Tecnoma Novatec Isobus User manual

Operating Handbook

990025 MARS 2012

Sign C

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

2/31

1

11

1SUMMARY

SUMMARYSUMMARY

SUMMARY

1SUMMARY...........................................................................................................................................2

2INTRODUCTION.................................................................................................................................4

3SECURITY INDICATIONS ................................................................................................................5

3.1 Exclusion clause: ........................................................................................................................5

3.2 Securit measures ......................................................................................................................5

4POWER UP..........................................................................................................................................7

5SCREENS............................................................................................................................................8

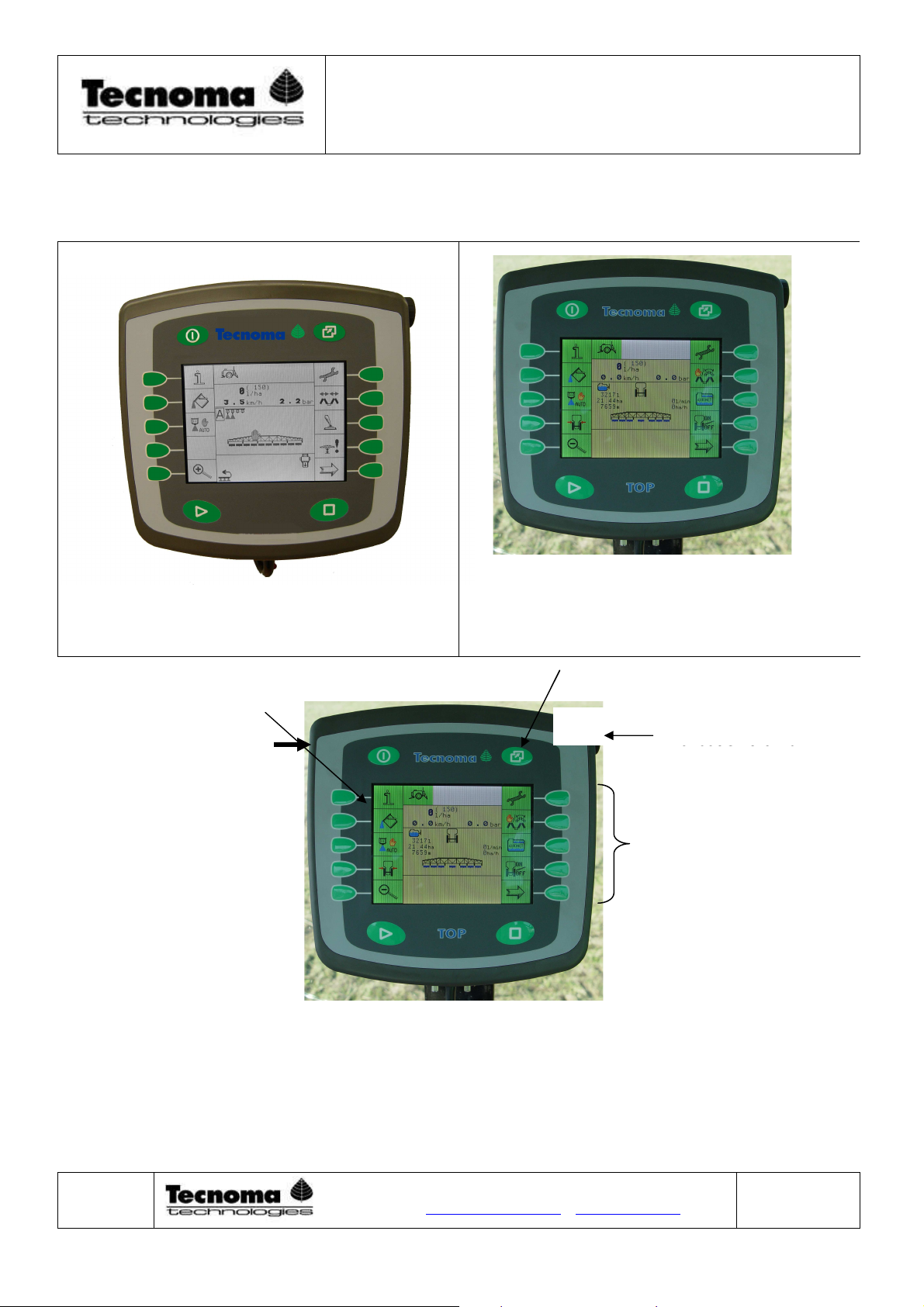

NOVATEC ISOBUS - ............................................................................................................................8

NOVATOP................................................................................................................................................8

5.1 S mbols of the work screen ......................................................................................................9

5.2 Description of on-screen icons..................................................................................................9

5.3 Settings screens........................................................................................................................11

5.3.1 Machine data page 1 .......................................................................................................11

5.3.2 Machine data page 2 ........................................................................................................12

5.3.3 Machine data page 3 ........................................................................................................12

6USE OF THE BOX............................................................................................................................13

6.1 Opening/closing of the boom (Work screen 1) .....................................................................13

6.1.1 Sequential mode ...............................................................................................................13

6.1.2 Simultaneous mode ..........................................................................................................14

6.1.3 Operating the boom with the jo stick.............................................................................16

6.2 Spra ing data (Work screen 2) .............................................................................................17

6.3 Programming the dose ( litre/ha) ................................................................................................17

6.4 Choice of the boom...................................................................................................................18

6.5 Choice of the wheel ..................................................................................................................18

6.6 Controlling sections ..................................................................................................................18

6.6.1 Opening/closing of sections with the handle (jo stick). ..............................................19

6.6.2 Opening/closing of section with the terminal ................................................................19

6.7 Occasional over and under dosing.........................................................................................20

6.8 Directional spra ing mode. (Allows to select sections individuall ) ..................................20

6.8.1 Directional mode with the JOYSTICK (central switch)................................................21

6.9 Volume in the tank. ...................................................................................................................21

6.10 Using the autonet option (h draulic version) ........................................................................22

6.11 Calibration of the speed sensor ..............................................................................................23

6.11.1 Direct input of number of pulses.....................................................................................23

6.12 Speed test. ....................................................................................................................................24

6.13 Modification of the boom width. ..............................................................................................24

6.14 Number of nozzles b section.................................................................................................25

6.15 Calibration of the automatic function height of boom on topfield. .....................................25

6.15.1 Screens...............................................................................................................................25

6.15.2 Use of the automatic function height of boom on topfield...........................................25

6.15.3 Activation of the automatic mode ...................................................................................26

6.16 TAG AXLE .................................................................................................................................26

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

3/31

6.16.1 Calibration of the tag axle................................................................................................26

6.16.2 Use of the tag axle ...............................................................................................................27

6.16.3 Automatic correction of super-elevation (Super-elevation sensor option) ...............27

6.17 Foam marker..............................................................................................................................28

6.18 Choice of nozzles and calibration...........................................................................................28

6.18.1 General information ..........................................................................................................28

6.18.2 Calibration procedure of a nozzle:..................................................................................29

