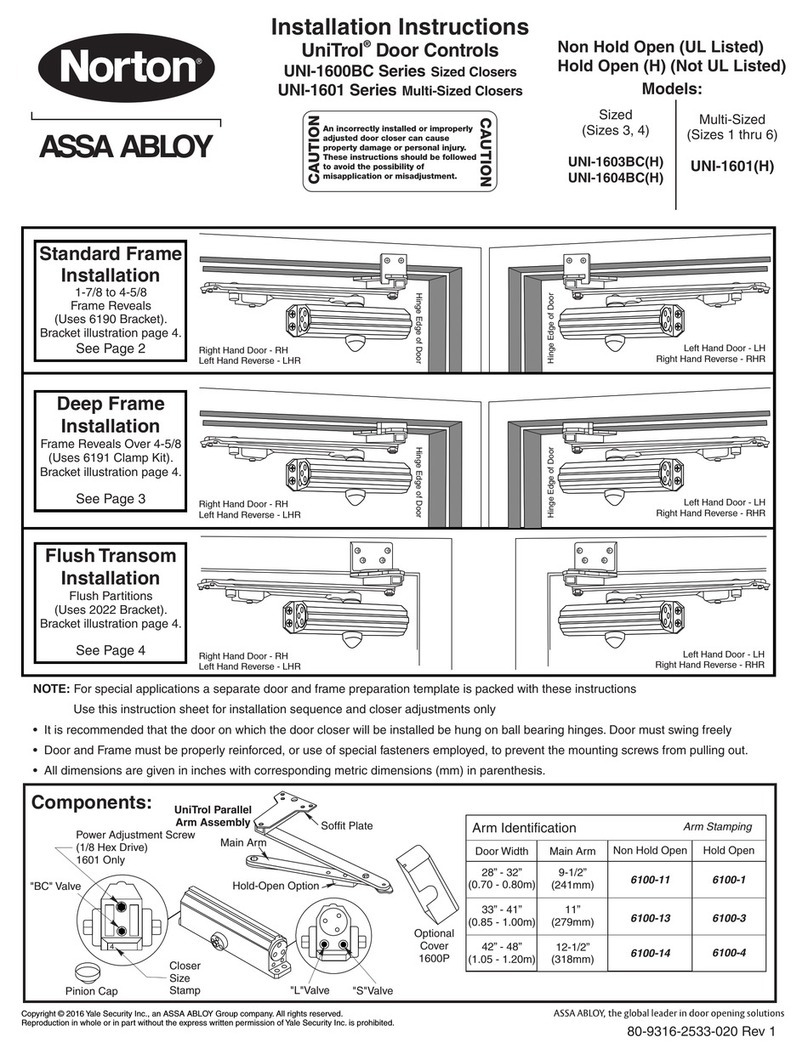

Assa Abloy

Assa Abloy Norton UniTrol UNI-1600BC Series installation instructions

Dormakaba

Dormakaba ED900 owner's manual

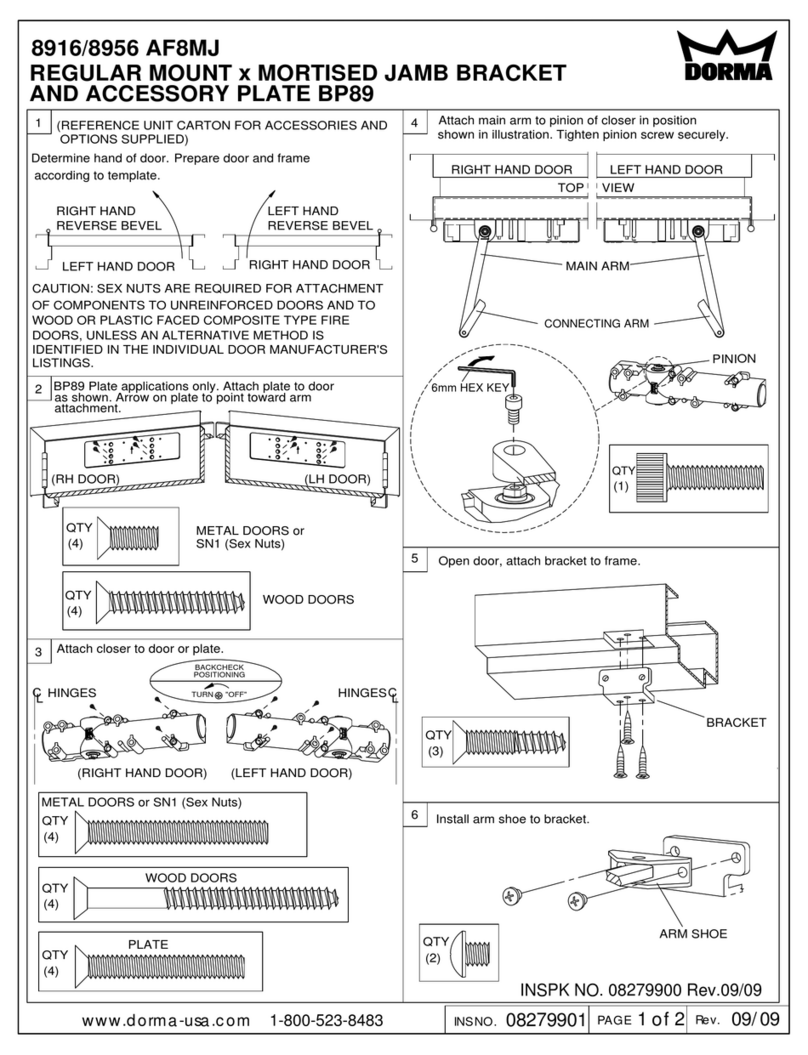

Dorma

Dorma 8916 AF8MJ manual

Videofied

Videofied Indoor Door Contact IDC200 Product installation sheet

STAMONY

STAMONY ST-DP-300 user manual