1. INTRODUCTION

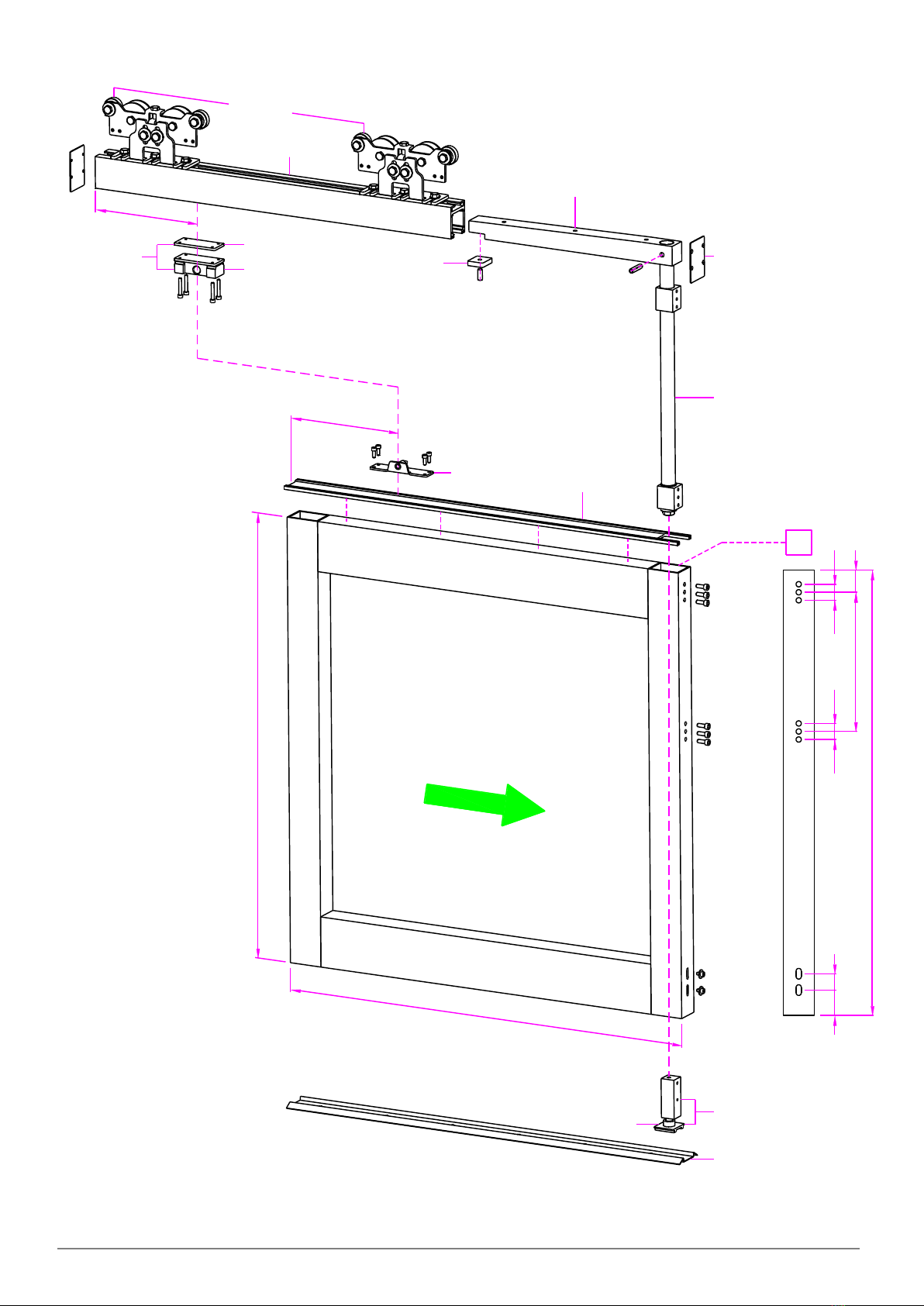

The break-out systems for sliding doors made from FACE are both available in kit and assembled into Metra frames NC50I, as

indicated in the sales list.

