Tecnoalarm Tecnofire TFA2-596 User manual

Installation

Release: 3.2

FW release: 2.0.00

Models: TFA2-596 - TFA4-1192

Programming SW release: 5.4

Update: 07/2019

Language: English

TFA2-596 - TFA4-1192

Addressable fire alarm systems

TFA2-596 - TFA4-1192

2

TFA2-596 - TFA4-1192 3

The manufacturer, Tecnoalarm S.r.l., declares that the present equipment complies with the Directives LVD 2014/35/EU

and EMC 2014/30/EU as well as the regulation CPR 305/2011.

The full text of the EU Declaration of Conformity is available at the following internet address:

www.tecnofiredetection.com.

In addition, the manufacturer declares that the listed products are certified according to the following standards:

Control panels EN 54-2:1997 + A1:2006

TFA2-596 Certification number 0051-CPR-0389

TFA4-1192 Certification number 0051-CPR-0388

Power supply EN 54-4: 1997 + A1:2002 + A2:2006

TFPS-5 Certification number 0051-CPR-0492

The certificates are available at the following internet address: www.tecnofiredetection.com.

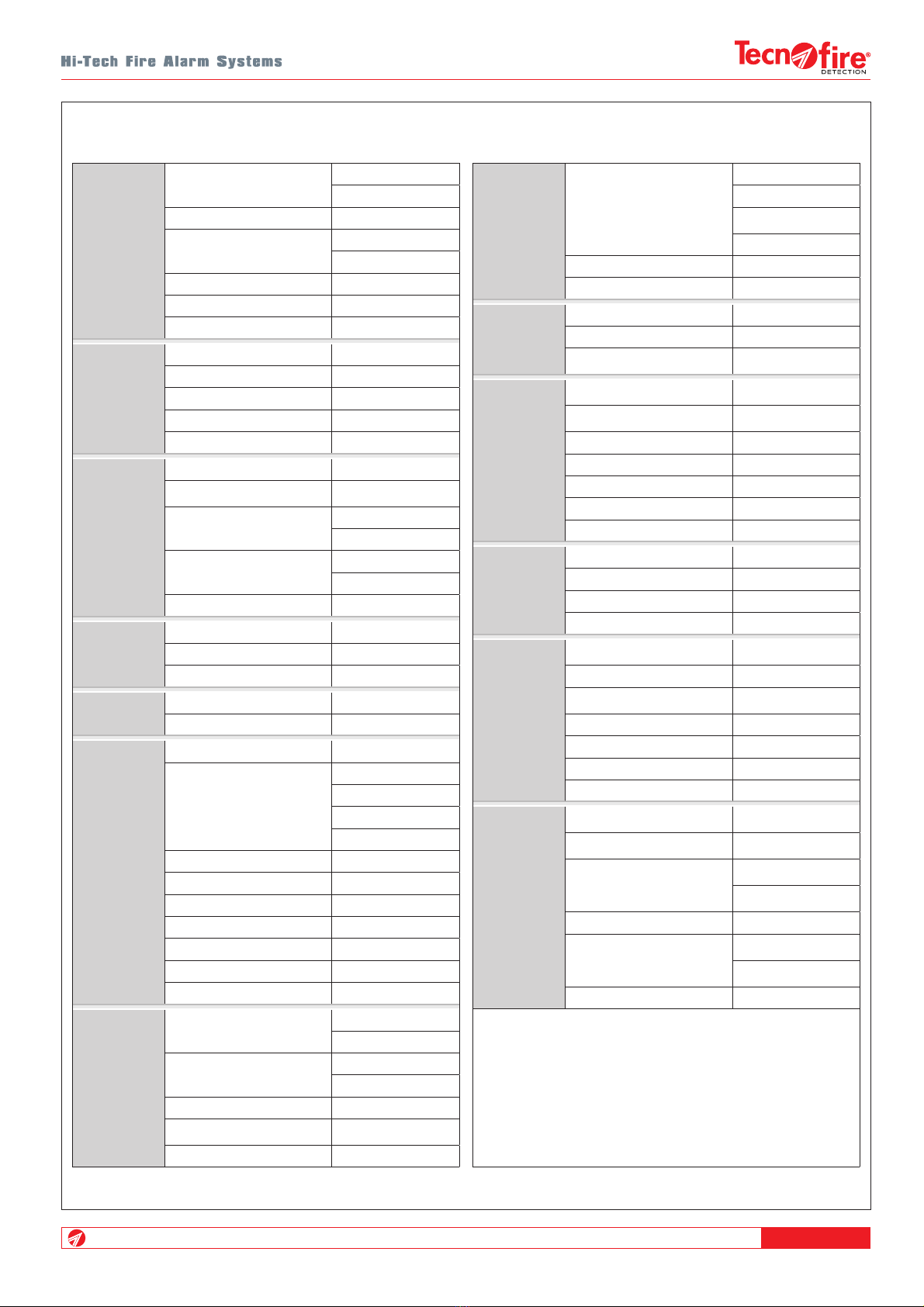

INDEX

The product features can be subject to change without notice. Unanthorized reproduction of distribution of this manual, or any