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

4/31

2

22

2INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

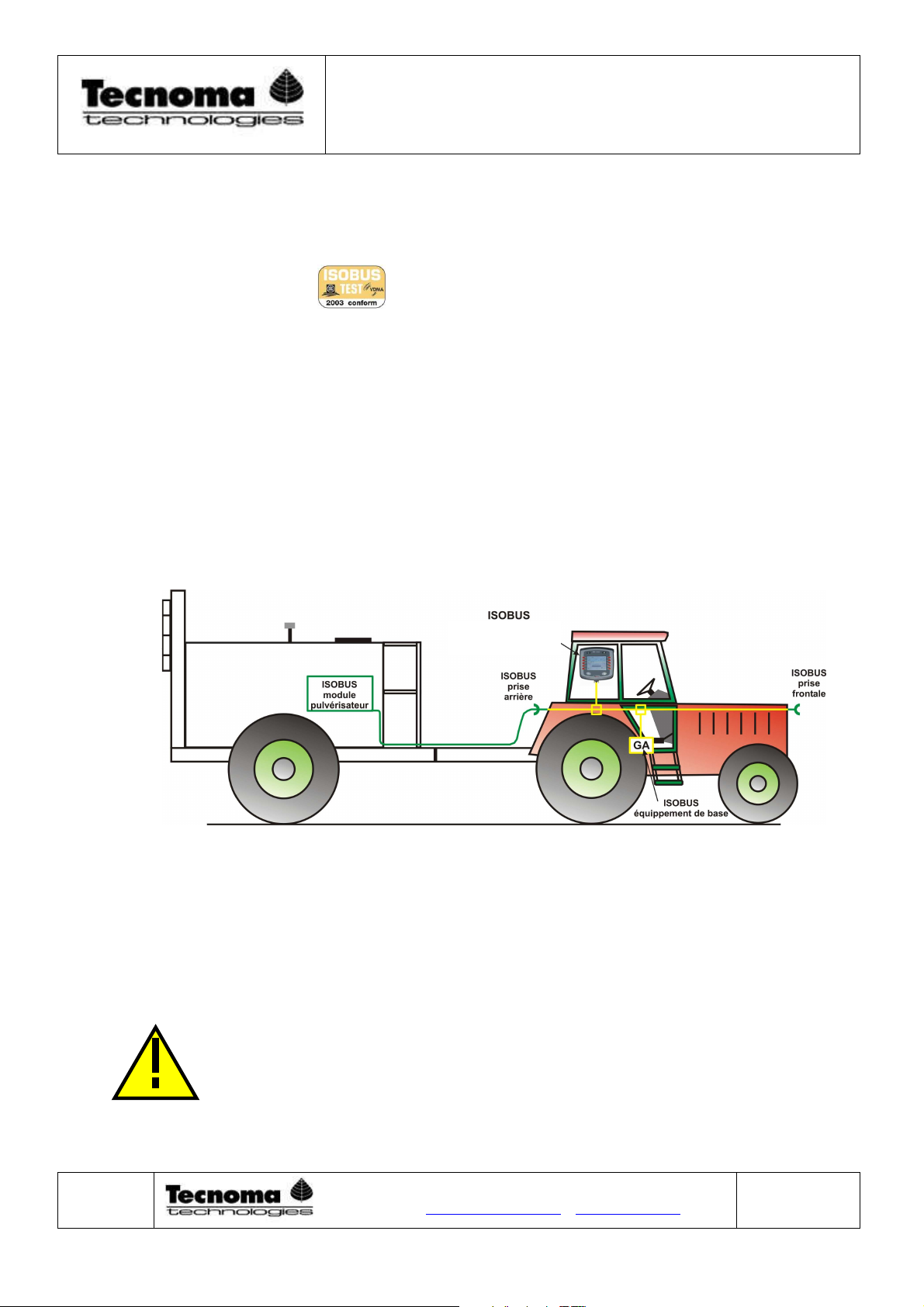

With the ISOBUS module, our spra er is equipped with a technique that we

developed according to the latest ISO standard. Your ISOBUS compatible

devices, based on the standard, can be connected to an tractor equipped

with an ISOBUS terminal. Starting now, the number of machines, equipment and

tractors equipped with ISOBUS compatible computers and terminals shall increase

rapidl . Therefore, ou are now at the cutting edge with the ISOBUS equipment of

our spra er.

The ISO NORM defines the means of transmission, the pin-and-socket connector

and the exchange of data from the ISOBUS. The latter works on the basis of an

ADC-Bus which is also used in the automotive industr as well as for industrial

vehicles. The ISOBUS regulates exchanges between control terminals, modules in

the tractor and the towed or carried equipment. The compatibilit of the devices is

reviewed b ISOBUS independent test institutes, in accordance with the ISO

11783 NORM. The equipment receives the ISOBUS certificate if it passes that test

successfull .

Basic assembly of the ISOBUS as per the ISO NORM 11783

Since the ISO norm allows an arbitrar combination of terminals, basic equipment,

modules etc., the description of all variants is be ond the scope of this guide. For this

reason, our examples in this guide are limited to the

NOVATEC ISOBUS - NOVATOP

. If

another terminal is used, the distribution of function ke s and the data entr ma be

different. You can find more information in the manual of our tractor’s terminal. Ask

our tractor dealer for necessar indications.

This description covers the maximum range of functions that the system can

provide you with. According to your sprayer equipment, some menus, control

buttons are not allocated on the terminal or do not possess a function.

NOVATEC Isobus

NOVATOP

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

5/31

3

33

3SECURITY

SECURITY SECURITY

SECURITY INDICATIONS

INDICATIONSINDICATIONS

INDICATIONS

3.1

3.13.1

3.1 E

EE

Exclusion

xclusionxclusion

xclusion

clause:

clause:clause:

clause:

The NOVATEC ISOBUS and NOVATOP regulations are exclusivel intended for

agricultural spra ers. An installation or use out of such a scope is not the responsibilit

of Tecnoma technologies.

The manufacturer is not liable for damages caused to people or objects. Onl the user

bears the responsibilit of an inappropriate uses.

The normal use foresees the respect of maintenance and operation conditions

prescribed b Tecnoma technologies.

The rules of anticipation of accidents, safet , industrial, medical and road regulations

recognized in general must be observed. All changes to the equipment exclude the

liabilit of Tecnoma technologies.

3.2

3.23.2

3.2 Securit m

Securit mSecurit m

Securit me

ee

ea

aa

asures

suressures

sures

Warning

WarningWarning

Warning!

!!

!

Alwa s

Alwa s Alwa s

Alwa s pa attention to this

pa attention to this pa attention to this

pa attention to this s mbol f

s mbol fs mbol f

s mbol for guidance on important securit measures. It

or guidance on important securit measures. It or guidance on important securit measures. It

or guidance on important securit measures. It

involves

involves involves

involves the

the the

the respect for the rules! Be careful!

respect for the rules! Be careful! respect for the rules! Be careful!

respect for the rules! Be careful! It concerns

It concerns It concerns

It concerns our safet

our safetour safet

our safet .

. .

.

Read the operating handbook

Read the operating handbookRead the operating handbook

Read the operating handbook,

, ,

, before using

before using before using

before using NOVATEC ISOBUS o

NOVATEC ISOBUS oNOVATEC ISOBUS o

NOVATEC ISOBUS or

rr

r NOVATOP

NOVATOP NOVATOP

NOVATOP

for

for for

for

the first time

the first timethe first time

the first time.

..

.

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

6/31

Please read carefull the

Please read carefull the Please read carefull the

Please read carefull the fo

fofo

following tips

llowing tipsllowing tips

llowing tips and safet

and safet and safet

and safet instructions:

instructions:instructions:

instructions:

Do not remove the stickers or the securit mechanisms.

Read and understand this manual before using the device. It is also important that

other operators of this device read and understand the manual.

Turn power off during maintenance or when using a charger (remove the ISOBUS

plug).

Never undertake maintenance or repairs on the device with the module on.

When performing welding works on the device or on a towed device, the

connection plug must be disconnected (remove the ISOBUS plug).

Use clear water for our tests. Use chemical products onl when all properties are

known.

Keep children awa from the device.

Do not expose the terminal and controller(s) and sensors to the direct beam of a

high pressure cleaner.

The controller should not be opened. An such manipulation leads to an

immediate and irrevocable loss of the guarantee.

Turn the ke s with the fingertip. Avoid using the nails.

If part of this guide should remain be ond understanding after reading it, get in

touch with our dealer or the customer service department of Tecnoma

technologies for an further explanation.

Read carefull all the safet instructions in the manual and the safet stickers of

the

device.

Safet stickers must alwa s be in a clearl readable state. Replace missing or

damaged stickers. Make sure that new parts of the device are equipped with the

latest safet stickers. You must order the replacement stickers from our

authorized distributor.

Keep the device and all its parts in a good condition. Unauthorized modifications

or misuse ma affect the smooth functioning and/or the safet and influence on

the life of the device and eliminate the device’s guarantee.

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

7/31

4

44

4POWER UP

POWER UPPOWER UP

POWER UP

Operation of the device requires to have the terminal powered up.

Observe the following sequence to power up the terminal.

Verif that the mechanical or h draulic power take

Verif that the mechanical or h draulic power takeVerif that the mechanical or h draulic power take

Verif that the mechanical or h draulic power take-

--

-off is disconnected

off is disconnectedoff is disconnected

off is disconnected.

..

.

(Never start PTO with the terminal off.)

Start the tractor or the self-propelled.

Turn on the terminal.

Engage the power take-off (PTO).

Observe the following sequence

Observe the following sequence Observe the following sequence

Observe the following sequence before shutting down the terminal

before shutting down the terminalbefore shutting down the terminal

before shutting down the terminal

Disconnect the power take-off of the tractor or the self-propelled. Turn off the terminal.

Stop the engine of the tractor or the self-propelled.

To move on the road with a lit box.

To move on the road with a lit box.To move on the road with a lit box.

To move on the road with a lit box.

Place the valves in agitation position before an movement on the road.

(check the position of the machine valves).

Otherwise

OtherwiseOtherwise

Otherwise,

, ,

, spra ing ma flow

spra ing ma flow spra ing ma flow

spra ing ma flow while

while while

while traveling be ond 10 km/h with the

traveling be ond 10 km/h with thetraveling be ond 10 km/h with the

traveling be ond 10 km/h with the AGP recir

AGP recir AGP recir

AGP recirculation

culation culation

culation

s stem

s stems stem

s stem and

and and

and the pneumatic spillproof

the pneumatic spillproofthe pneumatic spillproof

the pneumatic spillproof.

..

.