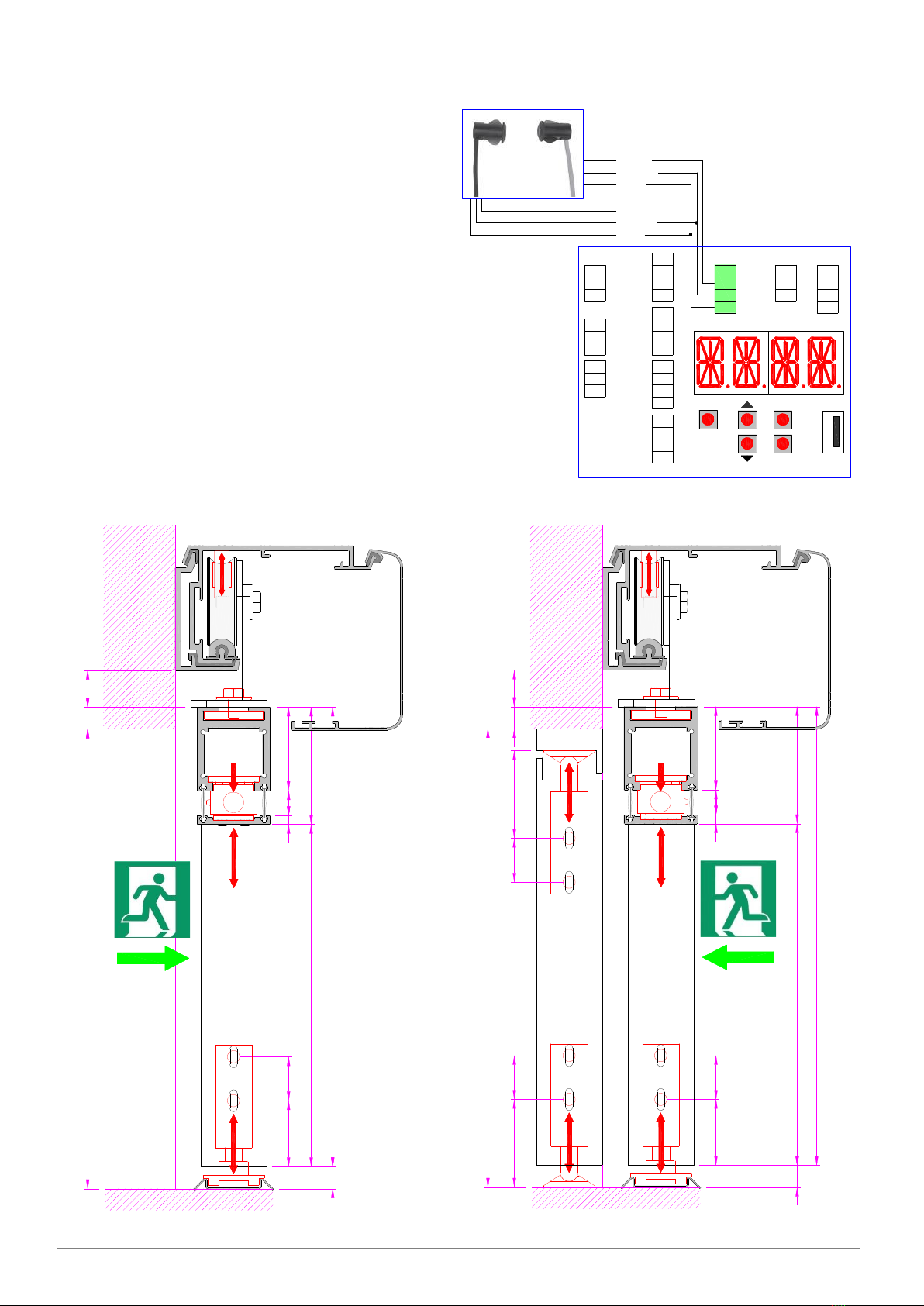

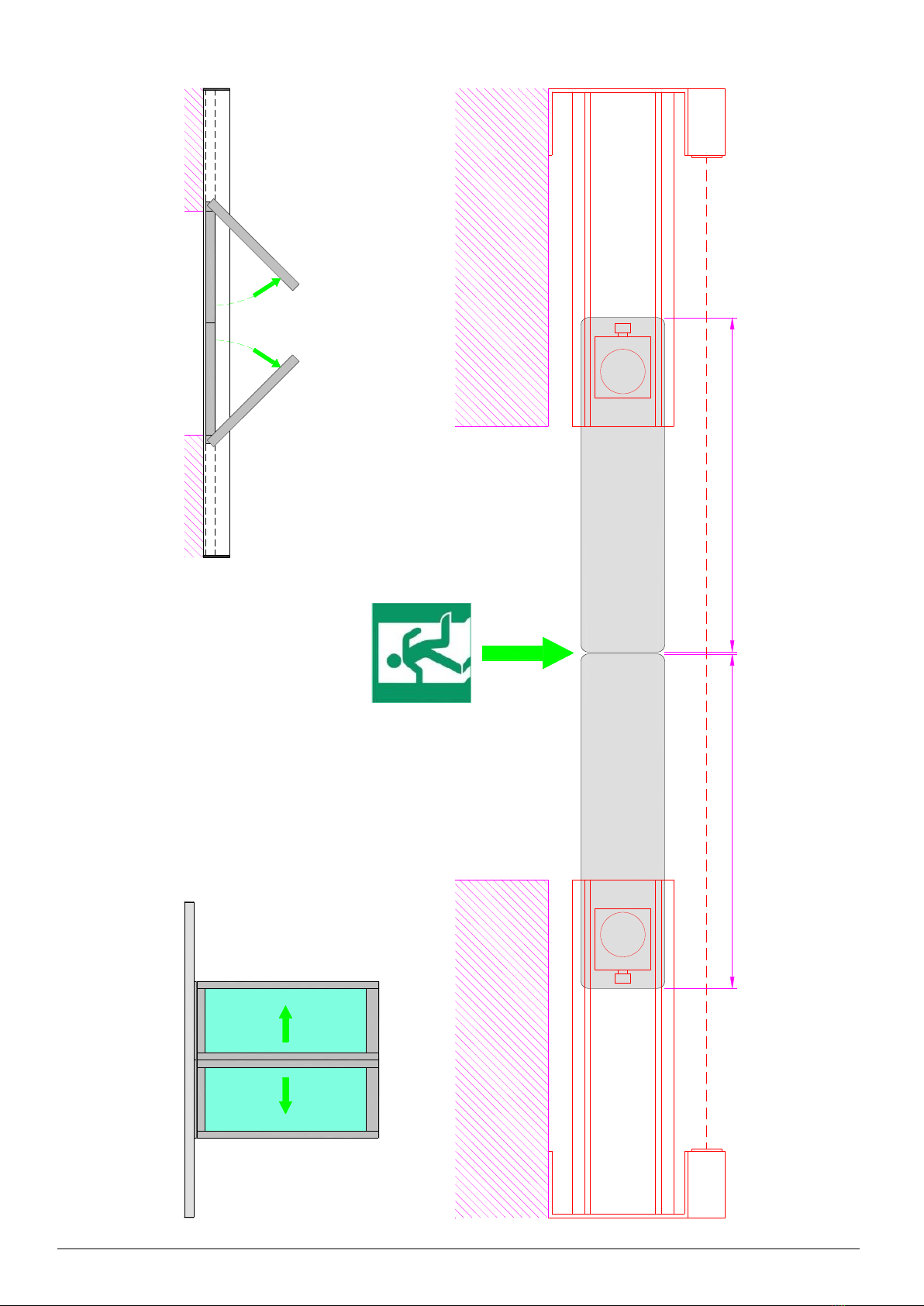

This manual provides the instructions to perform the assembly of the KBS1E break-out device for sliding door and KBS1D

break-out device for side wall, for Metra frames NC50I or for frames with similar size and of equivalent stability.

1.1 EC MARKING AND EUROPEAN DIRECTIVES

Break-out systems of the sliding doors and side walls are used in automatic doors for escape routes and

emergency exits. These automatic doors complete of break-out system, must comply with the European

standard EN 16005 and are CE-marked in accordance with the Machinery Directive (2006/42/EC).

Break-out systems of the KBS1E sliding doors and KBS1D side walls, in conjunction with the FACE

automation model SL5A and SF50 frame system (corresponding to the NC50I Metra systems), are approved by the Prima

Ricerca & Sviluppo S.r.l. laboratory and the test report is available at www.facespa.it in Download area.

All data and information contained in this manual have been drawn up and checked with the greatest care. However FACE

cannot take any responsibility for eventual errors, omissions or inaccuracies due to technical or illustrative purposes.

FACE reserves the right to make changes and improvements to their products. For this reason, the illustrations and the

information appearing in this document are not definitive.

This edition of the manual cancels and replaces all previous versions. In case of modification will be issued a new edition.