GENERAL SAFETY INSTRUCTIONS

Automatic swing door PREMIS 200 5

INSTALLATION WARNINGS

WARNING: Important safety instructions.

Follow all instructions because improper

installation may entail the risk of serious injury.

The weight of this device is less than 20Kg and

therefore, it is not necessary to use handling

devices.

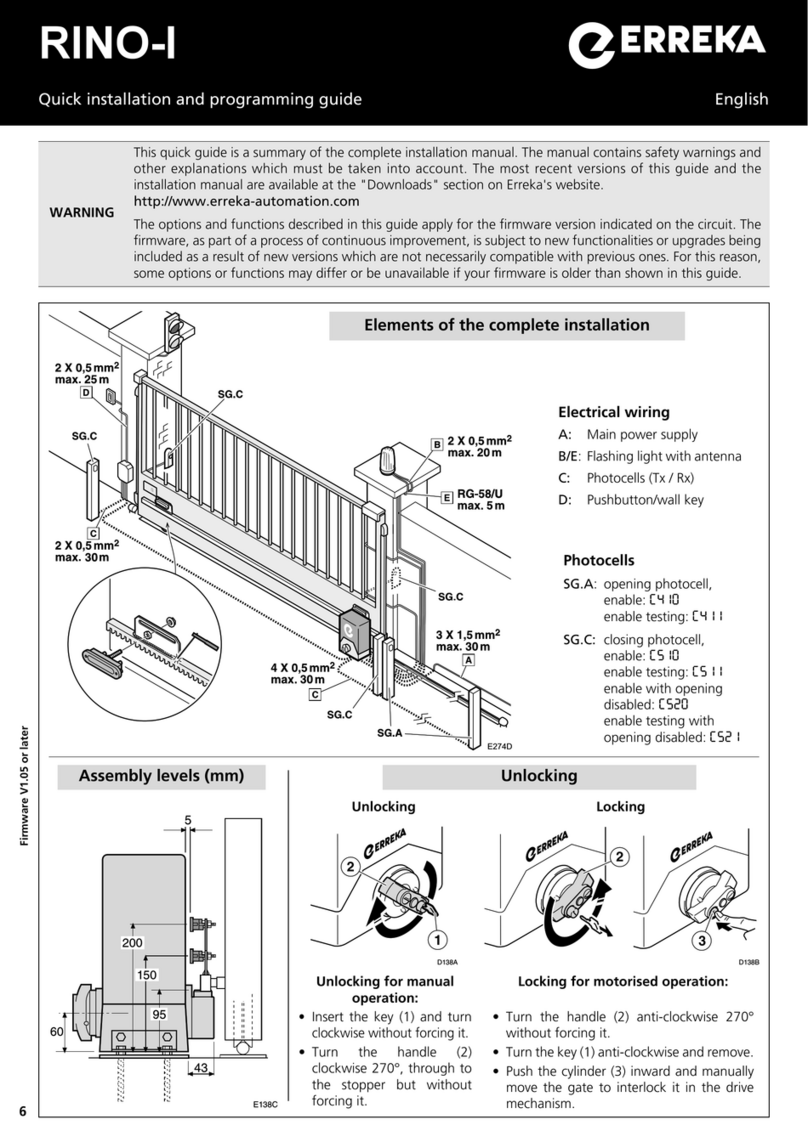

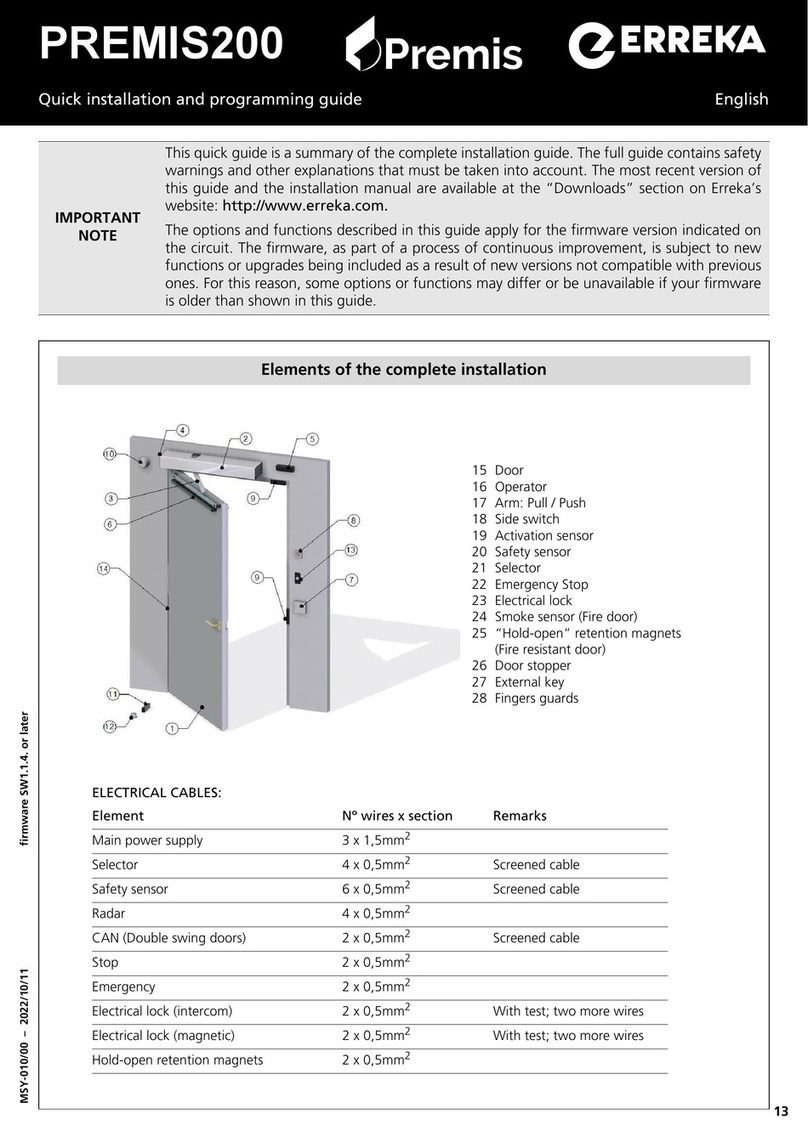

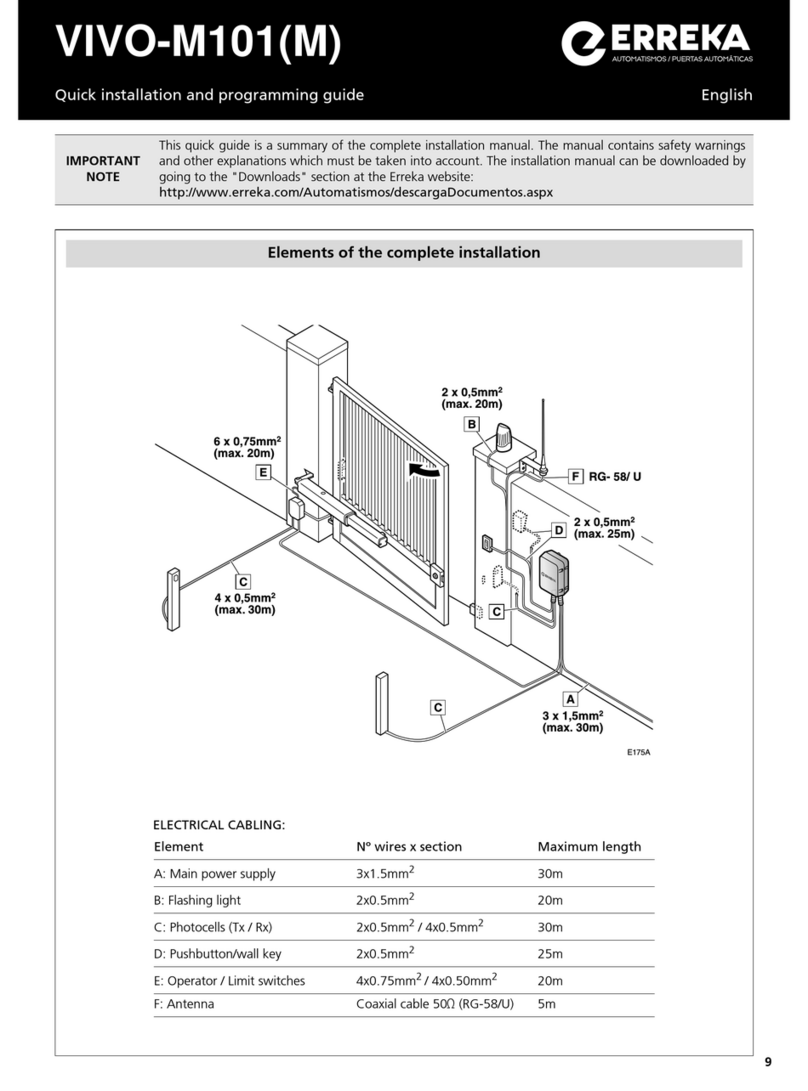

The necessary installation components are

indicated in the section "Elements of the

complete installation". The details and

instructions of all the components are

available on the web www.erreka.com.