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

8/31

5

55

5SCREENS

SCREENSSCREENS

SCREENS

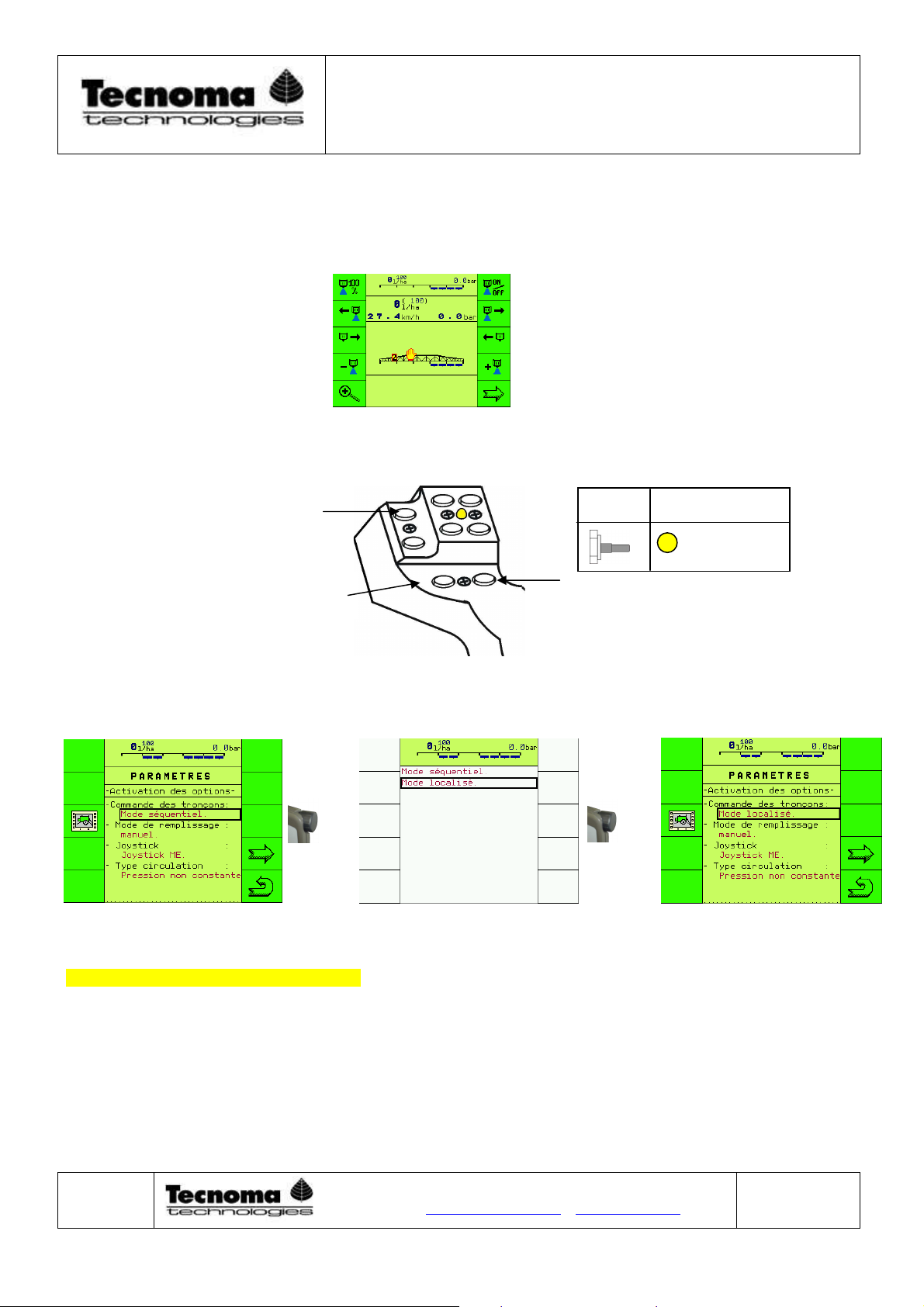

NOVATEC ISOBUS

NOVATEC ISOBUS NOVATEC ISOBUS

NOVATEC ISOBUS -

--

-

NOVATOP

NOVATOPNOVATOP

NOVATOP

Selection and

validation thumb

wheel

Sensory keys

corresponding to

the screen icon

On/Off

Key to service screen

Plug for USB key

(Only NOVATOP)

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

9/31

5.1

5.15.1

5.1 S mbols

S mbolsS mbols

S mbols of the work screen

of the work screen of the work screen

of the work screen

The functions are activated b pressing

The functions are activated b pressing The functions are activated b pressing

The functions are activated b pressing on

on on

on the sensor

the sensorthe sensor

the sensor ke s

ke s ke s

ke s on each side of the

on each side of the on each side of the

on each side of the

screen.

screen.screen.

screen.

To facilitate

To facilitate To facilitate

To facilitate the

the the

the understanding of oper

understanding of operunderstanding of oper

understanding of operations we

ations we ations we

ations we represent

representrepresent

represent the icon of the function

the icon of the function the icon of the function

the icon of the function.

..

.

5.2

5.25.2

5.2 Description

DescriptionDescription

Description of on

of on of on

of on-

--

-screen icons

screen iconsscreen icons

screen icons

S m

S mS m

S mbol

bolbol

bol

Description

DescriptionDescription

Description

Call of the settings screens. In the setting screens all adjustable values can be

Call of the settings screens. In the setting screens all adjustable values can be Call of the settings screens. In the setting screens all adjustable values can be

Call of the settings screens. In the setting screens all adjustable values can be

displa ed and modified. Other ke s allow t

displa ed and modified. Other ke s allow tdispla ed and modified. Other ke s allow t

displa ed and modified. Other ke s allow to move to different calibration screens.

o move to different calibration screens.o move to different calibration screens.

o move to different calibration screens.

Call

Call Call

Call for

for for

for folding screens. Depending on the functions of the

folding screens. Depending on the functions of the folding screens. Depending on the functions of the

folding screens. Depending on the functions of the boom

boomboom

boom, the ke s are

, the ke s are , the ke s are

, the ke s are

available on one or two screens.

available on one or two screens.available on one or two screens.

available on one or two screens.

This

This This

This ke

keke

ke is displa ed instead of the button

is displa ed instead of the button is displa ed instead of the button

is displa ed instead of the button

when the

when the when the

when the sequential boom mode

sequential boom mode sequential boom mode

sequential boom mode

is

isis

is programmed.

programmed. programmed.

programmed.

Th

ThTh

This

is is

is ke

keke

ke has two functions. A short press

has two functions. A short press has two functions. A short press

has two functions. A short press calls

callscalls

calls the classic folding mask. If the

the classic folding mask. If the the classic folding mask. If the

the classic folding mask. If the ke

keke

ke is

is is

is

pressed more than 2 seconds, the sequential

pressed more than 2 seconds, the sequential pressed more than 2 seconds, the sequential

pressed more than 2 seconds, the sequential folding

folding folding

folding mask appears.

mask appears. mask appears.

mask appears.

Ke allowing the access to the spra ing screen.

Ke allowing the access to the spra ing screen.Ke allowing the access to the spra ing screen.

Ke allowing the access to the spra ing screen.

Call of the packet

Call of the packetCall of the packet

Call of the packets

ss

s management screen.

management screen. management screen.

management screen. Totals

Totals Totals

Totals and

and and

and dail

dail dail

dail meters

meters meters

meters are grouped in

are grouped in are grouped in

are grouped in

the

the the

the packets management screen

packets management screenpackets management screen

packets management screen.

..

.

Call of the tank filling management screen and the autonet function. (This screen

Call of the tank filling management screen and the autonet function. (This screen Call of the tank filling management screen and the autonet function. (This screen

Call of the tank filling management screen and the autonet function. (This screen

groups all the tank functions and the autonet function control)

groups all the tank functions and the autonet function control)groups all the tank functions and the autonet function control)

groups all the tank functions and the autonet function control).

..

.

This ke enables or disables the tag axl

This ke enables or disables the tag axlThis ke enables or disables the tag axl

This ke enables or disables the tag axle and/or tracking axle or the articulated

e and/or tracking axle or the articulated e and/or tracking axle or the articulated

e and/or tracking axle or the articulated

drawbar. The function is available on the multifunctions handle.

drawbar. The function is available on the multifunctions handle.drawbar. The function is available on the multifunctions handle.

drawbar. The function is available on the multifunctions handle.