portion of it, on any device and in any form, is prohibited. The contents of this manual may be subject to change without notice.

TFA2-596 - TFA4-1192

4

TFA2-596 - TFA4-1192 5

INDEX

1 - GENERAL REFERENCES

7

2 - SYSTEM RESOURCES

9

3 - SYSTEM SPECIFICATIONS

11

4 - WARNINGS FOR INSTALLATION

4-1 Casing 15

4-2 Fixing of the casing 16

4-3 Connection cables 16

4-4 Compliance with EN 60950-1- Electrical Safety 17

4-5 Secondary power supply 18

5 - USER INTERFACE

5-1 Control panel 19

5-2 Access levels and codes 19

5-3 Function keys 20

5-4 Signaling LED 21

5-5 Viewing of operating states 22

5-6 Notification of operating states 24

5-7 Icons 26

6 - FAILURE NOTIFICATIONS

27

7 - POWER SUPPLY

29

7-1 Failure notifications of the power supply section 30

8 - DETECTION ZONES

8-1 Zones 33

8-2 Fire zones 34

8-3 Technical zones 36

8-4 Monitored system mode 38

TFA2-596 - TFA4-1192

6

9 - ELECTRONIC BOARDS

9-1 TFA2-596 terminals 41

9-2 Terminals 42

9-3 TFA4-1192 terminals 44

9-4 Terminals 45

9-5 CPU board 47

9-6 Power supply 49

10 - CONNECTION

10-1 Detection loop connection 51

10-2 Siren connection 52

10-3 RS485 bus connection 53

10-4 Potentiation of the secondary power supply 56

10-5 TFA2-596 additional power supply connection 56

10-6 TFA4-1192 upgrade of the secondary power supply 57

10-7 Telephone communicator 58

10-8 External Ethernet interface 60

10-9 Repeaters 61

TFA2-596 - TFA4-1192 7

Premise

Before proceeding with the installation, read this manual thoroughly. It contains important references and instructions concerning

the correct installation, operation and servicing of the fire alarm system.

Operational restrictions and purposes of a fire alarm system

It is fundamental to consider that a fire alarm system does not guarantee protection and immunity against material damages, of any

kind and nature, caused or induced by fire. It is equally important that the fire alarm system must be installed and kept in a state of

perfect functioning according to the instructions provided by the manufacturer.

The Tecnofire systems, designed for the detection, extinguishing, actuation, evacuation etc., are able to notify fire alarms promptly

to the final user and/or the personnel in charge. The systems process the events automatically and, according to programming,

transmit acoustic and/or telematic notifications apt to urge the evacuation of the premises, activate automatic control or

extinguishing systems and eliminate all situations and events that may feed the fire, with the aim of guaranteeing the safety of the

persons and safeguarding the property.

Installation requirements

Although this manual contains all the necessary procedures for a correct installation of the equipment, the interpretation and

correct application of its contents requires adequate training of the technical staff in charge of the installation. In particular,

the installer must have the necessary technical skills and acquaint himself with the valid European standards regarding both

the general requirements for fire alarm systems and the specific provisions for installation, electrical safety and maintenance.

In addition, he must have a thorough knowledge of the products, acquired through specific training at Tecnofire (division of

Tecnoalarm S.r.l.).

Environmental requirements

The control panel and all the system components must be installed inside structures or buildings with climatic characteristics

(temperature and non-condensing relative humidity) that comply with the standards applied during certification. Specific operating

temperature and humidity values are indicated in the relevant technical data tables.

Usage requirements

To avoid damage to the equipment or, even worse, dangerous malfunctions in detecting fire and actuating the devices and systems

that operationally dependent from the fire alarm system, it is mandatory to use only the components and devices indicated by

Tecnofire. The interfacing with third-party systems must be made with Tecnofire input and output modules, verifying each time the

full compatibility. If in doubt, always refer to the Tecnofire technical support service.