Before installing the device, verify that the

door is in good mechanical condition, that it is

correctly balanced and that it opens and closes

correctly.

The operator is intended to be installed at a

height bellow 3 m above ground level or

another level of access.

Ensure that entrapment between the driven

part and the surrounding fixed parts is

prevented due to the opening movement of

the driven part except in the LOW ENERGY

mode.

In FULL ENERGY operation, safety sensors

must be installed in order to comply with

Standard EN 16005.

In LOW ENERGY operation, it is not

mandatory to use safety sensors as long as it is

not used by children and the elderly. It is

advisable to protect the area of the hinges to

avoid entrapment.

The details for the installation of the device are

indicated in the "Installation" chapter of this

manual. If you install protective devices not

supplied with this device, refer to the

instructions for those components.

Details on how to regulate the controls are

indicated in the section "Installation - Door

Configuration" of this manual.

After installation, make sure that the

mechanism is properly regulated and that the

protection system and any manual release

devices work correctly.

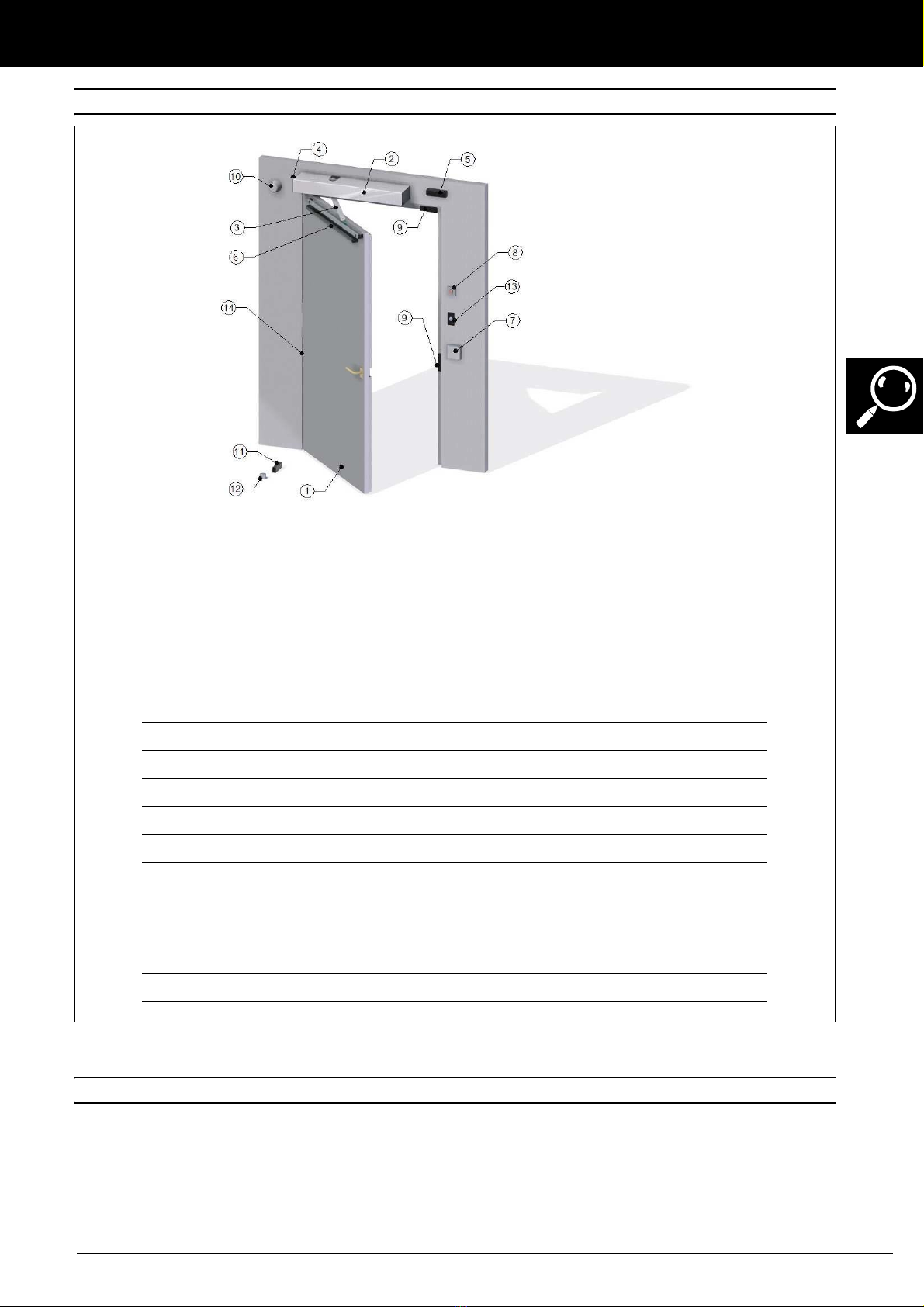

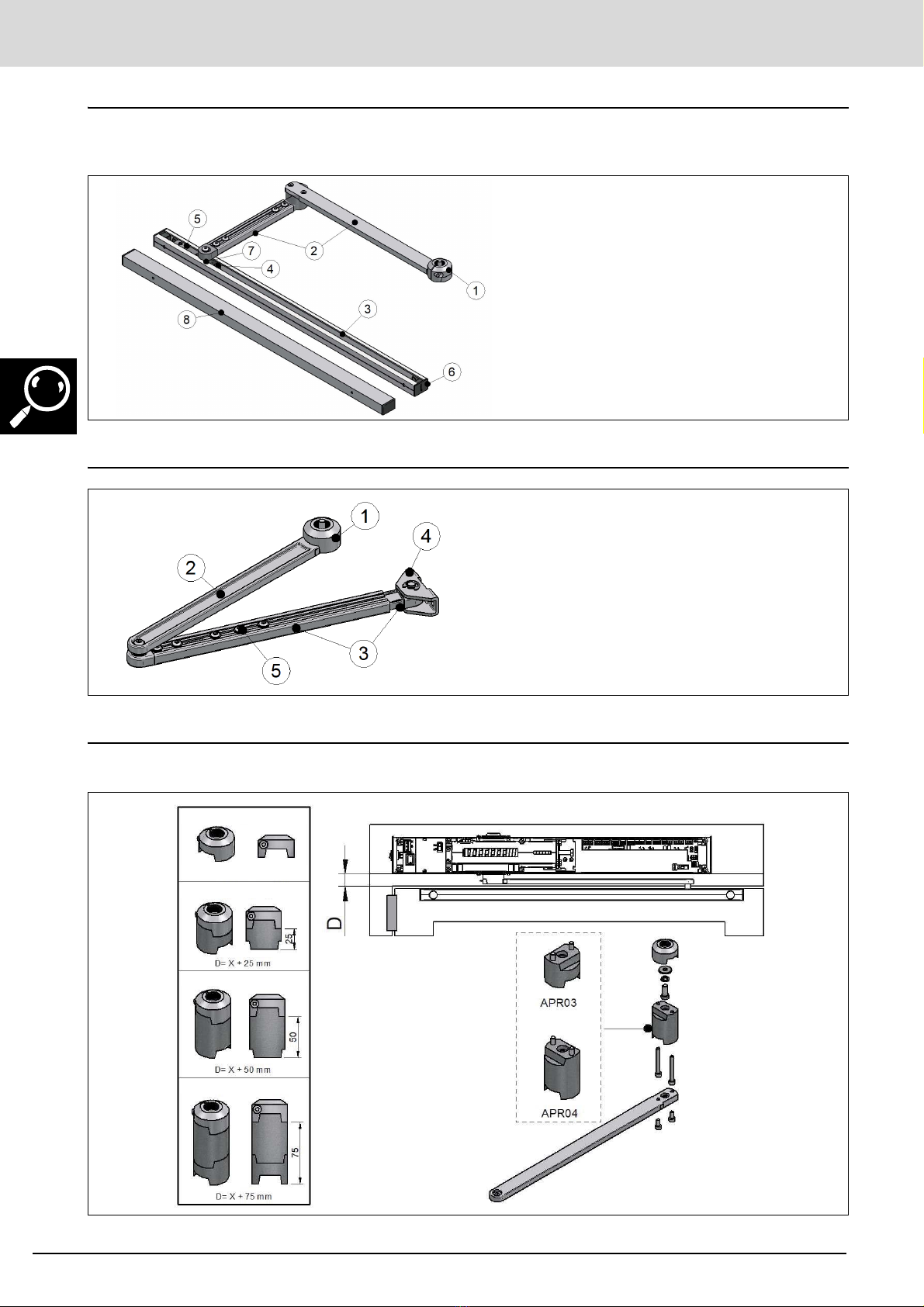

The list of all the components included in the

device is indicated in the section "Unpacking

and contents" of this manual.