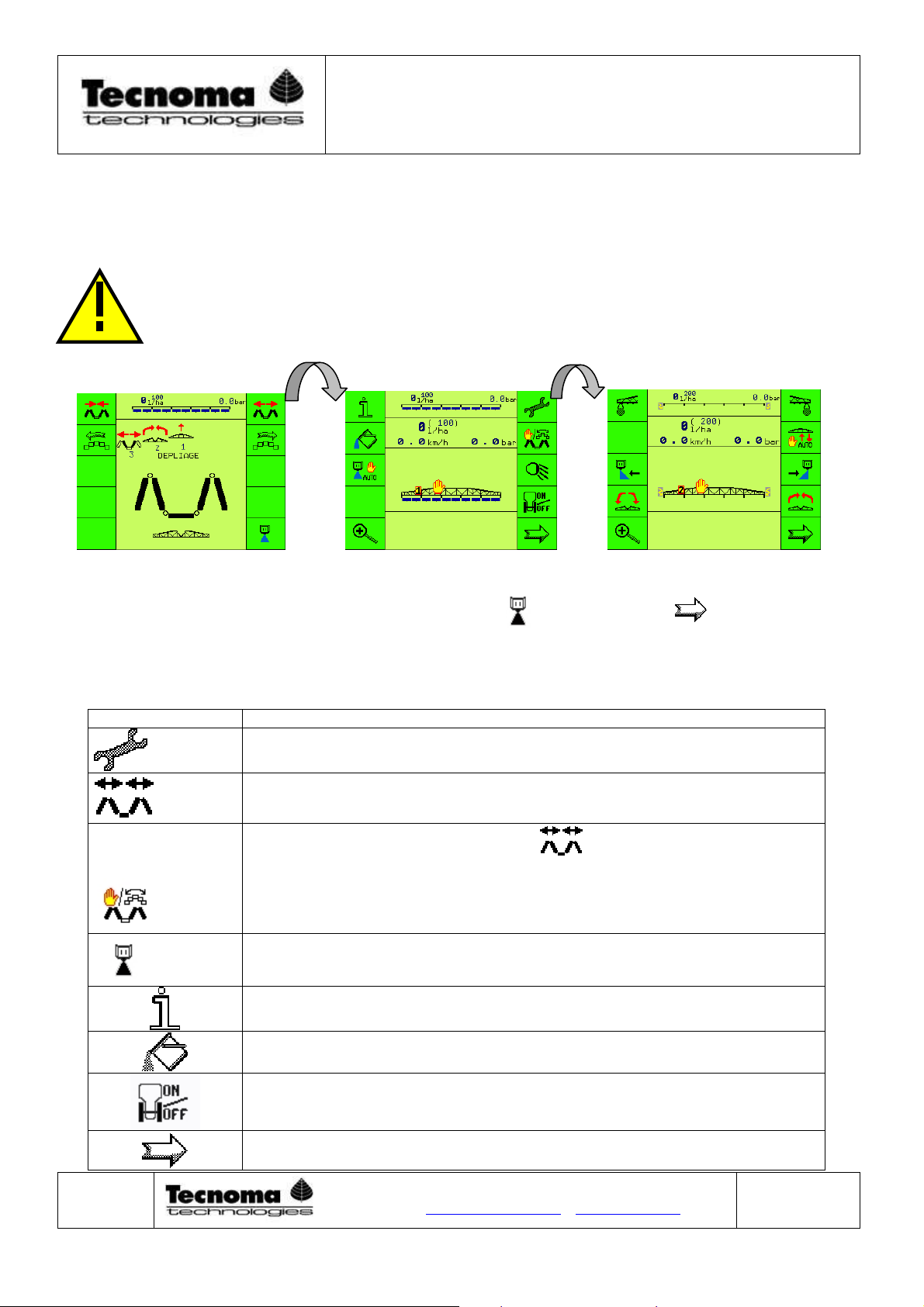

See following screen

See following screenSee following screen

See following screen

Screen at power on

of box

Work screen b

Work screen bWork screen b

Work screen b

pressing the button

pressing the button pressing the button

pressing the button

next to

next to next to

next to

Displa of the following

Displa of the following Displa of the following

Displa of the following

screen b pressing the

screen b pressing the screen b pressing the

screen b pressing the

button next to the icon

button next to the iconbutton next to the icon

button next to the icon

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

10/31

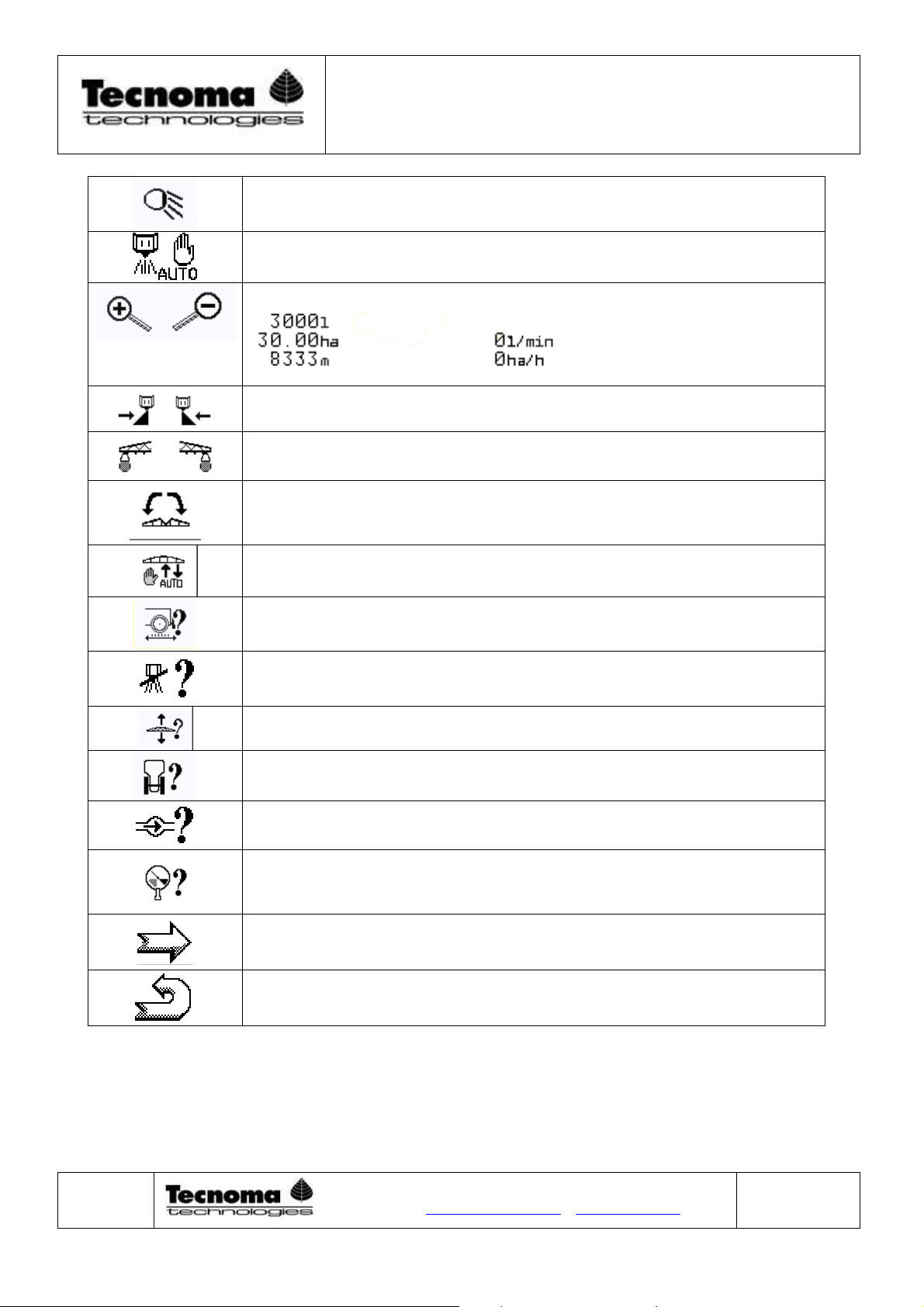

Work lights control

Work lights controlWork lights control

Work lights control.

..

.

Manual/automatic switch for spra ing functions.

Manual/automatic switch for spra ing functions. Manual/automatic switch for spra ing functions.

Manual/automatic switch for spra ing functions.

In valve autopiloting or manual mode.

In valve autopiloting or manual mode.In valve autopiloting or manual mode.

In valve autopiloting or manual mode.

Call or

Call orCall or

Call or deletion of supplementar data displa

deletion of supplementar data displa deletion of supplementar data displa

deletion of supplementar data displa

R

RR

R

and

andand

and

L

LL

L

ke s for opening closing of end

ke s for opening closing of endke s for opening closing of end

ke s for opening closing of end-

--

-nozzles right or left side

nozzles right or left side nozzles right or left side

nozzles right or left side

R

RR

R and

and and

and L

LL

L ke s for opening closing of

ke s for opening closing of ke s for opening closing of

ke s for opening closing of foam marker

foam markerfoam marker

foam marker

Ke of variable geometries

Ke of variable geometriesKe of variable geometries

Ke of variable geometries.

..

.

Ke activating

Ke activating Ke activating

Ke activating

the

the the

the height

heightheight

height

of boom in

of boom in of boom in

of boom in topfield

topfieldtopfield

topfield

Call

CallCall

Call of the calibration page of wheels

of the calibration page of wheels of the calibration page of wheels

of the calibration page of wheels 1, 2 o

1, 2 o 1, 2 o

1, 2 or

rr

r 3

3 3

3

Call of the choice page of the boom

Call of the choice page of the boomCall of the choice page of the boom

Call of the choice page of the boom 1 o

1 o 1 o

1 or

rr

r 2

2 2

2 and of setting the number of

and of setting the number of and of setting the number of

and of setting the number of

nozzles/sections

nozzles/sectionsnozzles/sections

nozzles/sections.

. .

.

Call of the calibration page of the distance control option

Call of the calibration page of the distance control optionCall of the calibration page of the distance control option

Call of the calibration page of the distance control option

Call of the calibration page of the tag axle

Call of the calibration page of the tag axleCall of the calibration page of the tag axle

Call of the calibration page of the tag axle

Cal

CalCal

Call of the calibration screen of the flow meter

l of the calibration screen of the flow meterl of the calibration screen of the flow meter

l of the calibration screen of the flow meter

Call

CallCall

Call of the page of nozzles choice b ISO color code and of the

of the page of nozzles choice b ISO color code and of the of the page of nozzles choice b ISO color code and of the

of the page of nozzles choice b ISO color code and of the setting

setting setting

setting of pressure

of pressure of pressure

of pressure

calculation displa ed on the screen. Attention pressure calculated and not

calculation displa ed on the screen. Attention pressure calculated and not calculation displa ed on the screen. Attention pressure calculated and not

calculation displa ed on the screen. Attention pressure calculated and not

measured b a pressure sensor.

measured b a pressure sensor.measured b a pressure sensor.

measured b a pressure sensor.

Next

Next Next

Next Page

PagePage

Page

Previous

Previous Previous

Previous Page

PagePage

Page

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

11/31

5.3

5.35.3

5.3 Settings

Settings Settings

Settings screens

screensscreens

screens

Settings

SettingsSettings

Settings page 1

page 1 page 1

page 1

Settings

SettingsSettings

Settings page 2

page 2 page 2

page 2

Settings

SettingsSettings

Settings page 3

page 3 page 3

page 3

5.3.1

5.3.15.3.1

5.3.1 Machine data

Machine dataMachine data

Machine data page

page page

page

1

1 1

1

Setting

SettingSetting

Setting

Description

DescriptionDescription

Description

Dose

DoseDose

Dose

Volume per programmed hectare. l/ha (liters/hectare)

Volume per programmed hectare. l/ha (liters/hectare)Volume per programmed hectare. l/ha (liters/hectare)

Volume per programmed hectare. l/ha (liters/hectare)

Nozzle

NozzleNozzle

Nozzle

Choice of work nozzle. The choice has n

Choice of work nozzle. The choice has nChoice of work nozzle. The choice has n

Choice of work nozzle. The choice has no bearing on the regulation. B

o bearing on the regulation. B o bearing on the regulation. B

o bearing on the regulation. B

choosing the work nozzle, the pressure is calculated and displa ed on the

choosing the work nozzle, the pressure is calculated and displa ed on the choosing the work nozzle, the pressure is calculated and displa ed on the

choosing the work nozzle, the pressure is calculated and displa ed on the

work screen.

work screen.work screen.

work screen.