Technical support

The technical support service of Tecnofire provides assistance in answering technical questions regarding the installation,

functioning and operation of the Tecnofire products.

Power supply

In the planning phase, to ensure the autonomy of service requested by the standards, it is important to size the primary (mains

power) and secondary (battery) power supply correctly.

It must be considered that, in case of power failure, the system ensures functioning by means of batteries for a limited period of

time, the length of which depends on the capacity and the state of efficiency of the batteries.

Induced damage

Prior to working on any system component, in order not to cause damage while installing or servicing the equipment, always

disconnect both the primary (mains power) and secondary (battery) power supply of the system. To avoid damage caused

by electrostatic discharges, handle the electronic boards of the devices with care and avoid direct contact with the electronic

components.

1 - GENERAL REFERENCES

TFA2-596 - TFA4-1192

8

Periodic maintenance

To guarantee the efficiency of the fire alarm system, it is necessary to provide for an appropriate maintenance program. The

frequency of maintenance depends on different aspects, however, it is recommended to have the system serviced at least

once every 6 months. The maintenance operations should be carried out by specialized technical staff. It is assumed that those

who designed and installed the system have the necessary information and knowledge to perform proper maintenance. The

maintenance guidelines are prescribed by the European standards.

The most important controls include:

• Checking the operational state of the primary (mains power) and secondary (battery) power supply of the control panel and

of the auxiliary power supplies

• Checking the operational state of the batteries and self-powered devices (sirens and telephone transmitters)

• Checking the functional efficiency of the detectors

• Checking the functional efficiency (cleanliness) of the smoke chamber of the optical detectors

• Checking the functional efficiency of the control panels and repeaters

• Verifying the efficiency of the acknowledgment, evacuation and system reset procedures

• Checking the functional efficiency of the manual call points

• Checking the functional efficiency of the optical-acoustic alarm devices

• Checking the functional efficiency of the alarm transmission equipment (ATE)

• Verifying the efficiency of the actuations through the input and output modules

• Verifying the correct coupling of the cables to the terminals

• Drafting of the final inspection report

TFA2-596 - TFA4-1192 9

2 - SYSTEM RESOURCES

The TFA2-596 and TFA4-1192 fire detection panels are designed and manufactured in accordance with the standards

EN 54-2:1997 + A1:2006 (control panel) and EN 54-4:1997 + A1:2002 + A2:2006 (power supply).

It was designed under a quality system certified ISO 9001 that involves the application of a set of rules for the design and all

subsequent activities necessary for the production. All the components of the equipment were selected for the intended purposes.

Their specifications are guarenteed, if the environmental conditions outside the casing correspond to those specified for the class

3K5 of the standard EN 60721-3-3:1995.

The control panels should be installed in indoor areas, monitoring of temperature and humidity is not required.

The control panels consist of a metal casing with space for two 12V/7.2Ah batteries, a CPU board, which integrates the user

interface consisting of a display and a keypad, a switching 24V/2.7Ah power supply (ALSW2827) and a terminal board.

The TFA2-596 control panel manages 2 and the TFA4-1192 manages 4 detection loops.

The number of available detection loops can be increased by connecting other control panels.

The maximum network configuration includes 16 control panels with 4 detection loops.

General specifications TFA2-596 TFA4-1192 Max. network configuration (16 control panels)

Repeaters 16 16 Max. 256 (16 x 16)

Detection loop 2 4 Max. 64 (4 x 16)

Detectors per loop 199 199

Total detectors 398 (199 x 2) 796 (199 x 4) Max. 12736 (796 x 16)

Modules per loop 99 99

Total modules 198 (99 x 2) 396 (99 x 4) Max. 6336 (396 x 16)

Zones 300 300 Max. 4800 (300 x 16)

Virtual zones 100 100 Max. 1600 (100 x 16)

Access periods 32 32 Max. 512 (32 x 16)

Access levels 44 4

Codes 10 10 10

Formulas 200 400 400

Alarm plans 100 200 200

N.B. Although the control panel with 4 loops is able to manage a total of 1,192 detection devices (detectors + call points), the standard EN 54-2 chapter 13.6 provides

that a failure may not affect more than 512 detectors and/or manual call points and their designated functions. Therefore, the maximum number of connectable

detectors/call points to each control panel is 512, multiplied by 16 control panels equals 8,192.