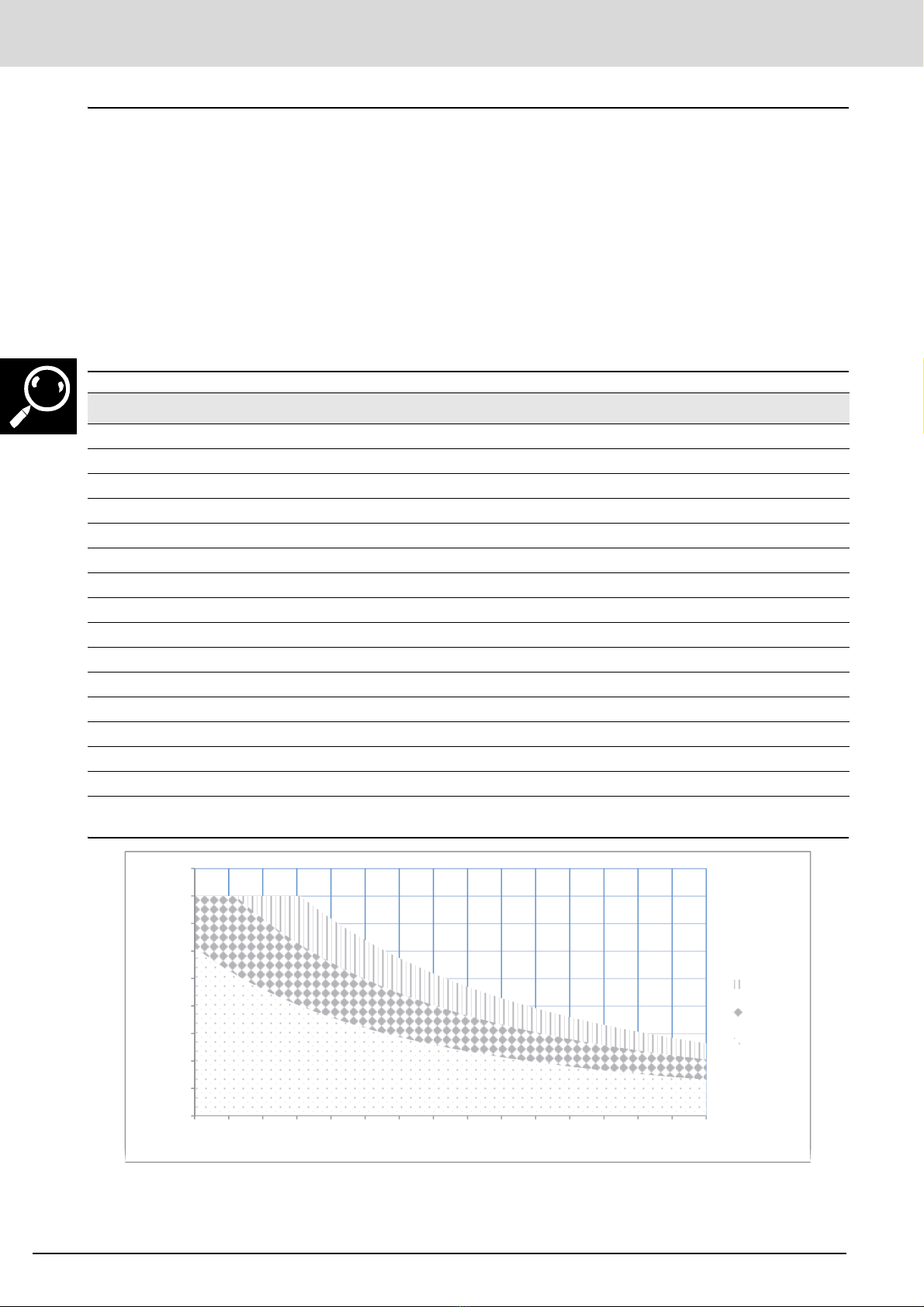

The specification of the type of door, gate or

window for which the appliance is intended,

size and mass of the activated part and

required torque are indicated in the "Operator

characteristics" section.

The position or positions the device can be

installed in can be seen in the "Operator

Installation" section of this guide.

WARNINGS FOR THE DISPOSAL

When this product reaches the end of its

useful life, it must be dismantled by qualified

personnel.

This product is made up of diverse materials,

some can be recycled and others must be

disposed of. It is necessary to find out about

the recycling and disposal systems provided by

the local regulations in force.

Some parts of this product may contain

polluting or hazardous substances that, if

released to the environment, could damage it

and human health.

It is forbidden to dispose of this

device together with household

waste. Carry out selective collection

according to local regulations.