Boom

BoomBoom

Boom n°

n° n°

n°

Two boom widths are possible. Choose the width of the job.

Two boom widths are possible. Choose the width of the job.Two boom widths are possible. Choose the width of the job.

Two boom widths are possible. Choose the width of the job.

!

This value must match the number of nozzles per section, because it

This value must match the number of nozzles per section, because itThis value must match the number of nozzles per section, because it

This value must match the number of nozzles per section, because it

influences the

influences the influences the

influences the surface

surface surface

surface extent and the

extent and the extent and the

extent and the quantit spread

quantit spreadquantit spread

quantit spread.

..

.

Wheel

WheelWheel

Wheel n°

n° n°

n°

Three t pes of wheels are possible. Choose the mounted wheels for the

Three t pes of wheels are possible. Choose the mounted wheels for the Three t pes of wheels are possible. Choose the mounted wheels for the

Three t pes of wheels are possible. Choose the mounted wheels for the

ongoing job.

ongoing job.ongoing job.

ongoing job.

Regulation f

Regulation fRegulation f

Regulation fact

actact

actor

oror

or

The regulation factor adjusts the responsiveness of the regulation. If during

The regulation factor adjusts the responsiveness of the regulation. If during The regulation factor adjusts the responsiveness of the regulation. If during

The regulation factor adjusts the responsiveness of the regulation. If during

an applic

an applican applic

an application at constant speed the amount currentl

ation at constant speed the amount currentl ation at constant speed the amount currentl

ation at constant speed the amount currentl spread

spreadspread

spread should differ

should differ should differ

should differ

from that required, the constant factor must be reduced. If during a change

from that required, the constant factor must be reduced. If during a change from that required, the constant factor must be reduced. If during a change

from that required, the constant factor must be reduced. If during a change

in speed the

in speed the in speed the

in speed the spread

spreadspread

spread quantit does not fit quite quickl to the required value,

quantit does not fit quite quickl to the required value, quantit does not fit quite quickl to the required value,

quantit does not fit quite quickl to the required value,

the factor should be increased.

the factor should be increased.the factor should be increased.

the factor should be increased.

Pr

PrPr

Press

essess

essure

ureure

ure max.

max. max.

max.

Pressure value calculated to the maximum before the outbreak of an

Pressure value calculated to the maximum before the outbreak of an Pressure value calculated to the maximum before the outbreak of an

Pressure value calculated to the maximum before the outbreak of an

warning. This setting has no impact on the regulation.

warning. This setting has no impact on the regulation. warning. This setting has no impact on the regulation.

warning. This setting has no impact on the regulation.

Pres

PresPres

Pressure

suresure

sure min.

min. min.

min.

Pressure value calculated to the minimum below which the warning is

Pressure value calculated to the minimum below which the warning is Pressure value calculated to the minimum below which the warning is

Pressure value calculated to the minimum below which the warning is

triggered. This setting has no impact

triggered. This setting has no impact triggered. This setting has no impact

triggered. This setting has no impact on the regulation.

on the regulation.on the regulation.

on the regulation.

Speed

SpeedSpeed

Speed min.

min. min.

min.

Speed below which spra ing is cut off.

Speed below which spra ing is cut off.Speed below which spra ing is cut off.

Speed below which spra ing is cut off.

The

TheThe

The logo

logo logo

logo app

app app

appears then in the work mask.

ears then in the work mask.ears then in the work mask.

ears then in the work mask.

Speed

SpeedSpeed

Speed auto min.

auto min. auto min.

auto min.

Speed below which the s stem no longer regulates the flow of the spra er.

Speed below which the s stem no longer regulates the flow of the spra er. Speed below which the s stem no longer regulates the flow of the spra er.

Speed below which the s stem no longer regulates the flow of the spra er.

The s stem goes into manual mode below th

The s stem goes into manual mode below thThe s stem goes into manual mode below th

The s stem goes into manual mode below this

isis

is speed.

speed. speed.

speed. If the

If the If the

If the defined

defined defined

defined value

value value

value

is 0, the function is disabled.

is 0, the function is disabled.is 0, the function is disabled.

is 0, the function is disabled.

Th

ThTh

The logo app

e logo appe logo app

e logo appears

earsears

ears as soon as the speed is below the minimal auto

as soon as the speed is below the minimal auto as soon as the speed is below the minimal auto

as soon as the speed is below the minimal auto

speed.

speed.speed.

speed.

Please make sure that the minimal speed is lower than the minimal auto

Please make sure that the minimal speed is lower than the minimal auto Please make sure that the minimal speed is lower than the minimal auto

Please make sure that the minimal speed is lower than the minimal auto

speed. Otherwise, onl the minimal speed will b

speed. Otherwise, onl the minimal speed will bspeed. Otherwise, onl the minimal speed will b

speed. Otherwise, onl the minimal speed will be taken into account.

e taken into account.e taken into account.

e taken into account.

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

12/31

5.3.2

5.3.25.3.2

5.3.2 Machine

Machine Machine

Machine data

datadata

data page 2

page 2 page 2

page 2

Setting

SettingSetting

Setting

Description

DescriptionDescription

Description

Tank v

Tank vTank v

Tank volume

olumeolume

olume

Volume of liquid in the tank. Value to enter when filling the main tank.

Volume of liquid in the tank. Value to enter when filling the main tank.Volume of liquid in the tank. Value to enter when filling the main tank.

Volume of liquid in the tank. Value to enter when filling the main tank.

Warning level

Warning levelWarning level

Warning level

If the amount remaining in the tank falls below this value, a warning is triggered.

If the amount remaining in the tank falls below this value, a warning is triggered.If the amount remaining in the tank falls below this value, a warning is triggered.

If the amount remaining in the tank falls below this value, a warning is triggered.

Pulse

PulsePulse

Pulse Flow

Flow Flow

Flow

The number of pulses

The number of pulses The number of pulses

The number of pulses in

inin

in lit

lit lit

litr

rr

re

ee

es

ss

s of the main flow

of the main flow of the main flow

of the main flow meter

meter meter

meter is entered here. The number

is entered here. The number is entered here. The number

is entered here. The number

of pulses per lit

of pulses per litof pulses per lit

of pulses per litr

rr

re is shown on

e is shown on e is shown on

e is shown on all Tecnoma

all Tecnoma all Tecnoma

all Tecnoma flow

flowflow

flow

meters.

meters. meters.

meters.

The

The The

The flow

flow flow

flow meter can be calibrated.

meter can be calibrated.meter can be calibrated.

meter can be calibrated.

!

This value must be defined ver precisel , because it directl affects the

This value must be defined ver precisel , because it directl affects theThis value must be defined ver precisel , because it directl affects the

This value must be defined ver precisel , because it directl affects the

quantit spread.

quantit spread.quantit spread.

quantit spread.

Pulse

PulsePulse

Pulse

return

returnreturn

return

The number of pulses in litres of the return flow meter for machines having the

The number of pulses in litres of the return flow meter for machines having the The number of pulses in litres of the return flow meter for machines having the

The number of pulses in litres of the return flow meter for machines having the

recirculation s stem option is entered here. The number of pulses per litre is shown

recirculation s stem option is entered here. The number of pulses per litre is shown recirculation s stem option is entered here. The number of pulses per litre is shown

recirculation s stem option is entered here. The number of pulses per litre is shown

on all Tecnoma flow meters.

on all Tecnoma flow meters. on all Tecnoma flow meters.

on all Tecnoma flow meters.

The flow meter can be calibrat

The flow meter can be calibratThe flow meter can be calibrat

The flow meter can be calibrated.

ed.ed.

ed.

!

This value must be defined ver precisel , because it directl affects the

This value must be defined ver precisel , because it directl affects the This value must be defined ver precisel , because it directl affects the

This value must be defined ver precisel , because it directl affects the

quantit spread

quantit spreadquantit spread

quantit spread.

..

.