Warning: the TFA2-596 and TFA4-1192 control panels are certified with the following options with requirements from EN 54-2

7.8 Outputs to fire alarm devices

7.11 Output delays

7.12 Dependencies on more than one alarm signal (type B)

8.3 Failure signals from points

9.5 Disablement of addressable points

10 Test conditions

Warning: the power supply of the TFA2-596 and TFA4-1192 control panels are certified to the requirements of EN 54-4

5.1 Power supply from the main power source

5.2 Power supply from the stand-by power source (battery)

5.3 Battery charging and check

5.4 Recognition and signaling of power supply failures

TFA2-596 - TFA4-1192

10

TFA2-596 - TFA4-1192 11

User interface

The front panel of the control panel hosts the user interface, consisting of 16 LED, a graphic color display and a keypad for management

of the fire detection system. The user interface integrates also a voice synthesis function that uses a customizable vocabulary.

Access levels

The control panel manages 4 levels of access: level 1 (not protected by code), level 2 (user), level 3 (installation and maintenance personnel

and level 4 (manufacturer).

Monitored system mode

The control panel provides for the monitored system mode, subject to the recognition of a level 2 code.

The monitored system mode is indicated by the relevant LED on the control panel and the relevant icon on the repeater panel.

System configuration

The configuration of the system can be performed locally through the control panel or remotely using a personal computer and the

programming software.

Integrated Ethernet hub

The control panel integrates an Ethernet interface which can communicate with the supervision centers on a local area network (LAN)

and/or a wide area network (WAN or VPN). The Ethernet interface which meets the 803.2 standard can transmit in a full/half duplex mode with

a transmission speed of 10 Mbit to 100 Mbit. The client/server communications are managed by 4 independent communication channels.

To forward notifications, the Ethernet interface uses 8 independent channels.

Communication protocols

The 8 channels for the event notification use both standard and proprietary TCP/IP protocols with an 128 bit AES encryption.

The channels can also manage encrypted transmissions using customized passphrases.

Control panel network

The network can be composed of a total of 16 addressable control panels connected through the RS485 serial bus.

The network is arranged in a hierarchy, one master control panel has the complete control over up to 15 slave control panels.

All information and signaling will be collected by the master. Network functioning is in compliance with the EN 54-13 standard.

Detection loop

The detection loop of the control panel can handle up to 199 detectors and 99 modules (maximum configuration in closed-loop mode).

Detectors

The control panel can directly manage the addressable detectors of the Tecnofire product line.

Conventional detectors can be managed through addressable interfaces.

Modules

The control panel can manage different types of specialized modules: input modules, output modules, sirens, call points, optical-acoustic

alarm devices, additional power supplies.

Telephone communicator

A total of 5 external PSTN telephone communicators with optional GSM-GPRS interface can be connected for transmitting voice, SMS,

GPRS notifications of alarms and signaling.

Repeater

The repeater panel has the task of repeating alarm signaling and decentralizing system management.

The repeater provides a 7 inches touch screen and a voice synthesis function.

3 - SYSTEM SPECIFICATIONS

The scope of the TFA2-596 and TFA4-1192 control panels is to build small, medium-sized and large addressable systems for the

automatic detection of fire. The systems can be composed of a network of maximum 16 control panels, permitting, in its maximum

network configuration, the management of up to 19,072 devices. Remember that the limit imposed by the EN 54 is 512 detectors

and/or manual call points for each control panel.

TFA2-596 - TFA4-1192

12

Synoptic repeater

The synoptic repeater panel performs the same functions as the repeater and, in addition, it manages dynamically or on request

up to 32 floor plans with up to 32 interactive icons each.

Additional power supply

The system provides for the use of additional power supplies, which allow to increase the power supply and autonomy of the system.

The power supplies can be freely distributed within the infrastructure of the loop. The Tecnofire power supplies are constantly supervised

by the control panel and comply with the applicable standard EN 54-4-A2:2006.

Zones

Each zone may control 1 to 32 detection and/or actuation devices, typically detectors and modules (maximum number of devices defined

by EN 54). The control panel controls up to 150 zones, which can be specialized as fire zones or technical zones.

Virtual zones

The control panel can manage up to 100 virtual zones. The virtual zone is an abstract set which includes detection and/or actuation devices,

typically detectors and modules. The virtual zones do not cause any kind of alarm notification, but can be recalled as operands within formulas.

The virtual zone may consist of devices, belonging to different loops and even to other virtual zones.

Formulas

The formulas determine the rules of behavior affecting the operation of the devices, on the basis of the dynamic behavior of the system.

Alarm plans

Each fire or technical zone can be associated with a specific alarm plan that, in the event of an alarm, is viewed by the control panel

and the repeaters of the system.

The alarm plan informs the operators about the behavior and the measures to be taken to deal with the alarm in the specific zone.