5.3.3

5.3.35.3.3

5.3.3 Machine data

Machine dataMachine data

Machine data page 3

page 3 page 3

page 3

Settings

SettingsSettings

Settings

Description

DescriptionDescription

Description

Control of the

Control of the Control of the

Control of the

sections

sectionssections

sections

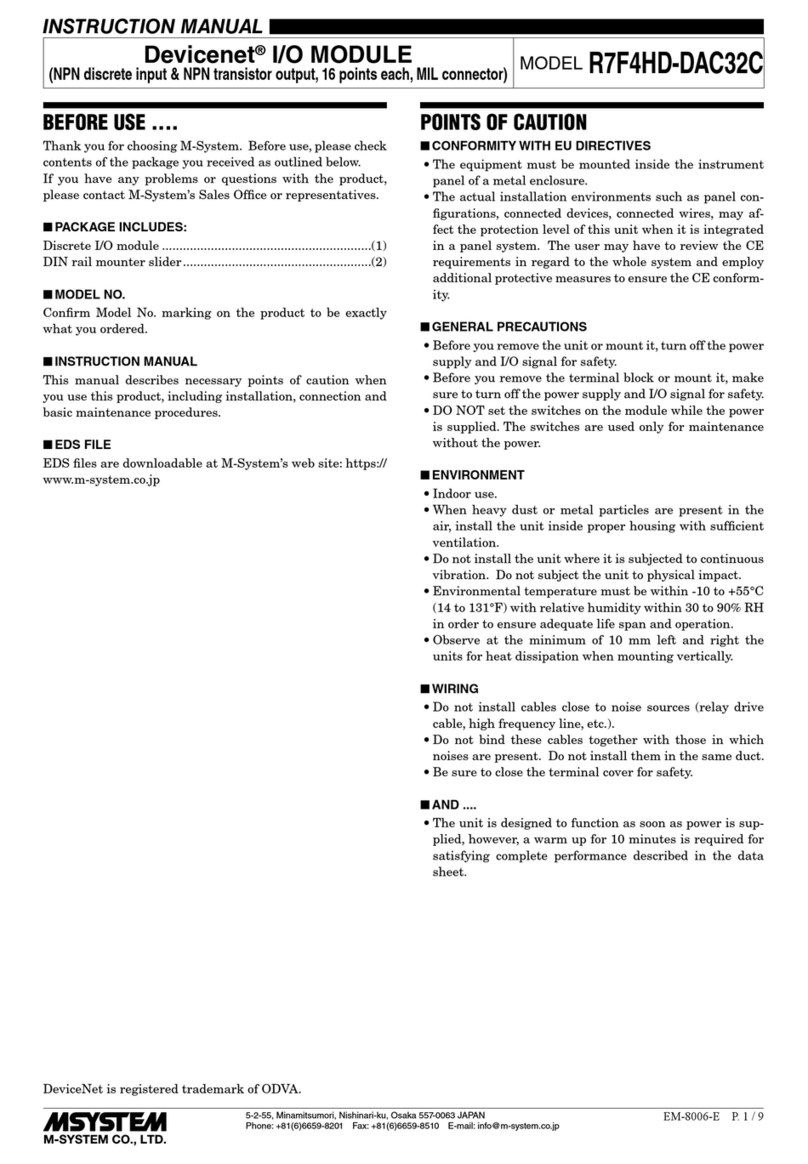

Call of the choices page between the sequential mode and the

Call of the choices page between the sequential mode and the Call of the choices page between the sequential mode and the

Call of the choices page between the sequential mode and the directional

directionaldirectional

directional mode.

mode. mode.

mode.

The

The The

The operating modes are described in the chap.

operating modes are described in the chap.operating modes are described in the chap.

operating modes are described in the chap.

!

An changes require to turn off and on the terminal to validate the change.

An changes require to turn off and on the terminal to validate the change.An changes require to turn off and on the terminal to validate the change.

An changes require to turn off and on the terminal to validate the change.

Mode of filling

Mode of fillingMode of filling

Mode of filling

There is no automatic mode of filling

There is no automatic mode of fillingThere is no automatic mode of filling

There is no automatic mode of filling.

..

.

Jo stick

Jo stickJo stick

Jo stick

Changing the operation mode of the Jo stick

Changing the operation mode of the Jo stickChanging the operation mode of the Jo stick

Changing the operation mode of the Jo stick.

. .

.

no Jo stick = all fun

no Jo stick = all funno Jo stick = all fun

no Jo stick = all functions correspond to icons. The multifunction handle can still be

ctions correspond to icons. The multifunction handle can still be ctions correspond to icons. The multifunction handle can still be

ctions correspond to icons. The multifunction handle can still be

used.

used.used.

used.

Jo stick ME = The h draulic functions required during the operation and the

Jo stick ME = The h draulic functions required during the operation and the Jo stick ME = The h draulic functions required during the operation and the

Jo stick ME = The h draulic functions required during the operation and the

controls of spra ing sections are available on the handle.

controls of spra ing sections are available on the handle.controls of spra ing sections are available on the handle.

controls of spra ing sections are available on the handle.

!

An changes require to turn off and on the

An changes require to turn off and on the An changes require to turn off and on the

An changes require to turn off and on the terminal to validate the change

terminal to validate the changeterminal to validate the change

terminal to validate the change.

..

.

C

CC

Circulation

irculationirculation

irculation t pe

t pe t pe

t pe

Choosing the t pe of movement

Choosing the t pe of movementChoosing the t pe of movement

Choosing the t pe of movement.

..

.

!

After changing this setting the computer must be turned off and reconnected.

After changing this setting the computer must be turned off and reconnected. After changing this setting the computer must be turned off and reconnected.

After changing this setting the computer must be turned off and reconnected.

The change is then taken into account

The change is then taken into accountThe change is then taken into account

The change is then taken into account .

. .

.

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

13/31

6

66

6USE OF THE

USE OF THE USE OF THE

USE OF THE BOX

BOXBOX

BOX.

..

.

Work screen

Work screenWork screen

Work screen 1

1 1

1

Work screen

Work screenWork screen

Work screen 2

2 2

2 Work screen

Work screenWork screen

Work screen 3

3 3

3

6.1

6.16.1

6.1 O

OO

Opening

peningpening

pening/

//

/closing of the boom

closing of the boomclosing of the boom

closing of the boom (

( (

(Work screen

Work screenWork screen

Work screen 1)

1) 1)

1)

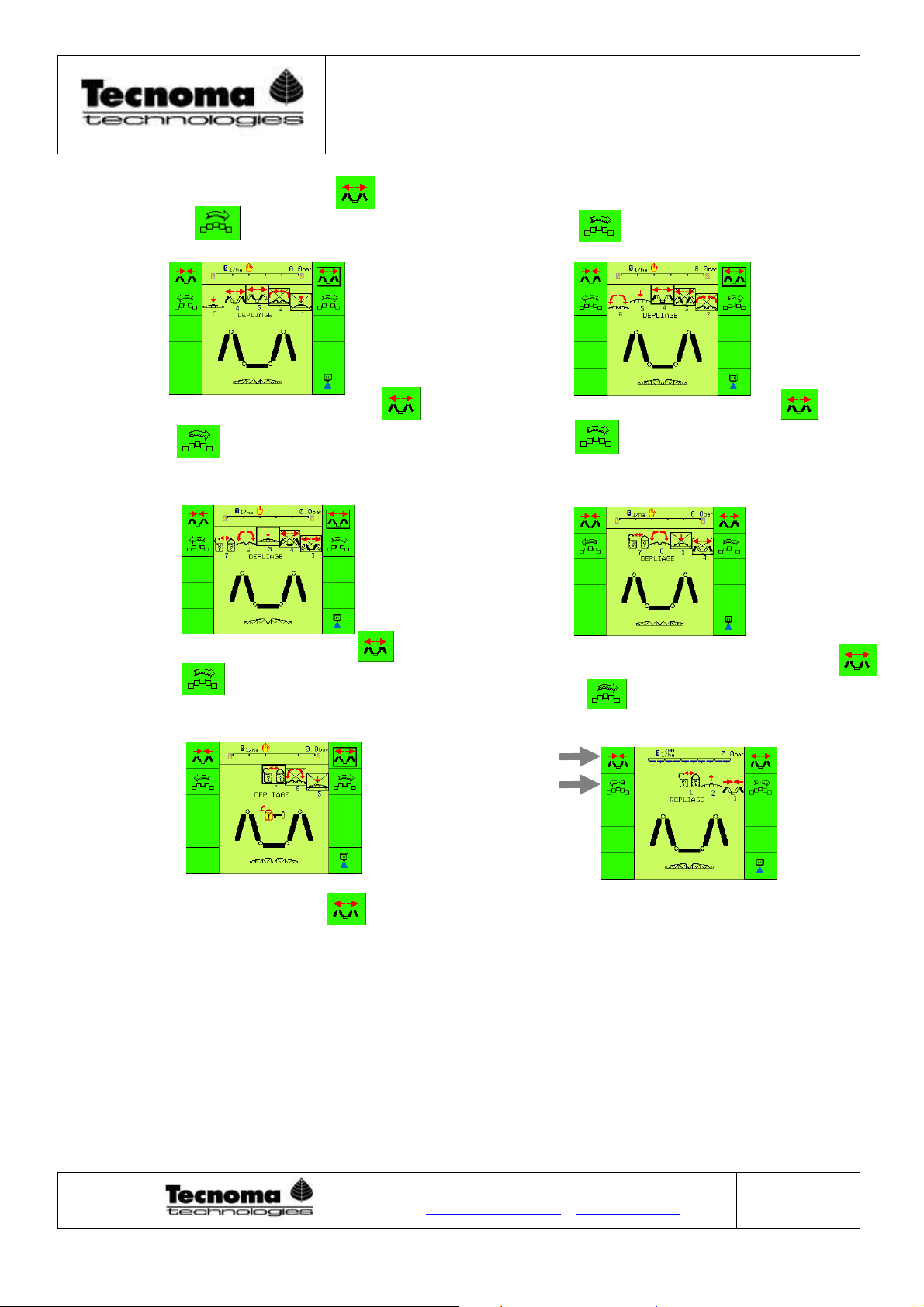

6.1.1

6.1.16.1.1

6.1.1 Sequential mode

Sequential modeSequential mode

Sequential mode

On power

On powerOn power

On power-

--

-up, the controls screen of the boom appears allowing the opening of the boom in seq

up, the controls screen of the boom appears allowing the opening of the boom in sequp, the controls screen of the boom appears allowing the opening of the boom in seq

up, the controls screen of the boom appears allowing the opening of the boom in sequential mode.

uential mode.uential mode.

uential mode.