Programmable outputs

In addition to the mandatory alarm, failure and reset outputs, the control panel features 2 programmable outputs. For each of them it is possible

to program a function and the logic status (standard or reversed).

Access periods

The control panel manages 8 access periods that can be recalled as operands within formulas governing the operation of the output modules,

sirens and optical-acoustic alarm devices.

The access periods invoked within a formula perform the operation requested by the associated operand.

The access periods can also be used to enable the monitored system mode.

Customizable calendar

The control panel is equipped with a customizable four-year calendar that manages all the operations controlled by the clock.

It is possible to define weekdays, holiday eves, holidays and automatic Daylight Saving Time setting.

Personal computer interface

The control panel has an USB interface dedicated to the connection of a personal computer with which it is possible to perform, depending

on the access level, all programming operations and the system firmware update.

Serial printer interface

The control panel provides a TTL port dedicated to connecting a PROG32 interface to which you can connect a serial printer.

Event buffer

The control panel stores in its non-volatile buffer up to 8192 events in descending chronological order.

The memory contents can be displayed via the control panel or sent to the printer through the TTL port. Events can be displayed and filtered

by the software. For this, the events are downloaded and saved in a log file on the software.

Communication analysis

The control panel constantly supervises all communications among the devices that make up the system and registers possible errors.

TFA2-596 - TFA4-1192 13

TFA2-596 • TFA4-1192 - Technical and functional specifications

Detectors

Modules

Zones

Total connectable detectors 796 (TFA4-1192)

398 (TFA2-596)

Total detectors per loop 199

Total connectable modules 396 (TFA4-1192)

198 (TFA2-596)

Total modules per loop 99

Total zones 300

Virtual zones 100

CPU

outputs

Hard-programmed relays 2

Programmable relays 3

Programmable open-collectors 3

Controlled siren output 1

Reset output 1

System

features

True color TFT display 480 x 272 pixel

Voice synthesis Customizable

vocabulary

Detection loops 4 (TFA4-1192)

2 (TFA2-596)

RS485 serial buses Master Bus (1 port)

Slave Bus (1 port)

Event buffer capacity 8192

Access

management

Access levels 4

Access codes 10

Monitored system mode ✓

Protocols Loop Fire-Speed

RS485 serial bus Fire-Bus

Ethernet hub

Type Standard 803.2

Connection channels

Local Server

Remote Server

Tecnoserver

Call back

Notification channels 8

IP addresses 16 (2 per channel)

Transmittable events 15 categories

Protocols 5 IP protocols

Encryption AES 128 bit

Transmission time SIA IP DC-09 10s

Call event queue 64 events

Automation

Formulas 400 (TFA4-1192)

200 (TFA2-596)

Alarm plans 200 (TFA4-1192)

100 (TFA2-596)

Access periods 32

Calendar Quadrennial

(programmable)

Test call with TCP/IP ✓

Expandability

Serial expansions (max. 16)

TFT-7

TFT-7S

Telephone

communicator

Ethernet interface

Network configuration 1 master + 15 slaves

Serial printer ✓

Electrical

specifications

CPU

CPU board consumption 200mA @ 24V DC

Electrical outputs I max. 50mA

Power supply voltage

(loop, serial bus, sirens) 20V…27.6V DC

Modular

power supply

Type A - switching

Fly-back

Operating voltage 230V AC +10%

-15% 50Hz

Power supply consumption 700mA AC

Rated output current 5A @ 27.6V DC

Max. current available 5A

Peak-to-peak ripple voltage ≤150mV p-p

Battery protection fuse T 1.6A

Battery

Capacity 2x 12Ah/12V

Flame class V-2 or superior

Cut-off voltage <17.6V DC

Recharge time 100% in 24h

Physical

specificatons

Environmental class 3K5

(EN 60721-3-3:1995)

Operating temperature -5°C...+40°C

Relative humidity

(without condensation) 10%...93%

Protection class IP30

Casing Aluminium - Steel

Dimensions (L x H x D) 441 x 347 x 149mm

Weight (without batteries) 6.2kg

Conformity

Fire alarm panel EN 54-2:1997 +

A1:2006

Power supply EN 54-4:1997 +

A2:2006

Certification number

0051-CPR-0388

(TFA4-1192)

0051-CPR-0389

(TFA2-596)

Year of CE marking 14

Number of declaration of

performance

002_TFA4-1192

(TFA4-1192)

003_TFA2-596

(TFA2-596)