The opening is done b appl ing the following sequences

The opening is done b appl ing the following sequencesThe opening is done b appl ing the following sequences

The opening is done b appl ing the following sequences

Folding Action

Folding ActionFolding Action

Folding Action

Unfolding Action

Unfolding ActionUnfolding Action

Unfolding Action

Pass

PassPass

Passing at jauge intervals to the right

ing at jauge intervals to the righting at jauge intervals to the right

ing at jauge intervals to the right

Pass

PassPass

Passing at intervals from right to left

ing at intervals from right to lefting at intervals from right to left

ing at intervals from right to left

Go to spra ing page

Go to spra ing pageGo to spra ing page

Go to spra ing page

Power up screen

Power up screenPower up screen

Power up screen

Box power up screen.

Opening/closing the boom in

sequential mode

Work screen displa b

Work screen displa b Work screen displa b

Work screen displa b

pressing on

pressing on pressing on

pressing on

Work screen displa b

Work screen displa b Work screen displa b

Work screen displa b

pressing on

pressing on pressing on

pressing on

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

14/31

1/ l

1/ l1/ l

1/ lift the boom b pressing on

ift the boom b pressing onift the boom b pressing on

ift the boom b pressing on

2/

2/ 2/

2/ Press on

Press on Press on

Press on

to move to the next

to move to the next to move to the next

to move to the next step

stepstep

step

3/ L

3/ L3/ L

3/ Lift the variable geometries b pressing on

ift the variable geometries b pressing onift the variable geometries b pressing on

ift the variable geometries b pressing on

4/

4/ 4/

4/ Press on

Press on Press on

Press on

to move to the next step

to move to the next stepto move to the next step

to move to the next step

5/

5/ 5/

5/ Open main

Open main Open main

Open main arm

armarm

arms

ss

s b pressing

b pressing b pressing

b pressing on

on on

on

6/

6/ 6/

6/ Press on

Press on Press on

Press on

to move to the next

to move to the next to move to the next

to move to the next step

stepstep

step

7/ O

7/ O7/ O

7/ Open forearms b pressing on

pen forearms b pressing on pen forearms b pressing on

pen forearms b pressing on

8/

8/ 8/

8/ Press on

Press on Press on

Press on

to move to the next

to move to the next to move to the next

to move to the next step

stepstep

step

9/

9/ 9/

9/ Lower the boom b pressing on

Lower the boom b pressing on Lower the boom b pressing on

Lower the boom b pressing on

10/

10/ 10/

10/ Press on

Press on Press on

Press on

to mov

to movto mov

to move to the next

e to the next e to the next

e to the next step

stepstep

step

12/

12/ 12/

12/ Lower the variable geometries b pressing on

Lower the variable geometries b pressing onLower the variable geometries b pressing on

Lower the variable geometries b pressing on

13/

13/ 13/

13/ Press on

Press on Press on

Press on

to move to the next

to move to the next to move to the next

to move to the next step

stepstep

step

14

1414

14/

/ /

/ Lock the

Lock the Lock the

Lock the boom

boom boom

boom whe

whe whe

whenever

never never

never it is equipped with the

it is equipped with the it is equipped with the

it is equipped with the

manual locking s stem b pressing

manual locking s stem b pressingmanual locking s stem b pressing

manual locking s stem b pressing

15/

15/ 15/

15/ displa of boom lo

displa of boom lodispla of boom lo

displa of boom locking

ckingcking

cking

The clos

The closThe clos

The closing

inging

ing is done with the reverse sequences

is done with the reverse sequences is done with the reverse sequences

is done with the reverse sequences

b pressing on the buttons to the left

b pressing on the buttons to the leftb pressing on the buttons to the left

b pressing on the buttons to the left.

..

.

6.1.2

6.1.26.1.2

6.1.2 Simultaneous

SimultaneousSimultaneous

Simultaneous mode

mode mode

mode

Go to the work screen 2 after power

Go to the work screen 2 after powerGo to the work screen 2 after power

Go to the work screen 2 after power-

--

-up. Press briefl on the boom ke , open the boom maneuvers page in

up. Press briefl on the boom ke , open the boom maneuvers page in up. Press briefl on the boom ke , open the boom maneuvers page in

up. Press briefl on the boom ke , open the boom maneuvers page in

independent controls mode. Press on

independent controls mode. Press onindependent controls mode. Press on

independent controls mode. Press on each function ke to open the boom. Beware the boom must be locked to

each function ke to open the boom. Beware the boom must be locked to each function ke to open the boom. Beware the boom must be locked to

each function ke to open the boom. Beware the boom must be locked to

open the arms.

open the arms.open the arms.

open the arms.

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

15/31

Press

briefly to

display the

boom

folding

page

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

16/31

6.1.3

6.1.36.1.3

6.1.3 Operating

OperatingOperating

Operating the boom

the boom the boom

the boom with the jo stick

with the jo stickwith the jo stick

with the jo stick

H draulic fu

H draulic fuH draulic fu

H draulic functions

nctions nctions

nctions with the handle

with the handlewith the handle

with the handle (jo stick).

(jo stick). (jo stick).

(jo stick).

Left forearm closing

Right forearm opening

Left forearm opening

Right forearm closing

Locking/unlocking

RAZ arrow or tracking axle towards

the right

Articulated drawbar or tracking axle

towards the left

Articulated drawbar or tracking axle

towards the right

Lift left variable geometr

Lift right variable geometr

Lower left variable geometr

Lower right variable geometr

Tilt correction mount left side

Tilt correction mount right side

Lift the boom

Lower the boom

Opening/closing of forearms in

function selector mode

Simultaneous opening/closing of arms

in function selector mode

Tilt correction in function selector

mode.

Green

GreenGreen

Green

Yellow

YellowYellow

Yellow

Red

RedRed

Red

LED Color

LED ColorLED Color

LED Color

Position

PositionPosition

Position

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

17/31

Flow in l/min.

6.2

6.26.2

6.2 Spra ing data

Spra ing dataSpra ing data

Spra ing data

(

( (

(Work screen

Work screen Work screen

Work screen 2)

2)2)

2)

Press on

Press on Press on

Press on

to move to spra ing mod

to move to spra ing modto move to spra ing mod

to move to spra ing mode

ee

e

Displa of additional data

Displa of additional dataDispla of additional data

Displa of additional data

b pressing on

b pressing on b pressing on

b pressing on

6.3

6.36.3

6.3 Programming the dose ( litre/ha)

Press on

Press on Press on

Press on

to displa page

to displa pageto displa page

to displa page 1

1 1

1 of settings

of settingsof settings

of settings.

. .

.

Page 1

Page 1 Page 1

Page 1 of settings

of settingsof settings

of settings

Volume/programmed hectare

Speed of work

Calculated pressure

Volume in l/ha

While working

Click while

Click while Click while

Click while

pressing on the

pressing on the pressing on the

pressing on the

button

buttonbutton

button

Turn the button to

Turn the button to Turn the button to

Turn the button to

place the

place the place the

place the

highlight on 1

highlight on 1highlight on 1

highlight on 1

Click twice

Click twiceClick twice

Click twice

Click twice

Click twice Click twice

Click twice

Click twice

Click twiceClick twice

Click twice

Remaining substance

in the tank

Treated surface

per hour

Surface that can be treated with

the substance

of the tank

Treatment

distance with the

remaining volume

in the tank

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

18/31

Sections 3, 4 and 5 are selected

Sections 3, 4 and 5 are selectedSections 3, 4 and 5 are selected

Sections 3, 4 and 5 are selected

Sections 3, 4 and 5 are open

Sections 3, 4 and 5 are openSections 3, 4 and 5 are open

Sections 3, 4 and 5 are open

6.4

6.46.4

6.4 Choi

ChoiChoi

Choice of the boom

ce of the boomce of the boom

ce of the boom

From the settings

From the settingsFrom the settings

From the settings

page 1

page 1 page 1

page 1

6.5

6.56.5

6.5 Choi

ChoiChoi

Choice of the

ce of the ce of the

ce of the wheel

wheelwheel

wheel

From the settings page

From the settings pageFrom the settings page

From the settings page 1, s

1, s 1, s

1, se

ee

elect

lectlect

lect wheel

wheel wheel

wheel 2

2 2

2 with the thumb wheel

with the thumb wheelwith the thumb wheel

with the thumb wheel

6.6

6.66.6

6.6 Contro

ControContro

Controlling sections

lling sectionslling sections

lling sections

The sections are

The sections areThe sections are

The sections are

represented b beams and angular

represented b beams and angular represented b beams and angular

represented b beams and angular s mbols

s mbols s mbols

s mbols below the

below the below the

below the boom

boomboom

boom. The beams

. The beams . The beams

. The beams correspond to

correspond to correspond to

correspond to

preselected sections. The triangles represent

preselected sections. The triangles represent preselected sections. The triangles represent

preselected sections. The triangles represent spra ing

spra ing spra ing

spra ing spectra

spectra spectra

spectra of open

of open of open

of open sections.

sections.sections.

sections.

Click once

Click once

Click once Click once

Click once

To choose the

To choose the To choose the

To choose the

boom n° 1

boom n° 1 boom n° 1

boom n° 1

Click once and

Click once and Click once and

Click once and

select wheel 1 with

select wheel 1 with select wheel 1 with

select wheel 1 with

the thumb wheel

the thumb wheelthe thumb wheel

the thumb wheel

Click once to

Click once to Click once to

Click once to

return to the

return to the return to the

return to the

settings screen.

settings screen.settings screen.

settings screen.

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

19/31

6.6.1

6.6.16.6.1

6.6.1 O

OO

Opening/closing of sections with the handle

pening/closing of sections with the handlepening/closing of sections with the handle

pening/closing of sections with the handle (jo stic

(jo stic (jo stic

(jo stick).

k).k).

k).

The switch

The switchThe switch

The switch

must be in central p

must be in central p must be in central p

must be in central position.

osition. osition.

osition. Yellow

Yellow Yellow

Yellow LED

LED LED

LED lit

litlit

lit

6.6.2

6.6.26.6.2

6.6.2 Opening/closing of section with the

Opening/closing of section with the Opening/closing of section with the

Opening/closing of section with the terminal

terminal terminal

terminal

The opening and closing from the terminal needs to go to page 3 of the settings and set without

The opening and closing from the terminal needs to go to page 3 of the settings and set without The opening and closing from the terminal needs to go to page 3 of the settings and set without

The opening and closing from the terminal needs to go to page 3 of the settings and set without

the jo stick using th

the jo stick using ththe jo stick using th

the jo stick using the

e e

e thumb wheel

thumb wheelthumb wheel

thumb wheel.

..

.

Re

ReRe

Restart the terminal after this change of option

start the terminal after this change of optionstart the terminal after this change of option

start the terminal after this change of option.

. .

.

To access the

To access the To access the

To access the nozzles control

nozzles control nozzles control

nozzles control screen from the terminal. Turn

screen from the terminal. Turnscreen from the terminal. Turn

screen from the terminal. Turn on

on on

on the terminal and then click

the terminal and then click the terminal and then click

the terminal and then click on

on on

on

then

then then

then 4

4 4

4 times

times times

times

on

on on

on

Back to the nominal dose

Back to the nominal doseBack to the nominal dose

Back to the nominal dose

General opening/closing

General opening/closingGeneral opening/closing

General opening/closing

Opening from right to left

Opening from right to leftOpening from right to left

Opening from right to left

Opening from left to right

Opening from left to rightOpening from left to right

Opening from left to right

Closing from left to right

Closing from left to rightClosing from left to right

Closing from left to right

Closing from right to left

Closing from right to leftClosing from right to left

Closing from right to left

Decreasing the dose

Decreasing the dose Decreasing the dose

Decreasing the dose b rate of

b rate of b rate of

b rate of 5%

5%5%

5%

In

InIn

Increasing the dose

creasing the dose creasing the dose

creasing the dose b r

b rb r

b rate of

ate of ate of

ate of 5%

5%5%

5%

The use of this mode does not allow using the jo stick an more

The use of this mode does not allow using the jo stick an moreThe use of this mode does not allow using the jo stick an more

The use of this mode does not allow using the jo stick an more.

..

.

Sections break from left to

Sections break from left to Sections break from left to

Sections break from left to

right

rightright

right

Sections break from

Sections break from Sections break from

Sections break from

right to left

right to leftright to left

right to left

Sections opening from left

Sections opening from left Sections opening from left

Sections opening from left

to right

to rightto right

to right

Sections opening from right to

Sections opening from right to Sections opening from right to

Sections opening from right to

left

leftleft

left

General closing or opening

General closing or openingGeneral closing or opening

General closing or opening

Green

GreenGreen

Green

Yellow

YellowYellow

Yellow

Red

LED

LEDLED

LED

Color

Color Color

Color

Position

PositionPosition

Position

INSTRUCTIONS FOR USE

OF REGULATIONS

NOVATEC ISOBUS AND NOVATOP

Tecnoma technologie – 54, rue Marcel Paul – BP 195 – 51206 Epernay

Tel +33(0)3 26 51 99 99 – Fax +33(0)3 26 51 83 51

e – mail tecnoma@tecnoma.com - www.tecnoma.com

SAS with a capital of 1 174 400 € – RCS Epernay B 350 484 309 – APE 293D

990025

Mars 2012

Page

20/31

6.7

6.76.7

6.7 Occasional over and under dosing

Occasional over and under dosingOccasional over and under dosing

Occasional over and under dosing.

..

.

On

On On

On Screen

ScreenScreen

Screen:

::

:

Back to the nominal dose

Back to the nominal doseBack to the nominal dose

Back to the nominal dose

General opening/closing

General opening/closingGeneral opening/closing

General opening/closing

Decreasing the dose b rate of

Decreasing the dose b rate ofDecreasing the dose b rate of

Decreasing the dose b rate of

5%

5%5%

5%

In

InIn

Increasing the

creasing the creasing the

creasing the dose b rate of

dose b rate ofdose b rate of

dose b rate of

5%

5%5%

5%

With the

With theWith the

With the jo stick

jo stick jo stick

jo stick

6.8 Directional

DirectionalDirectional

Directional spra ing m

spra ing m spra ing m

spra ing mode. (

ode. (ode. (

ode. (Allows to select sections individuall

Allows to select sections individuallAllows to select sections individuall

Allows to select sections individuall )

))

)

Displa settings page

Displa settings page Displa settings page

Displa settings page N°3

N°3N°3

N°3

Turn off the

Turn off theTurn off the

Turn off the terminal

terminal terminal

terminal to validate the change

to validate the changeto validate the change

to validate the change.

. .

. Turn on the

Turn on the Turn on the

Turn on the terminal

terminal terminal

terminal and go to the work page

and go to the work pageand go to the work page

and go to the work page.

..

.

Decreasing the dose b

Decreasing the dose b Decreasing the dose b

Decreasing the dose b

rate of

rate ofrate of

rate of

5%

5%5%

5%

In

InIn

In

creasing the dose b rate of

creasing the dose b rate ofcreasing the dose b rate of

creasing the dose b rate of

5%

5%5%

5%

Back to the nominal dose

Back to the nominal doseBack to the nominal dose

Back to the nominal dose

Yellow

YellowYellow

Yellow

LED Color

LED ColorLED Color

LED Color

Position

PositionPosition

Position

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

Vacon

Vacon NX IP54 installation instructions

M-system

M-system Devicenet R7F4HD-DAC32C instruction manual

PMFoundations

PMFoundations Clock Divider Assembly guide

Allen-Bradley

Allen-Bradley ControlLogix 1756-DH485 user manual

aquabrass

aquabrass TOTEM 3105 installation guide

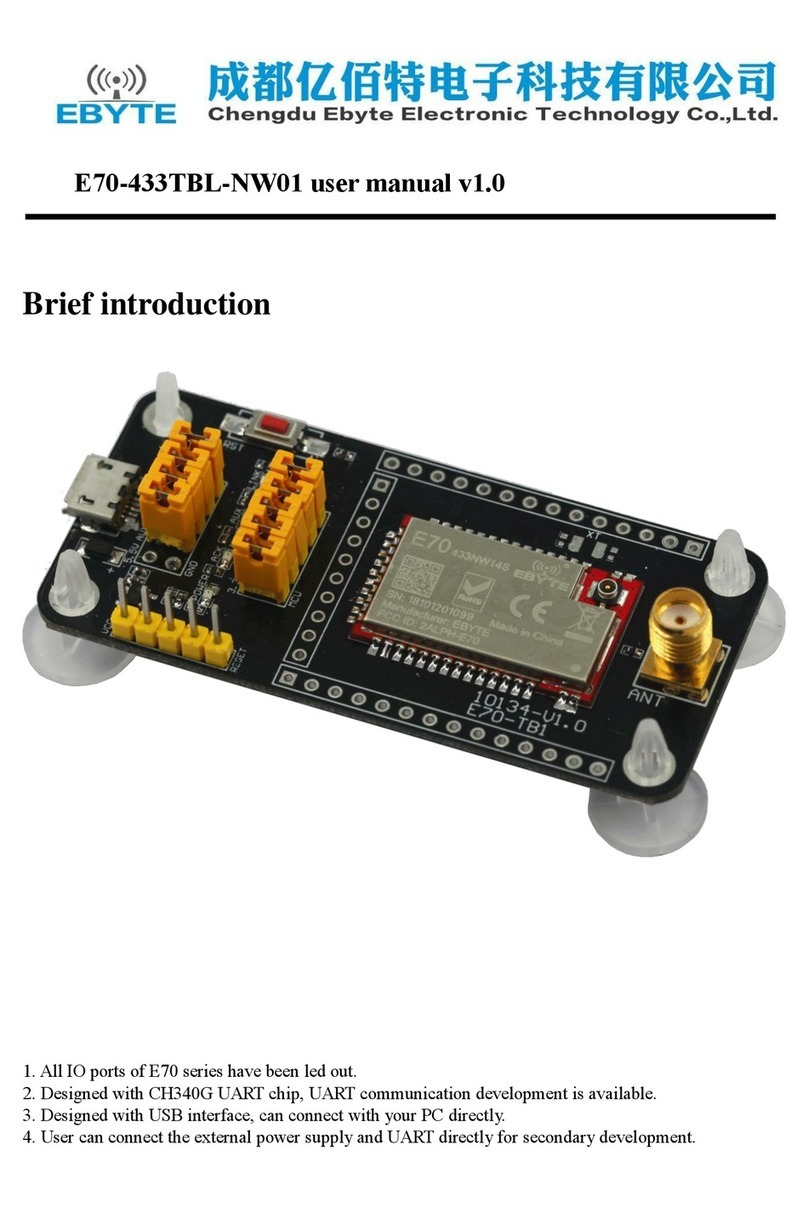

Ebyte

Ebyte E70-433TBL-NW01 user manual