Notified body IMQ

TFA2-596 - TFA4-1192

14

TFA2-596 - TFA4-1192 15

A E I

B F J

C G K

D H

A C

B D

29 30 31 32 33

C

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

OUT3 RESET

NC NC

NA NA ---

OUT4

OUT5

OUT6 -+

L1BL1A

-+

-+

SIR

-+-+ -+

34 35 36 37 38

-+

L2BL2A

-+

39 40 41 42 43

-+

L3BL3A

-+

44 45 46 47 48

-+

L4BL4A

-+

C

123456789101112

ALL

NC NA C

OUT1

NC NA C

OUT2

NC NA

C

FAULT

NC NA

49 50 51 52

-+

BA

BUS MASTER

53 54 55 56

-+

BA

BUS SLAVE

A

G G

G

G

G

G

D

K

I

J

F

H

H

B

H H C

E

D

BC

A

4-1 - Casing

4 - WARNINGS FOR INSTALLATION

CPU board 12V/12Ah batteries Speaker

Terminal board NTC probe for battery temperature monitoring USB port

ALSW285PFC power supply Mounting holes TTL port

Ground connectors Cable entry

ALARM

PREALARM

TECHNICAL ALARM

GENERAL FAILURE

PWR SPLY FAILURE

SYSTEM FAILURE

BATTERY

SIRENS STOPPED

EXCLUSION

SIREN FAIL./EXCL

IP/PSTN FAIL./EXCL..

ZONE IN TEST

SYSTEM MONITORED

MAINS PWR OK

NETWORKED DEVICES

TX CARRIED OUT

Signaling LED Function keys

Display Numeric keys

EVACUATE

RESET

ACK

MONITORED

STOP/RESET

SIR.

Control panel working

Level 2

Version: 2.0.00 ENG

Level 3 Level 4

16/02/2019 Access level 1 08:00:00

Fire control panel

TFA2-596 - TFA4-1192

16

allaRME

PREallaRME

0

23

56

89

Ok

ESC

Back

EVACUAZ.

PRESIDIATO

TACITAZ.

TAC/RIP

SIRENE

RESET

30cm

60cm

The casing of the control panel must be fixed in a position that guarantees adequate protection from accidental shocks and at

a height that grants full access to the operator. Consider the space necessary for fully opening the casing door (approx. 60cm).

Fix the casing horizontally on a solid surface using 4 dowels with 8mm diameter.

General warnings

For the safety of the operators protect the control panel, as any electronic device, against splashes and avoid placing recipients

containing liquids next to it. The control panel must be installed so as to ensure adequate ventilation. Do not cover the device with

things that may hinder correct heat dissipation.

Install the control panel at an adequate distance from heat sources (e.g. radiators) and any device that may cause electromagnetic

disturbances (e.g. radio antennas).

The cables to be used for the connections are defined by standards and installation regulations.

These are flame retardant, low smoke emission and halogen free cables.

The European standards specify the cables to be used for the construction of fire detection systems.

Among these standards we mention (non-exhaustive list):

EN 50200, EN 60228, EN 50363, EN 60332, EN 50267, IEC 60332, IEC 61034, IEC 6754.

The installer shall ascertain the current legislative requirements for his country.

For all the connections on the loop, it is recommended to use shielded multicore twisted-pair cables with flexible conductors.

For selecting the loop and 24V power supply cables to be used, refer to the below table that indicates, based on the extension of

the loop, the minimum section that must be observed.

MINIMUM CABLE SECTION

Loop extension Minimum section required Loop extension Minimum section required

750 meters 0.75mm² 1500 meters 1.5mm²

1000 meters 1mm² 3000 meters 2.5mm²

For reasons of electrical safety, the shieldings of the cables must be connected in order not to stop their path and must be

grounded inside the casing of the control panel.

The maximum length allowed for the laying of the detection loop is 3000 meters, as defined by the low voltage directive

LVD 2006/95/EU.

The maximum length allowed for the RS485 bus (Master Bus) is 1000m. For greater distances use a fiber optic connection by

connecting a TFSFC01 RS485-fiber optic converter.

The relays and the electrical outputs of the control panel and its expansion devices form a SELV voltages network (EN 60950-1).

These outputs can only be connected to circuits that comply with SELV voltages.

4-2 - Fixing of the casing

4-3 - Connection cables

TFA2-596 - TFA4-1192 17

!

!

4-4 - Compliance with EN 60950-1- Electrical Safety

Ground connection

The ground connection must comply with the valid European standards.

It is mandatory to connect the ground conductor between the casing and the door.

External circuit breaker

The power supply of the control panel is not equipped with a circuit breaker. To guarantee accordance of the installation with

the valid European standards, it is necessary to connect an external circuit breaker or a bipolar mains switch

(16A curve C, opening stroke min. 3mm) in an accessible part of the electric installation (230V AC).

The circuit breaker must be installed close to the control panel and must be clearly labeled.

Mains connection (230V AC)

The mains cable is not included. To reduce the risk of electric shocks in normal operating conditions, observe the following

precautions:

• Use a double insulated cable (with shielding) for the connection to mains power.

• The mains cable should have a diameter of minimum 3x 1.5mm2and, once it has been connected to the corresponding power

input, it should be attached with a cable tie to the casing (see figure).

• To guarantee the electrical safety and correct functioning, always connect the ground conductor between the corresponding

terminal and the threaded pin for ground connection and between the base and the door of the casing (see figure).

Connect and fasten the mains cable and the ground wire

as shown in the drawing,

The indicated connection mode ensures that,

in the event of accidental tearing of the cable,

the ground conductor will be the last to be detached.

TFA2-596 - TFA4-1192

18

29 30 31 32 33

0

21 22 23 24 25 26 27 28

--

T

4

OUT5

OUT6 -+

L1BL1A

-+

-+

SIR

-+-+

34 35 36 37 38

-+

L2BL2A

-+

39 40 41 42 43

-+

L3BL3A

-+

44 45 46 47 48

-+

L4BL4A

-+

49 50 51 52

-+

BA

BUS MASTER

Battery information

The batteries must always be two. Never use batteries of different

manufacturers and capacities. Capacities lower than 12Ah,

besides reducing the autonomy, distort its resistance values

causing possible improper failure signaling.

In accordance with the standards EN 54, it is mandatory to block

the two batteries using the provided fixing bracket.

The bracket must be screwed on the casing.

Self-regulation of the charging voltage

The power supply reads the temperature of the battery via the

NTC (Negative Temperature Coefficient) probe and adjusts the

charging voltage of the batteries according to the themperature

measured. The NTC probe must be connected to the dedicated

polarized connector, the sensing end of the probe should be

attached to the battery casing using an electrical tape.

Automatic disconnection

In the absence of the primary power supply voltage

(230V AC mains), the batteries automatically assume the power

supply of the system. When the battery voltage drops to a value

<18V for a duration of 15 minutes, the batteries automatically

disconnect, to prevent their deep discharge and consequent

functional degradation.

Battery bracket fastening

Insert the bracket into the two slots located at the bottom.

Rotate the bracket blocking the batteries and fasten

the bracket using the supplied screws.

4-5 - Secondary power supply

TFA2-596 - TFA4-1192 19

OK

1

4

7

2

5

8

0

6

9

3

ESC

ESC

BACK

BACK

5 - USER INTERFACE

The user interface of the control panel consists of a 480 x 272 pixels TFT color graphic display, 16 notification LED, 5 function

keys, 7 navigation keys and 10 number keys, with which the user can manage the system. The user interface is completed by

the speaker that, according to the functional states of the control panel, provides audible alarms or notifications by using the voice

synthesis function.

The control panel manages 10 access codes associated to 4 levels of access: level 1 (not protected by code), level 2 (user),

level 3 (installation and maintenance personnel) and level 4 (manufacturer).

Level 1

In stand-by, the control panel provides access to the functions reserved to the level 1, without having to enter a code.

The access level 1 allows to perform the following operations:

A - Access the upper levels with the keys 1 or 2 or 3 and the relevant code (password)

B - Acknowledge the alarm pressing the ACK key

C-Display the acknowledged, the ongoing alarms and those stored in the event categories folders.

Level 2

To access level 2 press the key 1 and enter the relevant user code, then press the confirmation key.

At level 2, it is possible to perform all the operations of the level 1, plus the followings:

A - Reset the control panel pressing the RESET key.

B-Switch the operating state of the control panel (monitored/not monitored).

C-Manually activate an evacuation alarm.

D - Access the list of menus reserved to level 2.

E - Stop and reset the sirens.

Level 3

To access level 3 press the key 2 and enter the relevant installer code, then press the confirmation key.

Access to level 3 is reserved to staff authorized to edit important operating parameters.

At level 3 it is possible to perform all the operations of the levels 1 and 2 and to access the menus reserved to level 3

(system configuration menu)

Level 4

To access level 4 close the JP6 KEY jumper, press the key 3 and enter the manufacturer code, then press the confirmation key.

Access to level 4 is reserved to highly qualified personnel authorised by the manufacturer to carry out technical services of special

importance.

At level 4 it is possible to perform all the operations of the previous levels and to access the menus reserved to level 4.

The following table shows how to enter the codes and access the different access levels:

Access level key + Code + Confirmation key.

5-1 - Control panel

5-2 - Access levels and codes

ALARM

PREALARM

TECHNICAL ALARM

GENERAL FAILURE

PWR SPLY FAILURE

SYSTEM FAILURE

BATTERY

SIRENS STOPPED

EXCLUSION

SIREN FAIL./EXCL

IP/PSTN FAIL./EXCL..

ZONE IN TEST

SYSTEM MONITORED

MAINS PWR OK

NETWORKED DEVICES

TX CARRIED OUT

Control panel working

Level 2

Release: 2.0.00 ENG

Level 3 Level 4

16/02/2019 Access level 1 08:00:00

Fire control panel

RESET

EVACUATE

ACK

MONITORED

STOP/RESET

SIRENS

TFA2-596 - TFA4-1192

20

21 3

1

+

1 1 1 1 1

+

1

2

+

1 2 3 4 5

+

1

3

+

5 4 2 3 1

+

1

ACCESS TO ACCESS LEVELS

Access level 1 is not protected by code

Access level 2

Access level 3

Access level 4

16/02/2019 08:00:00Access level 1

Level 2 Level 3 Level 4

Release: 2.0.00 ENG

Control panel working

Fire control panel

The table describes the keys on the front panel of the control panel.

5-3 - Function keys

Key Description Operational sequence

RESET

Reset (deletion) of all prealarm, fire alarm, technical prealarm,

technical alarm and failure notifications and reset of the control

panel to normal operating condition.

1 - Press RESET

2 - Enter level 2 code

The LED and display notifications are cleared.

EVACUATE

Activation of the programmed procedure for the evacuation alarm,

activation of the sirens and output modules programmed to be

activated by the evacuation alarm procedure.

1 - Press EVACUATE

2 - Enter level 2 code

3 - Confirm the operation

The ALARM LED turns on. The display shows Evacuation.

ACK

Acknowledges the alarms issued for prealarm, fire alarm, technical

prealarm, technical alarm and failure. Moreover, the local speakers of

all the control panels and repeaters are muted.

N.B. The button does not mute the sirens and does not stop the

external activation devices (output modules, sirens etc.).

1 - Press ACK

The code is not required.

The ALARM LED remains lit.

The display alarm notifications remain visible.

MONITORED Toggle of the Monitored system mode.

N.B. This function only works if the option has been programmed.

1 - Press MONITORED

2 - Enter level 2 code

The MONITORED SYSTEM LED turns on or off:

LED on = monitored, LED off = not monitored

stop/RESET

SIRENS

Stop and reset of all sirens programmed for prealarm, fire alarm,

technical prealarm, technical alarm and failure as well as all

external actuating devices (output modules, sirens etc.) if the

acknowledgment function has been programmed for each of them.

1 - Press STOP/RESET SIRENS

2 - Enter level 2 code

The SIRENS STOPPED LED turns on.

OK

Navigation and confirmation keys. The arrow keys allow navigation

of the menus. Depending on the context, you can change the

displayed page and/or increase and decrease programming

parameters. The OK key is to confirm the selection.

Move the cursor up - Increase the value

Move the cursor down - Decrease the value

Move the cursor left - Decrease the value

Move the cursor right - Increase the value

OK Confirm the selection

ESC

ESC The ESC key allows to exit from the menu or displayed function.

BACK

BACK The BACK key allows to move the cursor to the previous position

and erase its contents

19

...........

The number keys allow to enter the code and select the menus and

devices in a direct way.

21 3

Number keys 1, 2 and 3 are accompanied by an arrows up symbol.

Depending on the context, they are numeric keys or pointing keys.

The arrows indicate the pointing boxes displayed directly above

them: access to level 2, 3 and 4.

This manual suits for next models

3

Table of contents

Other Tecnoalarm Fire Alarm manuals

Popular Fire Alarm manuals by other brands

Notifier

Notifier ID50 SERIES Installation, comissioning & configuration manual

Edwards Signaling & Security Systems

Edwards Signaling & Security Systems AdaptaBeacon 116DEXSTC-FJ installation instructions

Simplex

Simplex Saturn 2500 operating instructions

Simplex

Simplex SafeLINC 4100 operating instructions

Zeta Alarm Systems

Zeta Alarm Systems INFINITY ID2 installation manual

Fire-Lite Alarms

Fire-Lite Alarms MS-2 instructions